Patents

Literature

43results about How to "Easy and fast commissioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

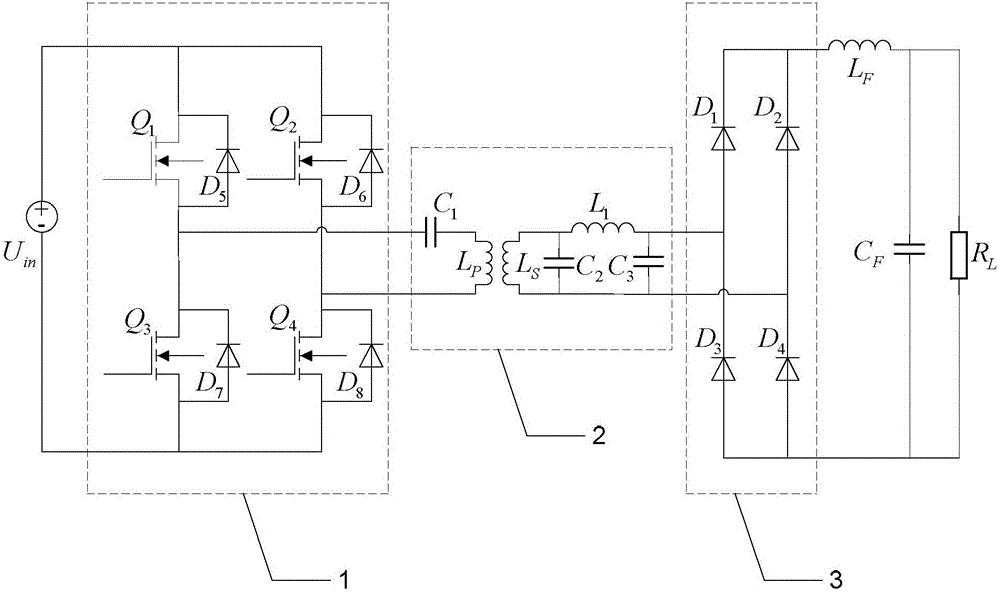

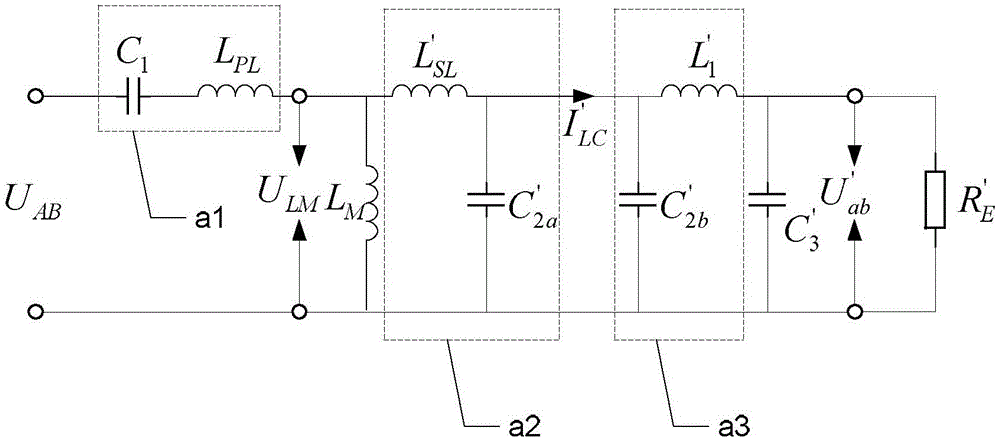

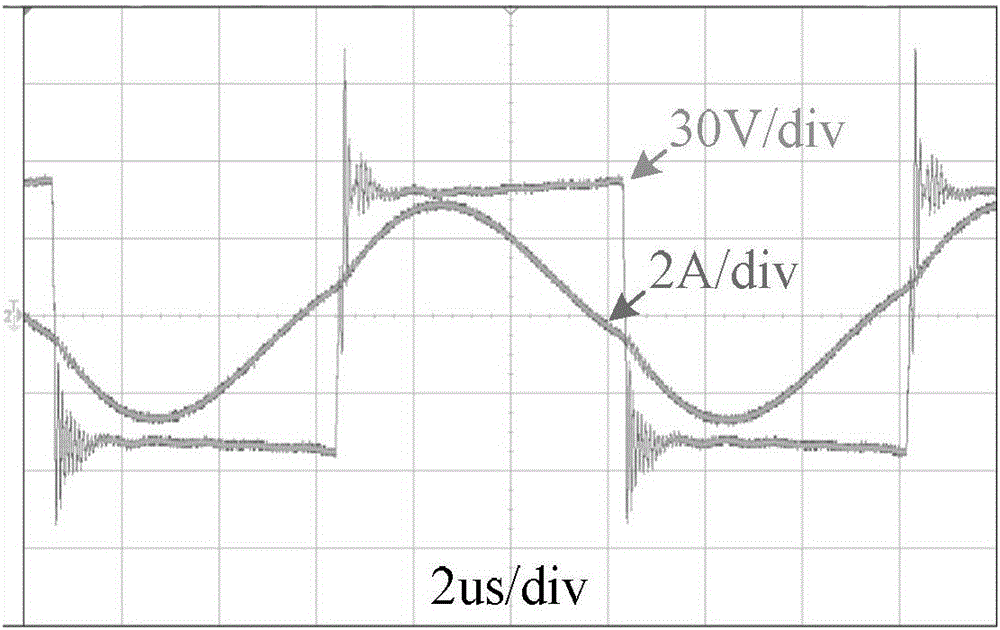

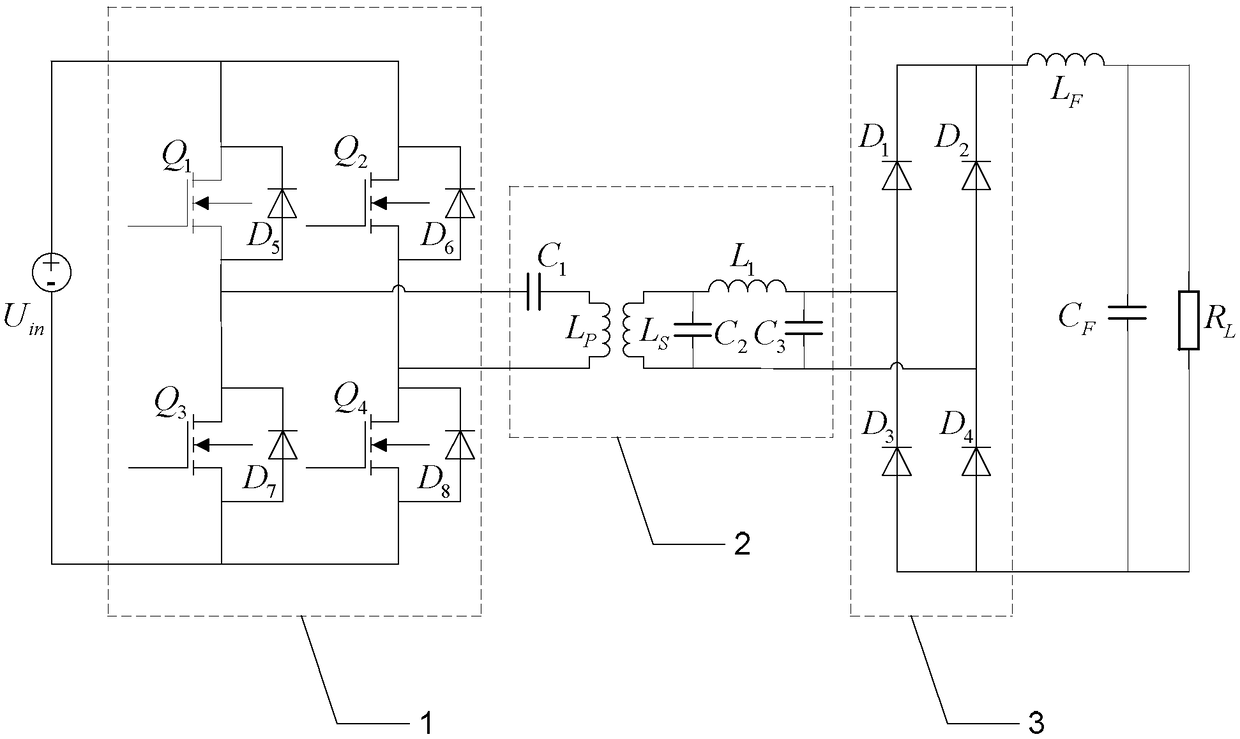

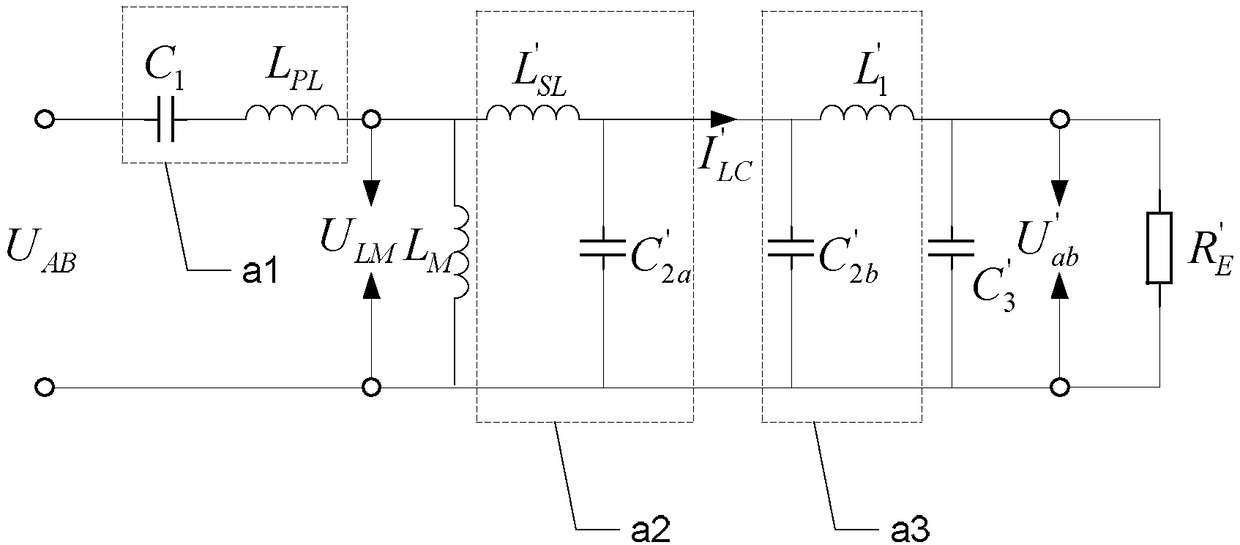

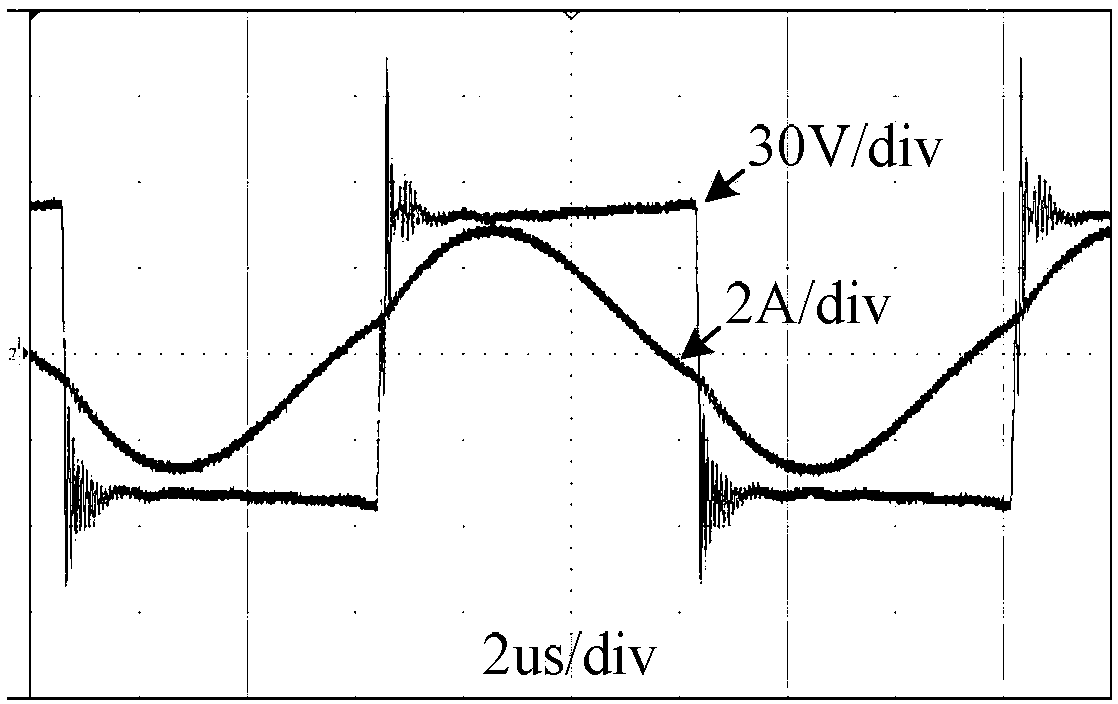

Wireless electric energy transmission system compensation topological structure

InactiveCN106533185AIncrease flexibilityEasy and fast commissioningEfficient power electronics conversionCircuit arrangementsCapacitanceEngineering

