Intelligent loading, proportioning and blending device for powders

A technology of mixing device and reclaiming device, which is applied in the direction of mixers, mixers with rotating containers, mixer accessories, etc., can solve the problems of rising incidence of occupational diseases of operators, easy dust pollution in the working environment, and easy accumulation of errors, etc. Achieve the effect of reducing manual participation, reducing dust flying, and reducing proportion error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0023] In the present invention, three spiral reclaiming devices are provided as the first embodiment of the present invention, which will be further described in detail below.

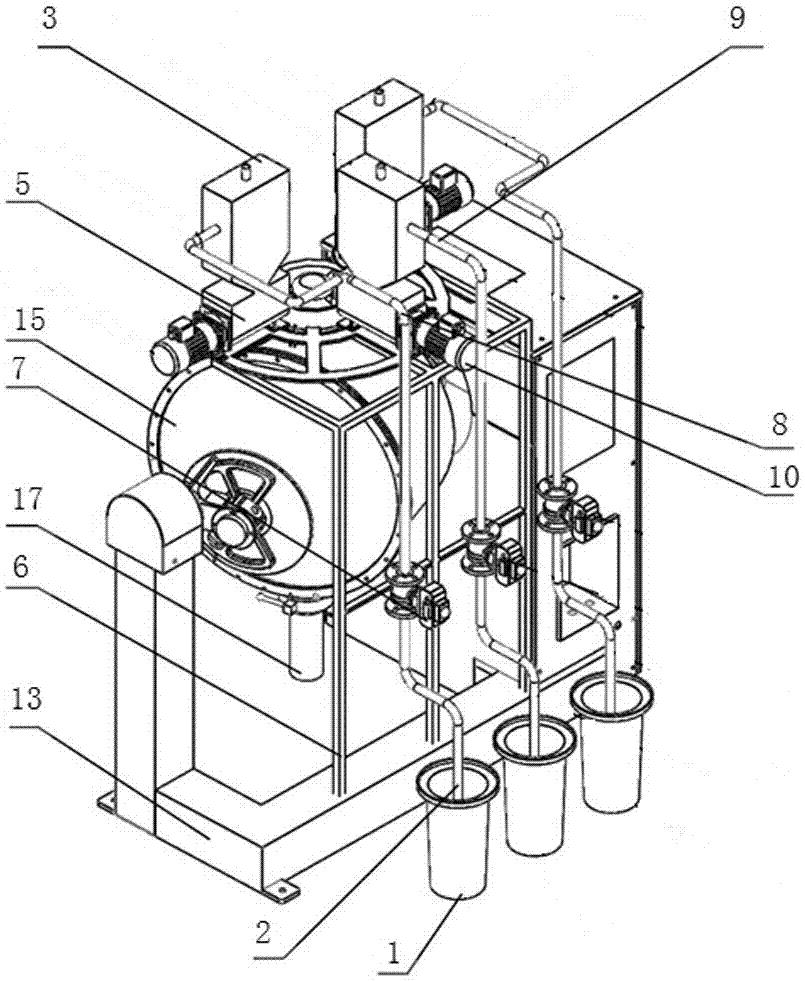

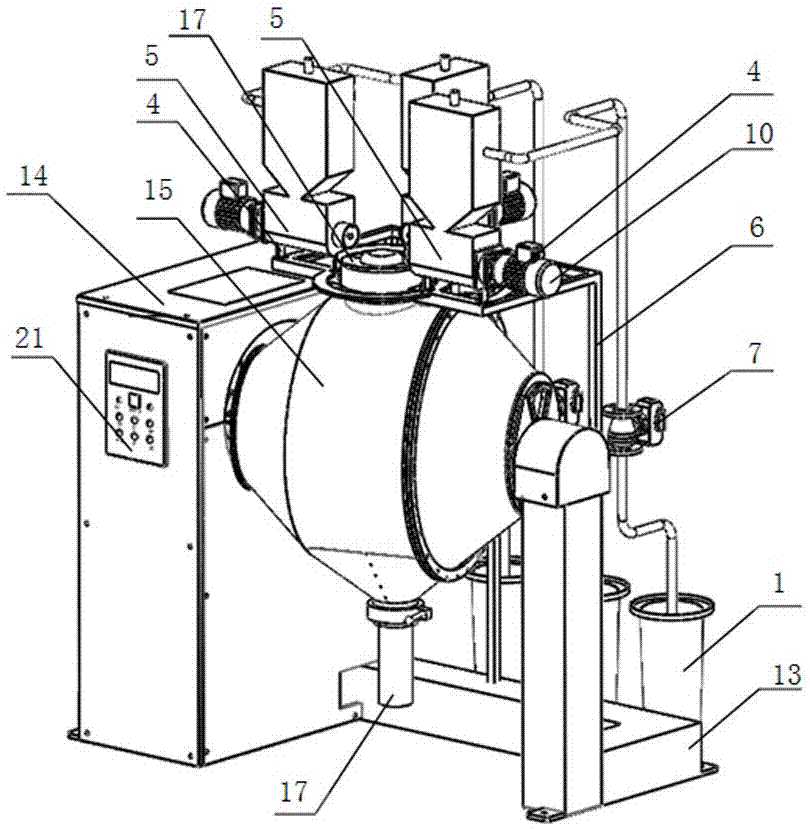

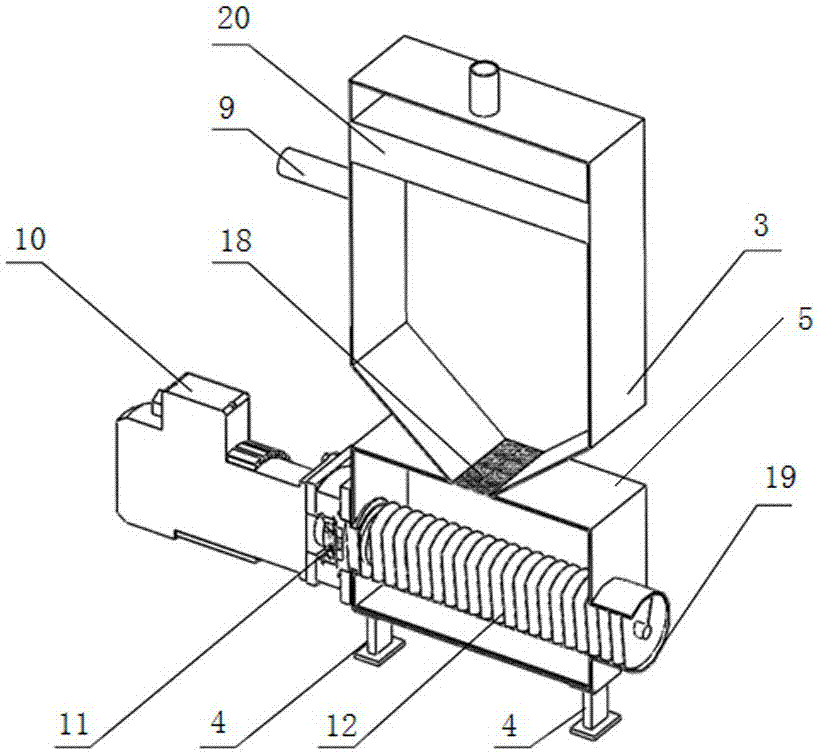

[0024] According to the first embodiment of the present invention, figure 1 It is the isometric view of the first embodiment of the present invention Figure 1 , figure 2 It is the isometric view of the first embodiment of the present invention Figure II , refer to figure 1 and 2 As shown, the powder intelligent feeding proportioning mixing device of the present invention includes: a base, a control cabinet, a feeding load-bearing frame, a powder mixing tank and three spiral feeding devices.

[0025] According to a first embodiment of the present invention, referring to figure 1 and 2 As shown, the base and the control cabinet are integrally structured, the control cabinet is provided with a control panel, and a control system is provided inside for controlling the automatic operation of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com