A production process of automatic fixed-ratio mixing of coatings

A production process and automatic technology, applied in mixers, fluid mixers, dissolving and other directions, can solve the problems of inaccurate proportioning and inconvenient transportation of mixed resins, so as to improve transportation and proportioning efficiency, improve efficiency, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

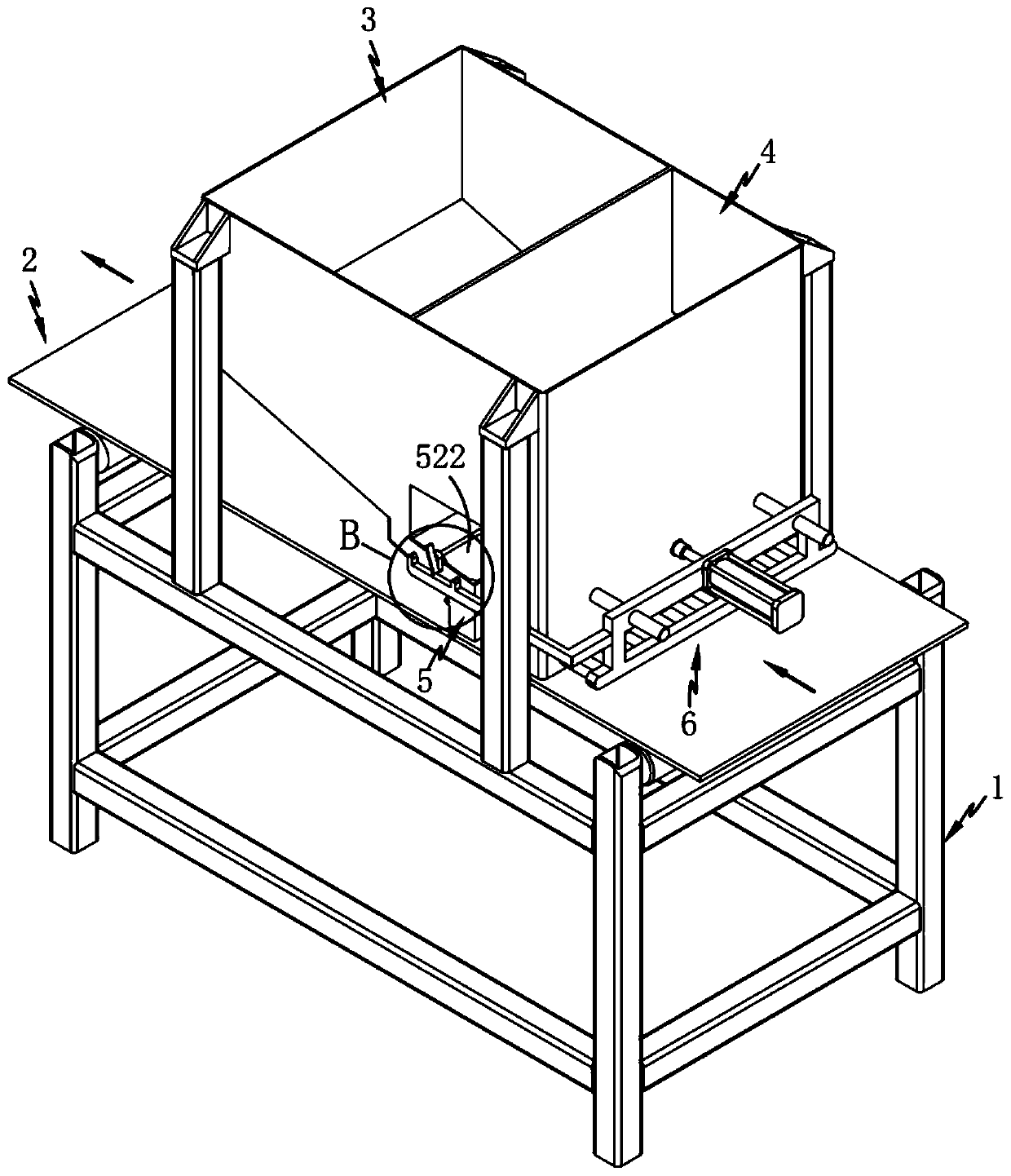

[0040] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

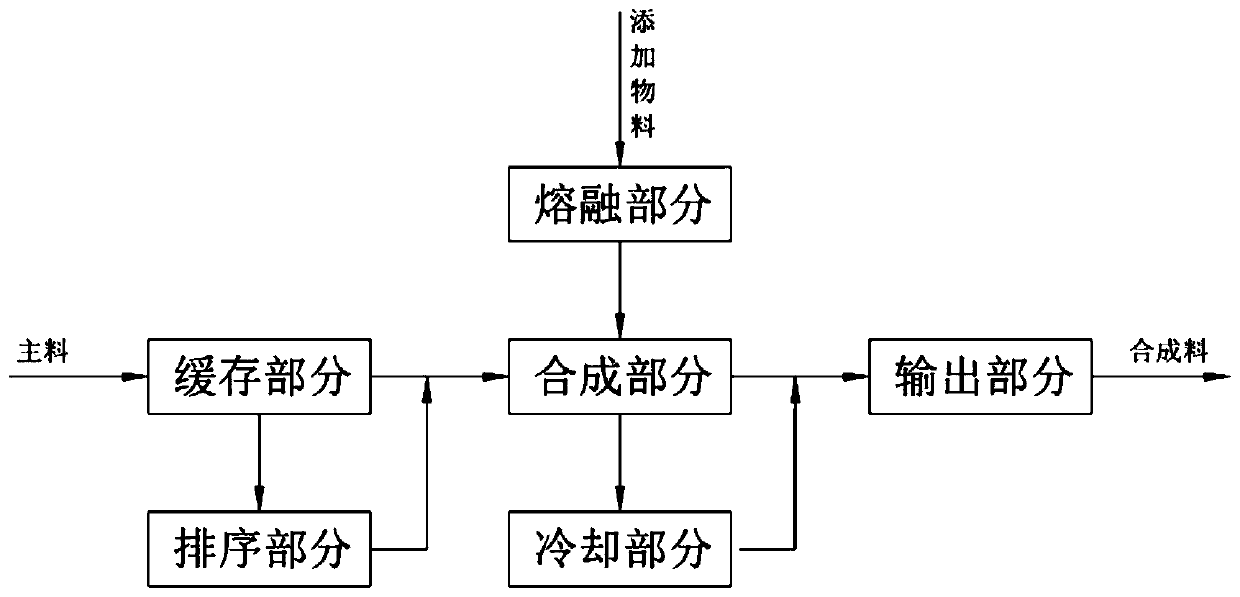

[0041] Refer to the attached figure 1 An automatic ratio-mixing production process of coatings according to Embodiment 1 of the present invention is described.

[0042] An automatic fixed-ratio mixing production process for coatings, comprising the following steps:

