Patents

Literature

39results about How to "Improve ratio efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

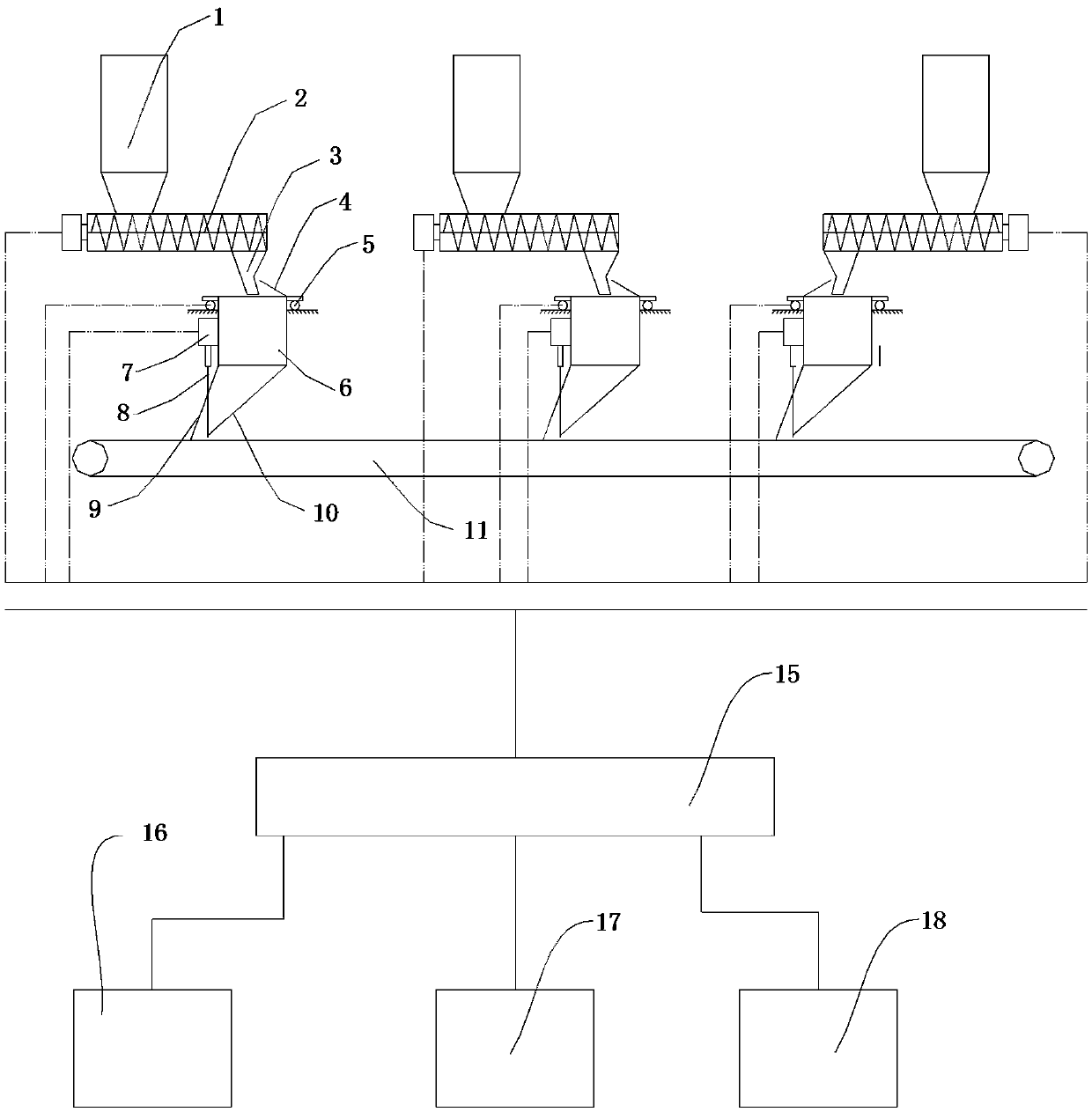

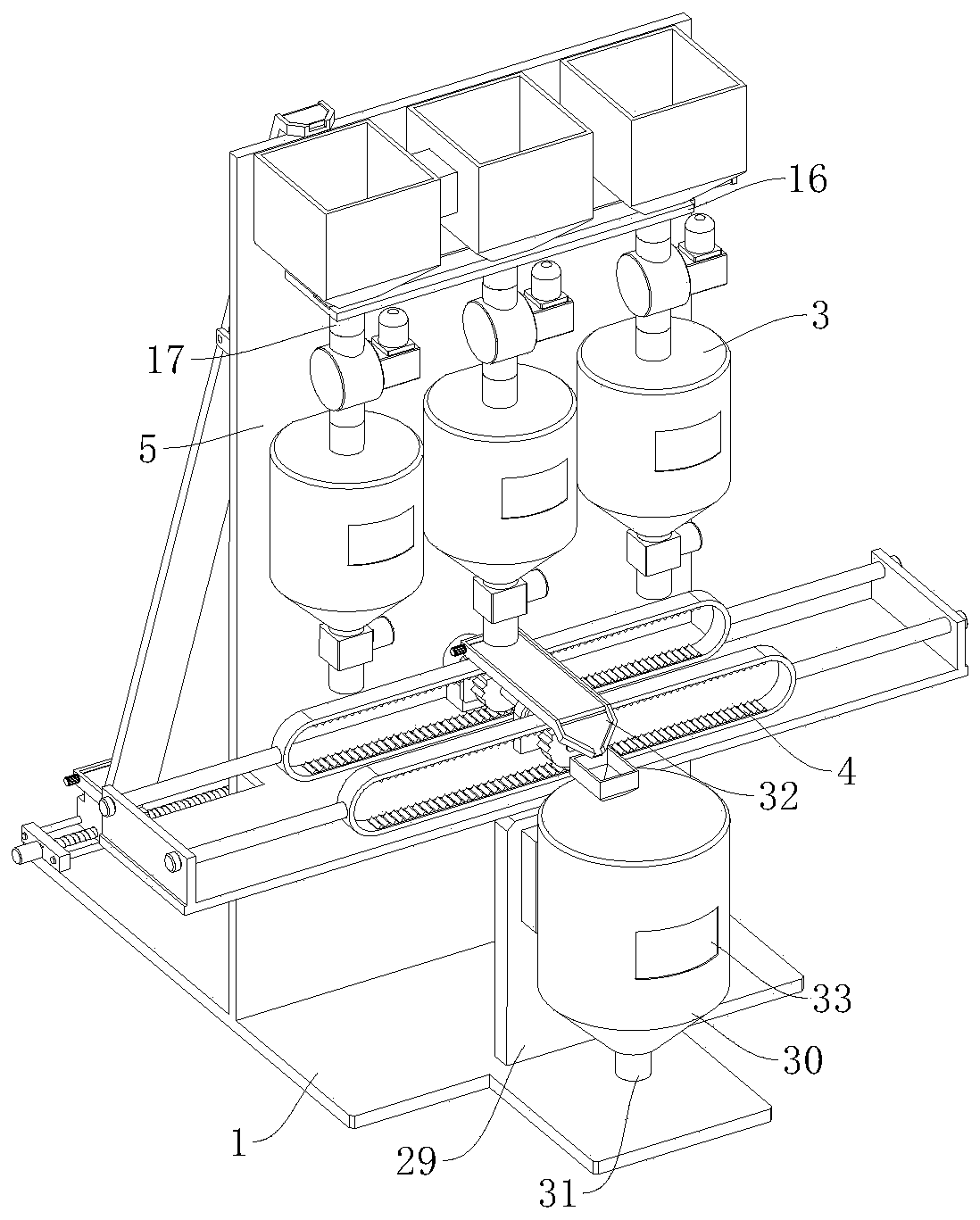

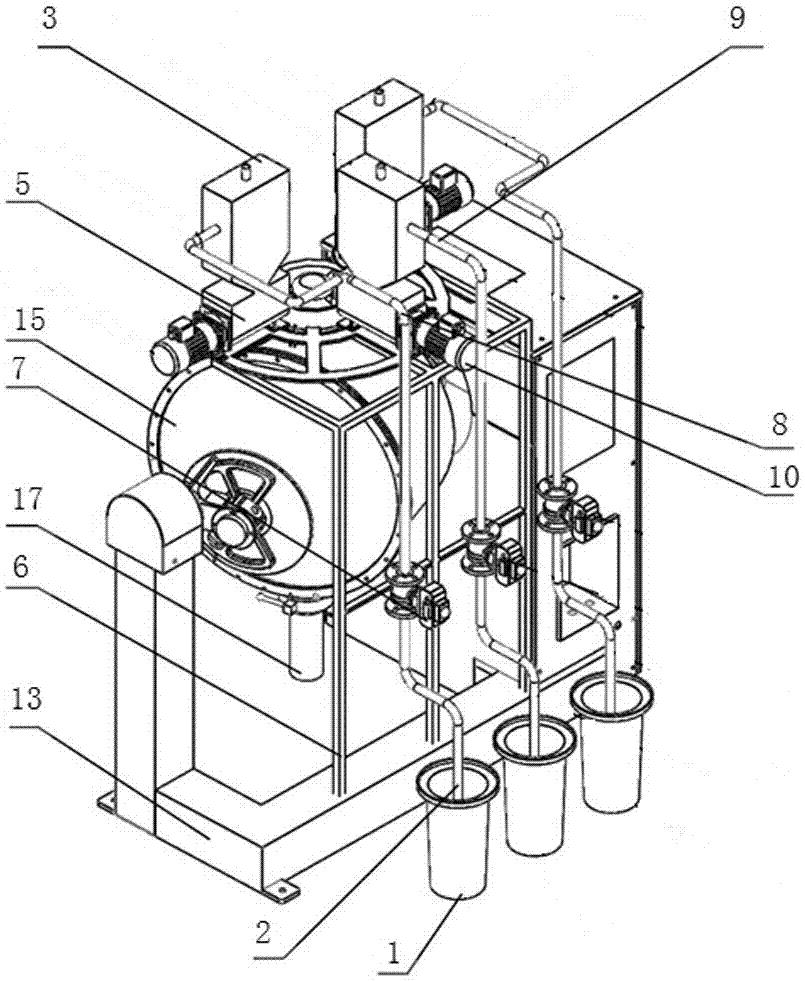

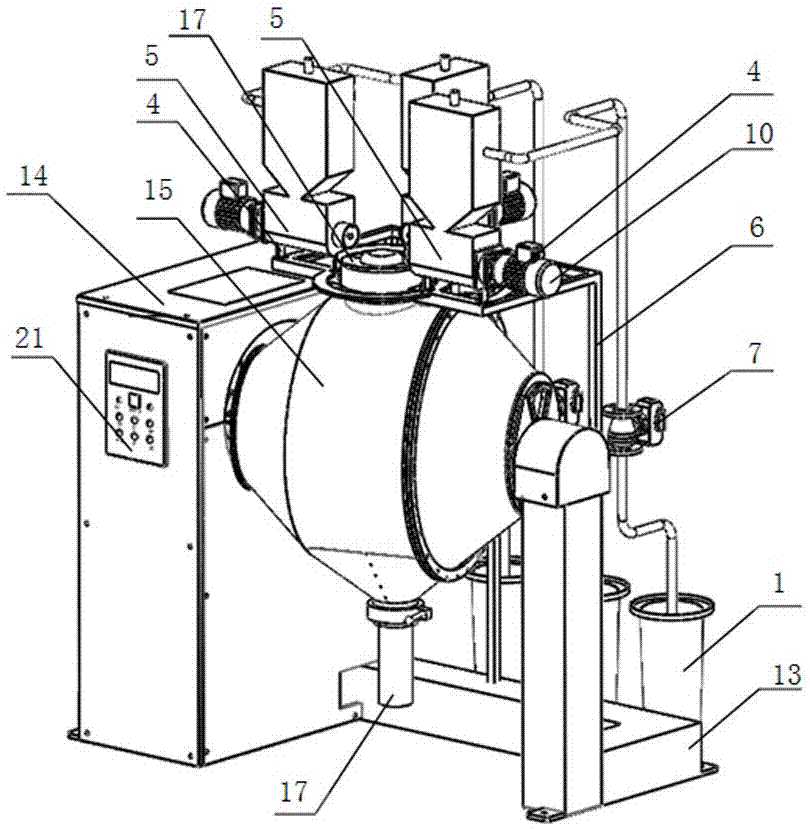

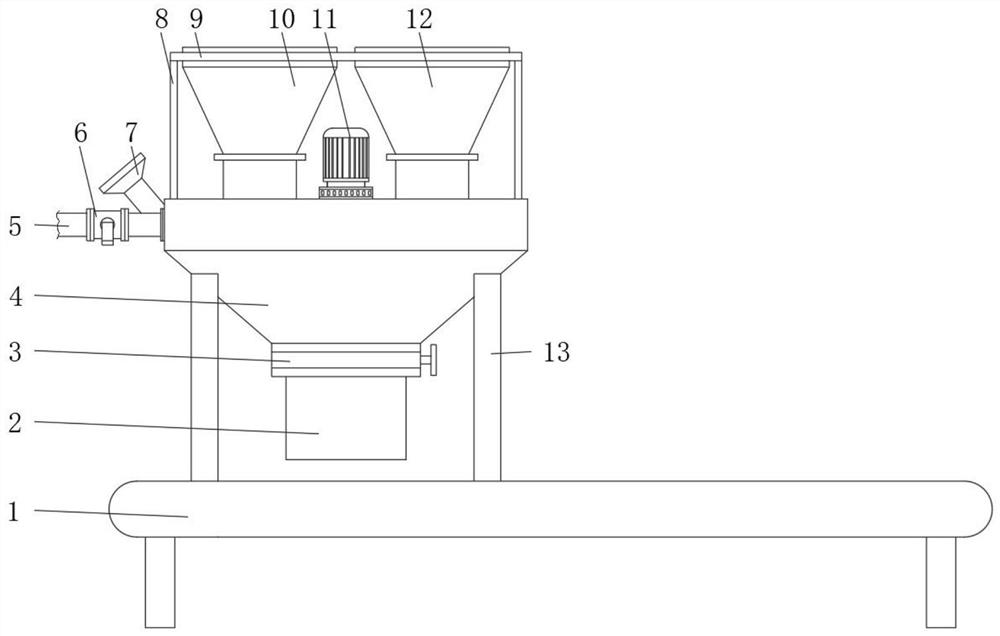

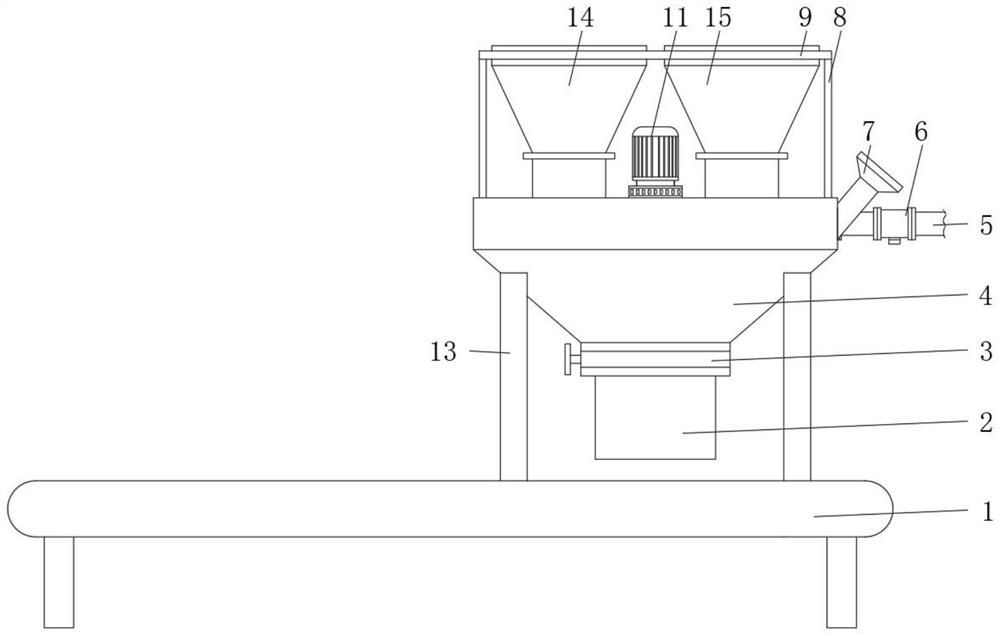

Automatic batching apparatus and batching method

ActiveCN104043376AReasonable structural designEasy to break awayMixer accessoriesEngineeringMechanical engineering

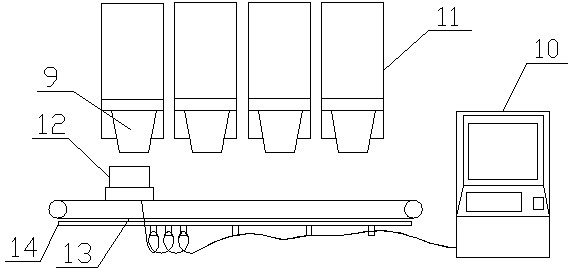

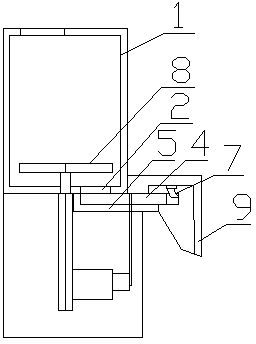

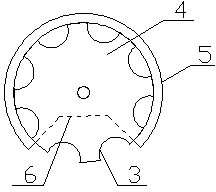

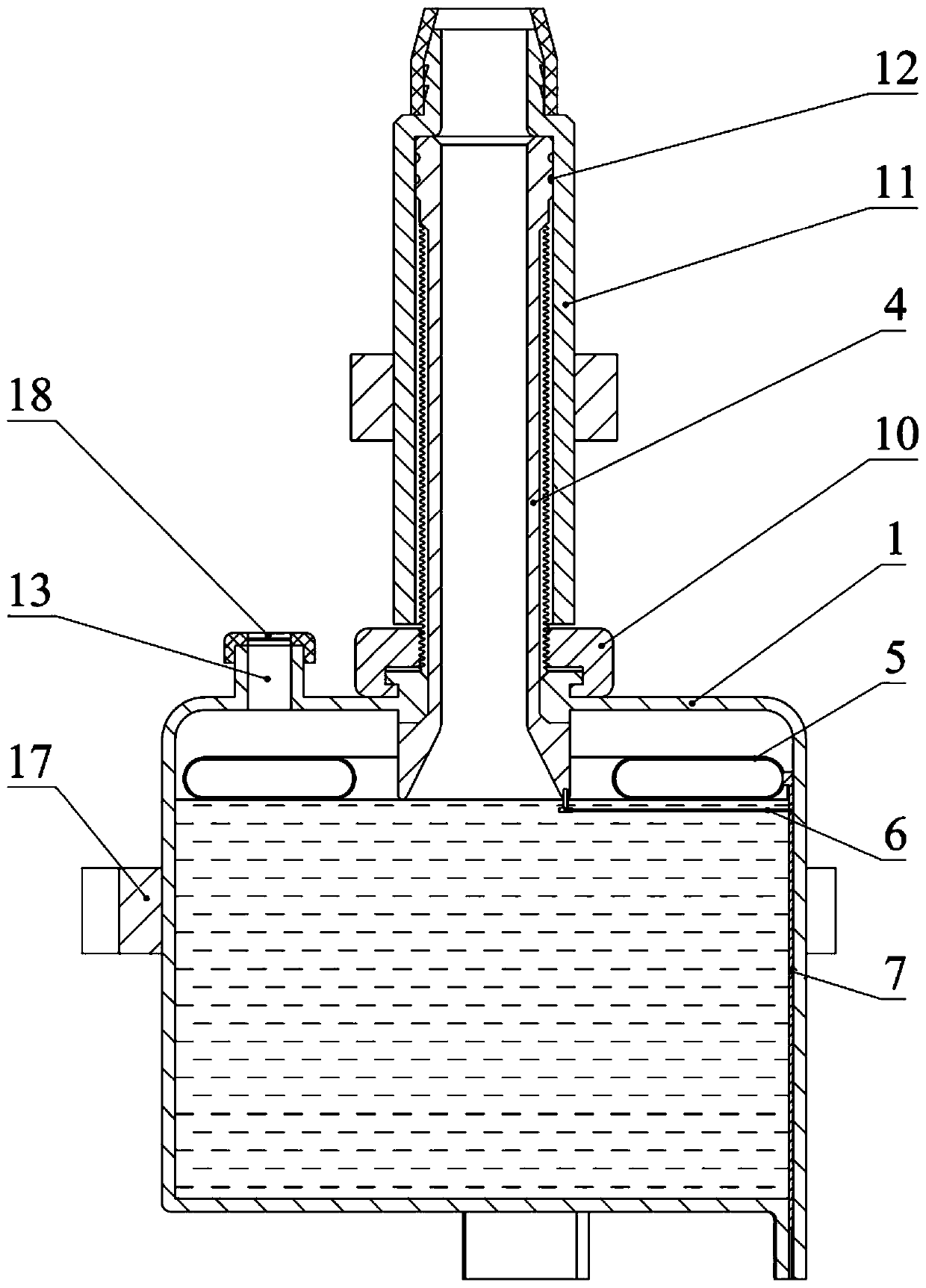

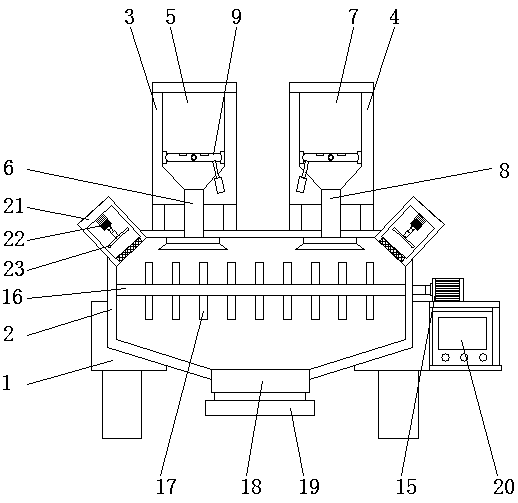

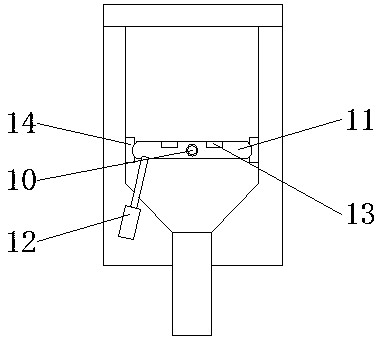

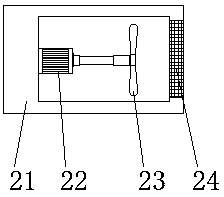

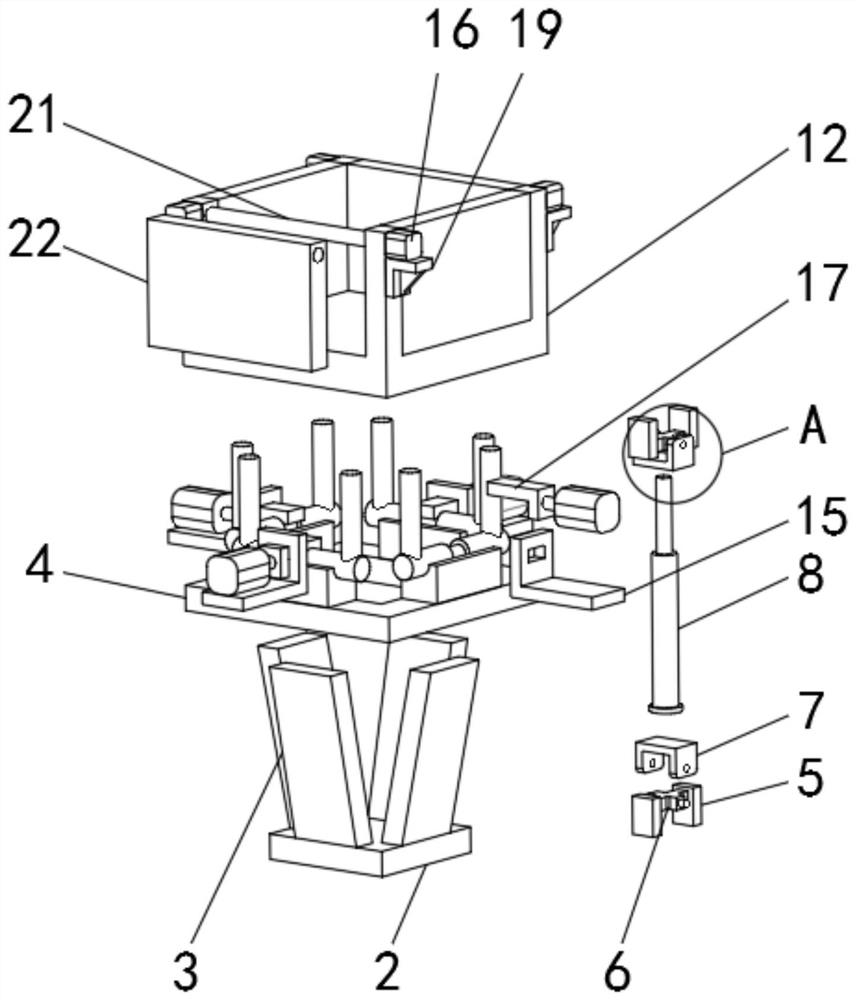

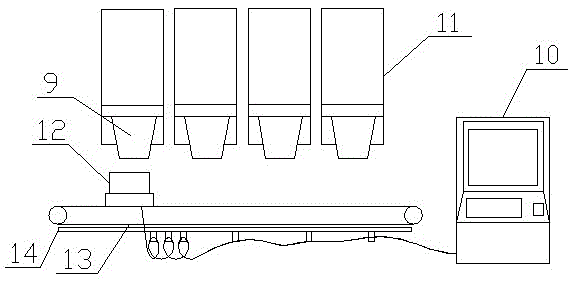

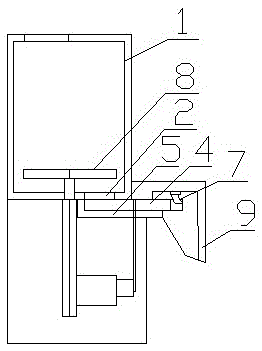

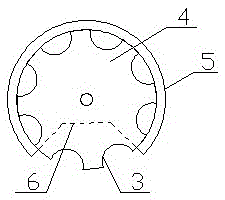

The invention provides an automatic batching apparatus and a batching method. The apparatus comprises a control cabinet, batching bins with blanking devices, a mobile weighing disc. The batching bins are provided with quantitative blanking devices, which are connected with the control cabinet; a plurality of batching bins are in linear arrangement; blanking ports of the batching bins are in a straight line, and a conveyor belt is arranged right below the blanking ports of the batching bins; the weighing disc comprises a weighing bucket and an electronic scale; and the electronic scale is placed on the conveyor belt, and is connected with the control cabinet through a circuit. The control cabinet conducts remote blanking control on blanking of batching bins and movement of the weighing disc. Compared with the current automatic blanking apparatus and blanking method, the apparatus and method provided by the invention save manpower and material source, realizes automatic operation, more precise and reliable dropping material control, and greatly improves the efficiency of material proportion.

