Fibers treated with polymerization compounds and fiber reinforced composites made therefrom

a technology of polymerization compounds and fiber reinforced composites, which is applied in the manufacture of final products, metal/metal-oxide/metal-hydroxide catalysts, machines/engines, etc., can solve the problems of fiber-reinforced thermoset articles, health and safety problems, and many applications of composite deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

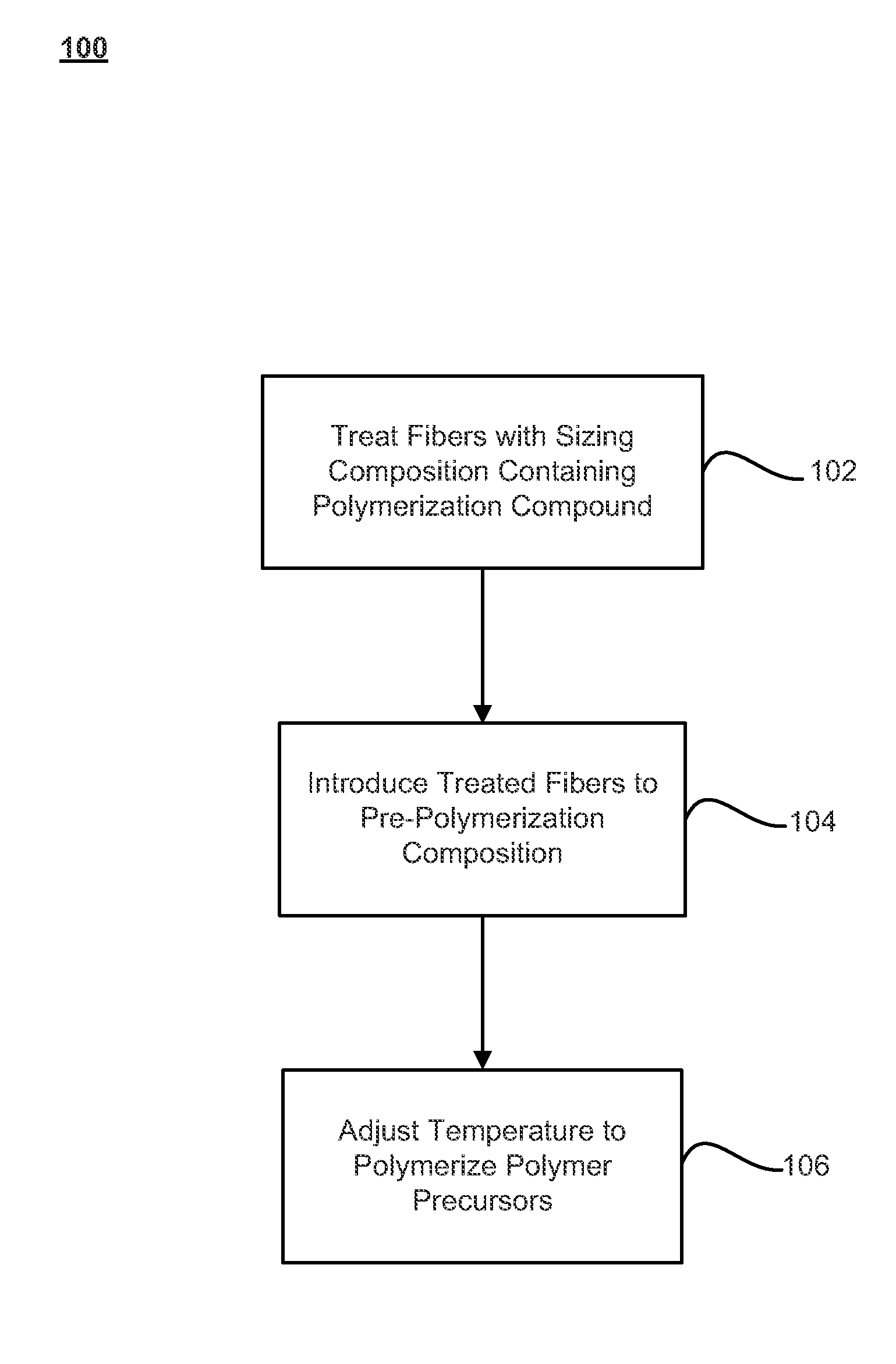

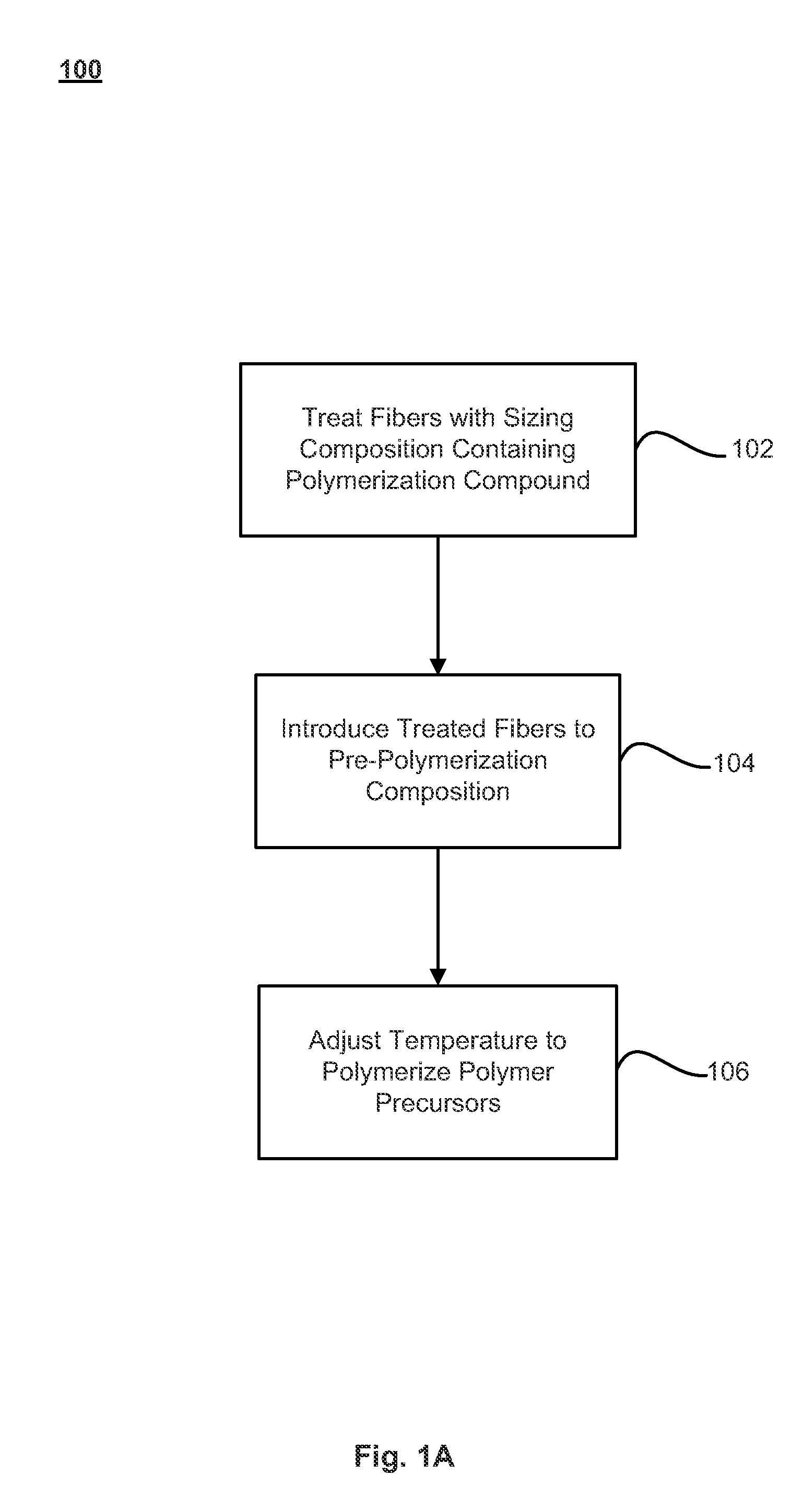

