Indirect control type digital servo valve

A digital servo and control technology, applied in the field of servo valves, can solve problems such as limited driving force, high cost, and limited anti-pollution ability, so as to improve adjustment efficiency and precision, reduce intermediate transmission links, and avoid oil leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

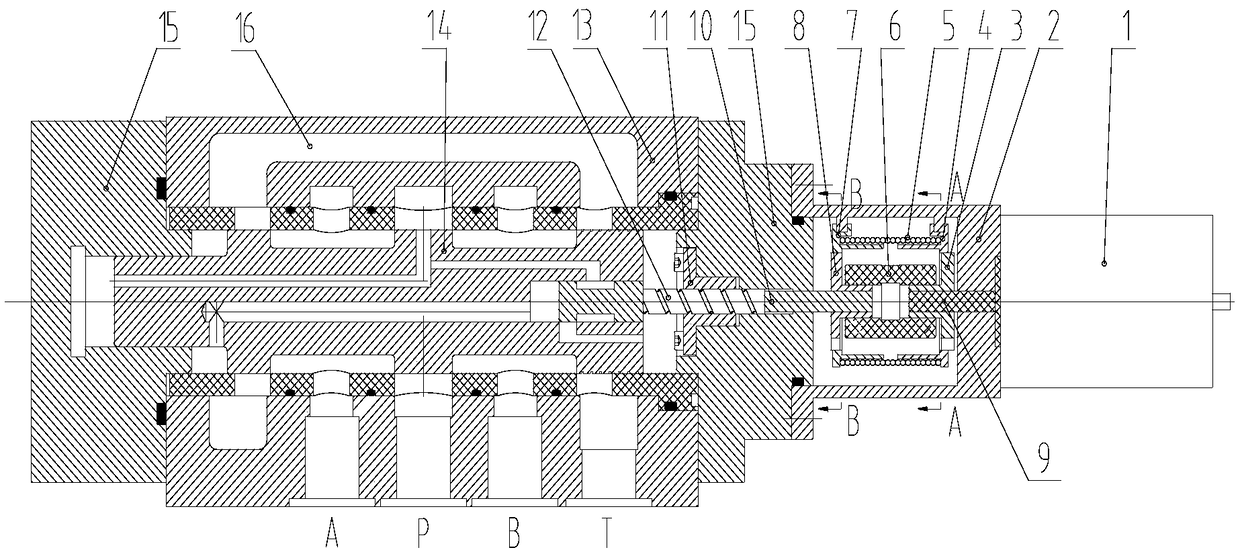

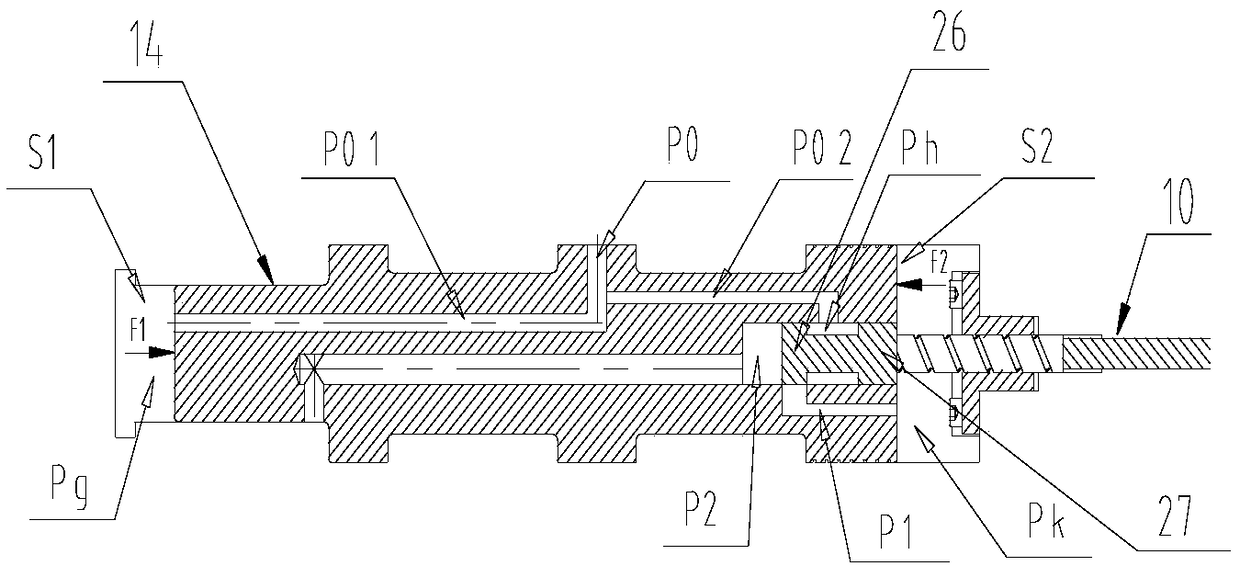

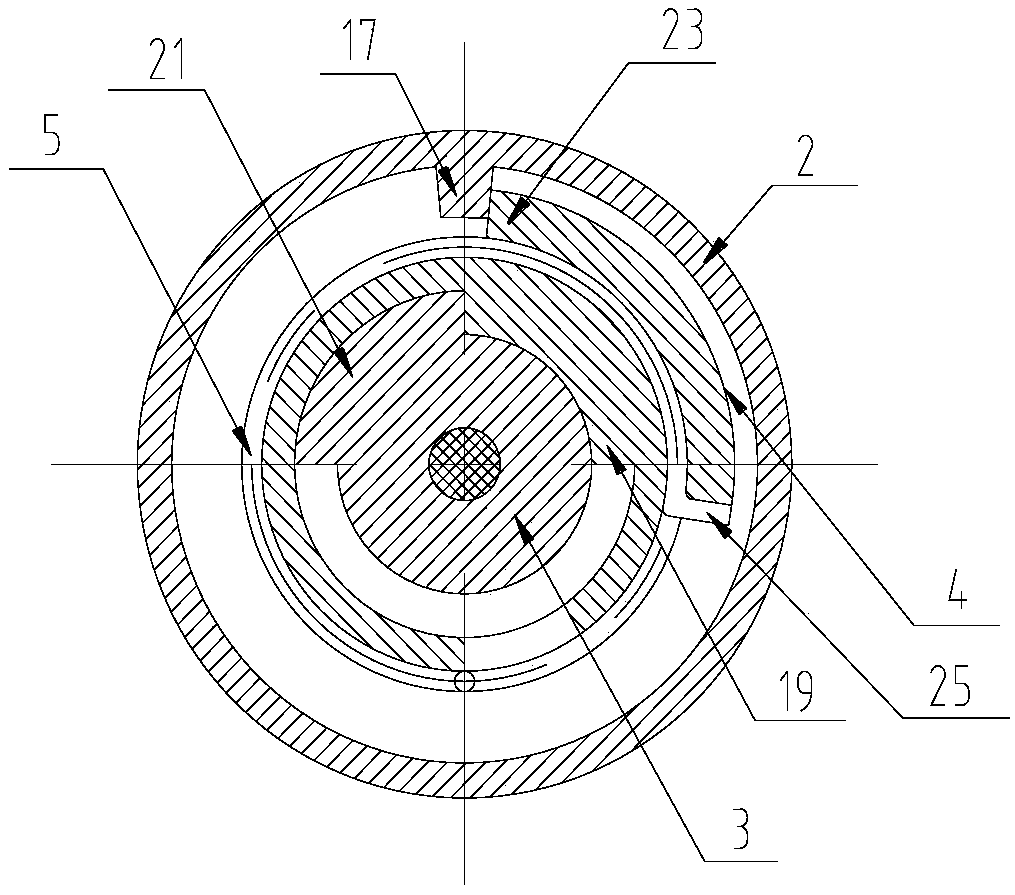

[0046] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

[0047] The axial direction, circumferential direction and radial direction described in this article are all referred to the main spool 14 or pilot spool 10 of the indirect control servo valve, the extension direction of the main spool 14 or pilot spool 10 is the axial direction, and The diameter direction of the main spool 14 or the pilot spool 10 is radial, and the outer wall of the pilot spool 10 is circumferential.

[0048] Words such as first and second described herein are only used to distinguish two or more components of the same or similar structure, or two or more structures of the same or similar structure, and do not represent a special limitation on the order.

[0049] Unless otherwise specified, the inside and outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com