Owner:TAIAN DEPU AUTOMATION EQUIP

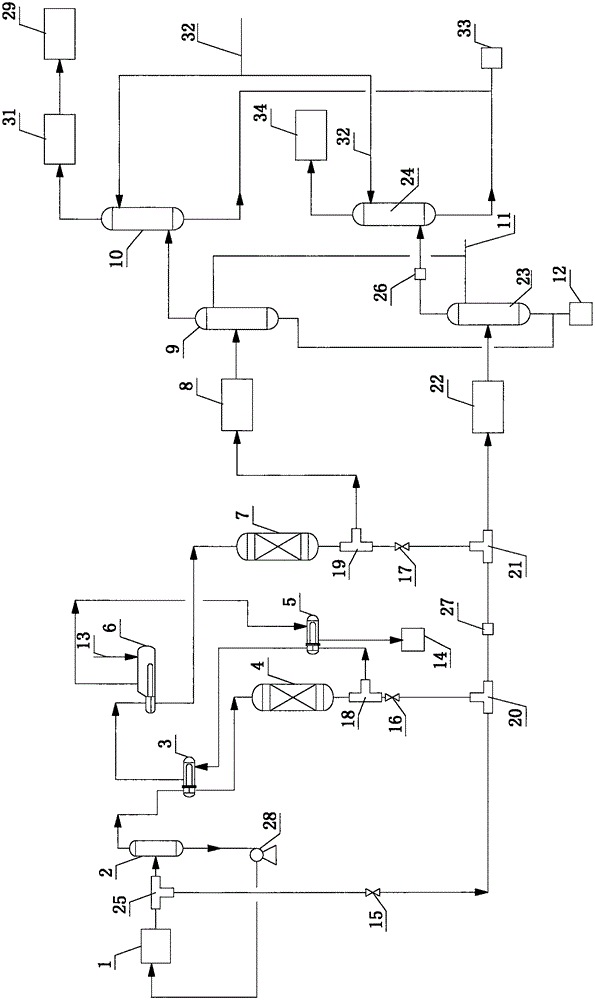

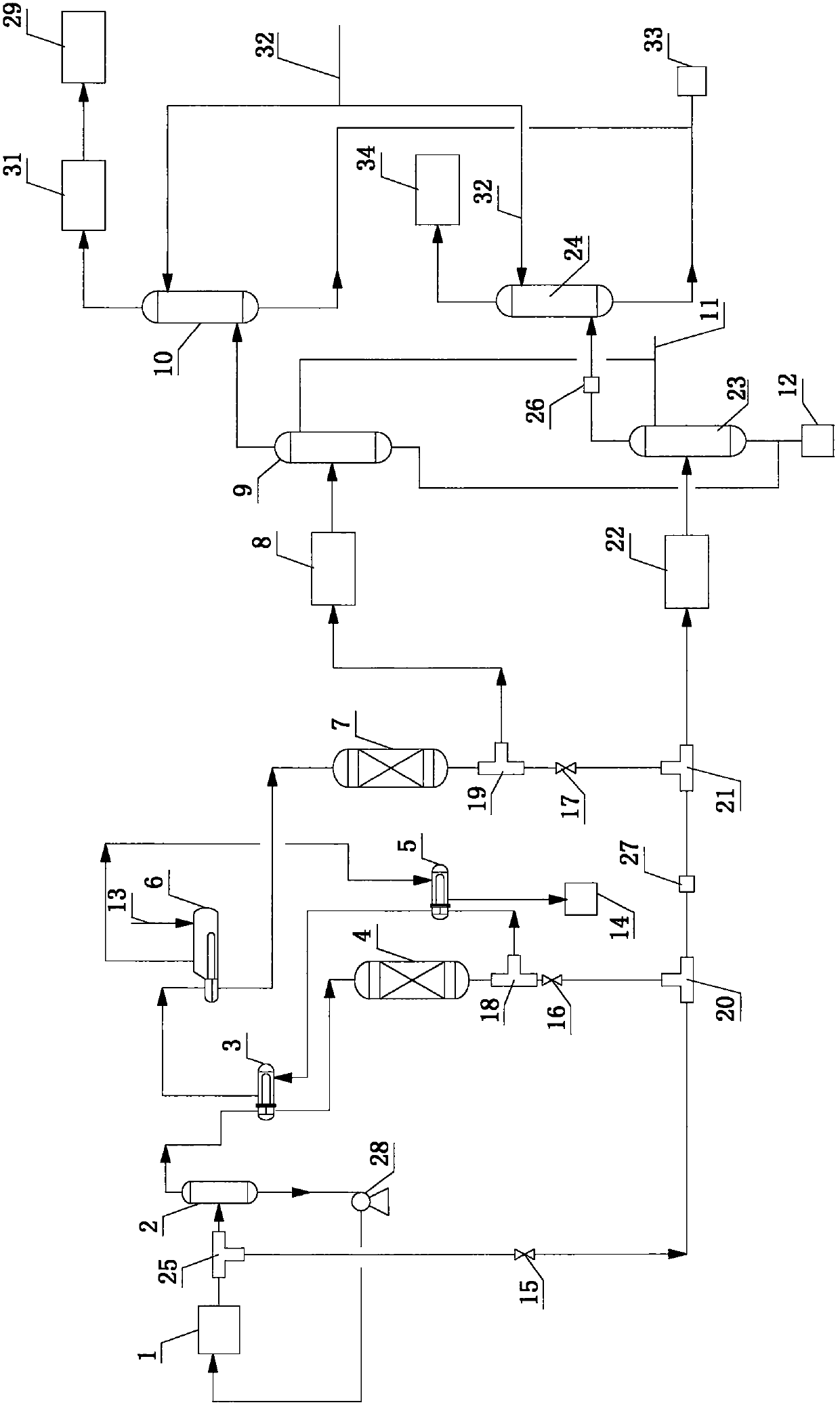

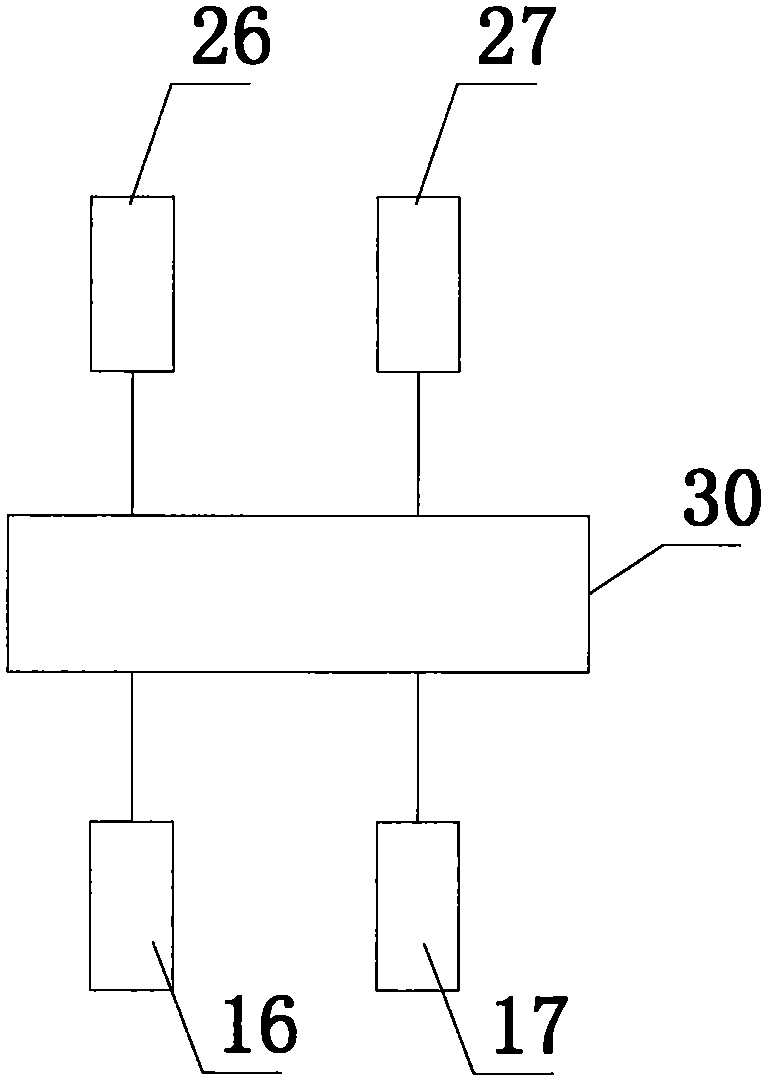

Device and method for making shifted gas for synthesis of ammonia synthesis poly-generation methanol

ActiveCN105565269AHigh proportioning efficiency and precisionRich adjustment meansHydrogenHydrogen/synthetic gas productionOnline analysisProcess engineering

The invention belongs to a device and method for making shifted gas for synthesis of ammonia synthesis poly-generation methanol. The device comprises a mechanical part and a control part. The mechanical part comprises a gasification washing tower, an outlet of the gasification washing tower is connected with an inlet of a second heat and condensate recycling unit through a pipe, the pipe between the outlet of the gasification washing tower and the second heat and condensate recycling unit is sequentially provided with a fifth tee joint, a first self-regulating valve, a first tee joint and a second tee joint, an outlet of the second heat and condensate recycling unit is connected with an inlet in the middle of a second ammonia-washing tower, and a gas phase outlet in the top of the second ammonia-washing tower is connected with an inlet in the lower portion of a shifted gas washing tower for synthesis of methanol through a pipe; the control part comprises a first online analysis and calculation display instrument, a second online analysis and calculation display instrument, a second self-regulating valve and a third self-regulating valve. The device and method have the advantages that matching efficiency and accuracy are high, a great number of regulating means are adopted, a great amount of high-quality steam is generated, and meanwhile the content of COS in the methanol removing and washing shifted gas is lowered.

Owner:HENAN XINLIANXIN FERTILIZER +2

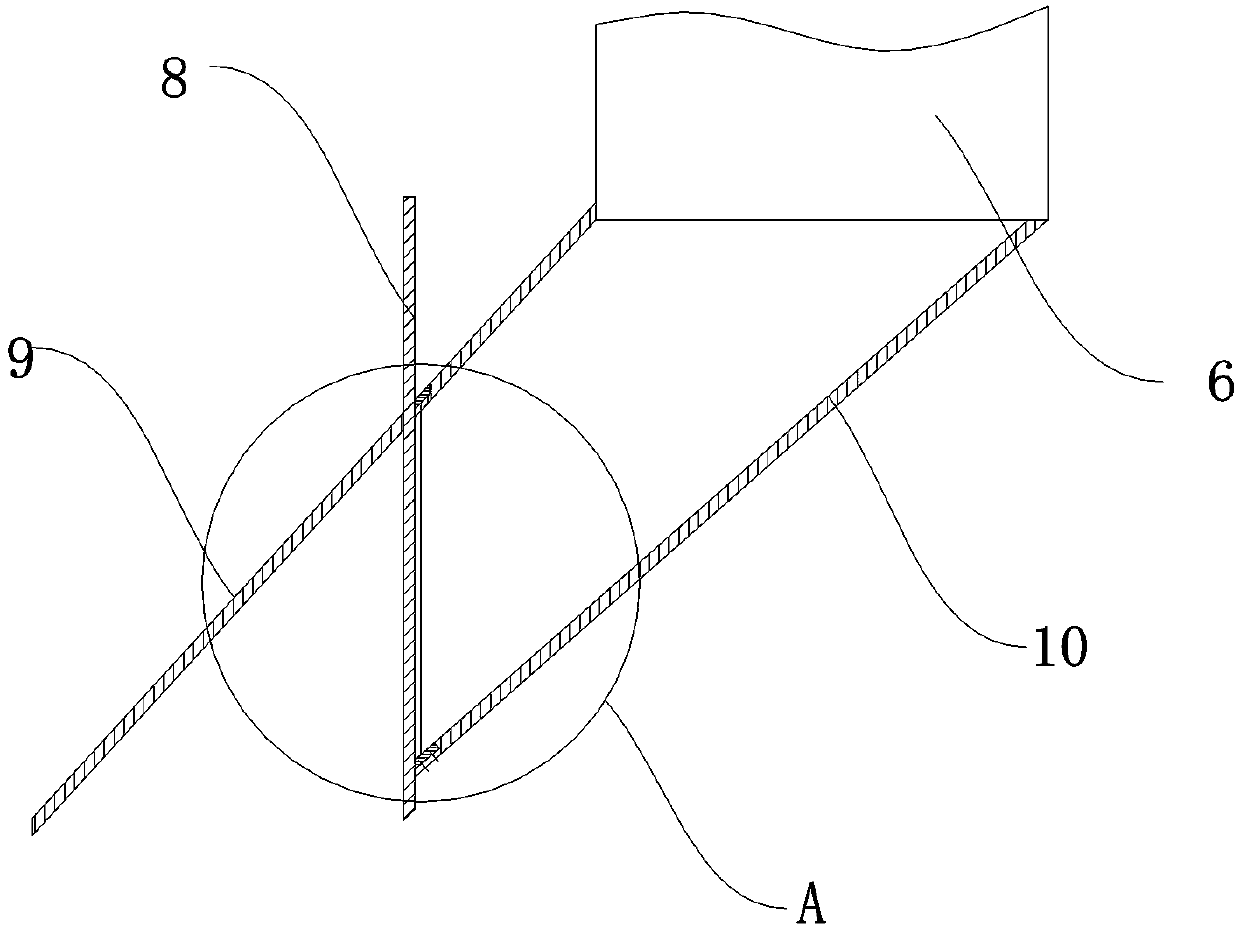

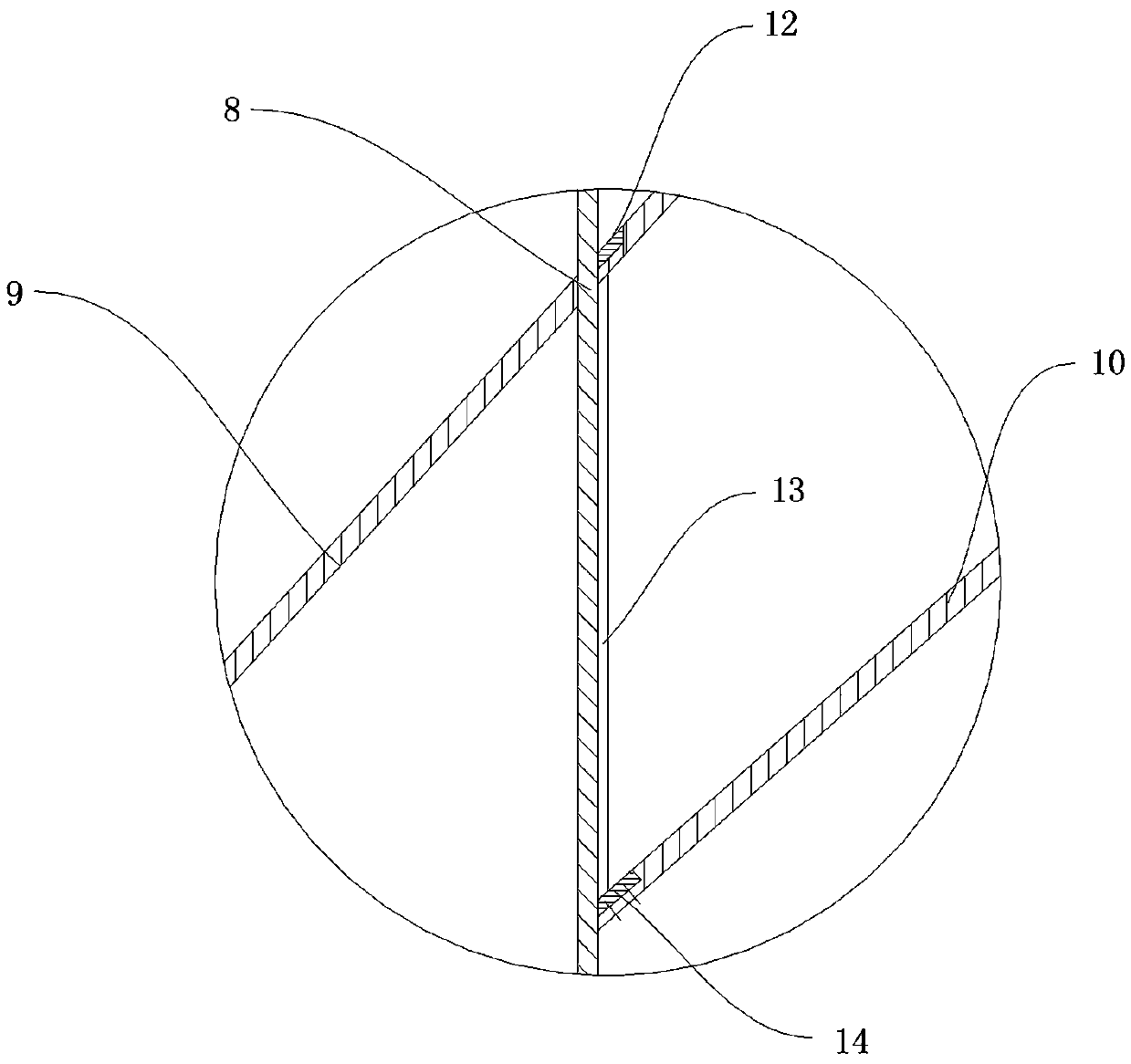

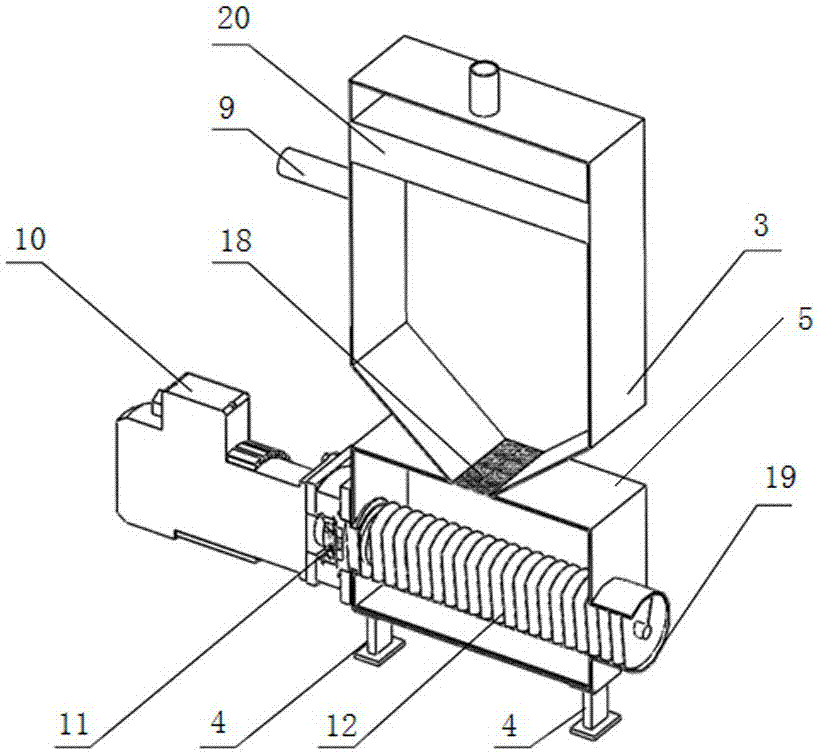

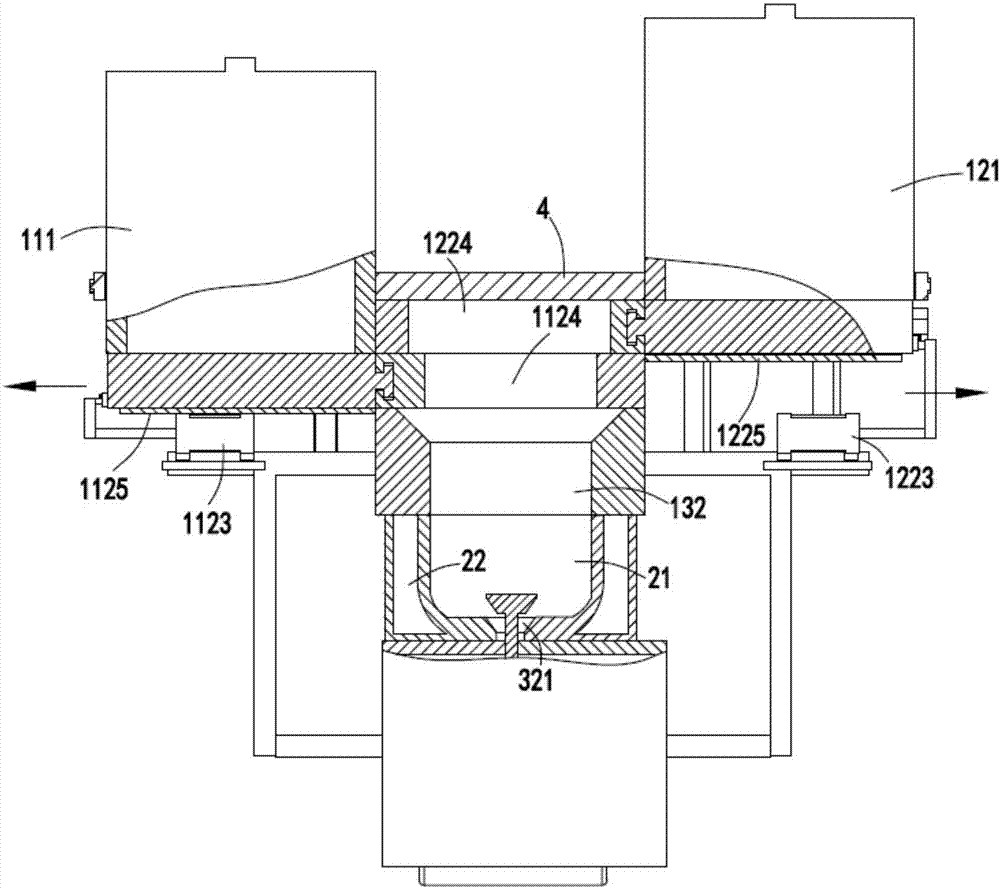

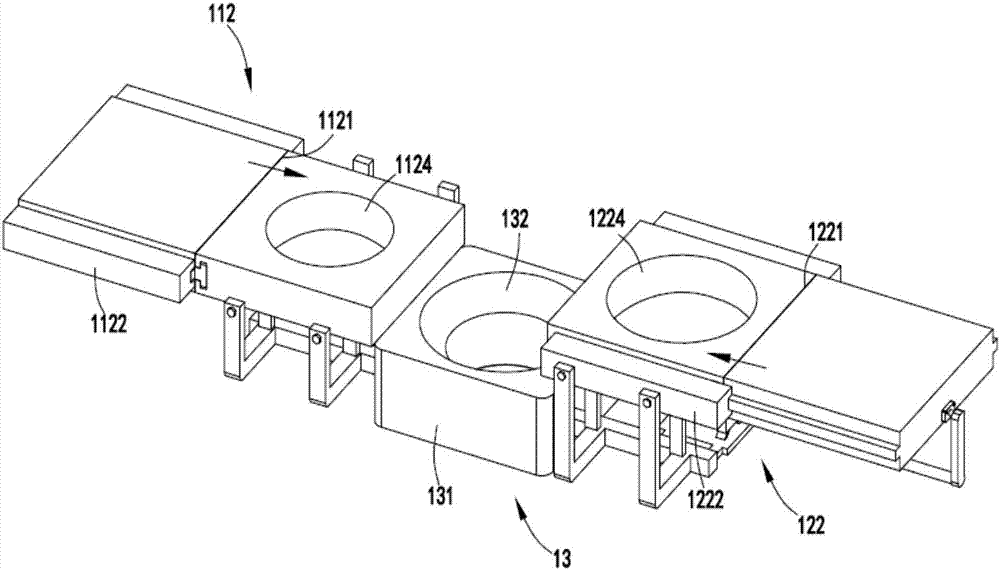

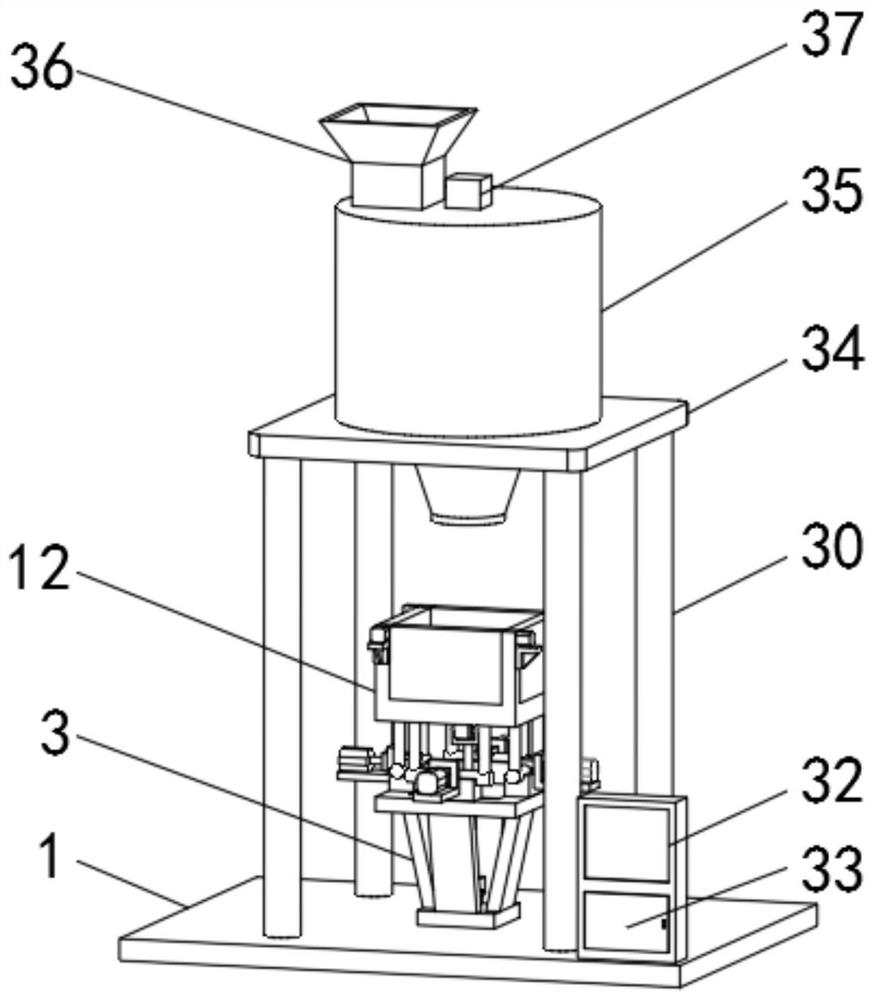

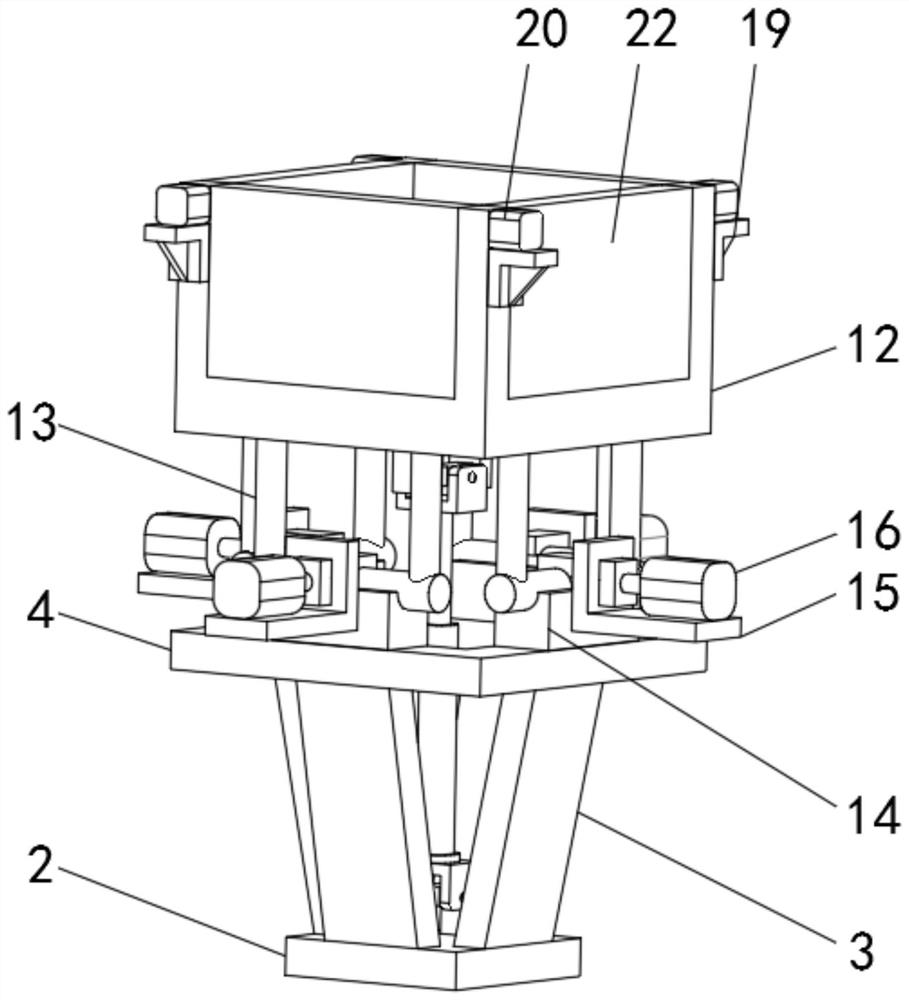

Powder batching device and powder batching control system thereof

The invention discloses a powder batching device which comprises a plurality of stock bins, weighing hoppers corresponding to the stock bins and a conveying device. A feeding device is arranged at thebottom of each stock bin, the feeding devices are used for feeding raw materials in the stock bins into the corresponding weighing hoppers, an inclined blanking hopper is arranged at the bottom of each weighing hopper, the upper side wall of each blanking hopper extends towards the conveying device to form a baffle, an inserting hole is formed in the joint of each baffle and the upper side wall of the corresponding blanking hopper, electronic scales for weighing the weighing hoppers are arranged at the tops of the weighing hoppers, a driving air cylinder is further installed on the side wallof each weighing hopper, an inserting plate is installed on a telescopic shaft of each driving air cylinder, the driving air cylinders drive the inserting plates to move downwards, and the inserting plates penetrate through the inserting holes and seal discharging holes of the blanking hoppers. The invention further discloses a powder batching control system. The powder batching device and the powder batching control system have the beneficial effects that automatic powder batching is realized; splashing powder is blocked through sealing between the inserting plates and the discharge holes ofthe blanking hoppers and the baffles; the waste of the powder is reduced, so that powder waste is reduced; and the leakage of powder can be avoided, and the proportioning precision of components is ensured.

