Automatic electric detonator packaging machine

An automatic packaging machine and electric detonator technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as low efficiency and unsafe safety, and achieve the effects of reducing production costs, improving intrinsic safety, and accurate and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

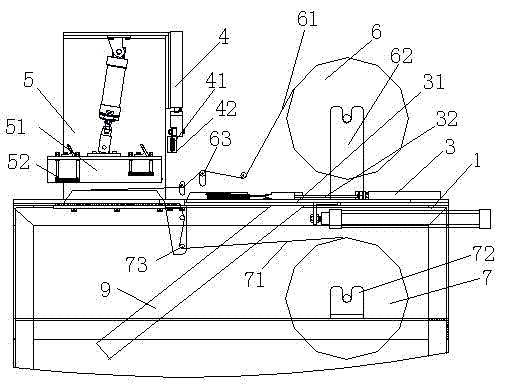

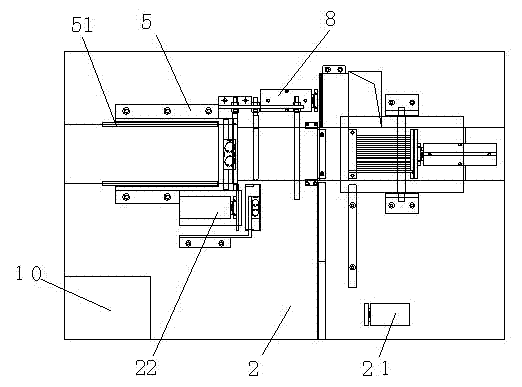

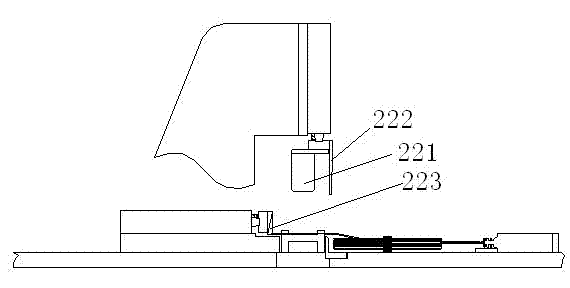

[0041] Below in conjunction with accompanying drawing, the present invention will be further described:

[0042] Such as Figure 1-Figure 4 As shown, the working process of the device is described as follows:

[0043] Work preparation: first check the initial position and reliability of each control mechanism and parts, and then prepare the upper and lower plastic films (ie upper and lower films) according to the specifications required by each, and place them in the corresponding position, and pass the The personnel pull the two plastic films to the side seal, and heat seal and cut off the front end of the first plastic bag.

[0044] Working steps: The electric detonator and the auxiliary mold at the upper station move to the mold feeding device, and are sent to the push tube into the bag device through the film feeding device. The rear mold pushes the front mold to move to the position of the folding device for the detection mold. The folding plate and the unloading detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com