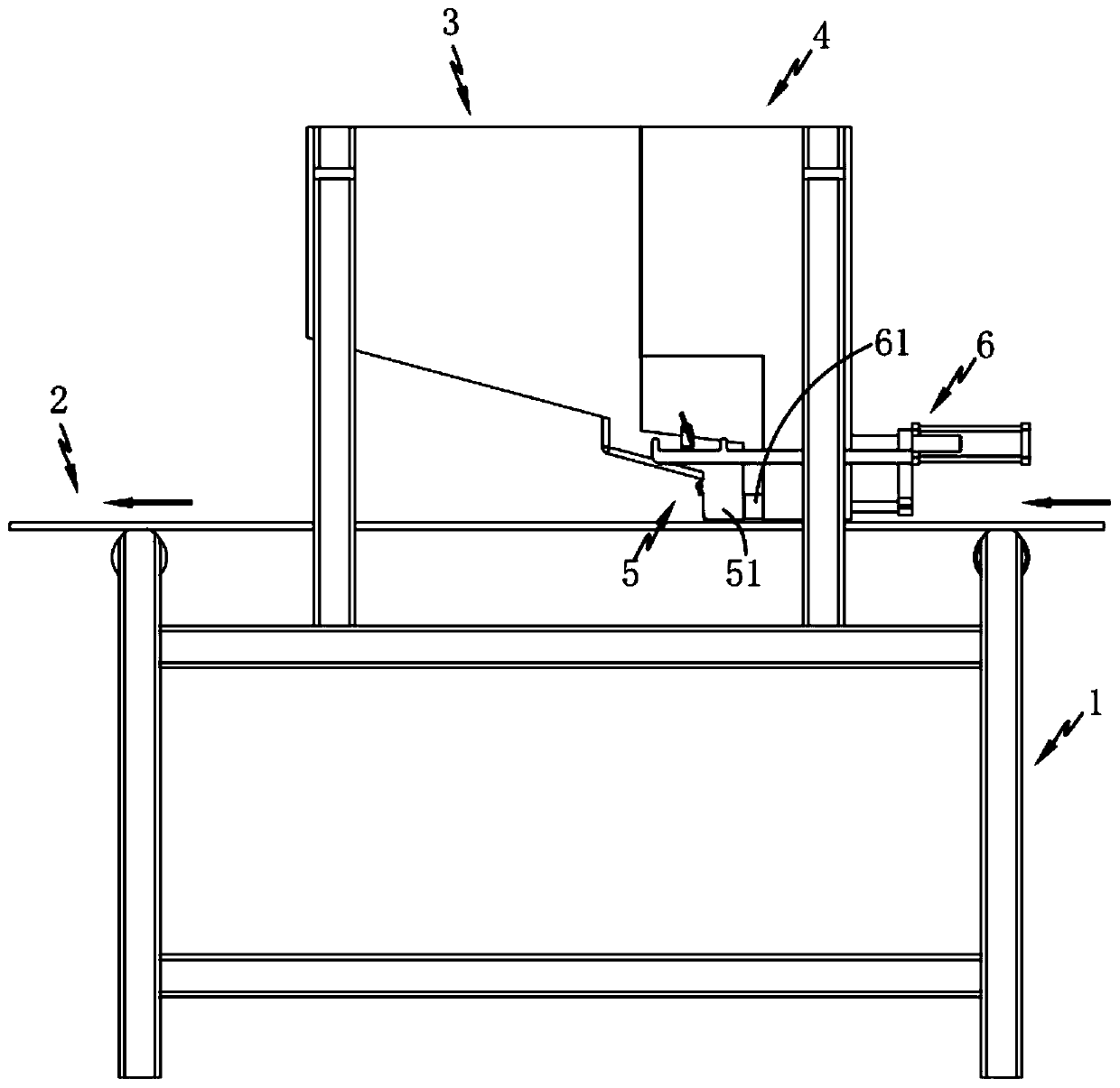

[0043] (a) the buffering part, when the single-layer main material 30 is cached in a flat state through the setting of the inclined plate, the rotation angle of the limiting plate 522 is set to carry out the intermittent output of the main material 30;

[0044] (b)...

Embodiment 2

[0050]Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that the material string 31 is arranged in the forming section in a rotating manner, and the material string 31 is positioned through the elastic baffle 53 arranged on one side of the output direction in the forming section, and The linear transmission of the material string 31 by the conveyor belt 2 realizes the rotation of the material string 31 in the forming section.

[0051] Wherein, the step c also includes a cooling part, during which the liquid additive material 41 is attached to the rotating material string 31, the additive material 41 bonded to the material string 31 is cooled by air flow, so that it is solid and attached to the material stri...

Embodiment 3

[0054] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the third embodiment and the first embodiment is that the angle setting of the limiting plate 522 is controlled by the drive rod 65 fixedly connected with the push assembly 6, and the drive rod 65 is fixedly connected with the push rod 62 Realize synchronous movement.

[0055] It should be noted that the angle setting of the limit plate 522 is controlled by the drive rod 65 fixedly connected with the push assembly 6, and the drive rod 65 and the push rod 62 are fixedly connected to realize synchronous movement, and the push rod 62 moves in a reciprocating manner. During the quantitative delivery of the added material 41, the limit plate 522 is driven to output the material string 31 in the buffer se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com