Owner:陕西公平电子衡器有限公司

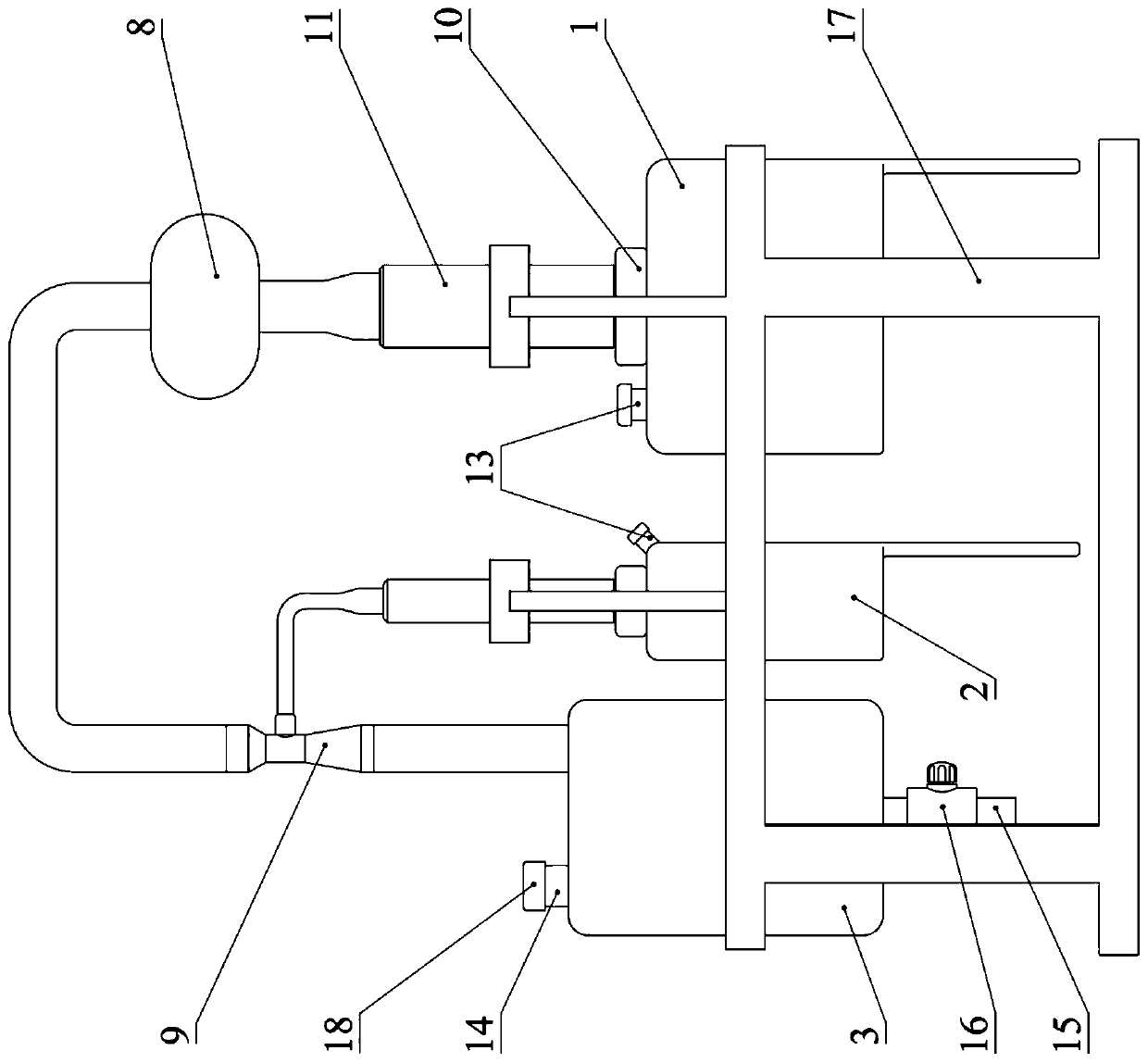

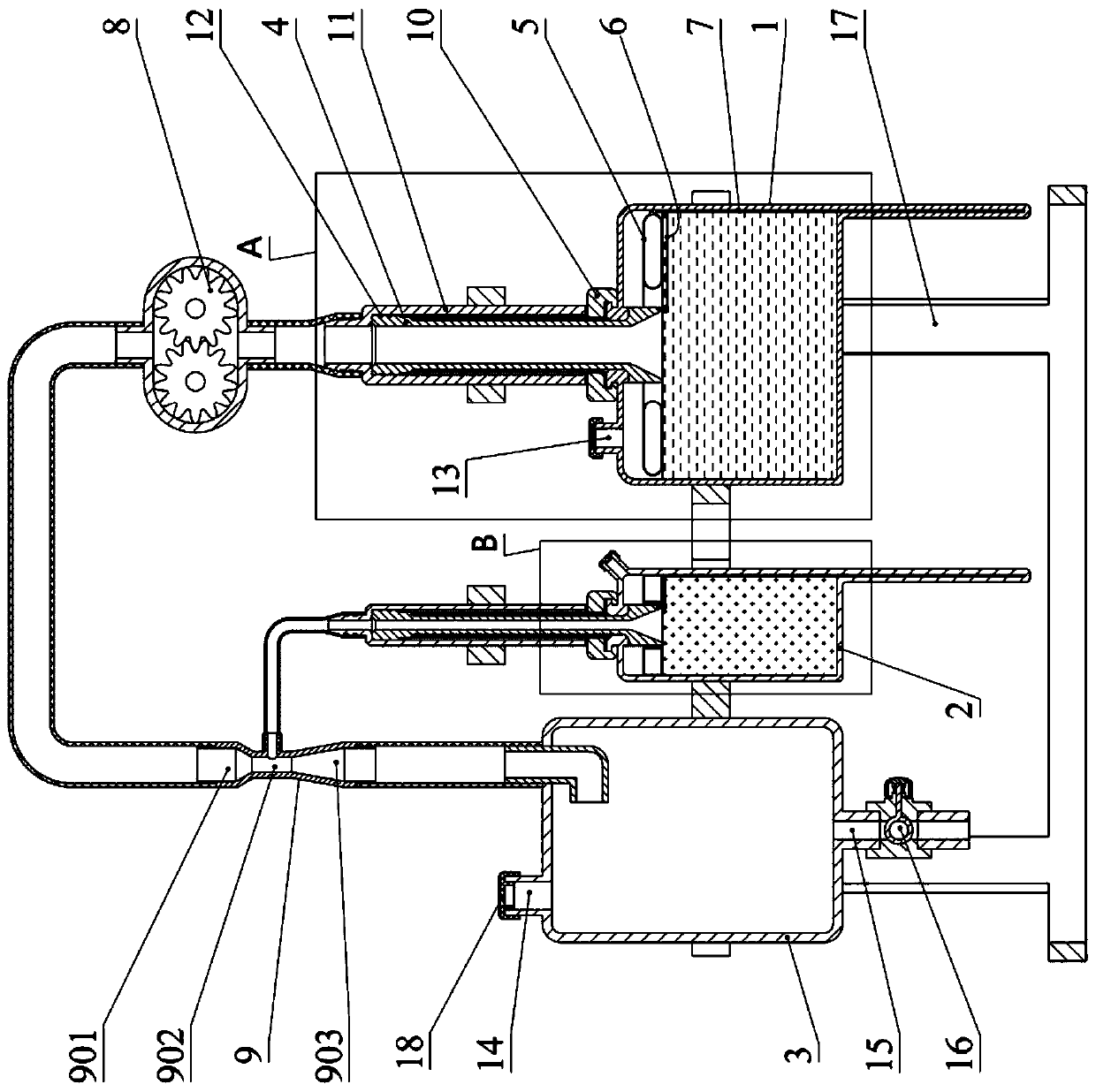

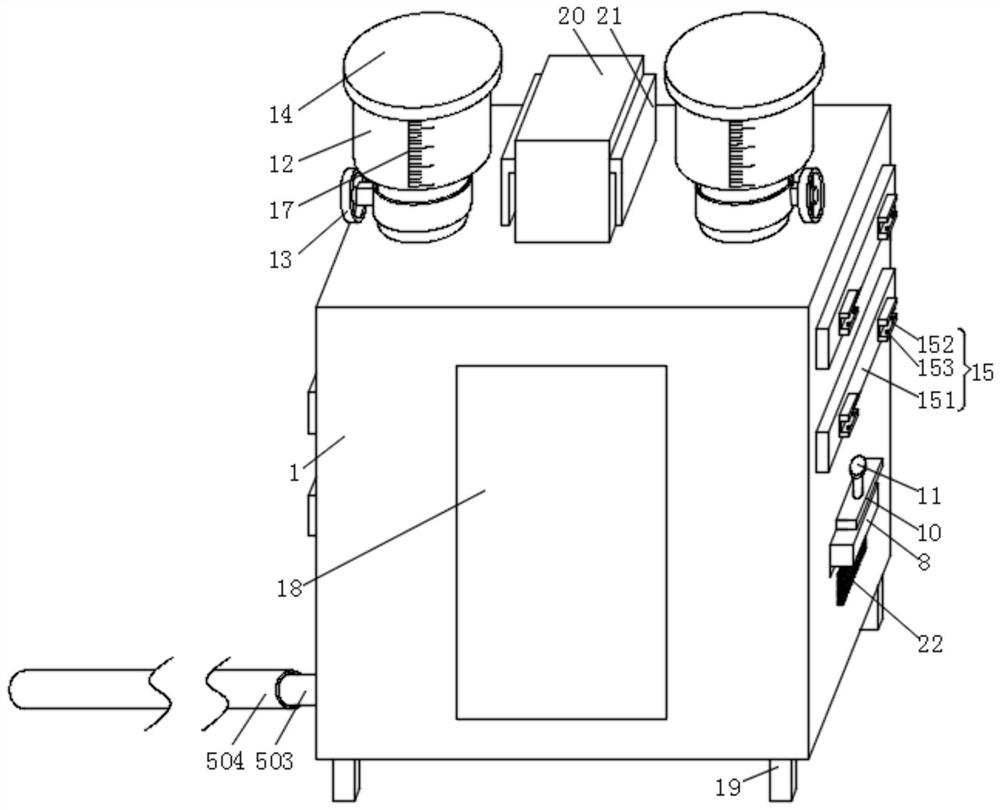

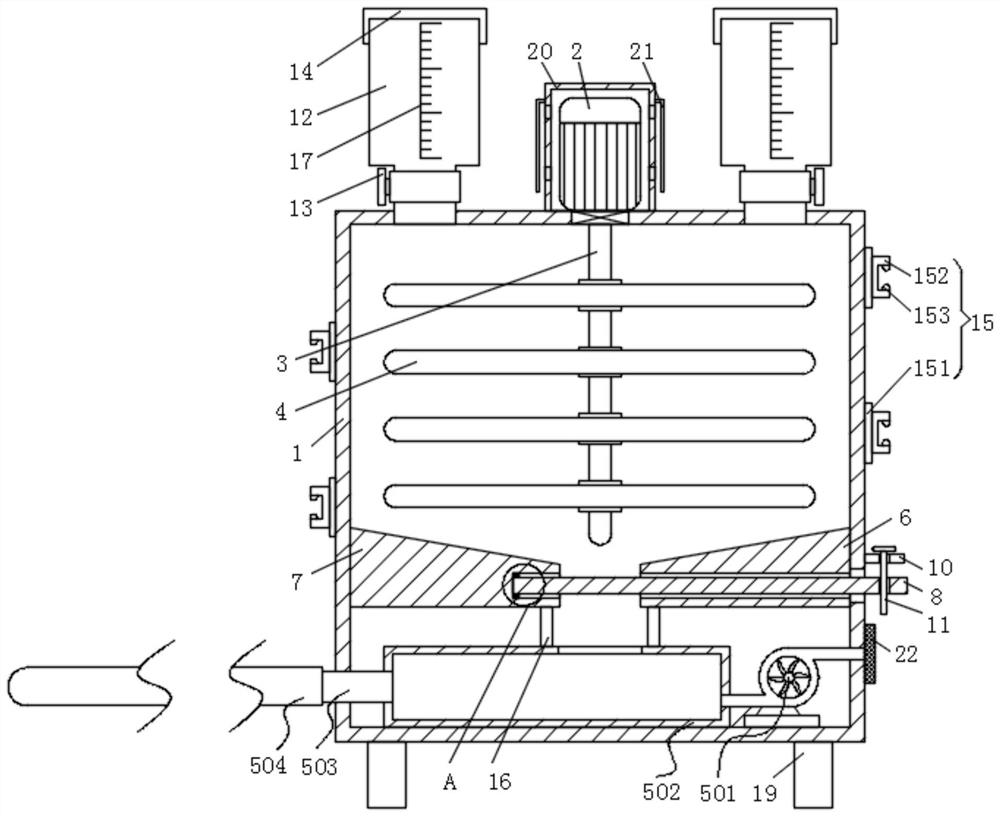

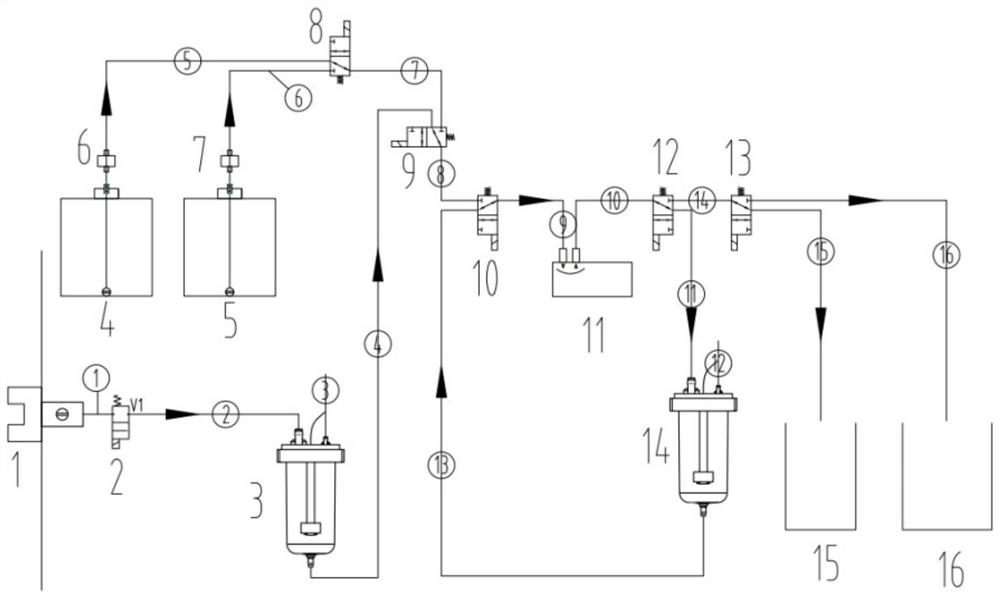

Cutting fluid concentration monitoring and automatic proportioning system and working method

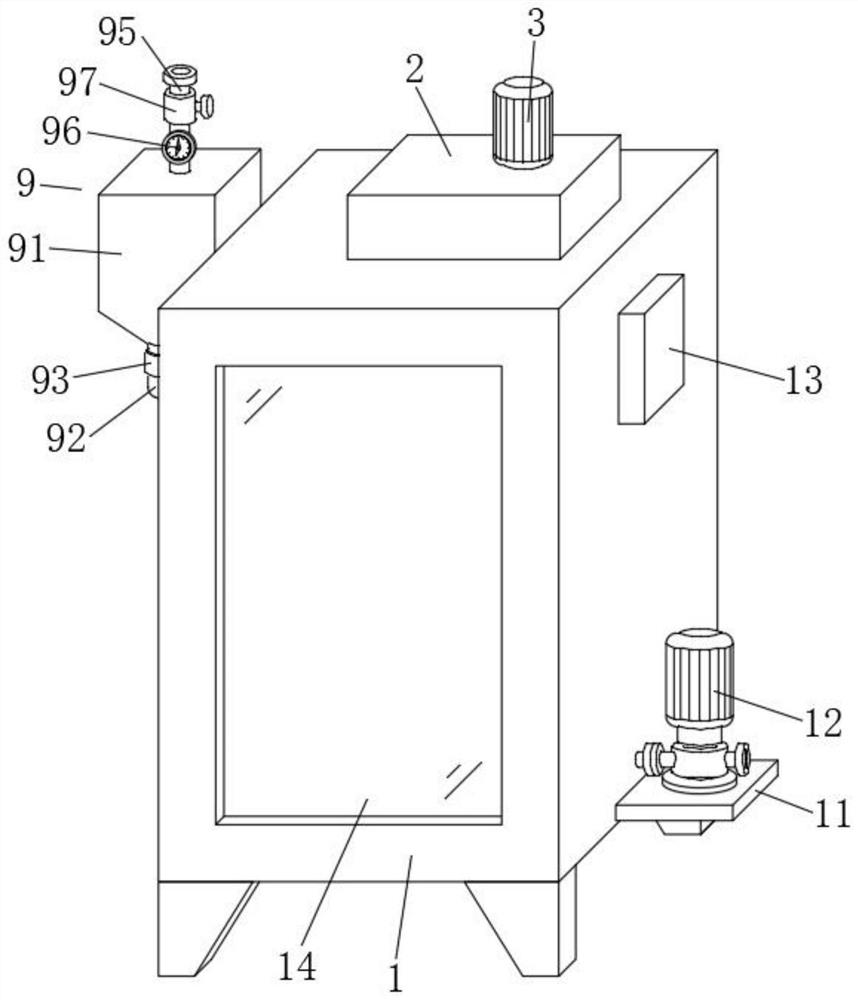

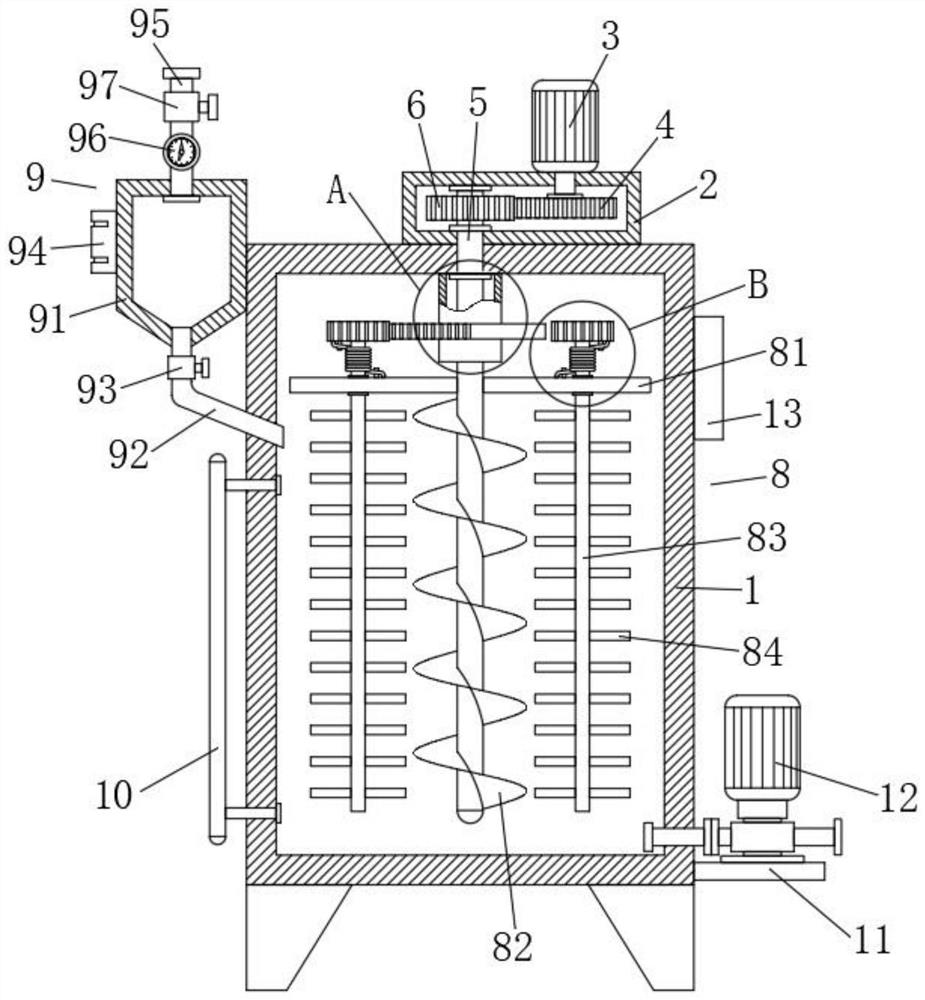

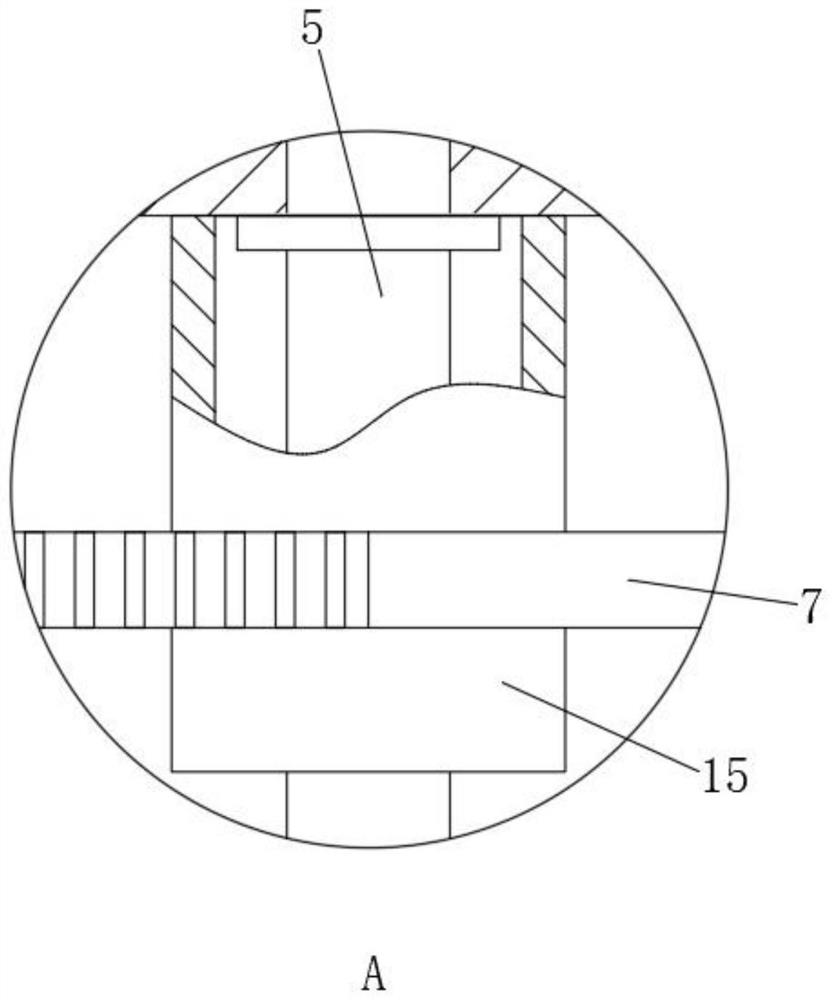

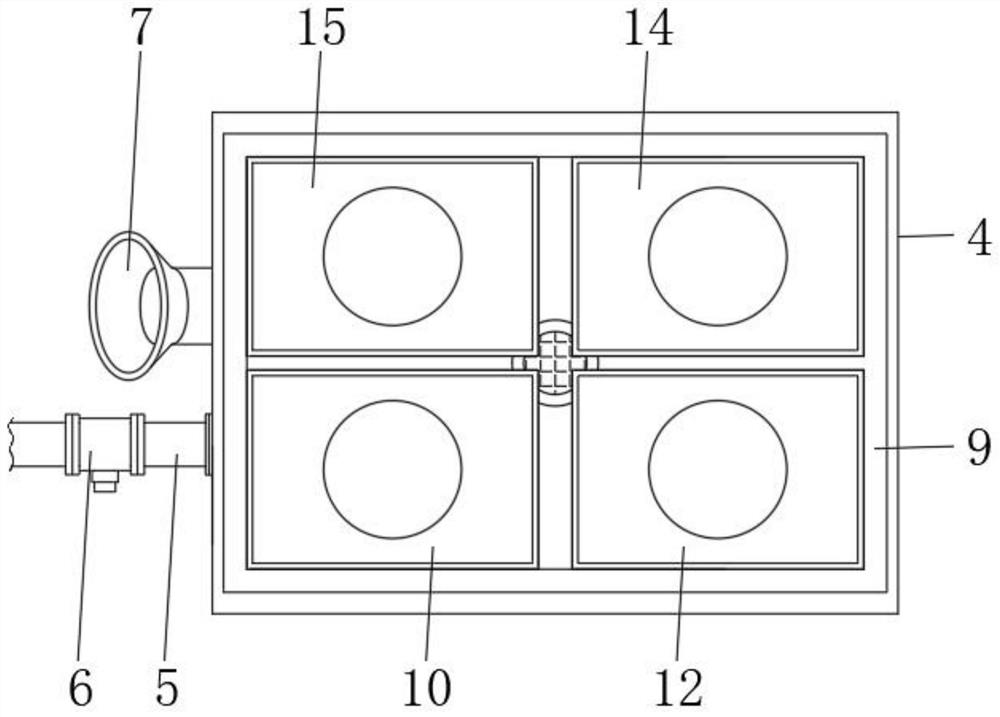

PendingCN113351071AIncrease concentrationConcentration detectionRotary stirring mixersMixer accessoriesGear driveGear wheel

The invention discloses a cutting fluid concentration monitoring and automatic proportioning system and a working method.The cutting fluid concentration monitoring and automatic proportioning system comprises a mixing box, a transmission box is fixedly connected to one end of the top of the mixing box, a servo motor is fixedly installed at one end of the top of the transmission box, and an output shaft of the servo motor extends into the transmission box and is fixedly connected with a driving gear; and a rotating shaft is rotationally connected to the position, located on one side of the driving gear, in the transmission box. The device is compact in structure, simple and convenient to operate and high in practicability.The gear is in transmission matching with a torsion spring to drive a mixing mechanism to revolve and rotate circularly, so that the mixing effect is greatly improved, the concentration in the mixing box can be detected in real time by arranging a cutting fluid concentration detector, and meanwhile, the mixing mechanism is arranged to automatically perform mixing, so that the mixing efficiency is improved. Manual operation is avoided, the proportioning efficiency is greatly improved, and actual use is facilitated.

Owner:中山市胜航机电科技有限公司

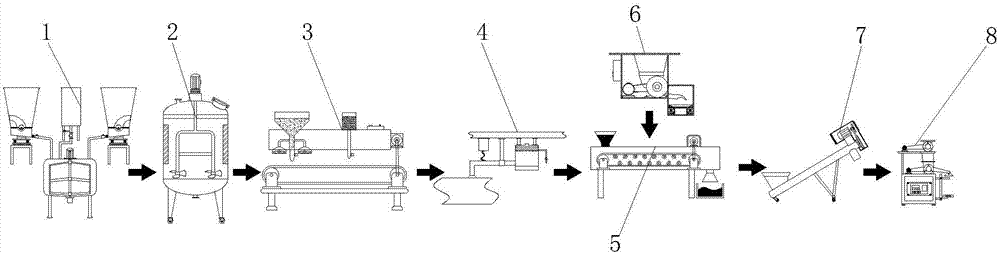

One-station type cement production system

The invention discloses a one-station type cement production system which comprises a grinding aid metering proportioning device, a grinding aid stirring device, an automatic grinding agent and cementraw material proportioning device, a grinding dust collection device, a sealed tube type conveyer belt, cement tank discharge equipment, cement lifting conveying equipment and packaging filling equipment, wherein a discharge hole of the grinding aid metering proportioning device is connected with the grinding aid stirring device through a conveyer belt; the discharge hole of the grinding aid stirring device is connected with the automatic grinding agent and cement raw material proportioning device through the conveyer belt; and the discharge hole of the automatic grinding agent and cement rawmaterial proportioning device is connected with the grinding dust collection device through the conveyer belt. The one-station type cement production system has the beneficial effects that grinding aids are automatically proportioned, accurate proportions are ensured, raw material waste is avoided, meanwhile the proportioning efficiency is improved, high stirring and mixing efficiency is achieved, and the labor is saved.

