Cutting fluid concentration monitoring and automatic proportioning system and working method

An automatic proportioning and cutting fluid technology, which is applied in chemical instruments and methods, mixer accessories, mixers, etc., can solve the problems of difficult control of the ratio of cutting stock solution and diluent, uneven mixing ratio, concentration detection error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

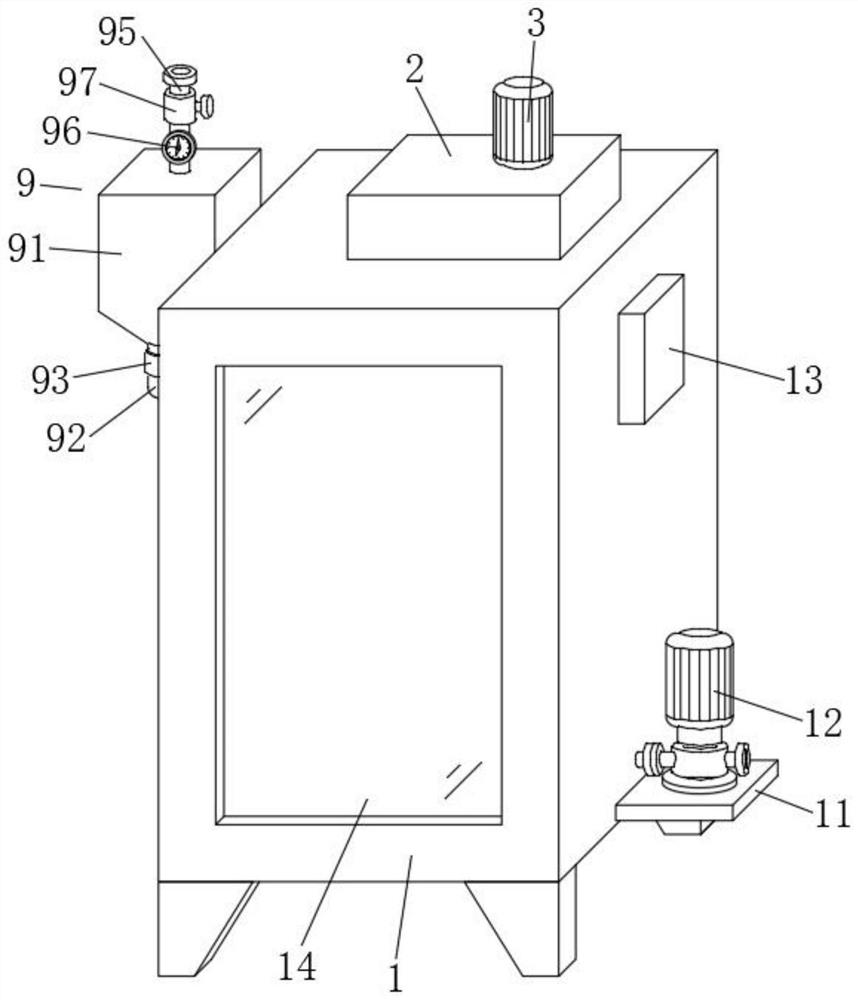

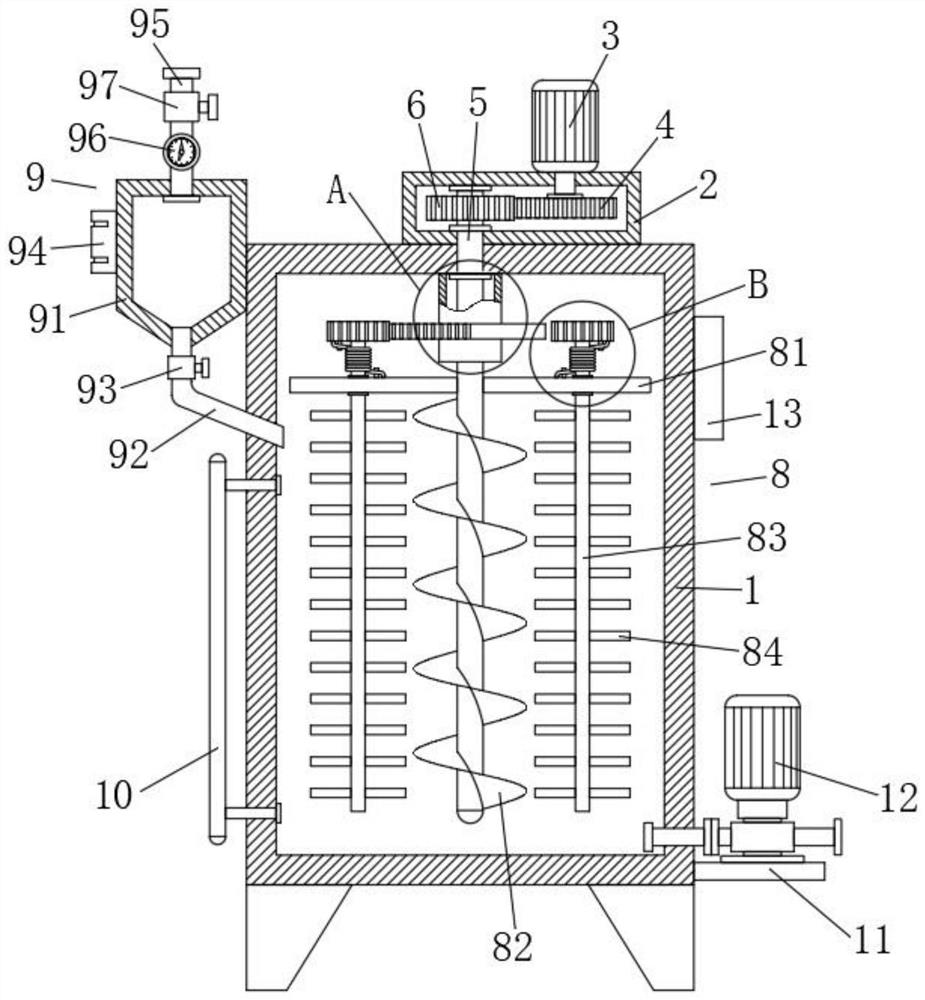

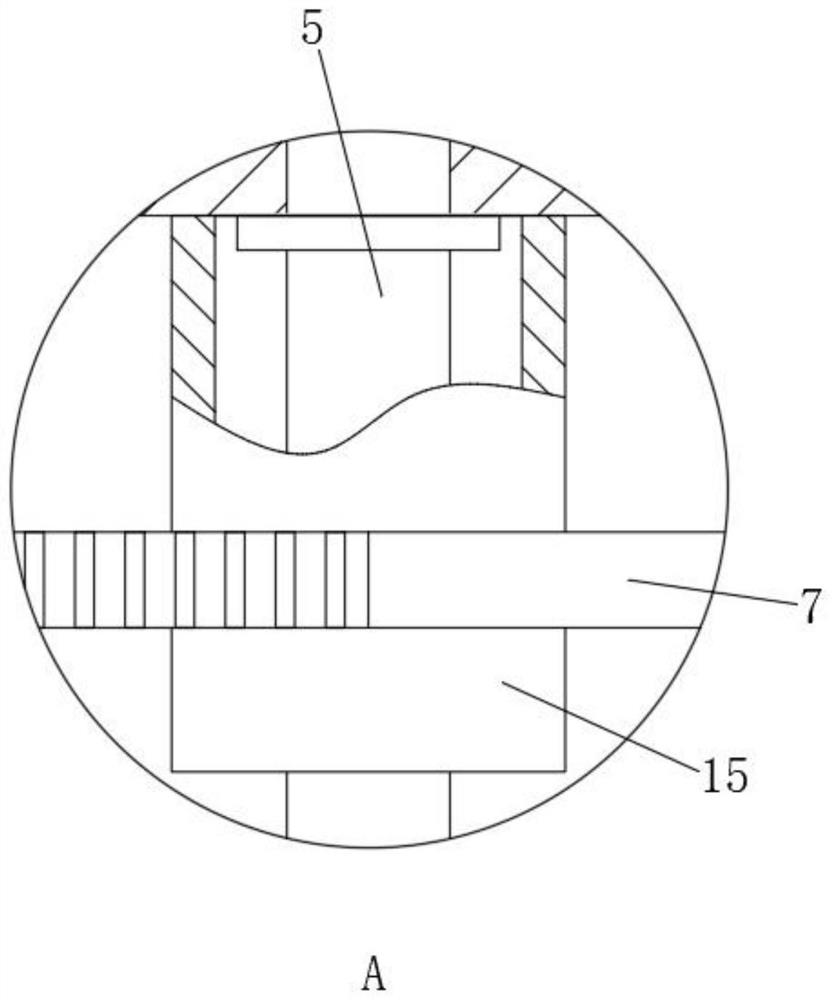

[0028] The cutting fluid concentration monitoring and automatic proportioning system includes a mixing box 1, one end of the top of the mixing box 1 is fixedly connected to a transmission box 2, and one end of the top of the transmission box 2 is fixedly installed with a servo motor 3, and the servo motor 3 The output shaft of the transmission box 2 extends to the inside of the transmission box 2 and is fixedly connected with the driving gear 4. The inside of the transmission box 2 and one side of the driving gear 4 are rotatably connected with a rotating shaft 5, and the outer side of the rotating shaft 5 is located at the driving One side of the gear 4 is fixedly connected with a driven gear 6, the driving gear 4 is meshed with the driven gear 6, and the servo motor 3 drives the driving gear 4 to rotate, thereby driving the driven gear 6 and the rotating shaft 5 to rotate, thereby Better complete power transmission; the bottom of the rotating shaft 5 extends to the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com