Membrane desulfurization of liquid hydrocarbons using an extractive liquid membrane contactor system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

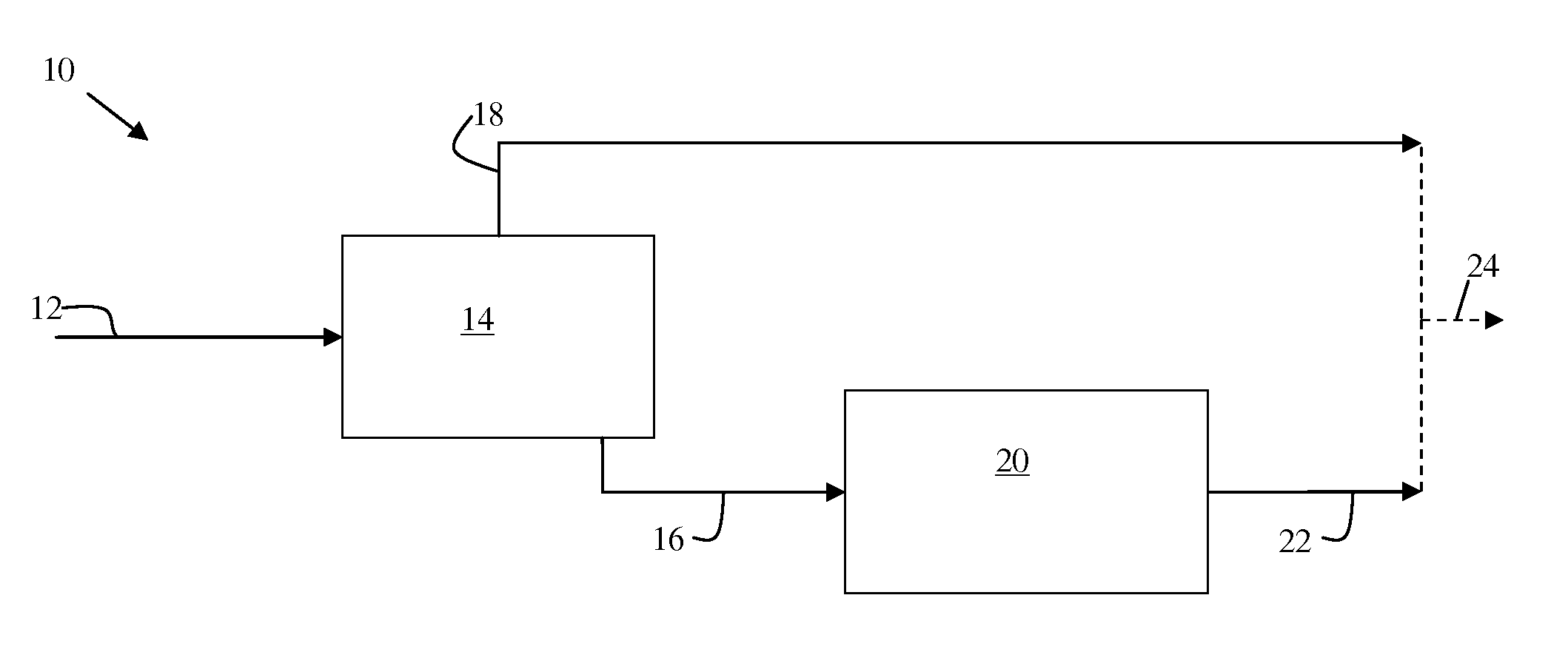

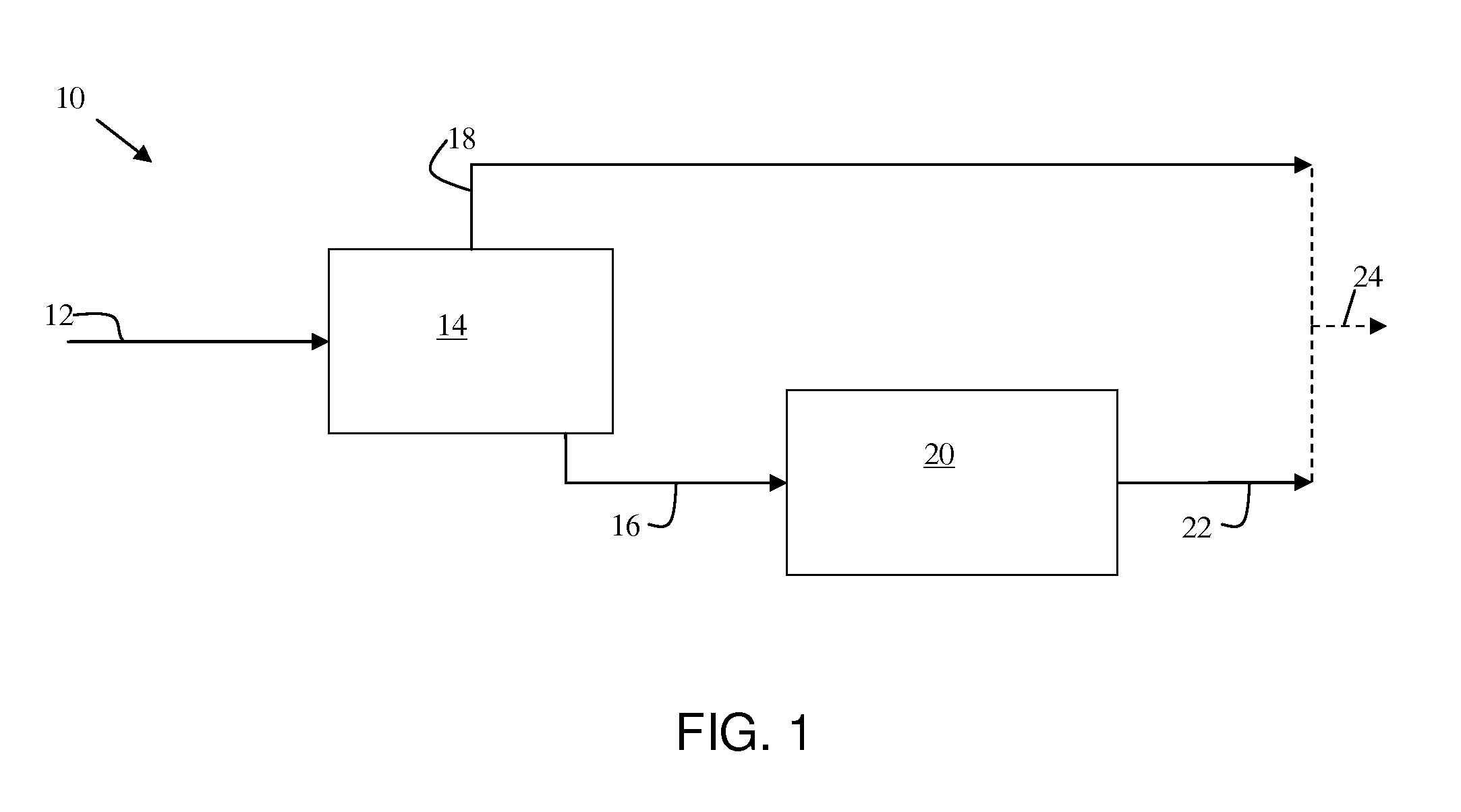

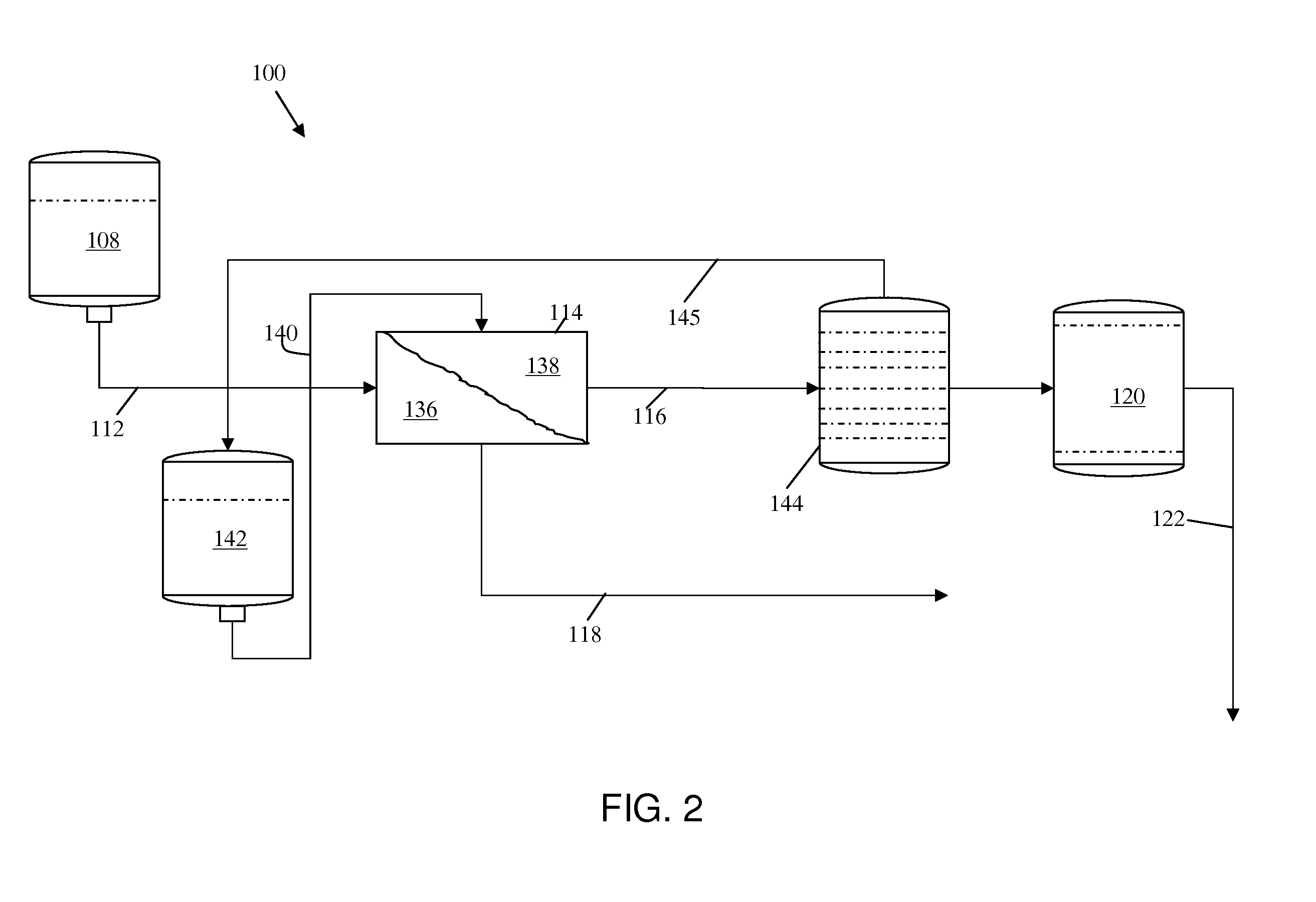

Image

Examples

example

[0050]Membrane contactors using polyvinylidene fluoride (PVDF) flat sheet ultrafiltration membranes were constructed and tested in accordance with the present invention. The membranes were about 125 μm in thickness, had pores of 0.1 μm or 0.2 μm, and a porosity of 70%, 75% or 80%. Furfural was used as the extractive solvent. The flow rate of both the extractive solvent and the hydrocarbon streams was set at 10 milliliters per minute. Table 3 provides the results indicating effective mass transfer coefficients (in centimeters per hour).

TABLE 3Mass TransferHydrocarbon streamMembrane ContactorCoefficientArab light crude 0.1 μm pore, 70% porosity0.25(1.9% w / w sulfur)Diesel (1.5% w / w sulfur)0.1 μm pore, 70% porosity0.19Diesel (1.5% w / w sulfur)0.1 μm pore, 75% porosity0.28Diesel (1.5% w / w sulfur)0.2 μm pore, 80% porosity0.37

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com