Owner:新化县天马水泥有限公司

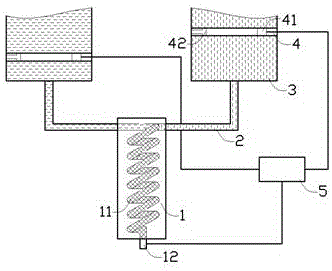

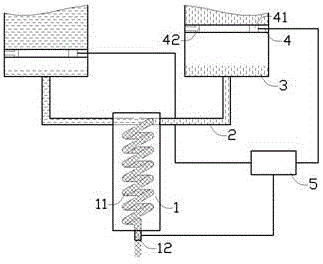

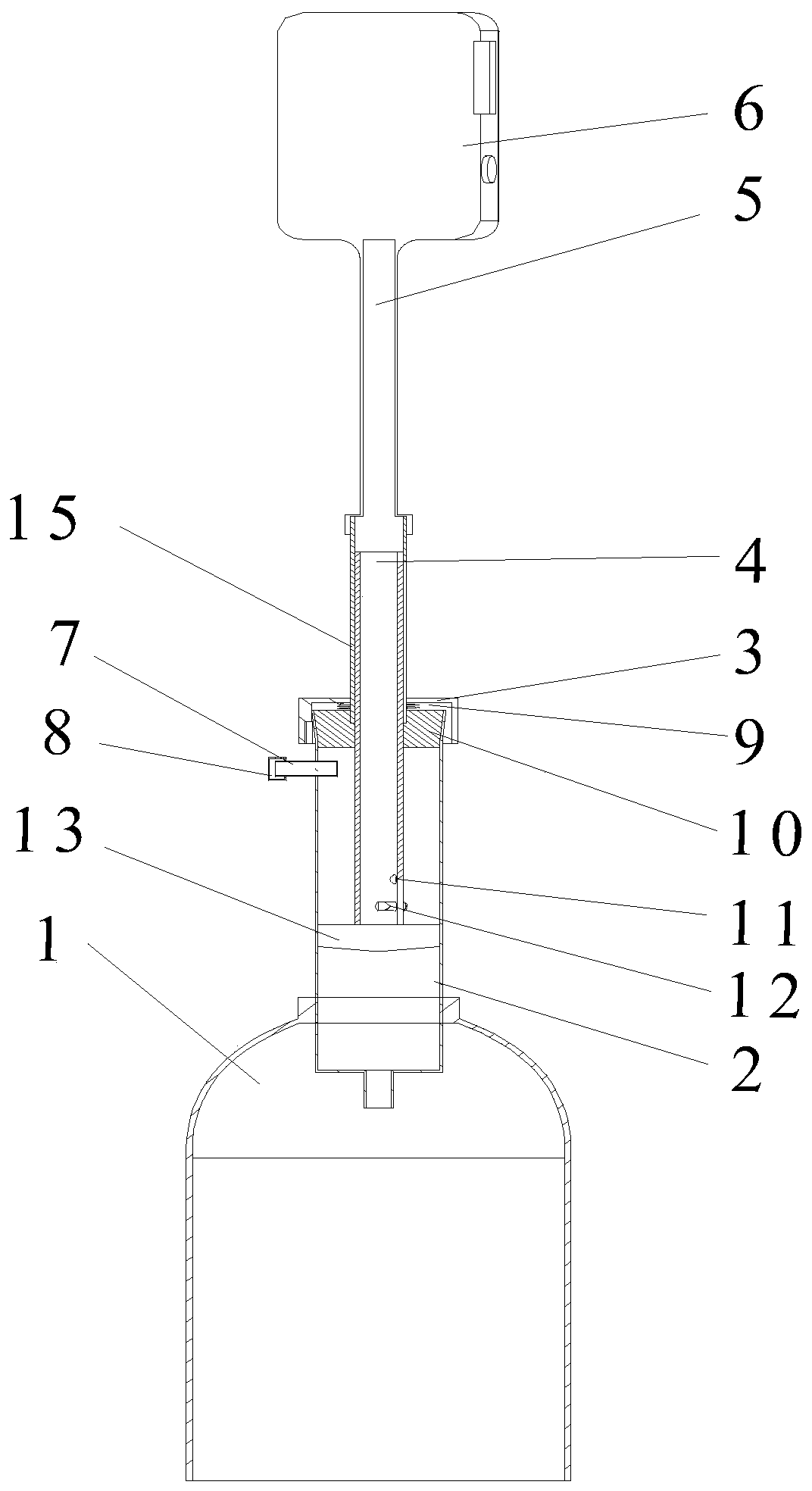

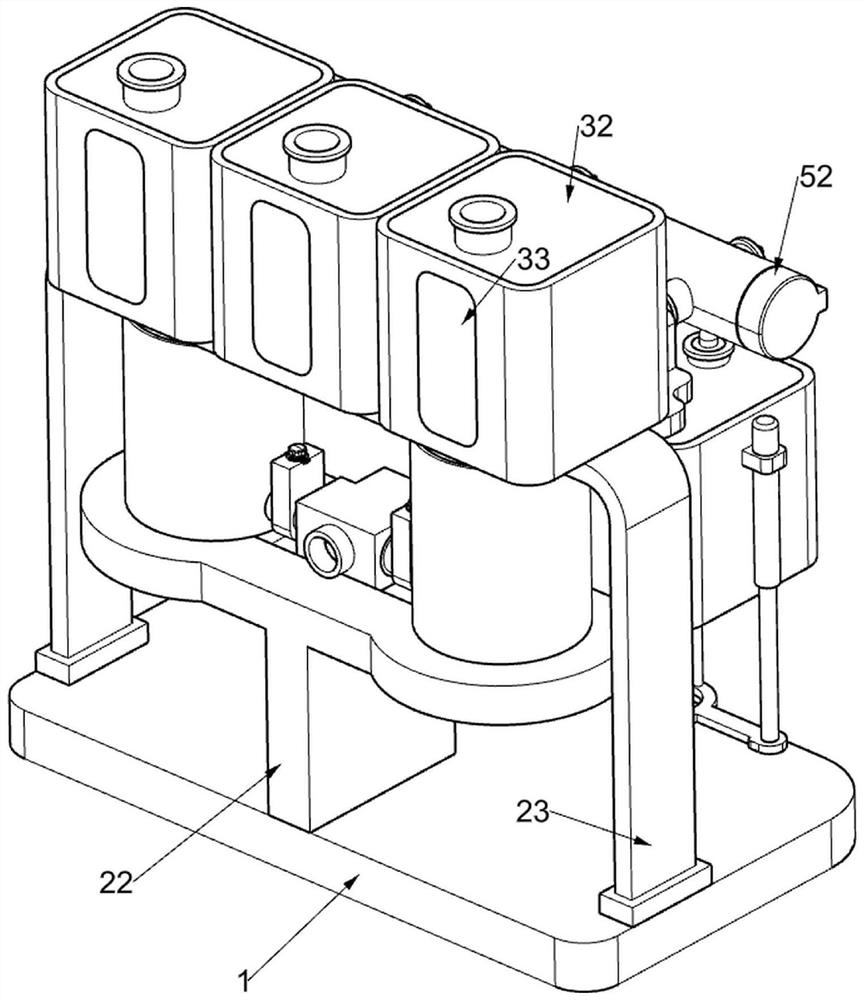

Anesthesiology department clinical concentration regulating type anesthetizing apparatus

InactiveCN110237765AImprove ratio efficiencyEnsure directTransportation and packagingMixer accessoriesBiochemical engineeringCalculation error

The invention relates to an anesthesiology department clinical concentration regulating type anesthetizing apparatus, which can solve the problems of complicated preparation operation, imprecise drug liquid medicine, easy ratio calculation error and easy reading error in the prior art. The technical scheme comprises a liquid storage tank, a medicine storage tank and a mixing tank, wherein the liquid storage tank and the medicine storage tank respectively have a quantitative sucking device arranged on the upper portion of the tank body, the quantitative sucking device comprises an inserting pipe vertically sliding on the tank body, and a float arranged on the inner side of the tank body, the upper end of the inserting pipe is arranged above the tank body, the lower end of the inserting pipe is arranged on the inner side of the tank body, the lower end of the inserting pipe has a pointer, the tank body has a scale ruler arranged on the inner side of the tank body and vertically sliding, the scale ruler is connected to the float, the pointing end of the pointer is close to the scale ruler, the apparatus further comprises a liquid pump and a venturi pipe, the sucking end of the liquid pump is communicated to the upper end of the inserting pipe corresponding to the liquid storage tank, the pumping end of the liquid pump is communicated to the inlet section of the venturi pipe, the throat channel of the venturi pipe is communicated to the upper end of the inserting pipe corresponding to the medicine storage tank, and the diffusion section of the venturi pipe is communicated to the inner side of the mixing tank.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Proportioning device for production of construction cement

InactiveCN109206032AIncrease the proportioning speedImprove ratio efficiencyRaw materialArchitectural engineering

Owner:湖南耒阳南方水泥有限公司

Automatic solution proportioning structure

InactiveCN106040063AReduce lossImprove ratio efficiencyRotary stirring mixersTransportation and packagingEngineeringFunnel shape

The invention provides an automatic solution proportioning structure, and relates to the field of automatic changing. The automatic solution proportioning structure solves the solution proportioning problem. The automatic solution proportioning structure comprises a mixing cavity, a conveying pipe, a solution storage cavity, an adjusting plate and an electronic valve; a solution outlet switch is designed at a solution outlet formed in the lower end of the mixing cavity; one end of the conveying pipe is fixedly connected with the mixing cavity, and the other end of the conveying pipe is fixedly connected with the solution storage cavity; the upper end of the solution storage cavity is fixedly connected with a solution conveying inlet; the adjusting plate comprises a solution inlet switch and an air inlet; the solution inlet switch is designed to be a funnel-shaped hinge switch; the solution inlet switch and the solution outlet switch are connected by the electronic valve; the air inlet is designed to be in a T shape, and the adjusting plate is transversely assembled in the solution storage cavity. Accordingly, automatic proportioning is conducted by adjusting the solution proportion, artificial proportioning losses are reduced, and the proportioning efficiency is improved.

Owner:SUZHOU RUIQI ELECTRONICS

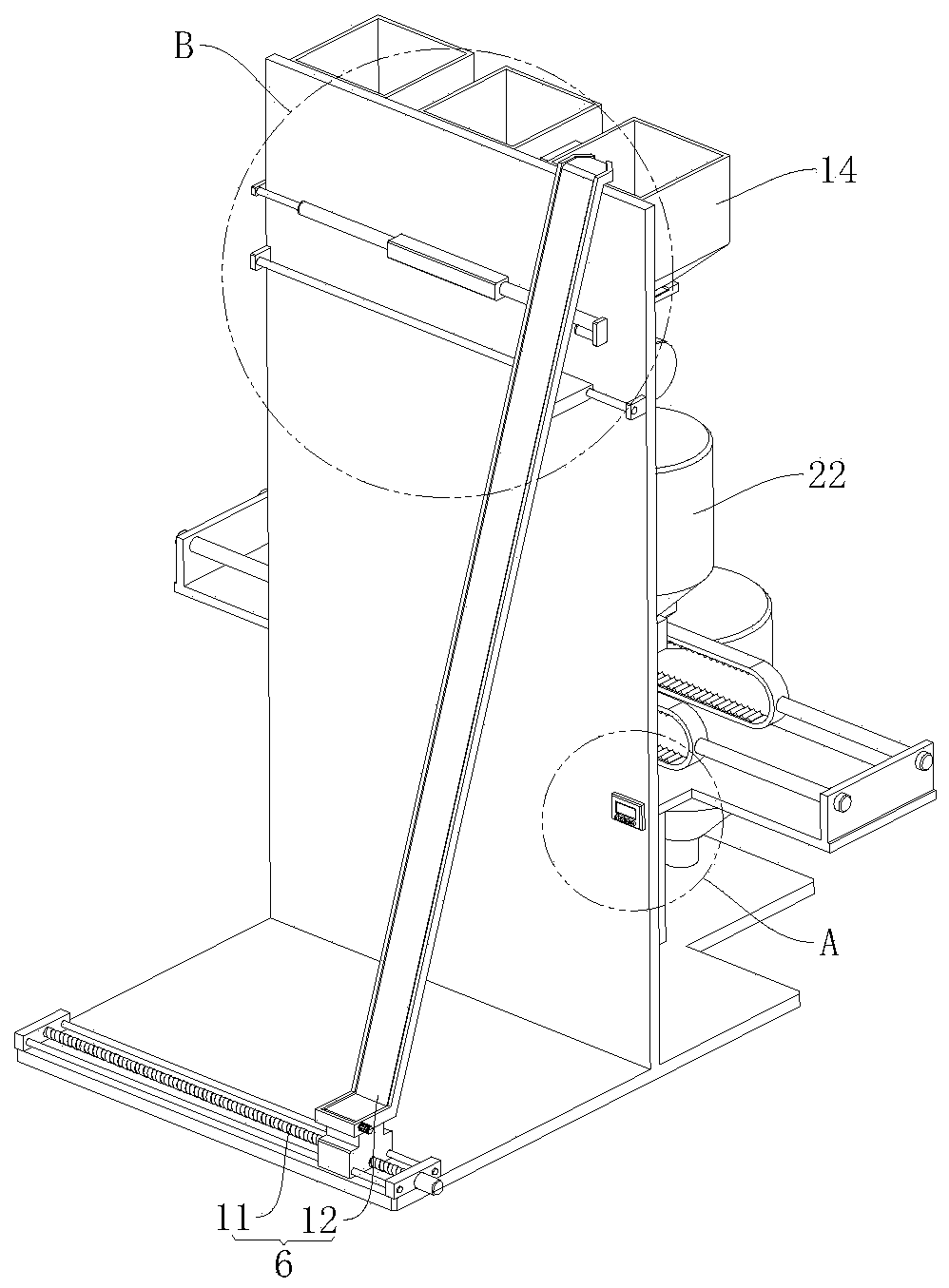

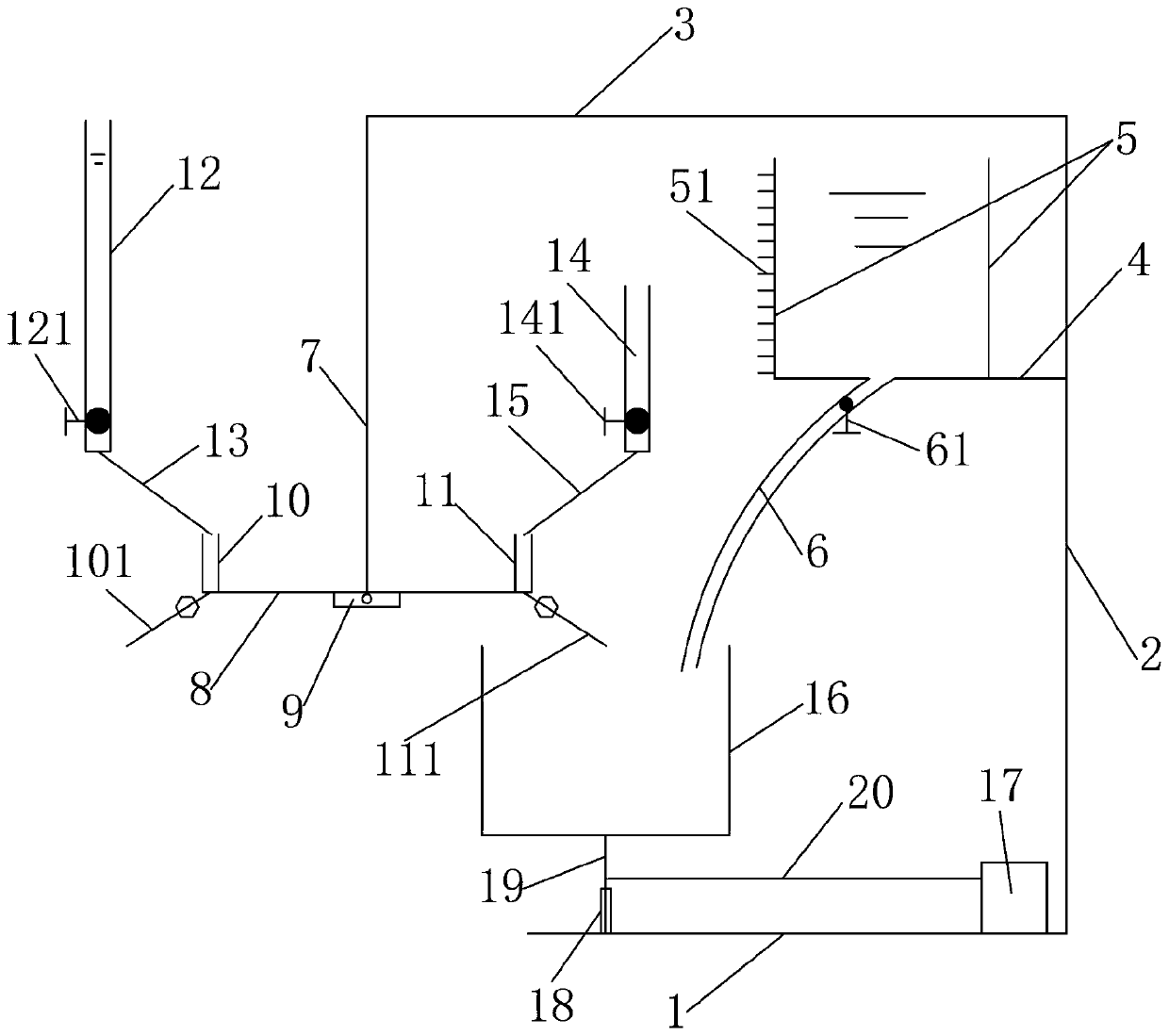

Automatic proportioning and conveying equipment for production of dry-mixed mortar

InactiveCN111559002AGuarantee processing qualityGuaranteed qualityMixing operation control apparatusIngredients weighing apparatusRotational axisElectric machine

The invention relates to the technical field of building material processing, in particular to proportioning and conveying equipment for production of dry-mixed mortar. The equipment comprises a base,and further comprises a controller, a proportioning mechanism and a conveying mechanism, wherein the proportioning mechanism is arranged on the outer wall of the upper half of a vertical plate for proportioning raw materials of the dry-mixed mortar; the proportioning mechanism comprises a loading component and three sets of feeding components; the conveying mechanism is arranged on the outer wallof the lower half of the vertical plate for conveying the raw materials of the dry-mixed mortar; the conveying mechanism comprises a drive motor, a rotating shaft and two sets of sliding components;and the loading component, the drive motor and the three sets of feeding components are all electrically connected to the controller. The proportioning and conveying equipment for production of dry-mixed mortar provided by the invention can accurately control the conveying volume of each raw material to ensure the processing quality, and avoid waste and save processing costs at the same time.

Owner:芜湖中民科技建材有限公司

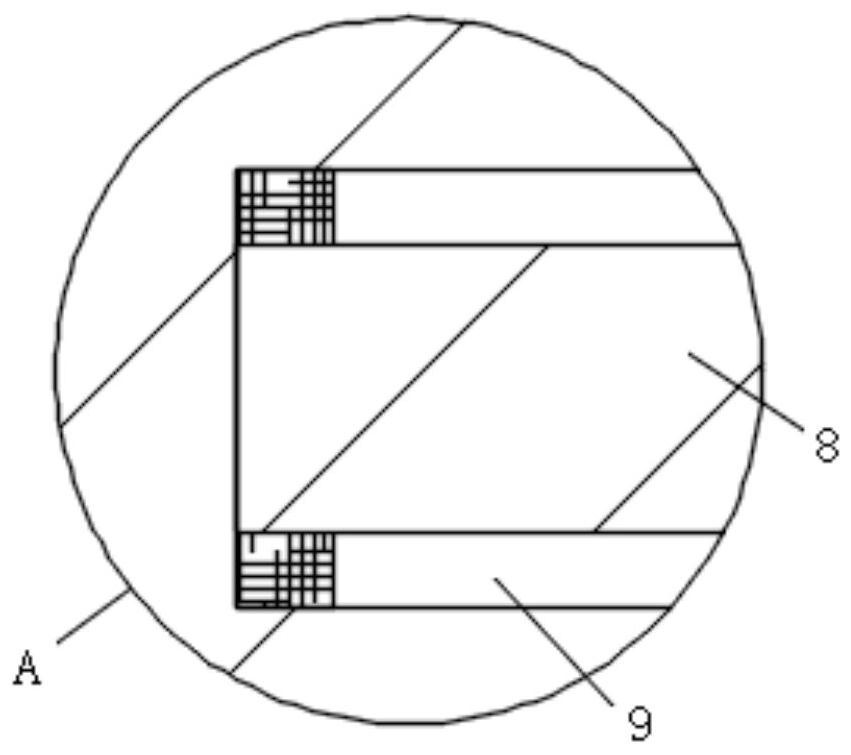

High-cleanness wet process equipment suitable for acid supply system

ActiveCN112735989AImprove cleaning efficiencyWash thoroughlySemiconductor/solid-state device manufacturingProcess equipmentWafer

The invention discloses high-cleanness wet method equipment suitable for an acid supply system. The high-cleanness wet method equipment comprises a working cabin, an acid mixing device and wafer cleaning equipment, the interior of the working cabin is divided into a plurality of cabins through breathable partition plates, and the acid mixing devices and the wafer cleaning devices are alternately installed in the cabins of the working cabin. A fan filtering unit is mounted on the working cabin; the wafer cleaning equipment comprises an equipment shell, a composite cavity structure arranged in the equipment shell and a wafer supporting structure arranged in the composite cavity structure. An air extractor communicated with the composite cavity structure and used for extracting waste gas in the composite cavity structure and at least one spraying pipe used for spraying cleaning liquid or gas to the surface of the wafer are installed on the equipment shell. The cleaning capacity is greatly improved, the cleaning efficiency and the cleaning effect are improved, and the wafer quality is effectively guaranteed.

