Carton forming machine and forming method implemented by same

A forming method and forming machine technology, applied to paper/cardboard containers, container manufacturing machinery, containers, etc., can solve problems such as non-conformity, easy color difference between upper and lower paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

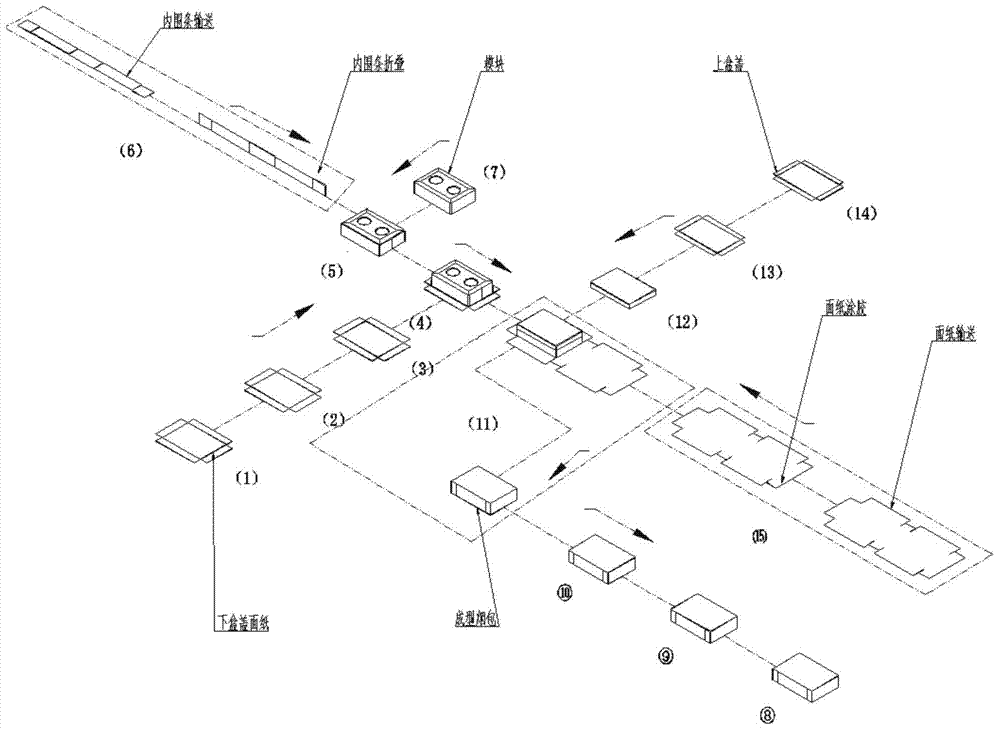

[0096] The technical solution of the present invention will be further described in conjunction with the accompanying drawings and embodiments. It is believed that the device structure and process of the present invention will be clear to those skilled in the art.

[0097] This set of carton forming machine is mainly composed of box cover forming device, inner wall forming device, integral forming device, groove cutting device and conveying device. The structure and process of each component will be described in detail below.

[0098] First of all, about the lid forming device. It consists of an upper cover forming device and a lower cover forming device, wherein the upper cover forming device is connected to the hemming forming mechanism by the paper feeding mechanism through the conveying mechanism, and the hemming forming mechanism is connected to the lower forming mechanism through the grasping mechanism. A production line; and the lower lid forming device is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com