Automobile brake wheel cylinder cup assembly line

A technology of automobile brake and assembly line, which is applied in the assembly line of automobile brake wheel cylinder cups, the press-fitting of pistons and dust covers, and the fields of brake wheel cup cups, which can solve the problems of low degree of mechanization, poor coordination and weak correlation And other problems, to achieve the effect of improving production efficiency, the same supporting force, and increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

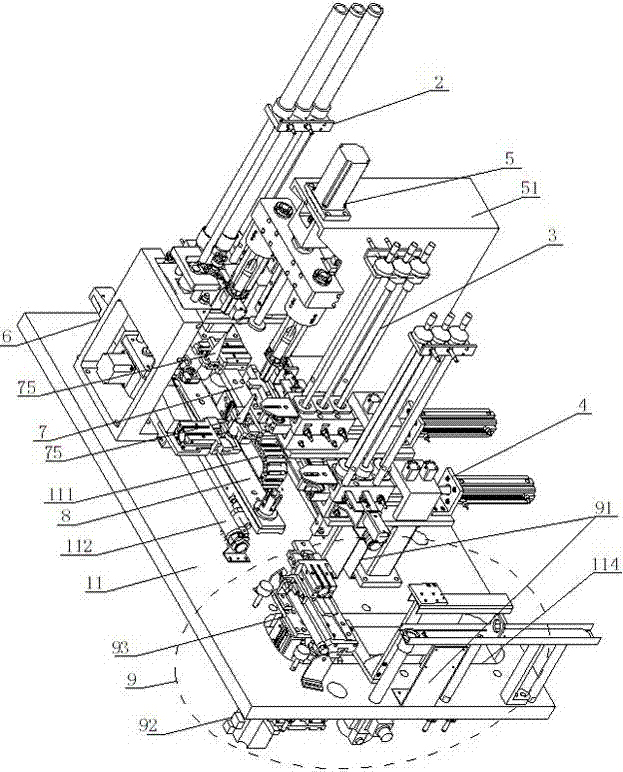

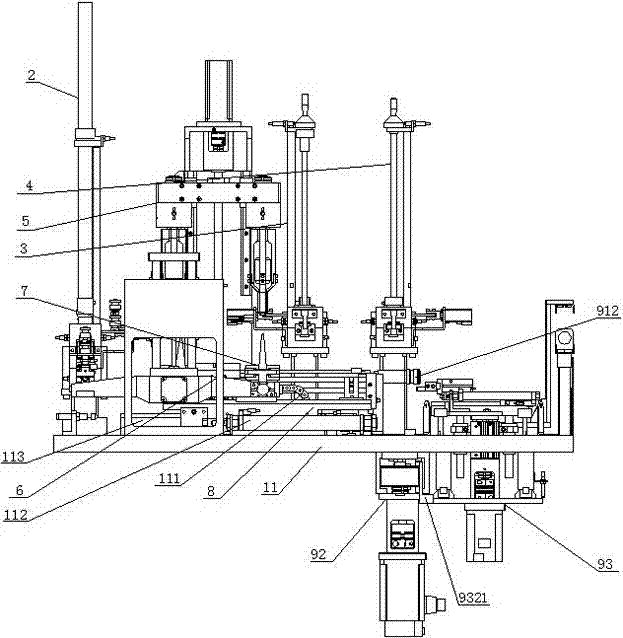

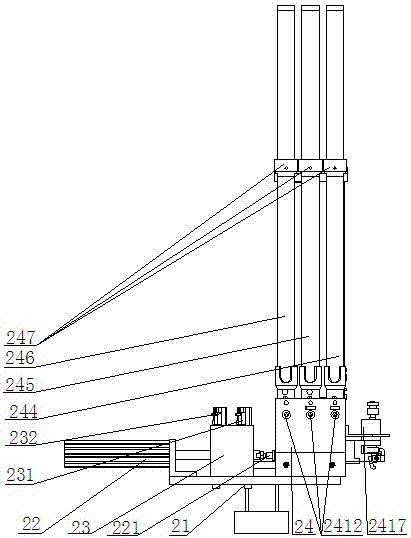

[0051] see figure 1 , figure 2 , Figure 22 and Figure 23 , the present embodiment includes a stand 1 and a base plate 11, the base plate 11 is fixed on the stand 1, and the assembly line also includes a piston discharge mechanism 2 fixed on the base plate 11, a leather cup discharge mechanism 3, and a dust cover discharge mechanism 4 , Press-fit mechanism 5, tapered rod manipulator mechanism 7, turning manipulator mechanism 6, workbench components 8, visual inspection mechanism 9.

[0052] The piston discharge mechanism 2, the press-fit mechanism 5, the cup discharge mechanism 3, and the dust cover discharge mechanism 4 are sequentially fixed on the bottom plate 11 in parallel; It is cooperating and fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com