Owner:ULTRON SEMICON (SHANGHAI) CO LTD +1

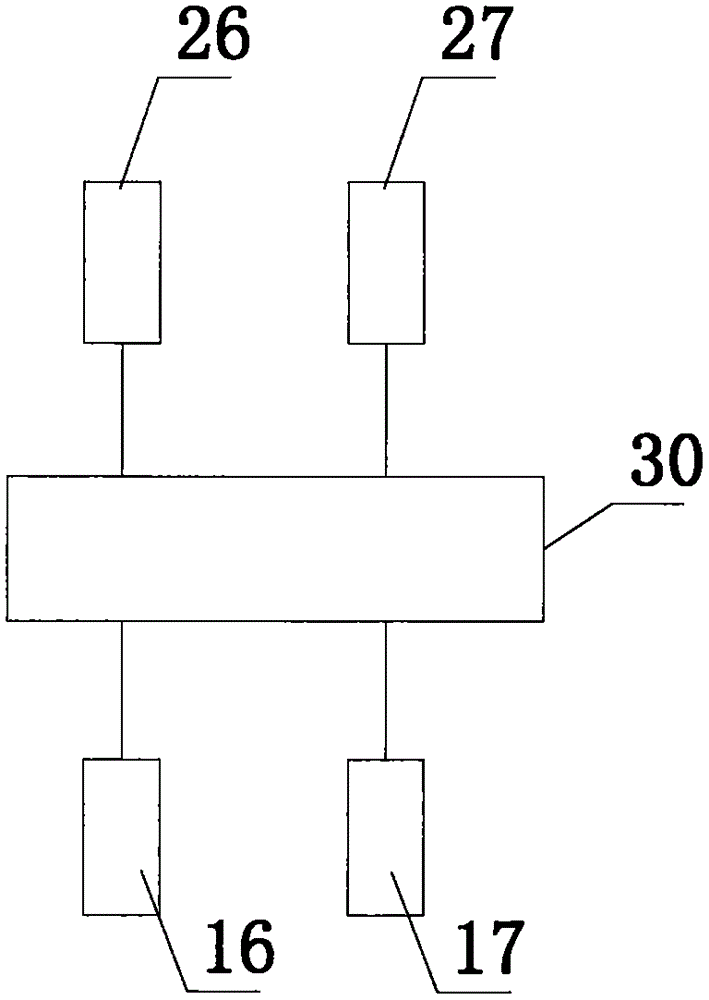

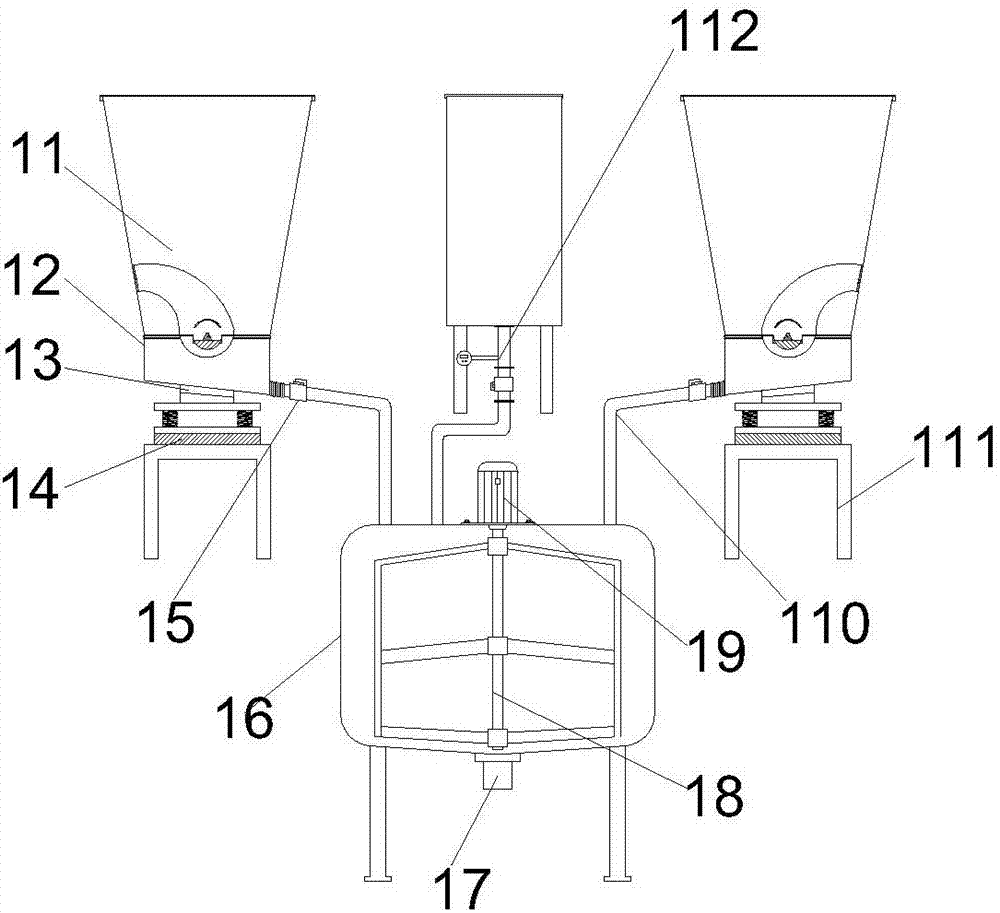

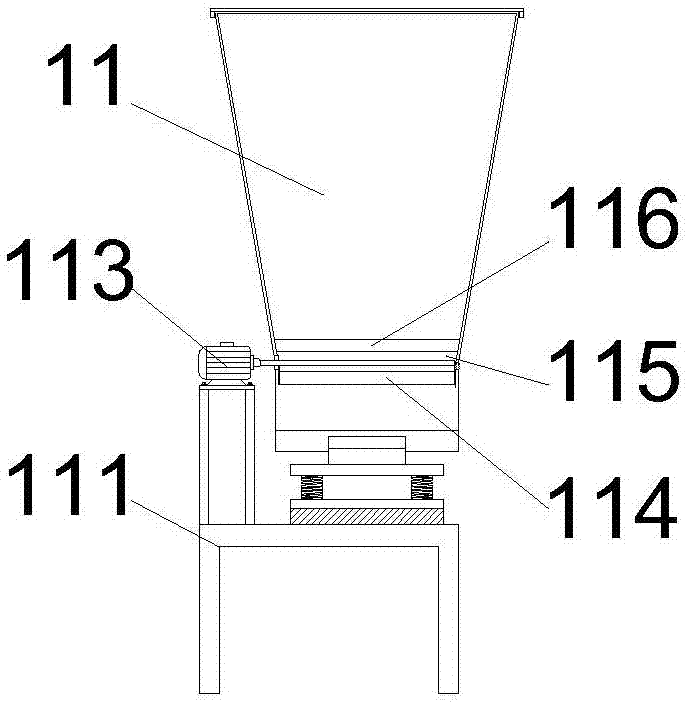

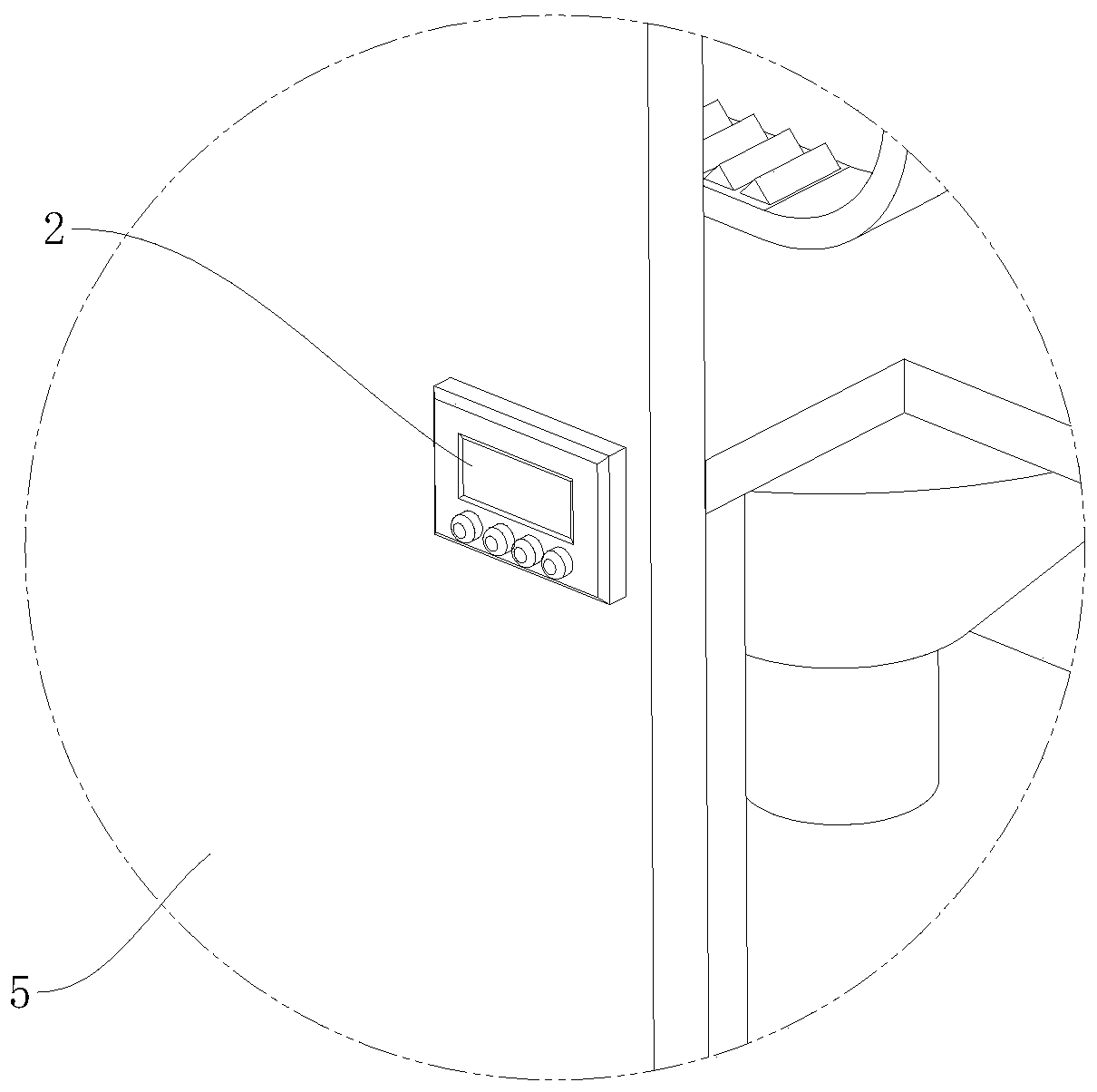

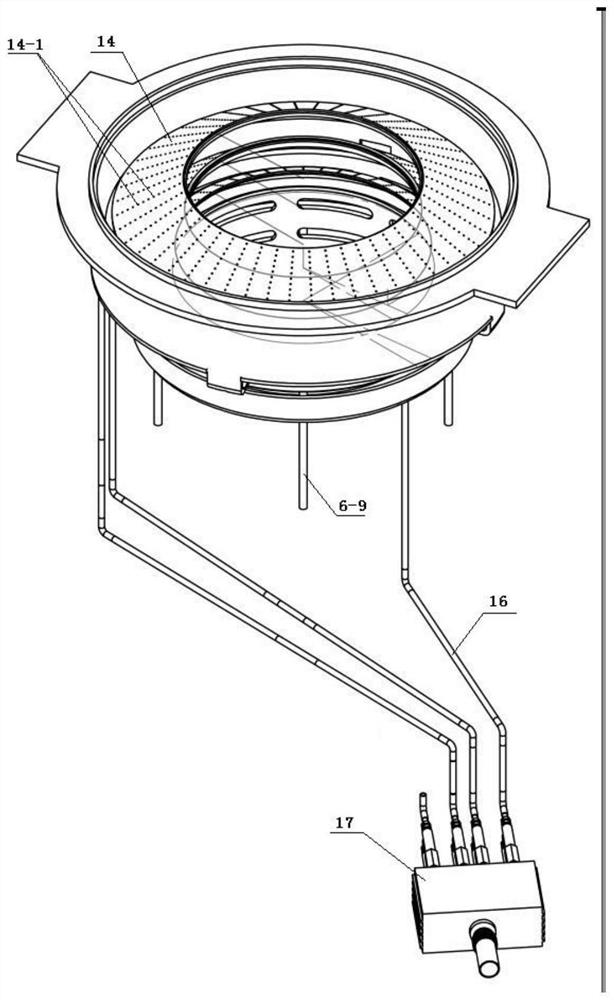

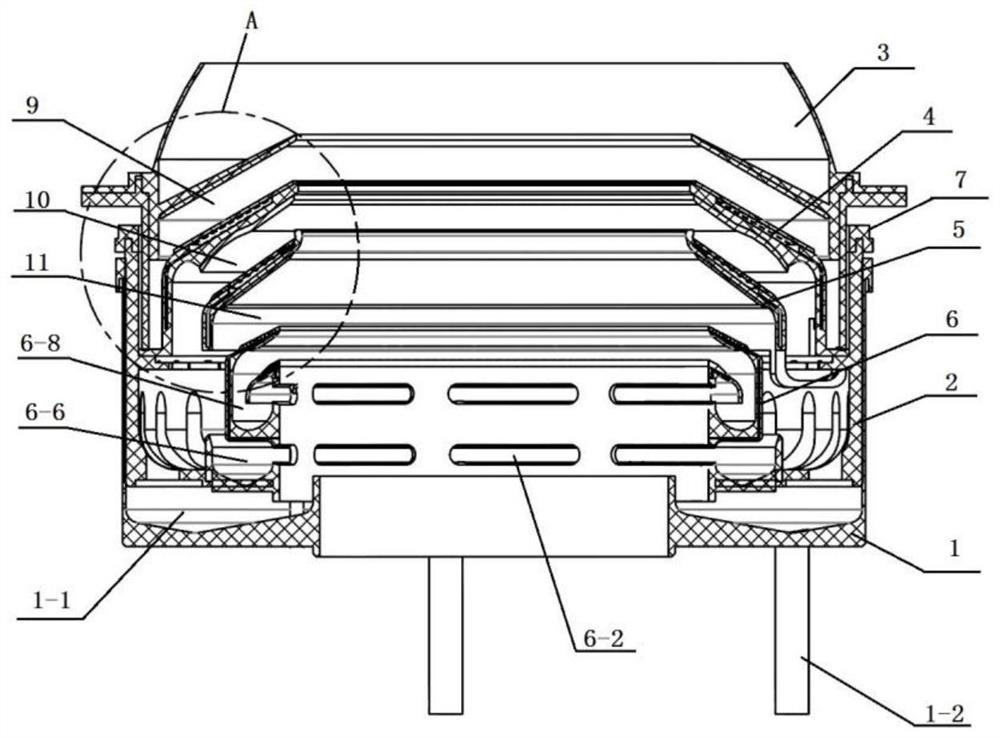

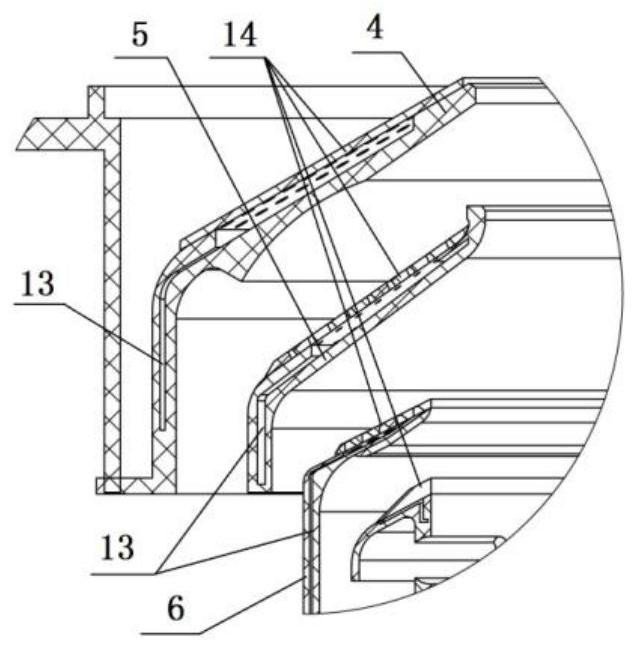

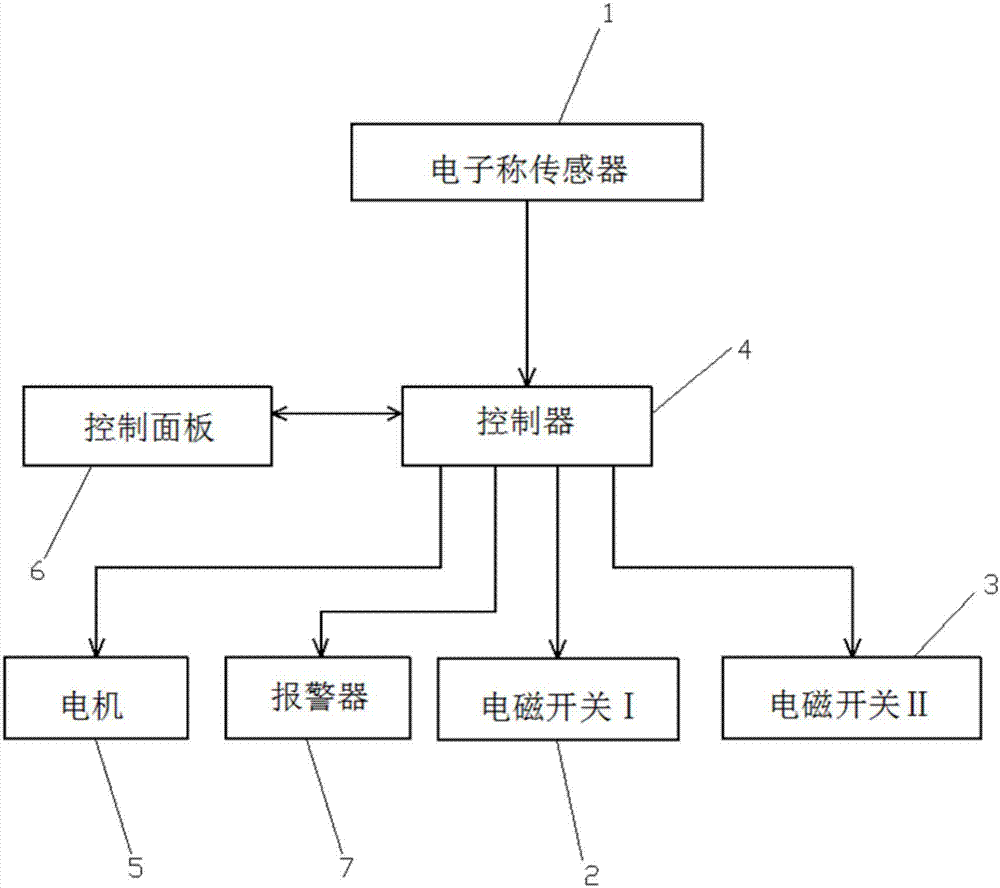

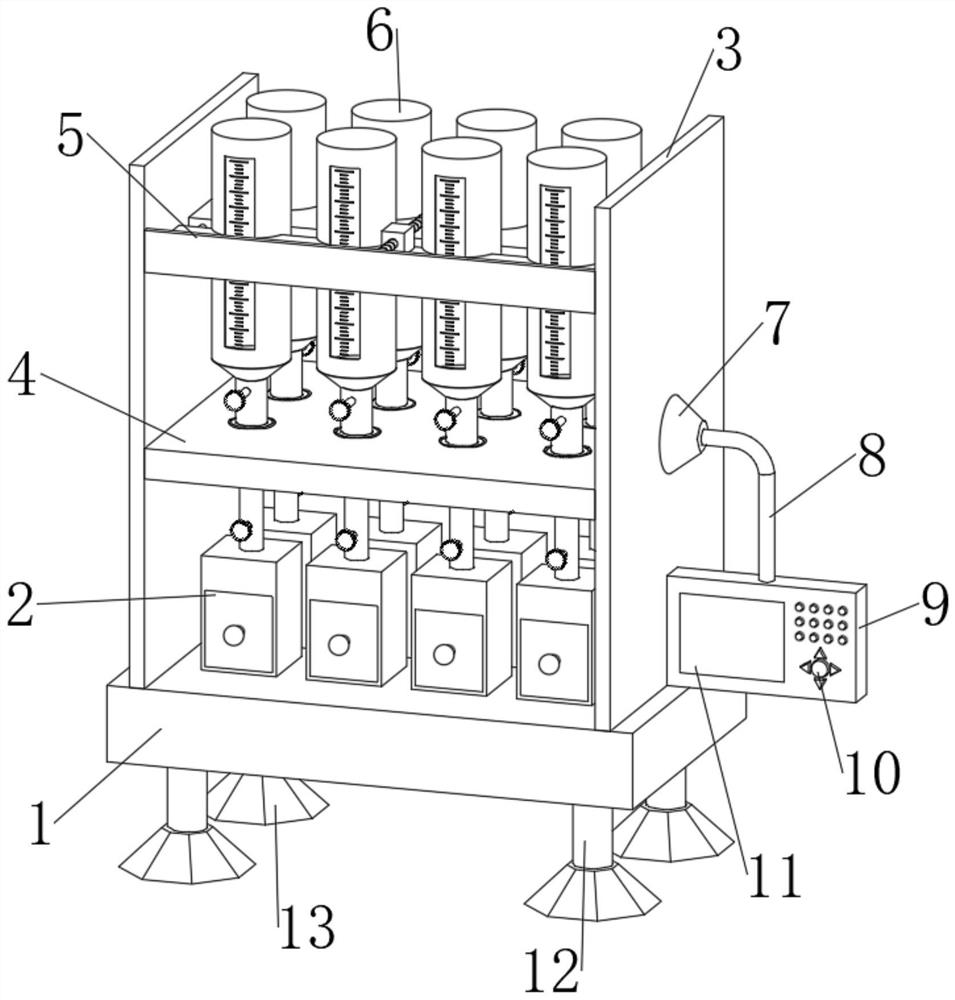

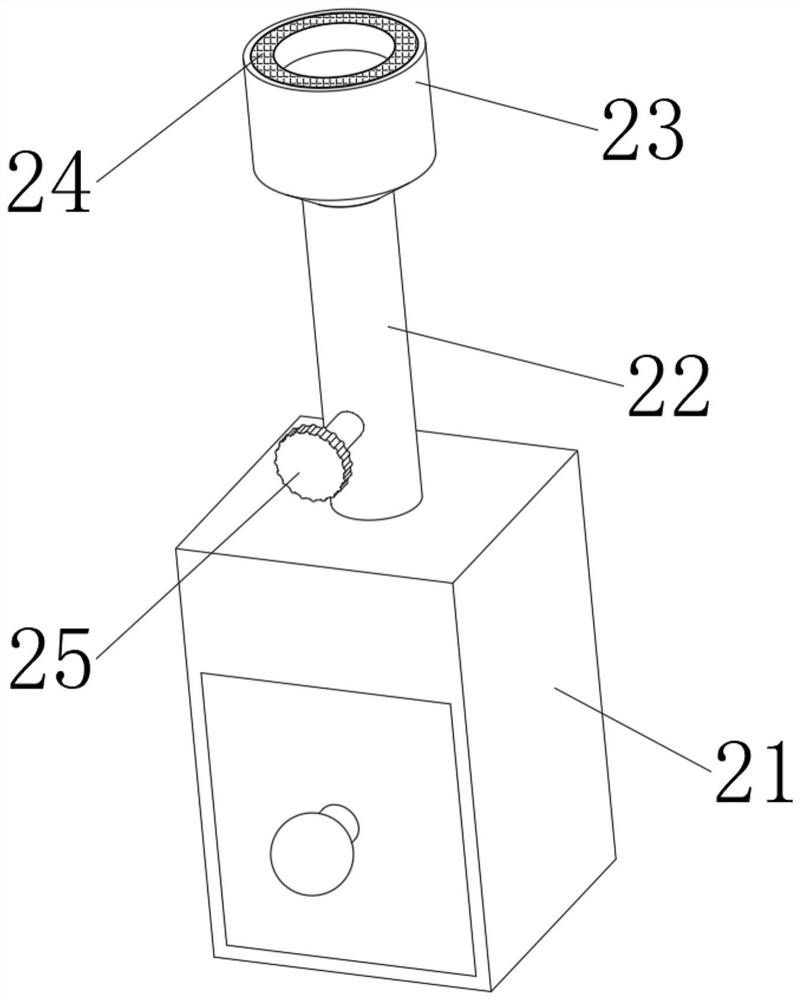

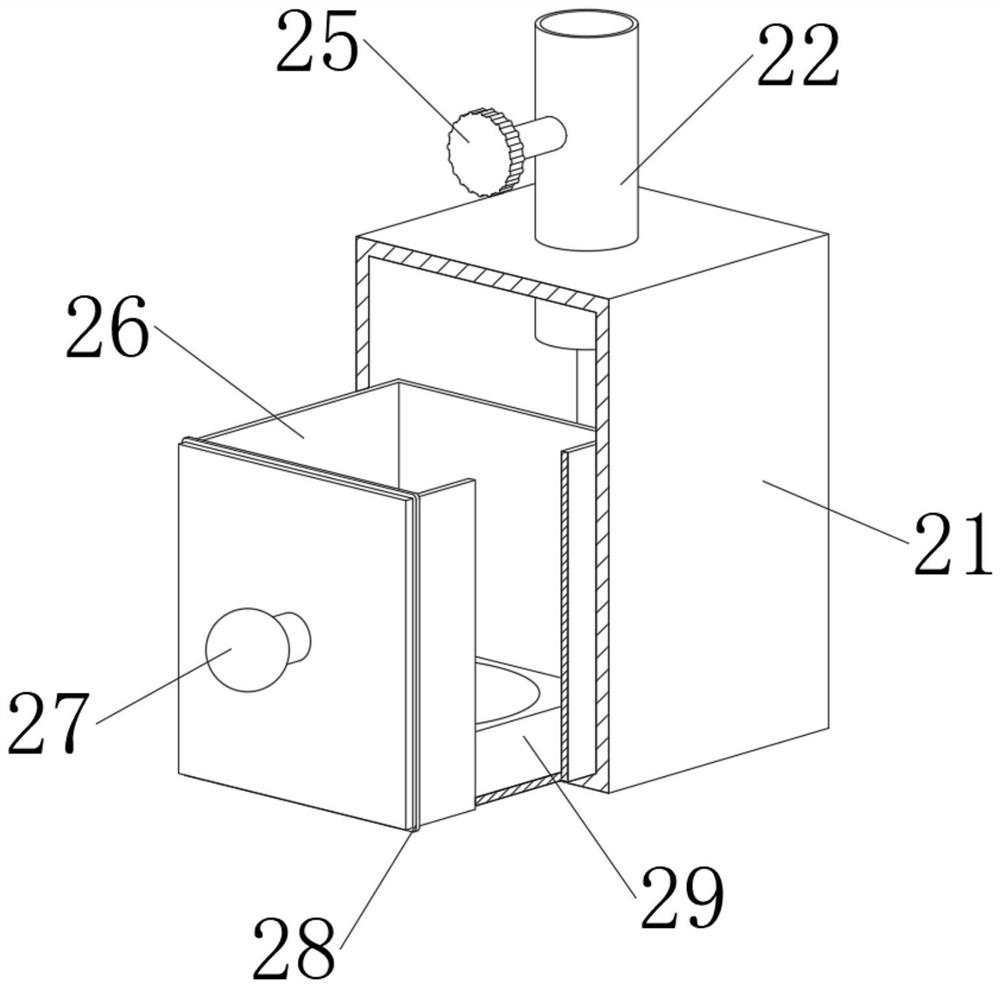

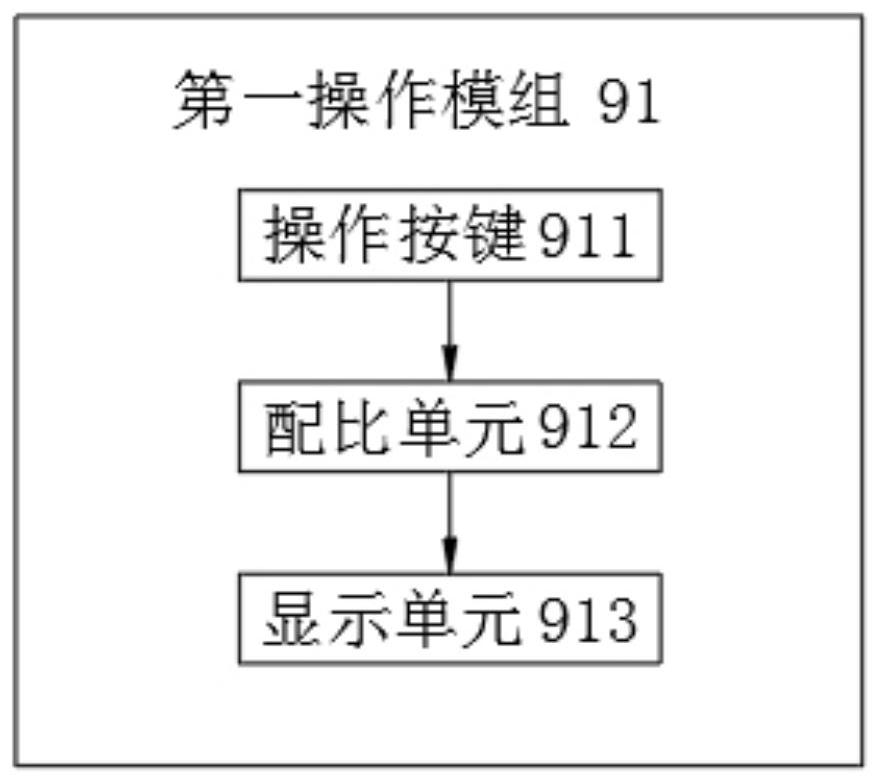

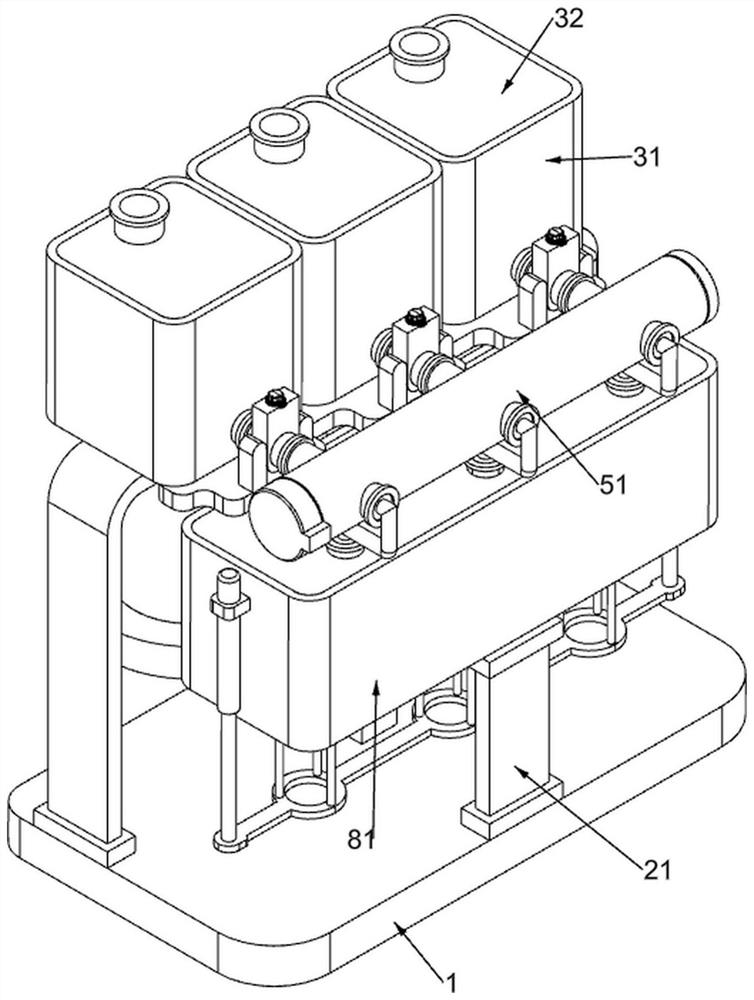

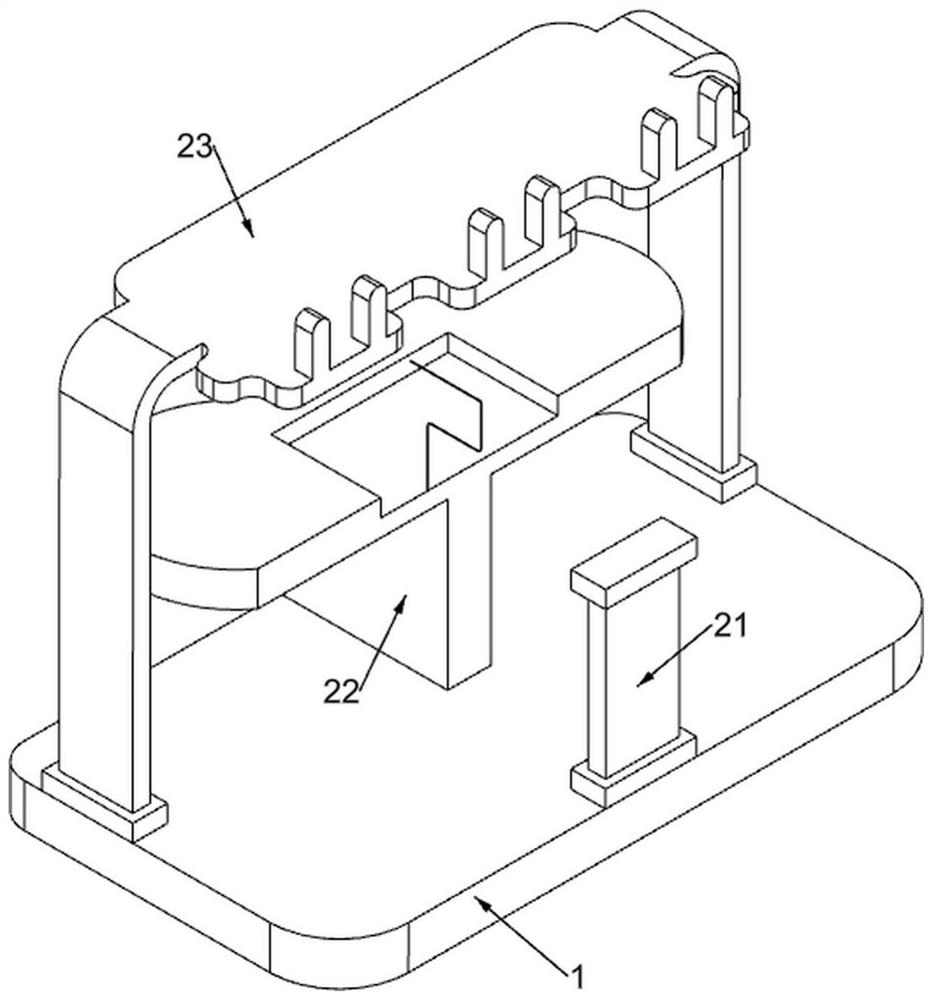

Automatic proportioning and mixing system for breeding feed

InactiveCN107183763APrecise and reliable ratioImprove ratio efficiencyFeeding-stuffElectric machineryEngineering

The invention provides an automatic proportioning and mixing system for breeding feed. The system is provided with a proportioning bin; the proportioning bin is provided with an electronic scale sensor, a first electromagnetic switch and a second electromagnetic switch; the electronic scale sensor, the first electromagnetic switch and the second electromagnetic switch are connected with a controller in a control cabinet through wires; the controller is connected with a motor of a smashing and stirring machine; an alarm device arranged on a proportioning bin installing frame is connected with the controller; the controller is connected with a control panel arranged on the control cabinet through a wire, and then input and display of feed proportioning parameters are achieved; the controller controls the electronic scale sensor, the first electromagnetic switch and the second electromagnetic switch to work to achieve automatic proportioning and mixing of the breeding feed. The control panel is used for inputting the feed proportioning parameters into the controller, automatic proportioning and mixing of the breeding feed are achieved after electronic devices are controlled by the controller to work, the material proportioning is accurate and reliable, the material proportioning efficiency is greatly improved, the labor intensity of breeding workers is reduced, and the system has high practical value.