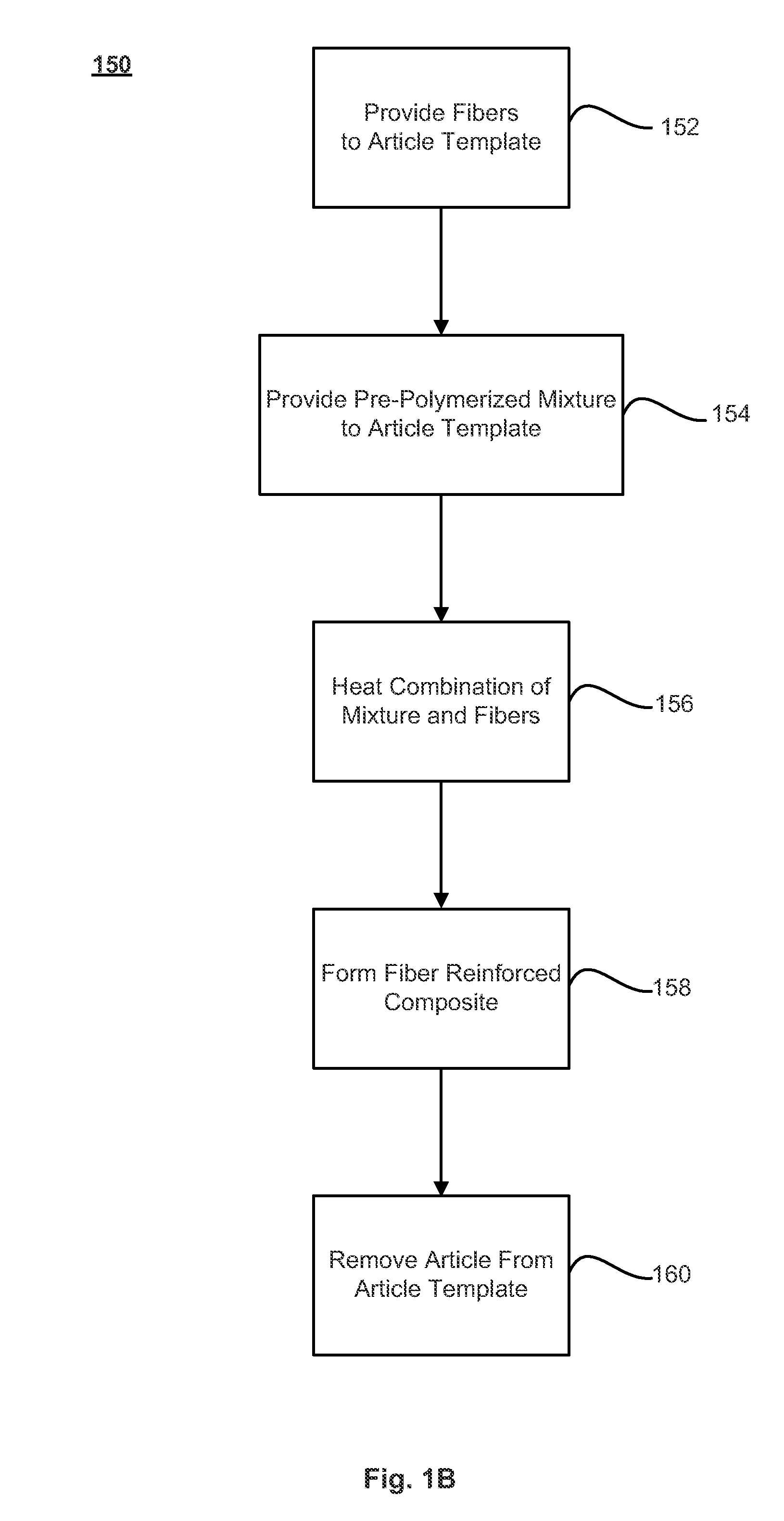

[0021]Articles made from fiber-reinforced plastic polymer composites are described, as well as methods of making these articles. These articles include, without limitation, equipment and parts for various transportation vehicles such as cars, trucks, boats, aircraft, trains, and non-motorized vehicles such as bicycles and sailboats, among other kinds of transportation vehicles. The articles may further include equipment and parts used in industrial applications, including parts for electric power generation, such as wind turbine blades.

[0022]The present composite materials may be used to make large-sized articles that were previously made from a greater number of smaller pieces which were coupled together to make the larger article. The ability of the composites to make the article from a smaller number of pieces, or even a single piece, reduces manufacturing complexity as well as the number of joints, fasteners, and seams that can weaken the overall structural integrity of the arti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com