An automatic batching device and batching method

A technology of batching bins and materials, applied in chemical instruments and methods, mixer accessories, dissolution and other directions, can solve the problems of incomplete falling, inability to repair, troublesome operation process, etc., and achieve accurate and controllable falling materials, fast wireless transmission speed, Control precise and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

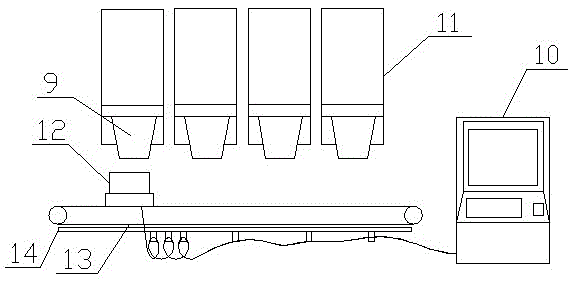

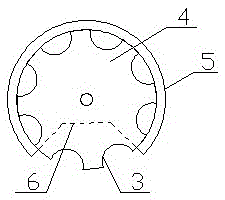

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment: a kind of automatic batching device, it comprises 10 control cabinets, batching bin 11 with feeding device, mobile weighing pan 12, batching bin 11 is provided with quantitative feeding device, the quantitative feeding device is connected to the control cabinet 10, the batching bin 11 is arranged in a plurality of lines, and its feeding port 6 is on a straight line, and a conveyor belt 13 is arranged directly below the feeding port of the batching bin 11, and the weighing pan includes The weighing bucket and the electronic measuring scale are placed on the conveyor belt 13, and the electronic measuring scale is connected with the control cabinet 10 through a line.

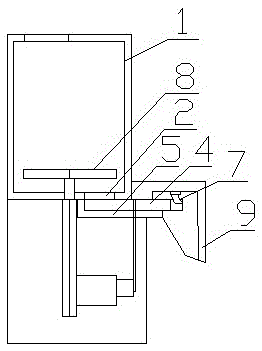

[0025] It includes a frame, on which there is a material tank 1, the lower end of the material tank 1 is provided with a feeding hole 2, and the lower end of the material tank 1 is slidably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com