Owner:BAOJI YINKANG MACHINERY EQUIP

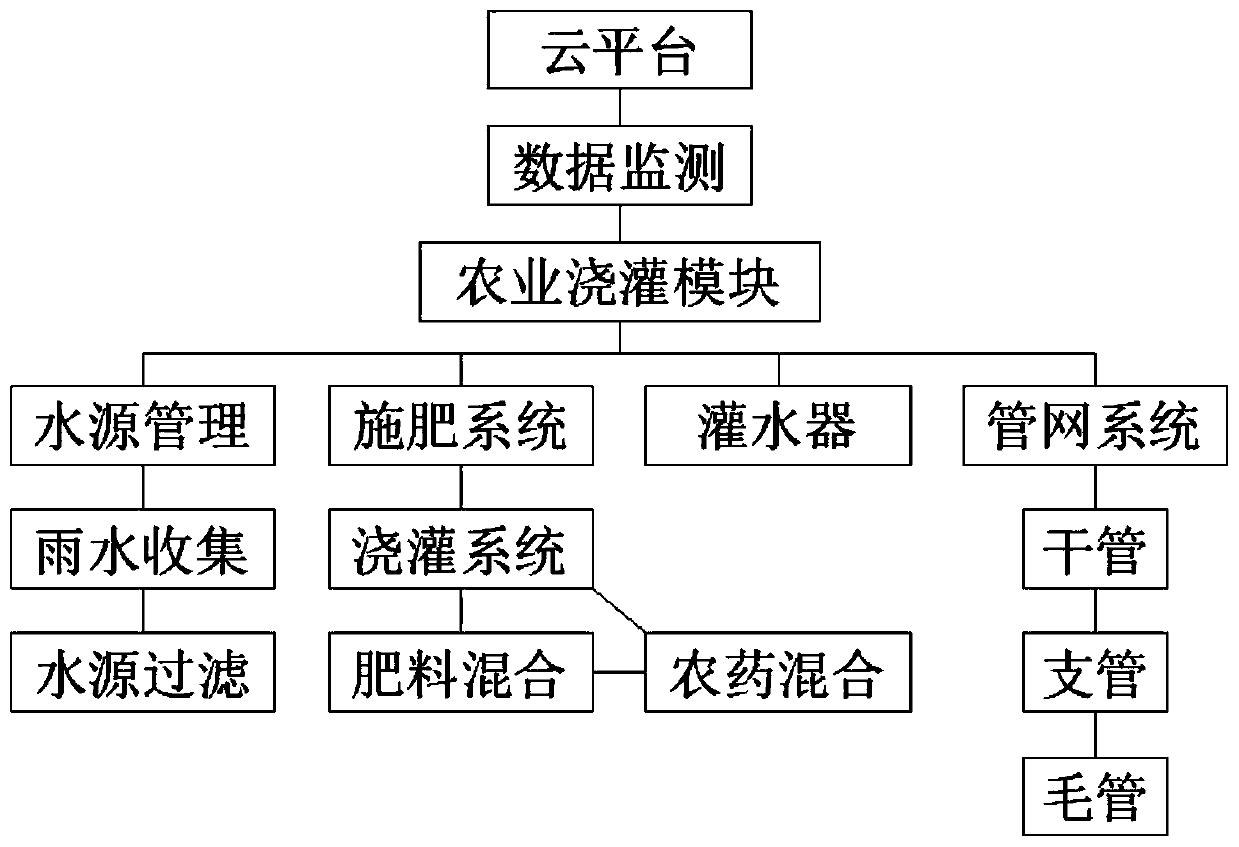

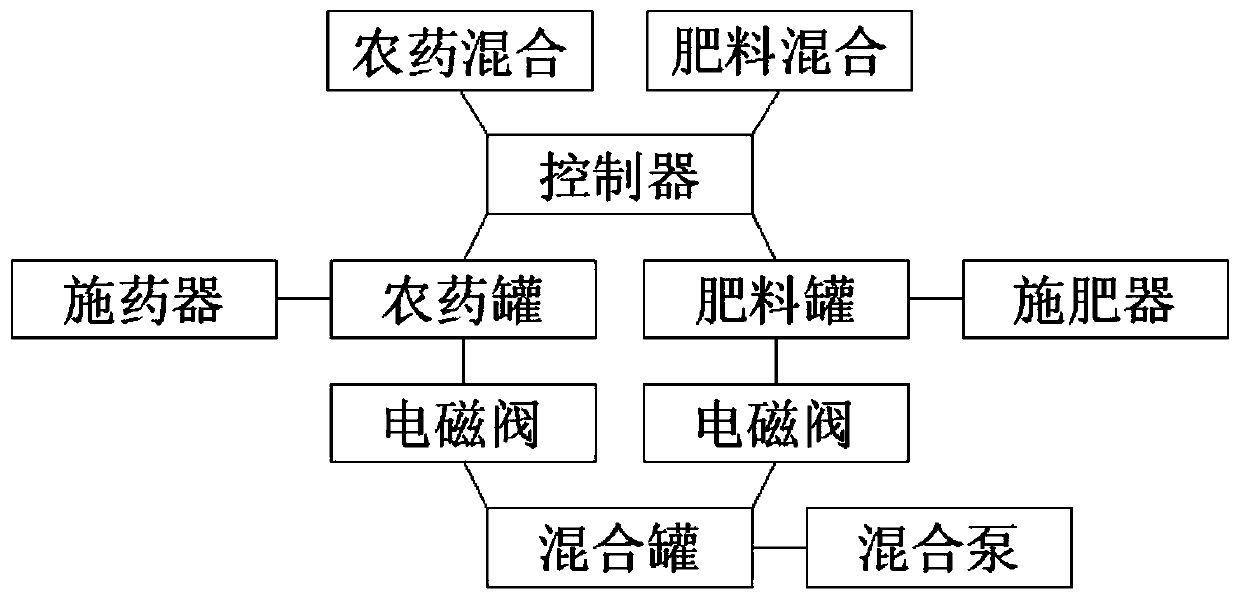

Cloud-based internet-of-things agricultural irrigation system

InactiveCN111183779APrecise applicationReduce manual operationsWatering devicesPressurised distribution of liquid fertiliserWater sourceAgricultural engineering

The invention discloses a cloud-based internet-of-things agricultural irrigation system. The cloud-based internet-of-things agricultural irrigation system comprises a cloud platform, a data monitoringmodule and an agricultural irrigation module, wherein the data detection module comprises a soil monitoring module, an environment monitoring module and a disease and pest monitoring module; the soilmonitoring module comprises a soil temperature and humidity sensor, a soil PH value monitor and a soil conductivity monitor; the environment monitoring module comprises a meteorological monitoring module and a ground surface environment monitoring module; and the agricultural irrigation module comprises a water source management module, a fertilization system module, an irrigation emitter and a pipe network system. The cloud-based internet-of-things agricultural irrigation system provided by the invention has the following beneficial effects: in the use process of the cloud-based internet-of-things agricultural irrigation system, a chemical fertilizer and a pesticide can be directly proportioned in the irrigation process through data monitoring, and directly injected into irrigation waterthrough mixing, and crops are irrigated, so manual operation is reduced, and the proportioning efficiency is improved; meanwhile, application of the pesticide and the chemical fertilizer is more accurate, and waste is reduced.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Intelligent loading, proportioning and blending device for powders

InactiveCN107961721APromote accumulationLow efficiencyRotating receptacle mixersTransportation and packagingIntelligent lightingAutomatic control

The invention relates to an intelligent loading, proportioning and blending device for powders, which mainly includes a material loading bearing frame, a powder mixing tank, and at least two spiral material fetching apparatuses. The powder inlet on the powder mixing tank is connected to the top of the material loading bearing frame; the powder mixing tank is arranged under the material loading bearing frame; each spiral material fetching apparatus includes a vacuum loading hopper, a spiral material fetching machine and a gravity sensor; a top feeding inlet on the spiral material fetching machine is connected to a material outlet of the vacuum loading hopper through a switch device, so that output quantity of the powder is controlled; the gravity sensor is arranged on the material loading bearing frame and is connected to the bottom of the spiral material fetching apparatus. The device allows auto-control, is high in effective, is environment-friendly and is convenient to use.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

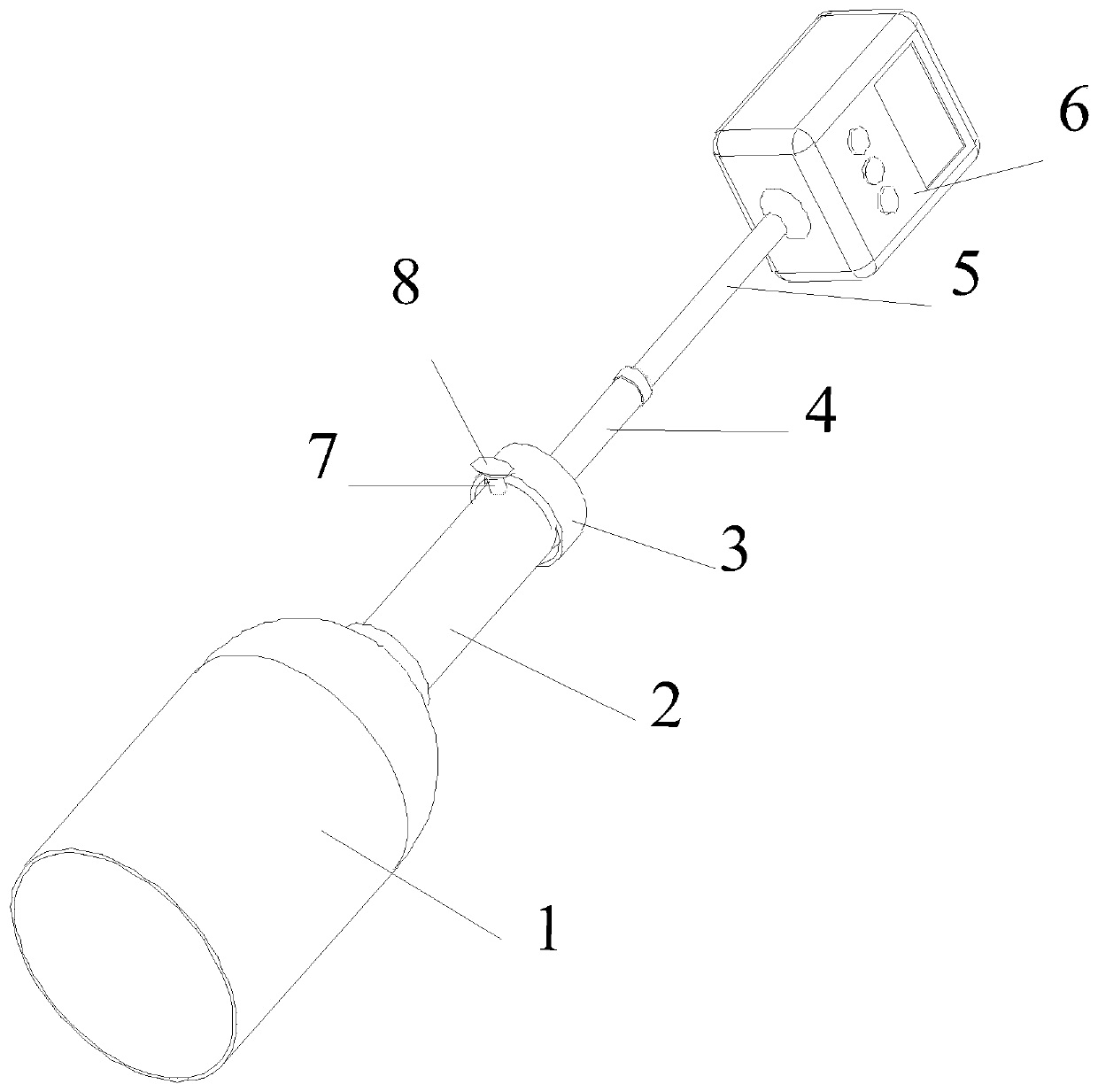

Negative pressure suction injector

PendingCN111419705AImprove ratio efficiencyReduce the frequency of drawing syringesPharmaceutical containersMedical packagingEngineeringPlunger

The invention discloses a negative pressure suction syringe, and relates to the technical field of medical instruments. The negative pressure suction syringe comprises a syringe barrel; a plunger is arranged in the syringe barrel; the lower side of the plunger is fixedly connected with a rubber plug; the rubber plug is slidably connected with the syringe barrel; a sealing plug is arranged at the upper end of the syringe barrel; the sealing plug is fixedly connected with the syringe barrel; a glass tube is arranged on the sealing plug; the glass tube is fixedly connected with the sealing plug;the plunger is slidably connected with the glass tube; the upper end of the glass tube is fixedly connected with an air pipe; the air pipe is fixedly connected with an air pump; an air hole is formedin the lower end of the plunger. An inner cavity of the syringe, the rubber plug arranged in the syringe and the sealing plug arranged at the upper end of the syringe jointly form a closed space, theair pump is started to work to exhaust air in the closed space, and an automatic suction function is achieved, so that working efficiency is improved, meanwhile, manual operation and automatic operation can be switched for use, operation is convenient, and applicability is wide.

Owner:NANJING FIRST HOSPITAL

Electrolyte supplementing device and method applied to production of soft package lithium battery core

ActiveCN113611989AGuaranteed stabilityAvoid Offset SituationsConveyorsCell component detailsElectrolytic agentEngineering

The invention discloses an electrolyte supplementing device applied to soft package lithium cell production. A conveying belt is arranged right above a device base, a battery bracket is connected right above the conveying belt in a clamping manner, the outer side of the conveying belt is in shaft connection with a guide back plate, and a rectangular clamping groove is formed right above the conveying belt. The device comprises a liquid storage box body, wherein a driving water pump is connected to the upper surface of the base in a penetrating mode, a liquid injection pipeline is connected to the output end of the driving water pump, a liquid injection needle is fixedly nested to the outer side of the liquid injection pipeline, and a sealing force arm is arranged on one side of the liquid injection needle; and the sealing force arm. The invention discloses an electrolyte supplementing device and method applied to production of a soft package lithium battery cell. The battery bracket and the clamping force arm b are arranged, the clamping force arm a at the bottom of the battery bracket is used for clamping and limiting the upper surface of the conveying belt, the clamping force arm a is clamped and fixed according to the width of a clamping groove of the conveying belt, and the stability of the battery bracket in the assembling and locking process is ensured.

Owner:广东嘉尚新能源科技有限公司

Automatic pesticide proportioning device based on Internet of Things

ActiveCN113145009AAvoid mixingGuaranteed purityShaking/oscillating/vibrating mixersTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses an automatic pesticide proportioning device based on the Internet of Things. The automatic pesticide proportioning device comprises a proportioning mechanism and a pesticide discharging mechanism, wherein the proportioning mechanism comprises a plurality of liquid storage bottles and a filling and distributing device, wherein the plurality of liquid storage bottles are connected with the filling and distributing device through a plurality of pipelines, an adjustable pump is arranged in the filling and distributing device, one side of the filling and distributing device is provided with a fixed table, a slideway is arranged at the bottom of the fixed table and is matched and connected with the fixed table, a pesticide discharging mechanism is arranged at the bottom of a partition plate and comprises a supporting plate and a plurality of lifting rods, the supporting plate is fixedly connected with the side walls of the lifting rods, and the other ends of the lifting rods are fixedly connected with the partition plate. By adopting the design of automatic proportioning of pesticides, farmers can select and determine the variety, concentration, quantity and the like of required pesticides according to the actual conditions of different crops, automatically calculate a proportion according to different conditions, and control the quantity of raw pesticides by controlling the on-off time and the flow of the adjustable pump, so the purpose of accurate proportioning is achieved.

Owner:珠海市现代农业发展中心

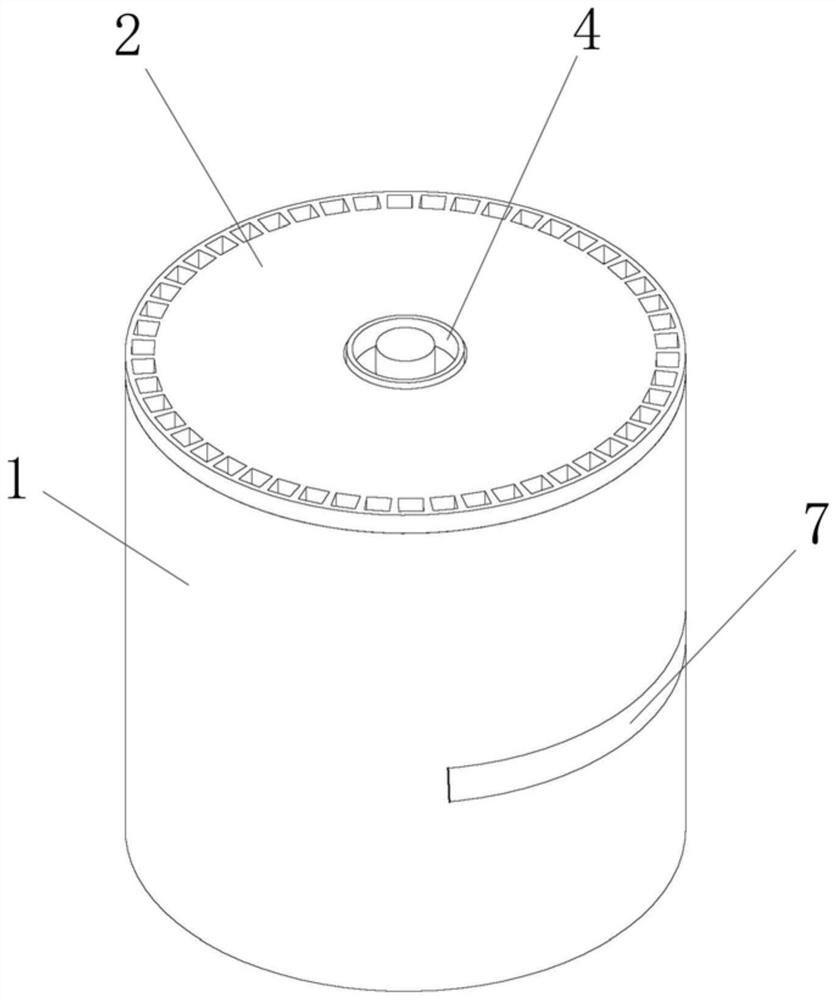

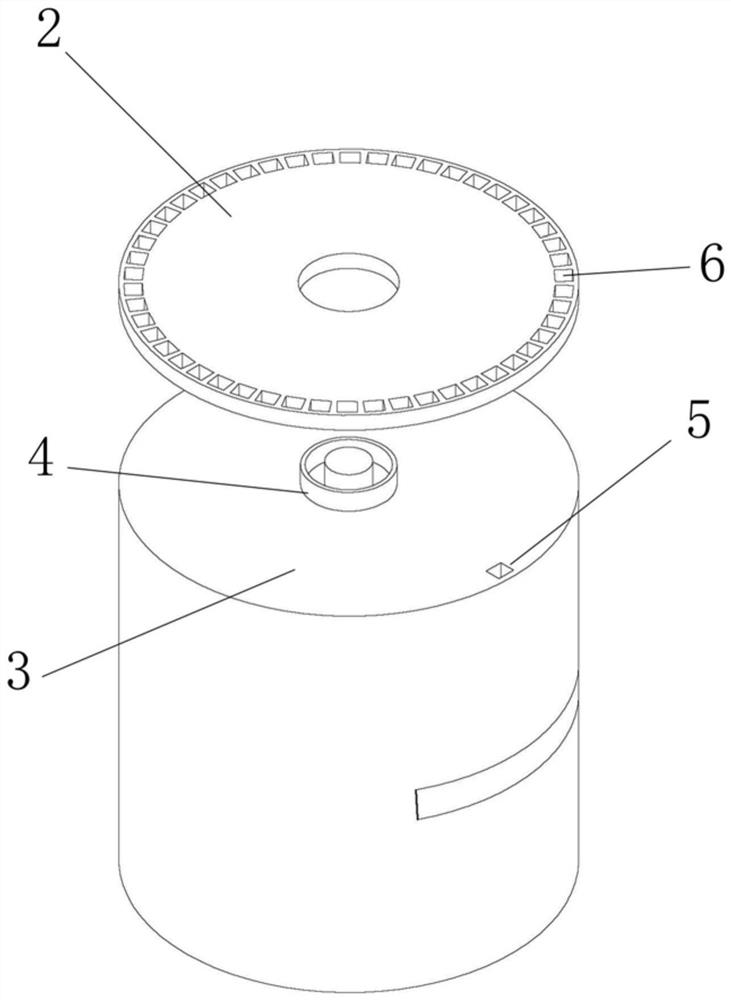

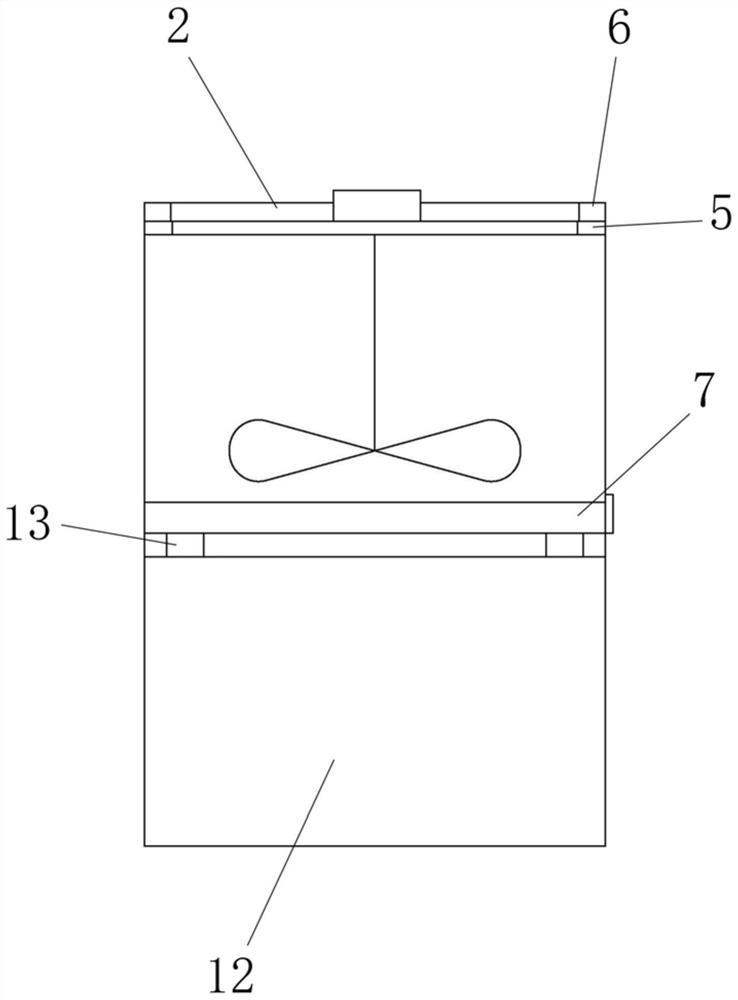

Proportioning device and preparation method of polycarboxylate superplasticizer

PendingCN112387151AStable UniformityImprove ratio efficiencyTransportation and packagingRotary stirring mixersElectric machineSuperplasticizer

The invention relates to the field of polycarboxylate superplasticizer production, in particular to a proportioning device and a preparation method of a polycarboxylate superplasticizer. The proportioning device comprises a mixing barrel, a batching disc and a finished product part, the mixing barrel comprises a barrel cover and a barrel body, an annular plate, a leakage port and a stirring motorare arranged on the barrel cover, and the stirring motor is placed in the annular plate; an output shaft of the stirring motor extends downwards into the barrel body, the lower end of the output shaftis connected with a stirring net, the periphery of the annular plate is sleeved with the batching disc, material containing grids distributed circumferentially are arranged on the batching disc, andthe material mixing barrel and the finished product part are separated through a drawing partition plate; and the drawing partition plate extends into the finished product part through a finished product side opening located in the side face of the finished product part. The proportioning efficiency can be improved, proportioning mass floating is reduced, and the uniformity of the polycarboxylatesuperplasticizer is stabilized.

Owner:ZHEJIANG DADONGWU GROUP CONSTR OF THE NEW MATERIAL

Pellet feed feeding machine for pond fish culture

InactiveCN112772514ASolve the mixing problemReduce laborRotary stirring mixersTransportation and packagingAnimal scienceEngineering

The invention relates to the technical field of pond fish culture, and discloses a pellet feed feeding machine for pond fish culture. The pellet feed feeding machine comprises a box body, the top of the box body is provided with a motor, the output end of the motor penetrates through the interior of the box body and is rotatably connected with a stirring rod through a bearing, and the surface of the stirring rod is fixedly sleeved with stirring blades. By means of the pellet feed feeding machine, the problems that an existing pellet feed feeding machine for pond fish culture cannot stir feed in the feeding machine and cannot accurately proportion the feed and antibiotics are solved; through the arrangement of the stirring blades, the feed in the feed feeding machine can be stirred, it is avoided that manual stirring and separating are needed due to the fact that the feed is solidified, the labor amount of operators is reduced, and the practicability of the device is improved; and meanwhile, the feed and the antibiotics can be accurately proportioned by observing two feeding cylinders and scale marks, so that the feed proportioning efficiency is improved, and the proportioning accuracy is high.

Owner:福建省华渔生态科技有限公司

Diet proportioning device for conditioning endocrine dyscrasia

InactiveCN114295187APrecise control of ratioEnsure conditioning effectWeighing auxillary devicesSpecial purpose weighing apparatusAnimal scienceObstetrics

The diet proportioning device comprises a base, a plurality of proportioning mechanisms are fixedly connected to the middle of the upper end of the base, supporting plates are fixedly connected to the left portion and the right portion of the upper end of the base, and a placing plate is jointly and fixedly connected between the middles of the opposite faces of the two supporting plates; a plurality of storage tanks are clamped in the middle of the upper end of the placing plate, a fixing mechanism is jointly and fixedly connected between the upper portions of the opposite faces of the two supporting plates, and a fixing base is fixedly connected to the middle of the right end of the supporting plate on the right side; a fixing frame is fixedly connected to the middle of the right end of the fixing base in a penetrating mode, and supporting bases are fixedly connected to the lower portions of the outer surfaces of the four supporting legs in a penetrating mode. According to the diet proportioning device for conditioning endocrine dyscrasia, the whole recording device can be used for weighing and proportioning food materials, and the diet proportioning device is high in practicability and suitable for wide application.

Owner:陈芳

Automatic proportioning device and method for diluent

The invention provides an automatic proportioning device and method for diluent. The proportioning device comprises: a diaphragm pump; a concentrated cleaning liquid structure, which is connected to the diaphragm pump; a water inlet structure, which is connected to the diaphragm pump; and a diluent buffer structure, which is connected to the diaphragm pump, wherein the concentrated cleaning liquid structure can communicate with the diaphragm pump, the water inlet structure can communicate with the diaphragm pump, the diluent buffer structure can communicate with the diaphragm pump, and the diaphragm pump, the concentrated cleaning liquid structure, the water inlet structure and the diluent buffer structure are connected through a pipeline structure. The whole proportioning process is completed by adopting the single diaphragm pump, so operation, debugging and maintenance are simple, the proportioning efficiency and accuracy of cleaning liquid are improved, and preparation cost is reduced.

