Preparation device and preparation method of shift gas for ammonia synthesis co-production methanol synthesis

A technology for methanol synthesis and gas shift, which is applied in hydrogen/synthesis gas production, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of passive urea production, unfavorable production costs, and reduction of medium-pressure superheated steam, and achieves a proportion of High efficiency and precision, high quality steam volume, and the effect of reducing COS content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

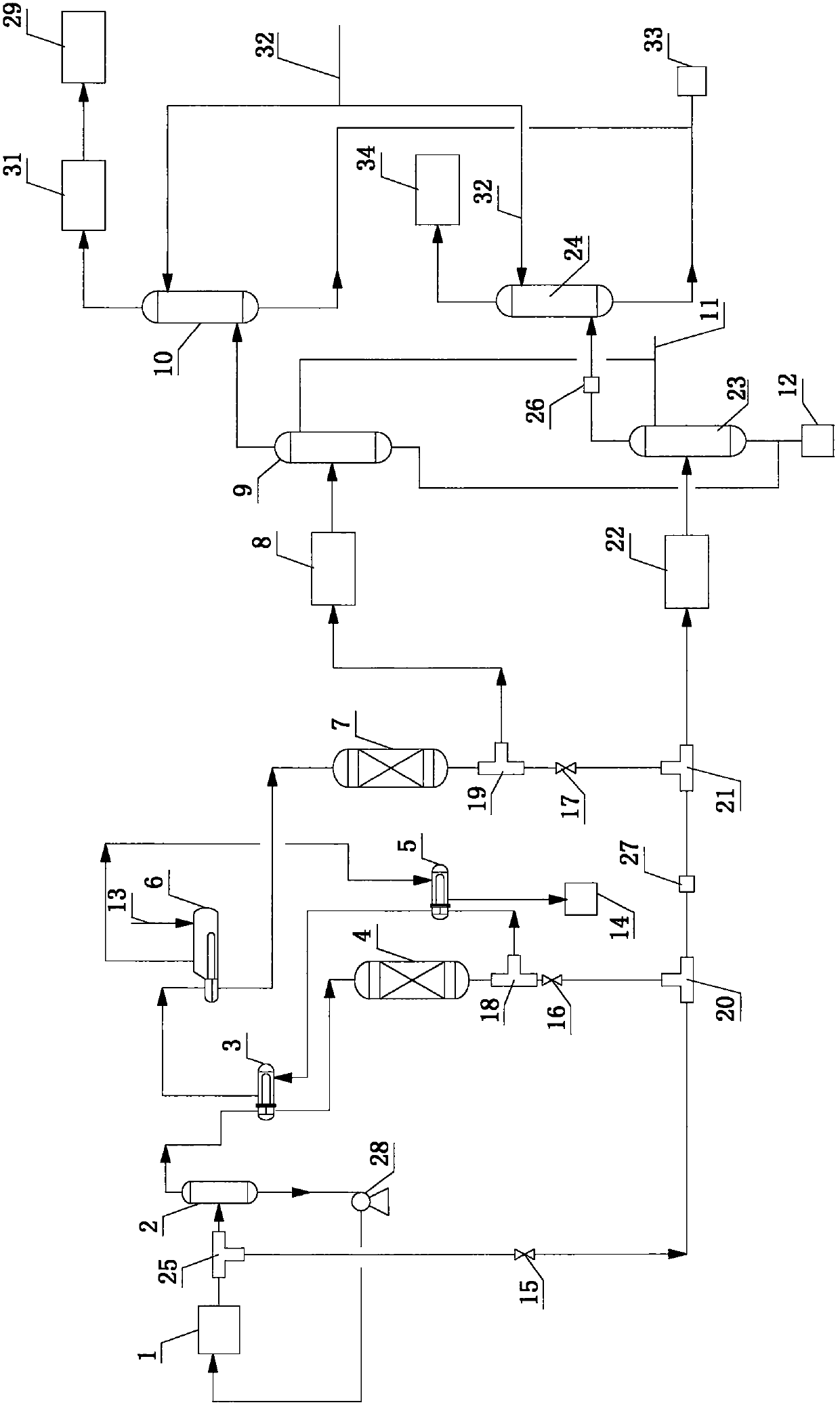

[0045] A method for preparing ammonia synthesis co-production methanol synthesis shift gas, comprising the following steps:

[0046]1. The crude gas saturated with steam from the gasification water washing tower 1 is divided into two parts, one part enters the gas-liquid separator 2 through the third end of the fifth three-way 25, and the other part passes through the fifth three-way 25 and the third A self-regulating valve 15, the first three-way 20 and the second three-way 21 are connected to the second heat and condensate recovery unit 22; the temperature of the crude gas is: 225-240°C, the pressure is: 5.3-8.5Mpa, Volume fraction of carbon monoxide: 40-55%;

[0047] 2. After the crude gas entering the gas-liquid separator 2 described in step 1 is separated from the gas and liquid, the water in the liquid phase enters the gasification through the liquid phase outlet at the bottom of the gas-liquid separator 2, the condensate pump 28 and the inlet of the gasification water w...

Embodiment 2

[0060] A method for preparing ammonia synthesis co-production methanol synthesis shift gas, comprising the following steps:

[0061] 1. The crude gas saturated with steam from the gasification water washing tower 1 is divided into two parts, one part enters the gas-liquid separator 2 through the third end of the fifth three-way 25, and the other part passes through the fifth three-way 25 and the third A self-regulating valve 15, the first three-way 20 and the second three-way 21 are connected to the second heat and condensate recovery unit 22; the temperature of the crude gas is: 225-240°C, the pressure is: 5.3-8.5Mpa, Volume fraction of carbon monoxide: 40-55%;

[0062] 2. After the crude gas entering the gas-liquid separator 2 described in step 1 is separated from the gas and liquid, the water in the liquid phase enters the gasification through the liquid phase outlet at the bottom of the gas-liquid separator 2, the condensate pump 28 and the inlet of the gasification water ...

Embodiment 3

[0075] A method for preparing ammonia synthesis co-production methanol synthesis shift gas, comprising the following steps:

[0076] 1. The crude gas saturated with steam from the gasification water washing tower 1 is divided into two parts, one part enters the gas-liquid separator 2 through the third end of the fifth three-way 25, and the other part passes through the fifth three-way 25 and the third A self-regulating valve 15, the first three-way 20 and the second three-way 21 are connected to the second heat and condensate recovery unit 22; the temperature of the crude gas is: 225-240°C, the pressure is: 5.3-8.5Mpa, Volume fraction of carbon monoxide: 40-55%;

[0077] 2. After the crude gas entering the gas-liquid separator 2 described in step 1 is separated from the gas and liquid, the water in the liquid phase enters the gasification through the liquid phase outlet at the bottom of the gas-liquid separator 2, the condensate pump 28 and the inlet of the gasification water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com