High-quality marking machine capable of realizing automatic matching of paint

An automatic proportioning, high-quality technology, used in roads, road repairs, roads, etc., can solve the problems of easy-to-deposit paint flow and cut-off, inability to automatically and quickly control, and lack of quantitative proportioning raw materials to save costs and time. , Simple structure, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

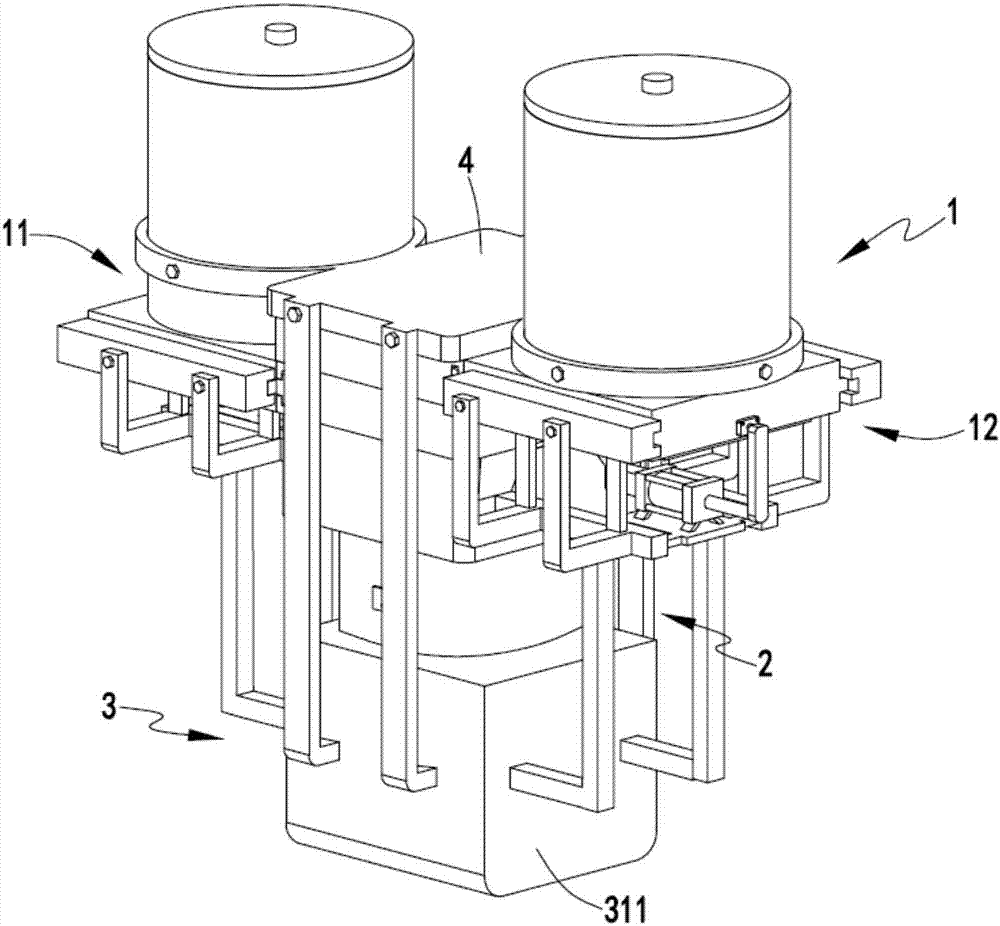

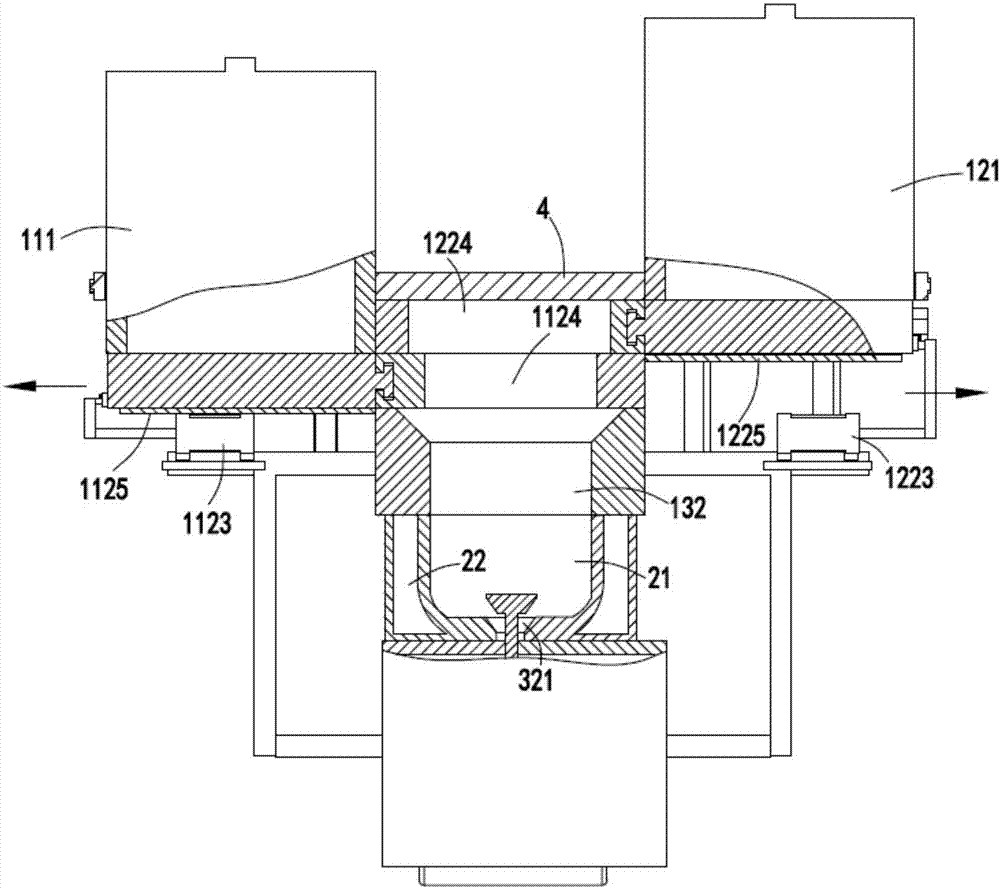

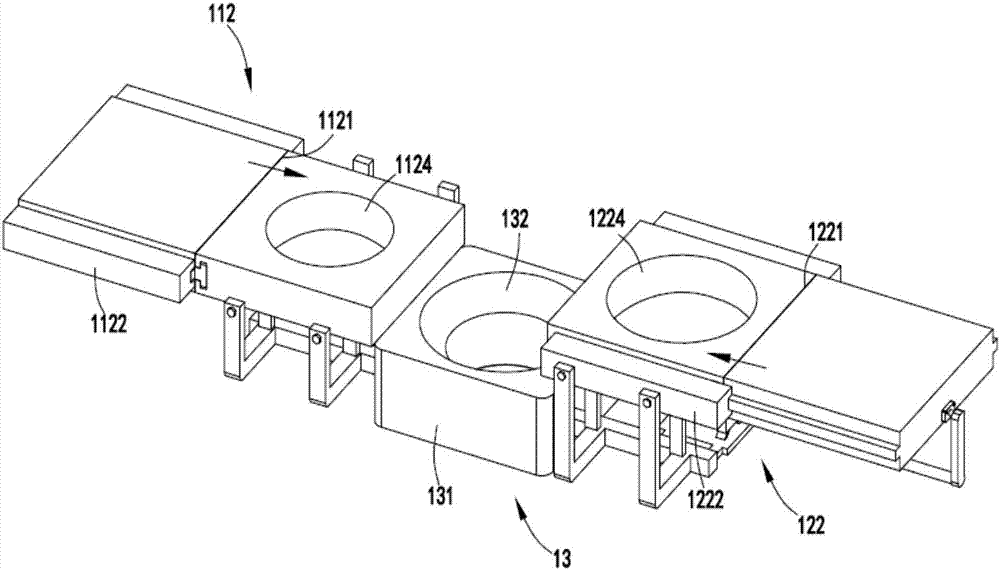

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a high-quality marking machine with automatic proportioning of paint includes a feeding part 1, and the feeding part 1 includes a feeding mechanism a11 for quantitatively conveying petroleum resin downward and for quantitatively adding powder The unloading mechanism b12 conveyed downward;

[0040] The hot-melt part 2, the hot-melt part 2 is used to accept the petroleum resin and the added powder delivered by the unloading mechanism a11 and the unloading mechanism b12 respectively, and heat the petroleum resin and the added powder to melt it into a paint; as well as

[0041] The marking part 3 includes a marking mechanism 31 for applying paint to the road surface and a control mechanism 32 for controlling the transfer of the paint of the hot-melt part 2 to the marking mechanism 31 .

[0042] By setting the blanking part 1 with batching function on the hot-melt scribing equipment,...

Embodiment 2

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: as a preference, the thread rolling device 313 includes a sliding seat 3131, a bracket 3132, a roller 3133 rotatably arranged on the bracket 3132, and on the bracket 3132 A sliding bar 3134 is provided to cooperate and slide with the sliding seat 3131, and a spring 3135 is provided between the sliding bar 3134 and the sliding seat 3131;

[0056] The stirring device 314 includes a turntable 3141 coaxially arranged with the roller 3133, a stirring member 3142 rotatably arranged in the paint box 311, and one end is eccentrically and rotatably arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com