Owner:DIRUI MEDICAL TECH CO LTD

Dispersant proportioning device and proportioning method for granule test

ActiveCN109591193BGuaranteed accuracyEfficient ratioRotating receptacle mixersMixing operation control apparatusRotational axisPolymer science

The invention discloses a dispersant proportioning device and a proportioning method for granule test, comprising a support base, a glass tank, a water tank, a hanging wire, a dispersant storage container, a tray and a measuring cylinder, the support base is fixed with a support vertical frame, the support vertical The top of the frame is fixed with a horizontal bracket, the top of the suspension wire is fixed on the horizontal bracket, the bottom end of the suspension wire is fixed at the center of the tray, and the bottom of the tray center is fixed with a horizontally arranged sealed glass tube. The inner cavity of the sealed glass tube is sealed and filled with liquid. There is a bubble in the liquid of the glass tube, the bottom of the measuring cylinder is connected to the conduit A, the bottom of the dispersant storage container is connected to the conduit B, the top of the support seat is equipped with a motor and a rotating shaft seat, and the center of the bottom of the glass jar is fixed with a rotating shaft. The bottom is communicated with a right conduit, the water tank is placed on the platform to be provided with a water tank, and the bottom of the water tank is communicated with a water delivery pipe. The invention can realize the high-efficiency proportioning of the dispersant used in the particle test, improves the safety of the test, and thus improves the level of scientific research.

Owner:SHANXI PROVINCIAL RES INST OF COMM

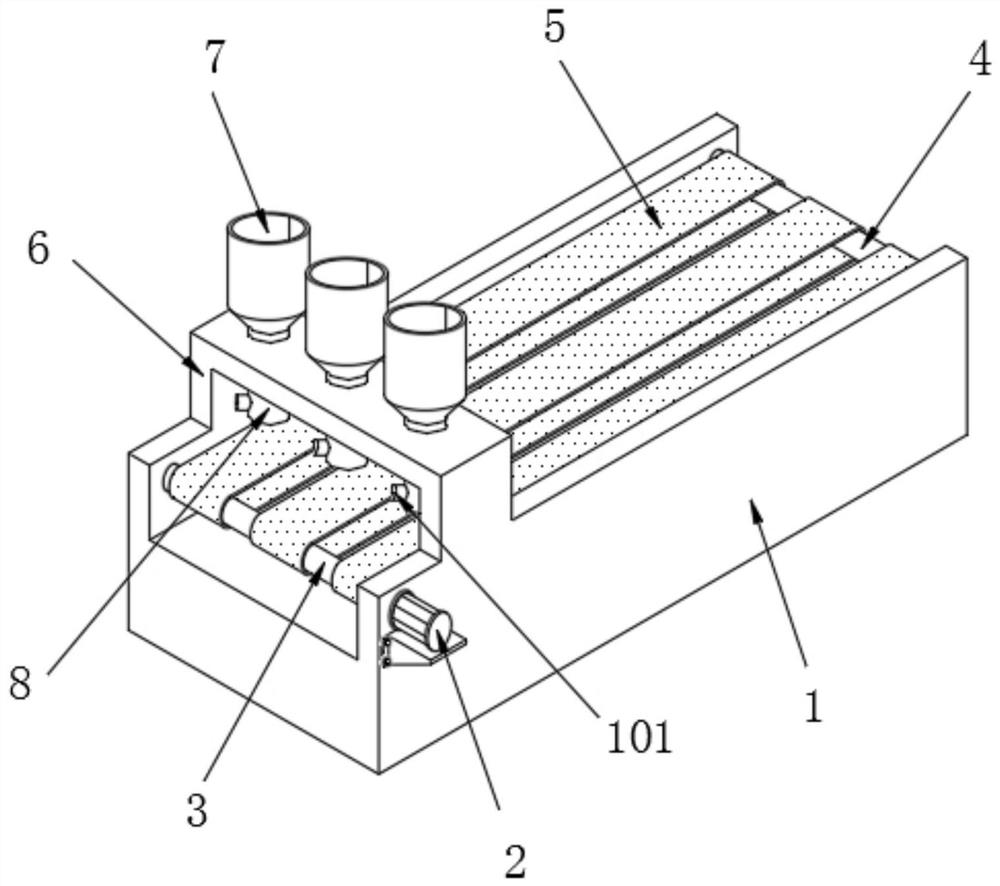

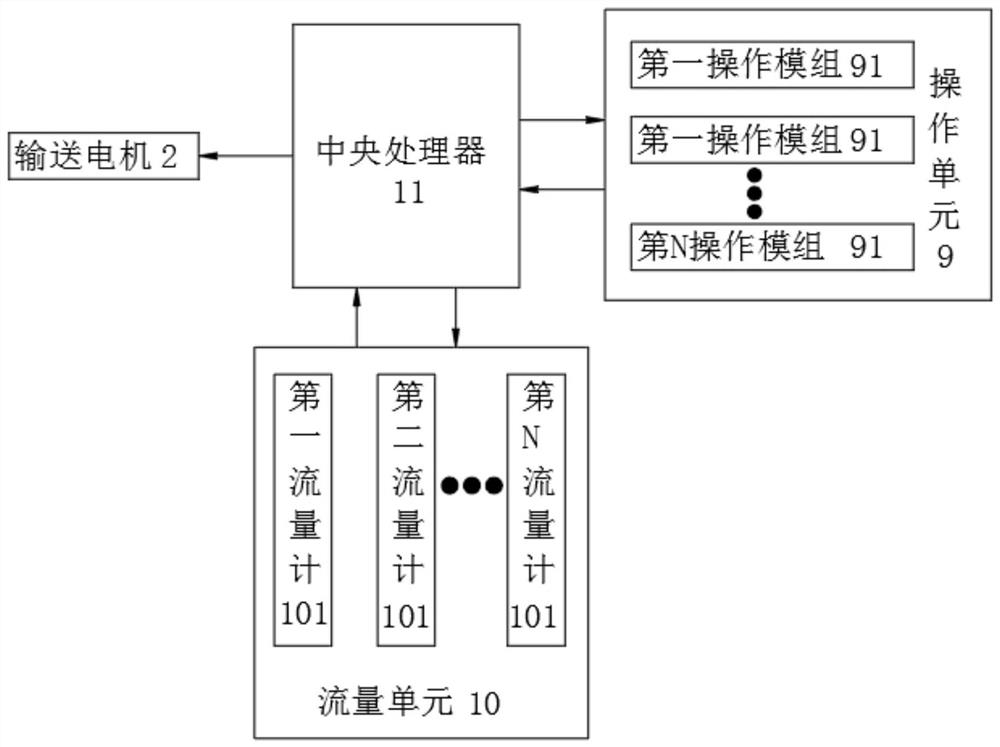

Multi-belt-line coal blending ship loader and refined coal blending modification system thereof

InactiveCN111689178AImprove ratio efficiencyShorten the timeConveyorsControl devices for conveyorsElectric machineDrive shaft

The invention discloses a multi-belt-line coal blending ship loader and a refined coal blending modification system thereof, and relates to the technical field of ship loader coal blending modification. The loader comprises a machine body, wherein a conveying motor is embedded in the front surface of one side of the machine body, a main transmission shaft is horizontally connected to one end of the conveying motor, one end of the main transmission shaft is rotatably connected with one side face of the interior of the machine body, and an auxiliary transmission shaft is horizontally and rotatably connected with the interior of the other side of the machine body. According to the multi-belt-line coal blending ship loader and the refined coal blending modification system thereof, belts are arranged uniformly between the main transmission shaft and the auxiliary transmission shaft in a sleeving mode, the output end of a central processing unit is electrically connected with the input end of the conveying motor through a wire, raw materials of coal can be subjected to conveying and blending through the multiple belts, various raw materials of the coal can be separated individually to fall onto the corresponding belts for blending and conveying, the traditional mode that one belt is used for blending and conveying is replaced, and the coal blending efficiency is improved.

Owner:国能珠海港务有限公司

Preparation device and preparation method of shift gas for ammonia synthesis co-production methanol synthesis

ActiveCN105565269BGuaranteed accuracyGuaranteed efficiencyHydrogenHydrogen/synthetic gas productionGas phaseProcess engineering

The invention belongs to a device and method for making shifted gas for synthesis of ammonia synthesis poly-generation methanol. The device comprises a mechanical part and a control part. The mechanical part comprises a gasification washing tower, an outlet of the gasification washing tower is connected with an inlet of a second heat and condensate recycling unit through a pipe, the pipe between the outlet of the gasification washing tower and the second heat and condensate recycling unit is sequentially provided with a fifth tee joint, a first self-regulating valve, a first tee joint and a second tee joint, an outlet of the second heat and condensate recycling unit is connected with an inlet in the middle of a second ammonia-washing tower, and a gas phase outlet in the top of the second ammonia-washing tower is connected with an inlet in the lower portion of a shifted gas washing tower for synthesis of methanol through a pipe; the control part comprises a first online analysis and calculation display instrument, a second online analysis and calculation display instrument, a second self-regulating valve and a third self-regulating valve. The device and method have the advantages that matching efficiency and accuracy are high, a great number of regulating means are adopted, a great amount of high-quality steam is generated, and meanwhile the content of COS in the methanol removing and washing shifted gas is lowered.

Owner:HENAN XINLIANXIN FERTILIZER +2

Traditional Chinese medicine processing, mixing and proportioning device

InactiveCN114504987AControl traffic sizePrecise ratioShaking/oscillating/vibrating mixersTransportation and packagingMedicineEngineering

The invention relates to the field of medicine processing, in particular to a traditional Chinese medicine processing, mixing and proportioning device which comprises a mounting bottom plate frame, an I-shaped supporting rod, an arc-shaped supporting frame, a connecting frame with a rod, a liquid medicine storage assembly and the like. An I-shaped supporting rod is fixedly connected to the rear side of the top surface of the mounting bottom plate frame, an arc-shaped supporting frame is fixedly mounted on the front side of the top surface of the mounting bottom plate frame, a rod connecting frame is also fixedly mounted on the front side of the top surface of the mounting bottom plate frame, and three liquid medicine storage assemblies are fixedly mounted on the top surface of the rod connecting frame. By adjusting the three adjusting lead screws above and observing the indication of the adjusting lead screws to the annular dial, the size of an opening of the slotted connecting valve is known, then the flow of liquid medicine is controlled, the proportion of the liquid medicine flowing out of the slotted connecting valve is controlled, the purpose of accurately proportioning the liquid medicine is achieved, and meanwhile the medicine proportioning efficiency is improved.

Owner:WUXI NO 2 PEOPLES HOSPITAL

Proportioning device for super-retarded concrete and proportioning process thereof

PendingCN112757489AImprove ratio efficiencyShorten the timeMixing operation control apparatusIngredients proportioning apparatusCoalStructural engineering

The invention discloses a proportioning device for super-retarded concrete and a proportioning process thereof. The proportioning device comprises a conveyor body, a discharging channel and a mixing box, four second supporting columns are welded to one side of the upper surface of the conveyor body in a rectangular array mode, and the top ends of the four second supporting columns are welded to the outer side of the bottom of the mixing box respectively; a first feeding hopper, a second feeding hopper, a third feeding hopper and a fourth feeding hopper are sequentially fixed to the upper surface of the mixing box, a water inlet pipe is fixed to the front of one side of the mixing box, a feeding pipe is fixed to the rear of one side of the mixing box, a discharging valve is fixed to an outlet in the bottom of the mixing box, the lower surface of the discharging valve is welded to the top end of a discharging channel, and four partition plates are welded in the discharging channel at equal intervals. The raw materials are selected according to the proportion of 185Kg / m<3> of water, 2,925Kg / m<3> of cement, 515Kg / m<3> of coal ash, 7,675Kg / m<3> of sand, 10,595Kg / m<3> of gravel and 5.7 Kg / m<3> of water reducing agent. The concrete produced according to the process ratio has the advantages of good workability and capability of meeting the requirements of a construction site.

Owner:安徽省友邦混凝土有限公司

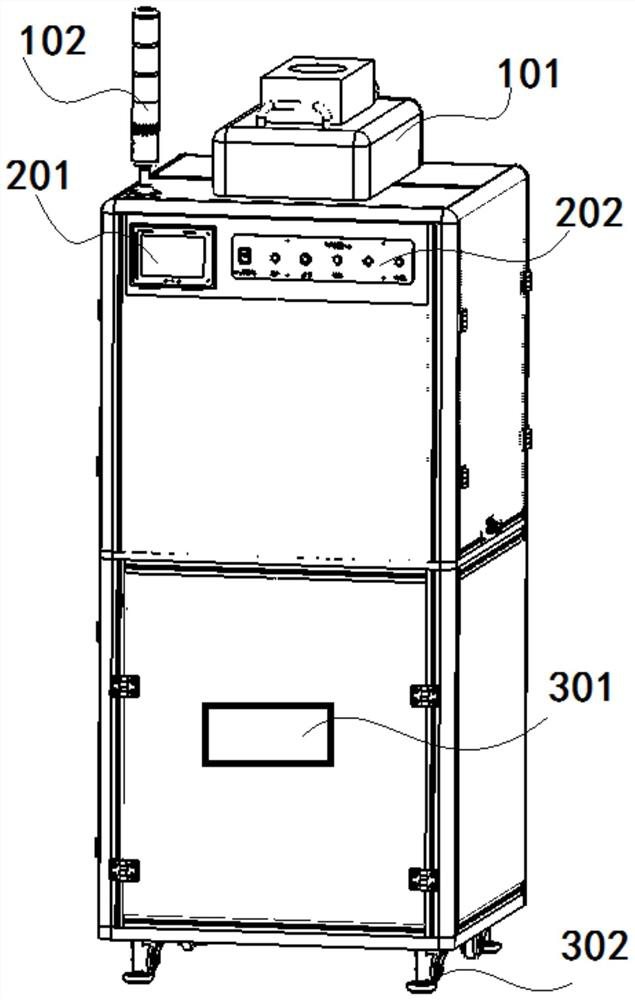

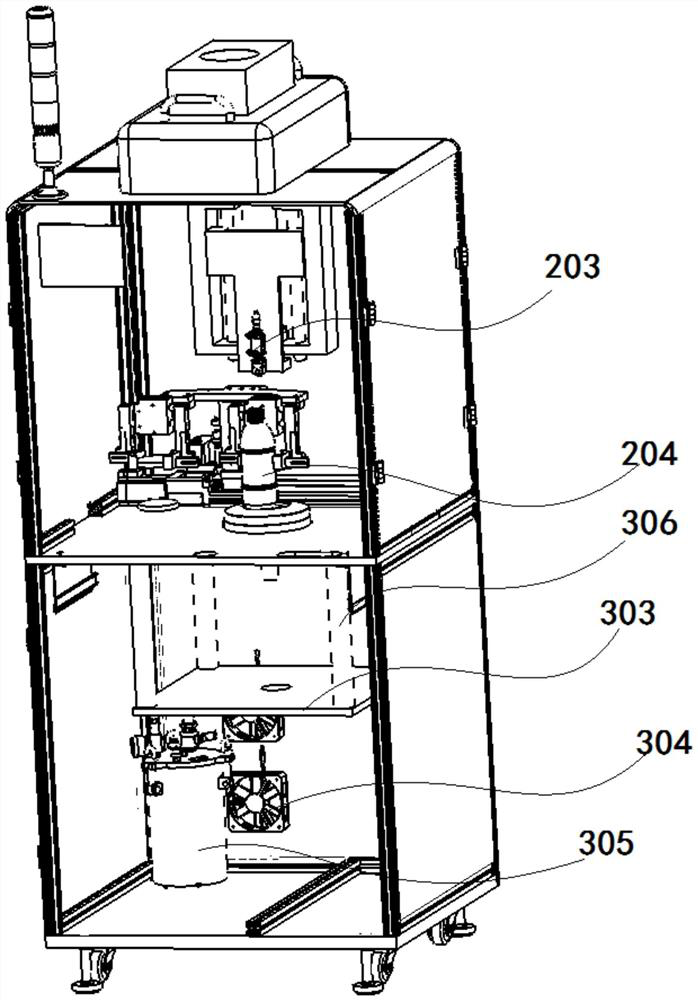

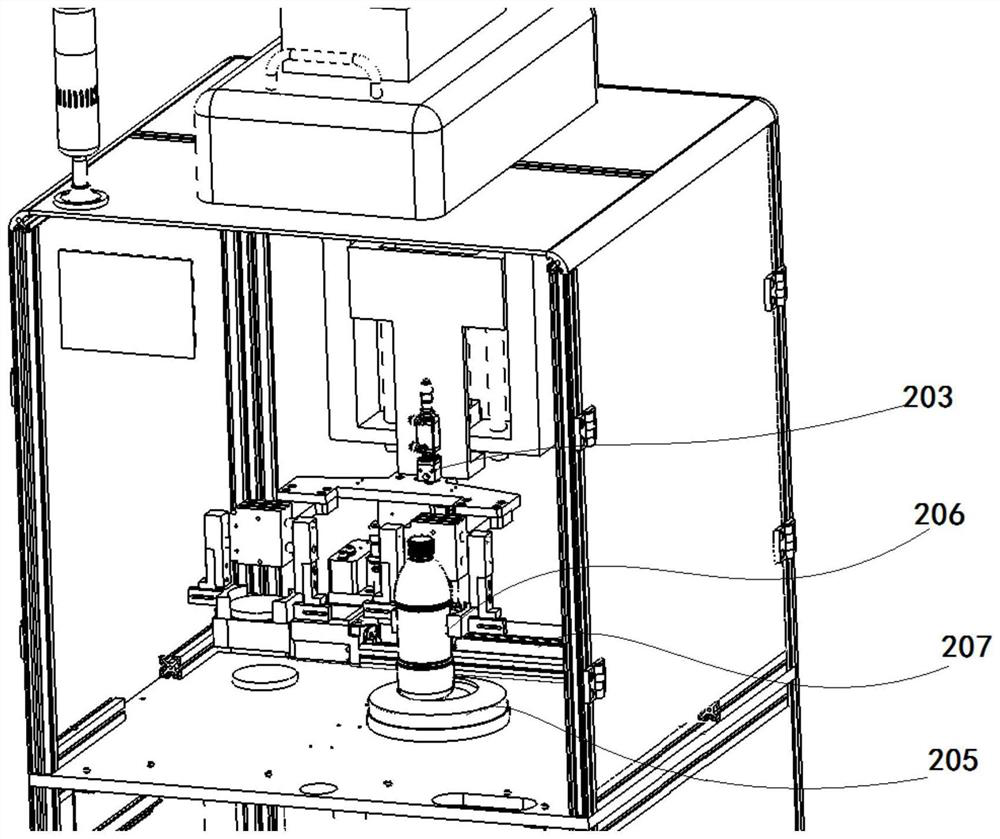

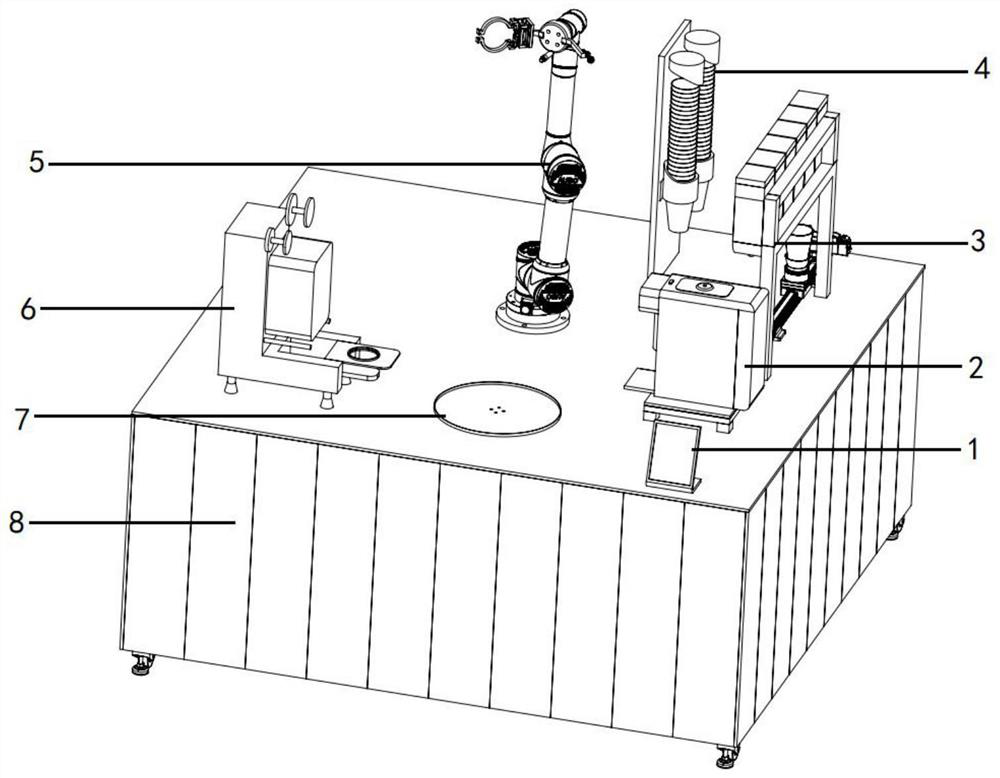

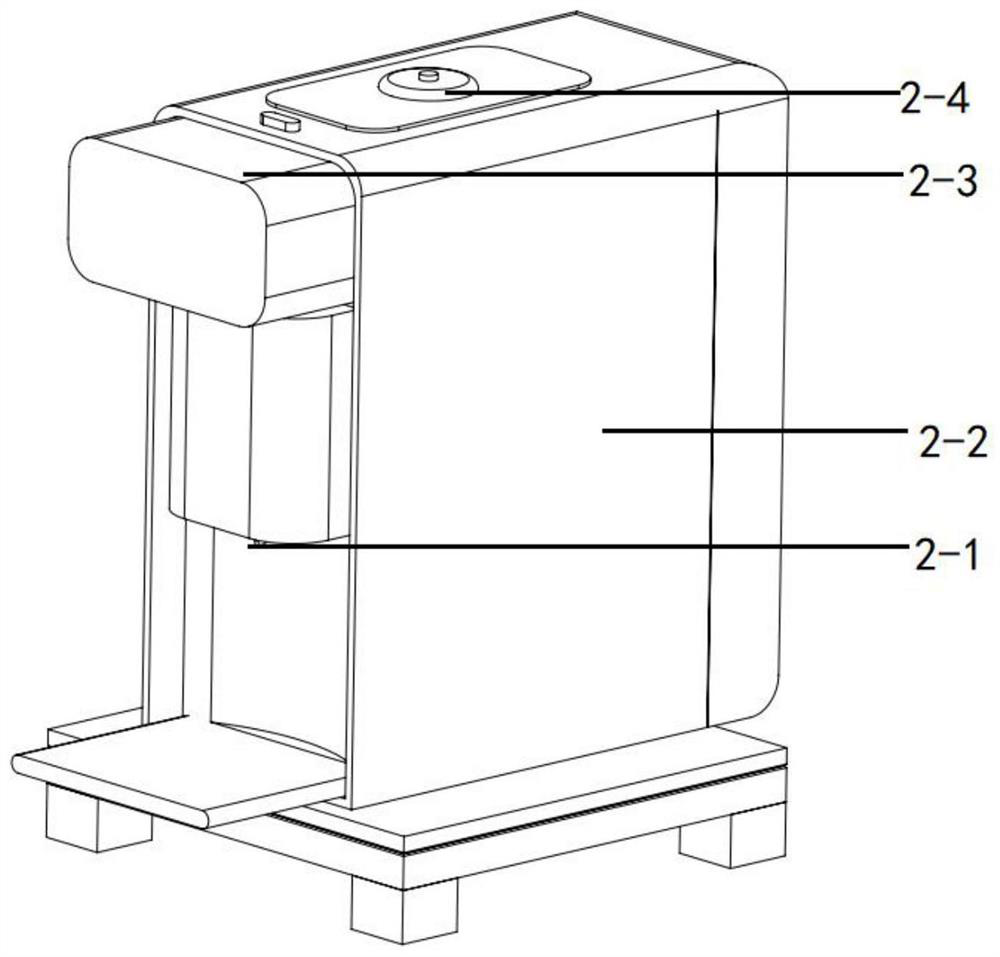

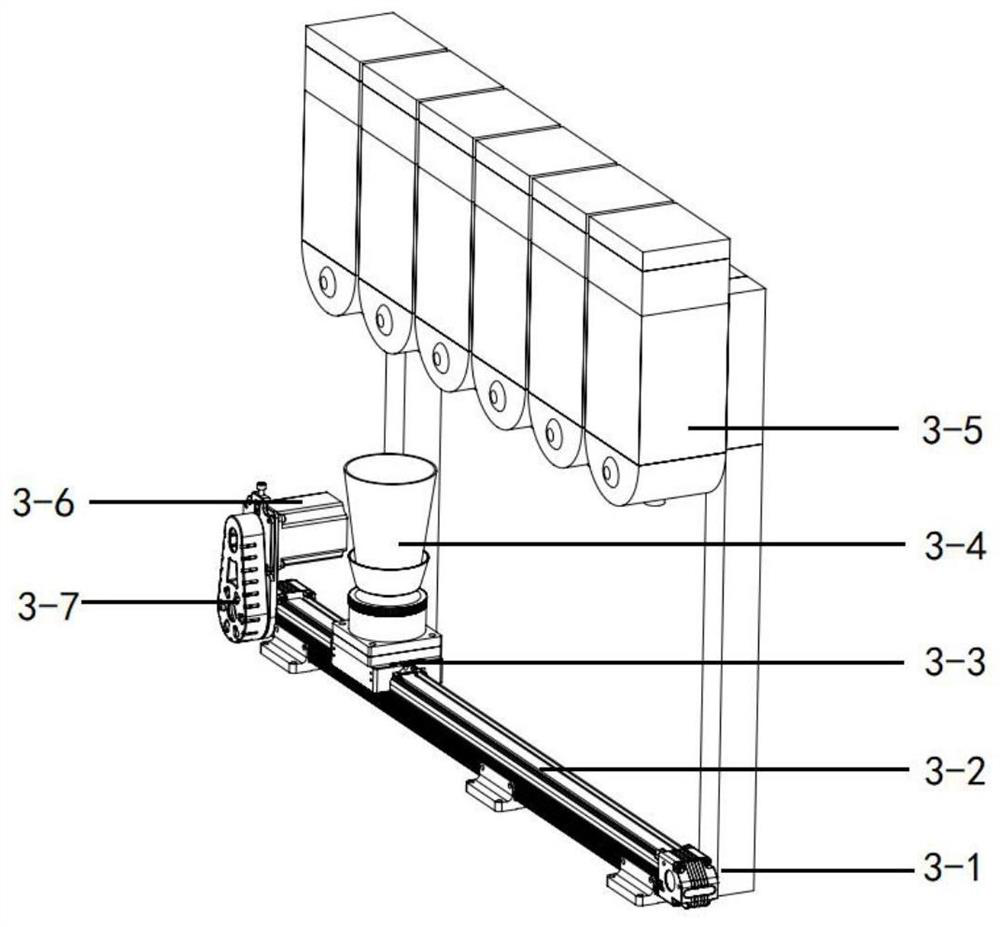

Five-cereal soybean milk making system based on collaborative robot

PendingCN112173197AImprove ratio efficiencyPrecise ratio of raw materialsPackagingMilk substitutesCollaborative roboticsProcess engineering

The invention provides a five-cereal soybean milk making system based on a collaborative robot. The five-cereal soybean milk making system is characterized by comprising an operating table, a man-machine interaction panel, an intelligent five-cereal soybean milk machine, a five-cereal ingredient module, a soybean milk cup storage module, an automatic sealing machine, the collaborative robot and atray, wherein the man-machine interaction panel, the intelligent five-cereal soybean milk machine, the five-cereal ingredient module, the soybean milk cup storage module, the automatic sealing machine, the collaborative robot and the tray are all mounted on the operating table; the collaborative robot is positioned in the center of the operating table; a user can adjust the proportion of soybean milk raw materials according to own preferences, and can also select five-cereal soybean milk with the set proportion; meanwhile, a quantitative proportion mode is adopted in the making process of thefive-cereal soybean milk, so that the proportion efficiency of the five-cereal soybean milk raw materials is improved, and the accurate proportion of the raw materials is guaranteed; the made five-cereal soybean milk is good in mouth feel and rich in nutrition; and the whole process is automatically operated, so that the five-cereal soybean milk can be enjoyed by only one key, and the five-cerealsoybean milk making system is convenient and quick.

