Automatic proportioning and mixing system for breeding feed

An automatic proportioning and feed technology, applied in the field of breeding, can solve the problems of high labor intensity, labor, and busy feeding process, and achieve the effect of reducing labor intensity, simple operation process and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

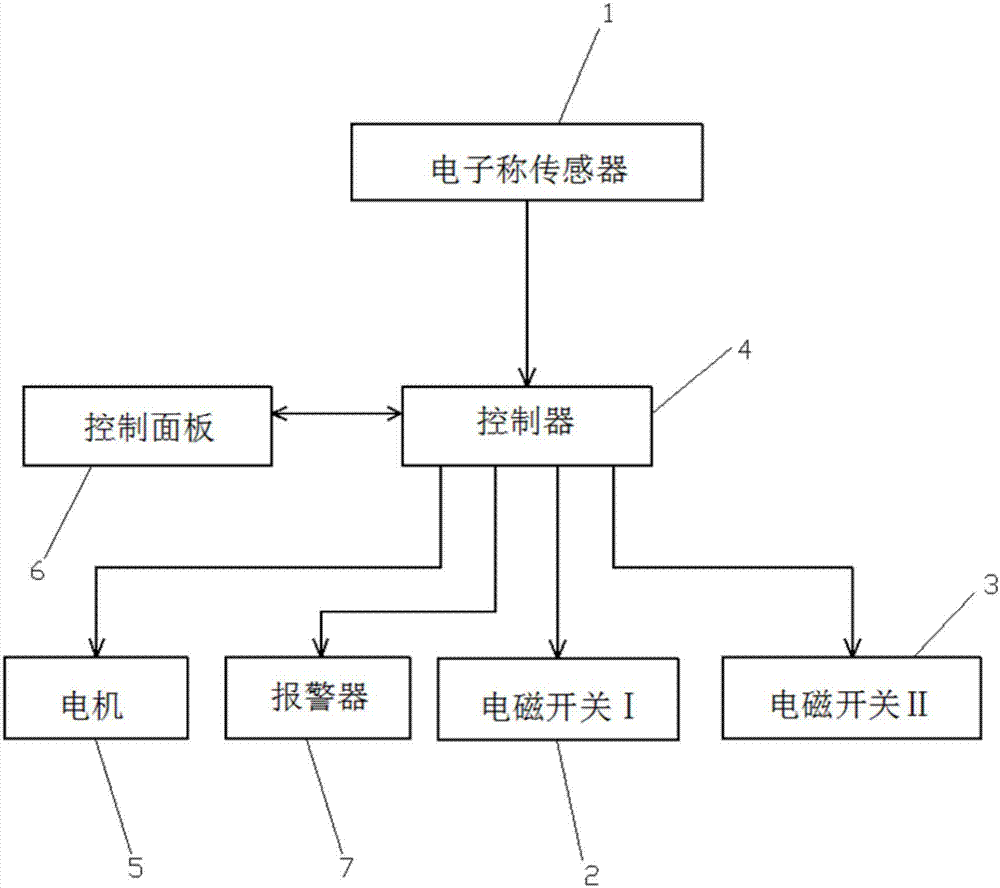

[0011] Attached below figure 1 An embodiment of the present invention is described.

[0012] The automatic proportioning and feeding system for breeding feed has a proportioning bin, and the proportioning bin is equipped with an electronic scale sensor 1 for weighing, an electromagnetic switch I2 for discharging and a proportioning unit for redundant materials. The electromagnetic switch Ⅱ3 discharged from the warehouse and the electronic weighing sensor 1, electromagnetic switch Ⅰ2 and electromagnetic switch Ⅱ3 are all connected to the controller 4 in the control cabinet through wires, and the controller 4 is connected to the motor 5 of the grinding mixer and installed in the proportioning bin The alarm 7 on the installation frame is connected with the controller 4, and the controller 4 is connected with the control panel 6 on the control cabinet through wires to realize the input and display of the feed ratio parameters, and the controller 4 controls the electronic scale sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com