Owner:TIANJIN BONUO ROBOT TECH CO LTD +3

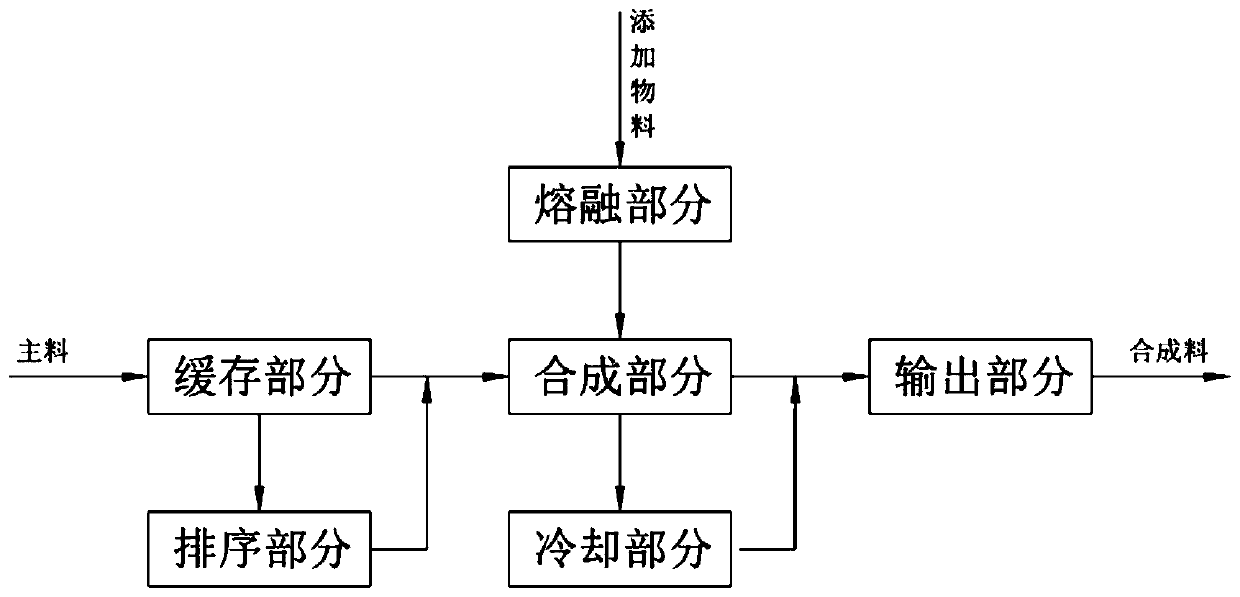

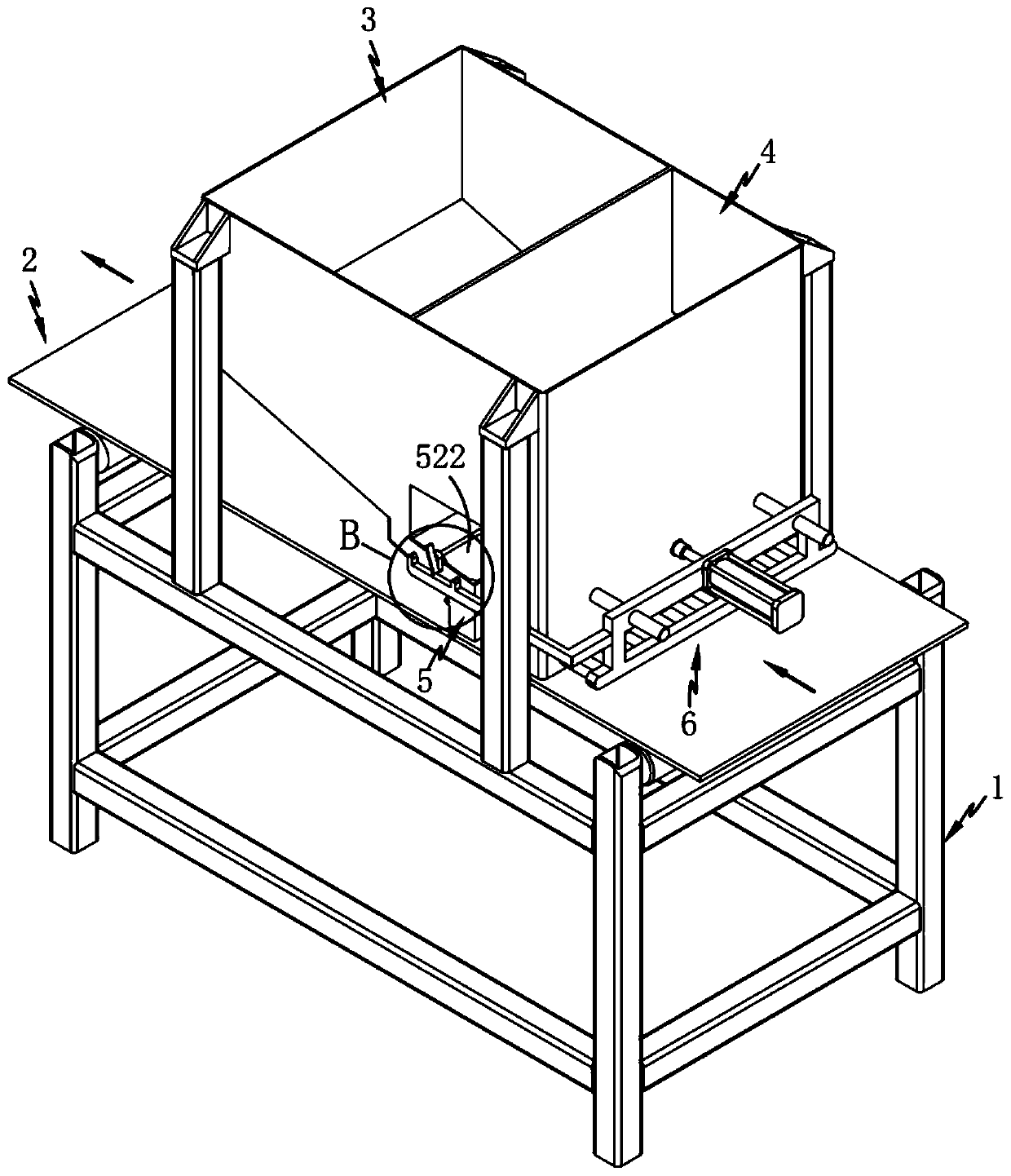

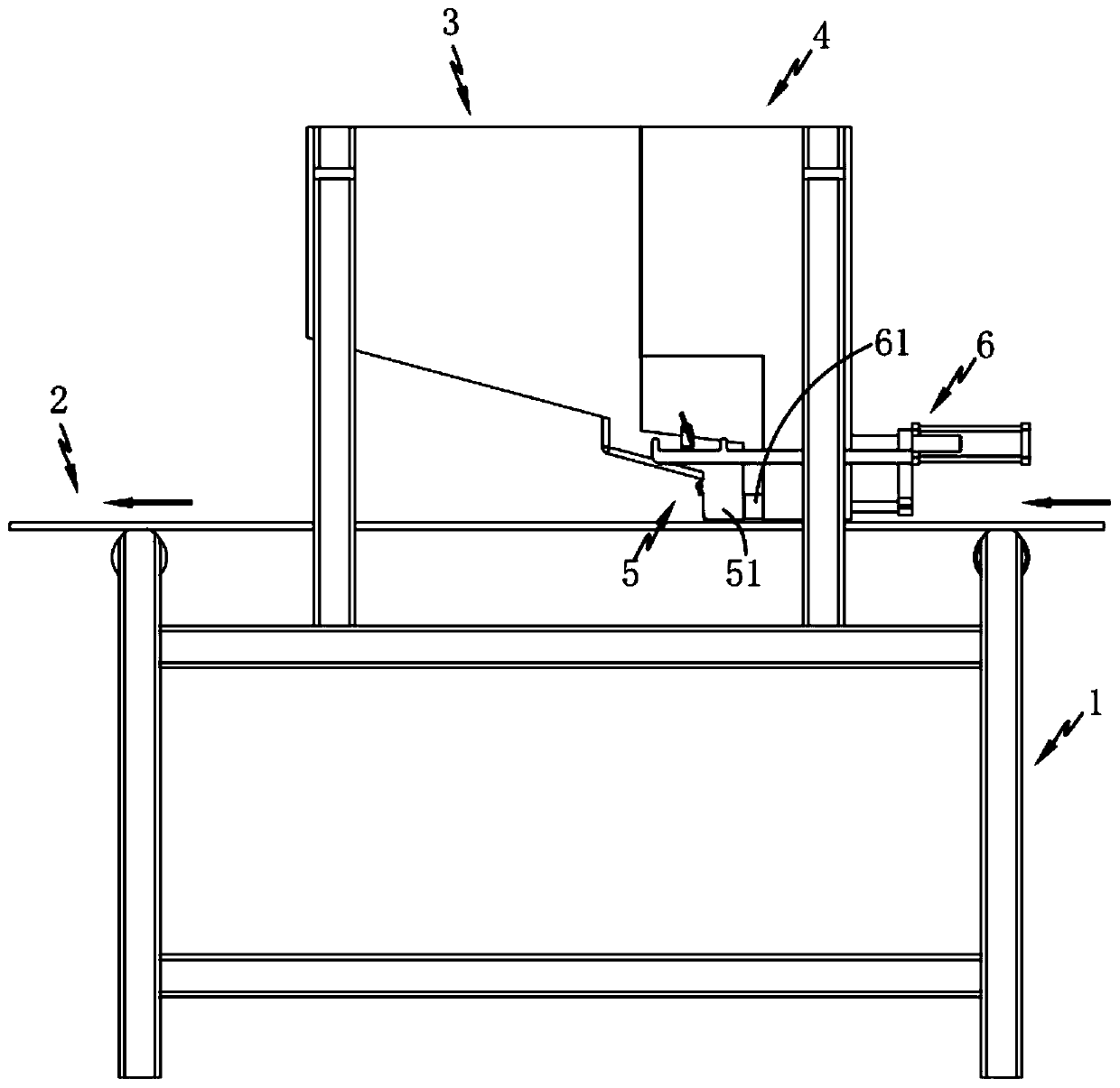

A production process of automatic fixed-ratio mixing of coatings

ActiveCN107486051BImprove delivery efficiencyImprove ratio efficiencyFlow mixersTransportation and packagingContact formationHybrid type

The invention relates to an automatic fixed-ratio mixing production process for coatings, which includes a buffering part, a melting part, a forming part and an output part. The single-layer main material is buffered in a flat state through the inclined plate setting, and the rotation angle of the limiting plate is Set up, carry out the intermittent output of the main material, combined with the push rod to drive the added material to move to the melting section, and carry out the liquefaction treatment of the added material by heating; the main material is in the form of a material string in the forming section, and the melted added material is transported through the push rod In contact with the main material, the main material and the added material form a synthetic material, and the finished material is driven by a conveyor belt in a linear transmission mode to drive the synthetic material to be output; the liquefied added material is in contact with the material string in the state of rotation to form a linearly arranged synthesis It solves the technical problems of inaccurate mixing resin ratio and inconvenient transportation existing in the prior art.

Owner:蓝威涂料(上海)有限公司

High-quality marking machine capable of realizing automatic matching of paint

The invention relates to a high-quality marking machine with automatic proportioning of paint, which comprises a feeding part, and the feeding part includes a feeding mechanism a for quantitatively conveying petroleum resin downward and a quantitatively downward feeding mechanism for adding powder The conveying blanking mechanism b; the hot-melt part, the hot-melt part is used to accept the petroleum resin and the added powder transported by the blanking mechanism a and the blanking mechanism b respectively, and heat the petroleum resin and the added powder to make It melts into paint; and a marking part, which includes a marking mechanism for applying the paint to the road surface and a control mechanism for controlling the transfer of the paint of the hot-melt part to the marking mechanism; the present invention overcomes the The problem that the scribing equipment does not have the function of quantitatively proportioning raw materials, the paint is easy to deposit during use, and the outflow and cut-off of the paint cannot be automatically and quickly controlled.

Owner:长兴小浦凯荣机械加工厂

Coal cinder treatment system for engineering construction

ActiveCN113370395AImprove the vibration effectSpeed up sievingSolid waste managementMixing operation control apparatusHydraulic cylinderArchitectural engineering

The invention relates to the technical field of coal cinder recycling, and discloses a coal cinder treatment system for engineering construction. The coal cinder treatment system comprises a mounting plate, a bottom plate is fixedly connected to the middle of the upper surface of the mounting plate, supporting beam plates are fixedly connected to the four sides of the upper surface of the bottom plate, a supporting plate is fixedly connected to the upper surfaces of the supporting beam plates, vertical plates are fixedly connected to the two sides of the upper surface of the bottom plate, and cross-shaped connecting blocks are rotationally connected to the opposite sides of the vertical plates. Second hydraulic cylinders in different directions drive L-shaped limiting frames to limit supporting frames, meanwhile, through the cooperation effect of hydraulic cylinders, the cross-shaped connecting blocks, second cross-shaped connecting blocks and the like, coal cinder conveying on mixing and proportioning lines in different directions is achieved, the proportioning efficiency is further improved, the problem of low treatment efficiency caused by the fact that a pretreatment system before mixing needs to be stopped and pretreatment can be continued after mixing and stirring are finished is solved, feeding for the mixing and proportioning lines in different directions is realized, and the mixing and proportioning efficiency is improved.

Owner:SHAOYANG BAOSHENG ENVIRONMENTAL PROTECTION TECHNOPLOGY CO LTD

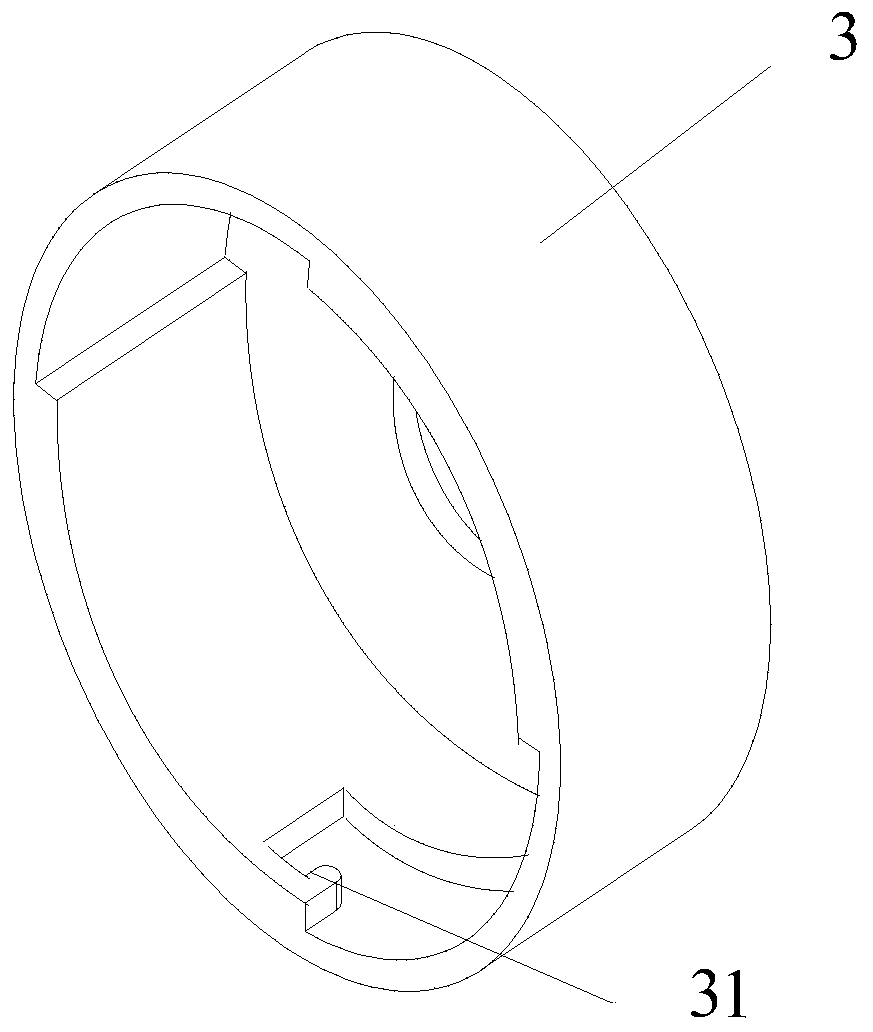

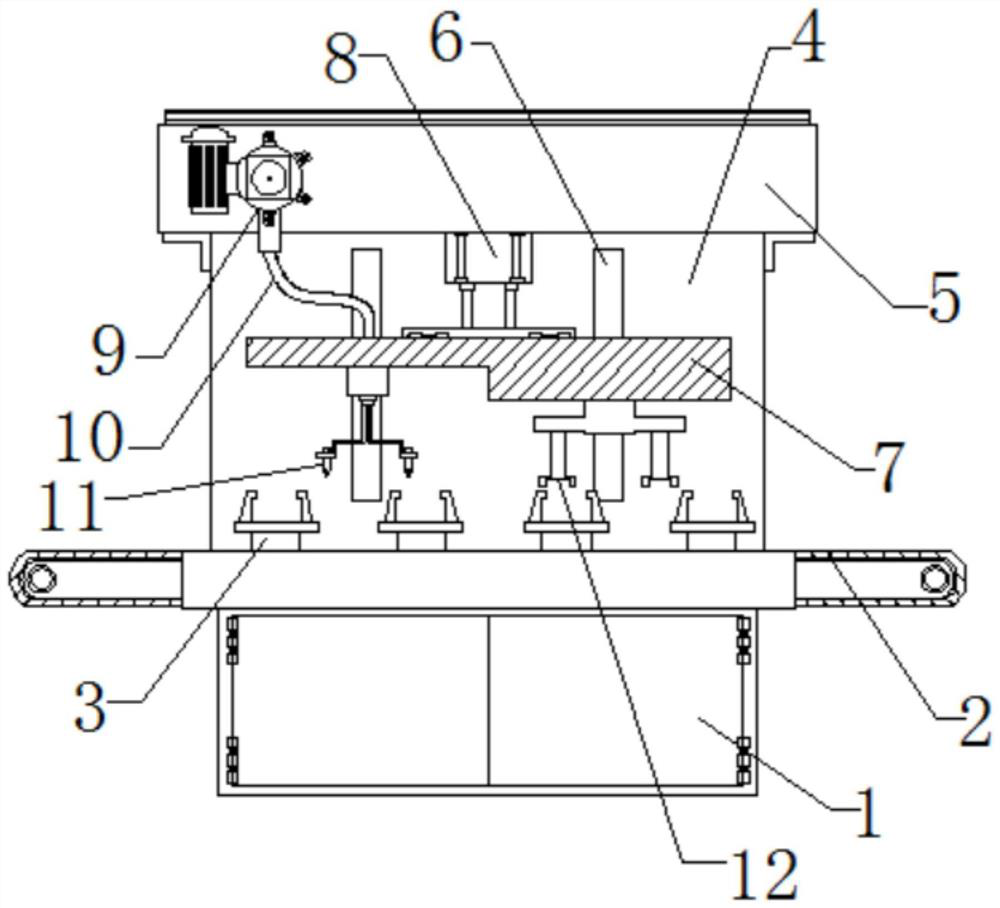

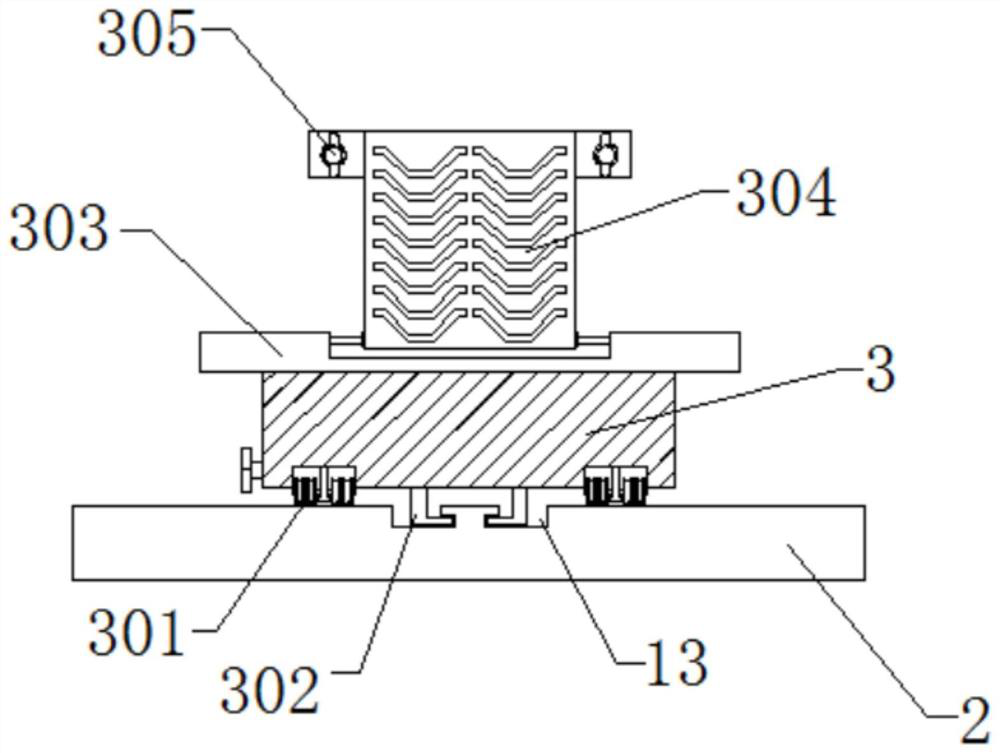

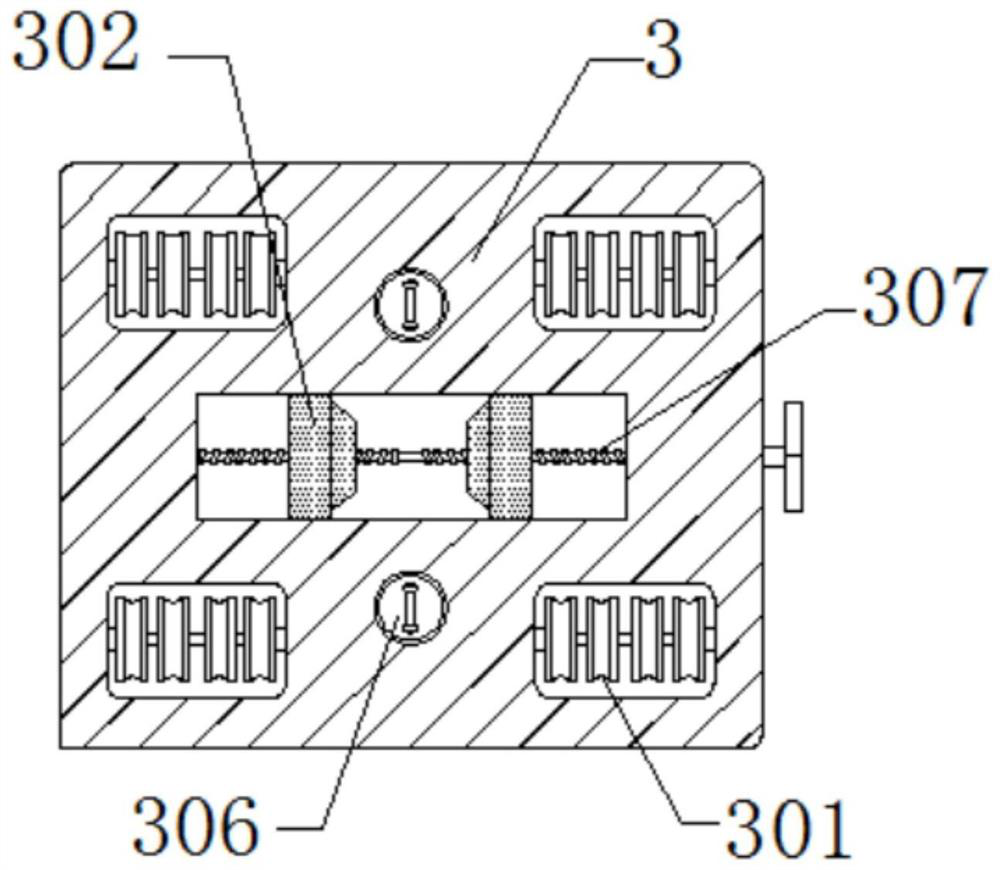

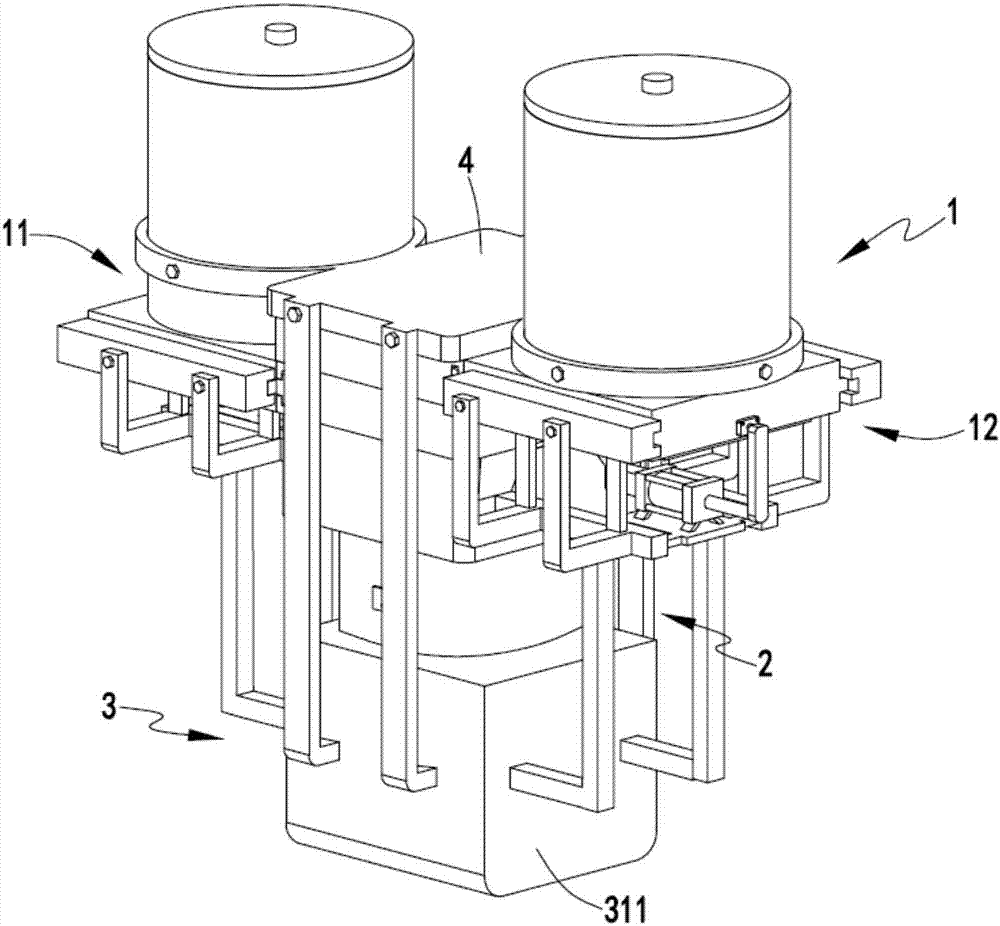

An automatic batching device and batching method

ActiveCN104043376BReasonable structural designEasy to break awayMixer accessoriesEngineeringConveyor belt

The invention provides an automatic batching apparatus and a batching method. The apparatus comprises a control cabinet, batching bins with blanking devices, a mobile weighing disc. The batching bins are provided with quantitative blanking devices, which are connected with the control cabinet; a plurality of batching bins are in linear arrangement; blanking ports of the batching bins are in a straight line, and a conveyor belt is arranged right below the blanking ports of the batching bins; the weighing disc comprises a weighing bucket and an electronic scale; and the electronic scale is placed on the conveyor belt, and is connected with the control cabinet through a circuit. The control cabinet conducts remote blanking control on blanking of batching bins and movement of the weighing disc. Compared with the current automatic blanking apparatus and blanking method, the apparatus and method provided by the invention save manpower and material source, realizes automatic operation, more precise and reliable dropping material control, and greatly improves the efficiency of material proportion.

Owner:TAIAN DEPU AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com