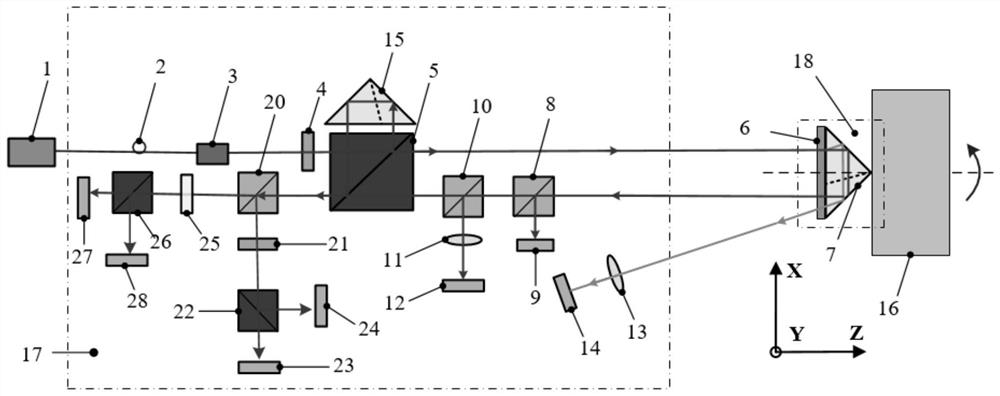

The invention provides a wireless electric energy transmission system compensation topological structure, relates to the wireless electric energy transmission system compensation topological structure, and aims at solving the problems that the existing wireless electric energy transmission system compensation topological structure is high in the number of compensation devices, high in system cost and low in power density. The S / CLC compensation topology comprises a primary series compensation capacitor, a loosely coupled transformer, a secondary parallel compensation capacitor, a secondary series compensation inductor and a phase shifting capacitor. The primary series compensation capacitor is connected with a full-bridge inverter. The primary series compensation capacitor is connected with the primary self-inductor of the loosely coupled transformer. The primary self-inductor of the loosely coupled transformer is connected with the full-bridge inverter. The secondary self-inductor of the loosely coupled transformer is connected with the secondary parallel compensation capacitor and the secondary series compensation inductor. The secondary self-inductor of the loosely coupled transformer is connected with the secondary parallel compensation capacitor, the phase shifting capacitor and a full-wave rectifier. The secondary series compensation inductor is connected with the phase shifting capacitor and the full-wave rectifier. The wireless electric energy transmission system compensation topological structure is used for wireless electric energy transmission.

Owner:HARBIN INST OF TECH

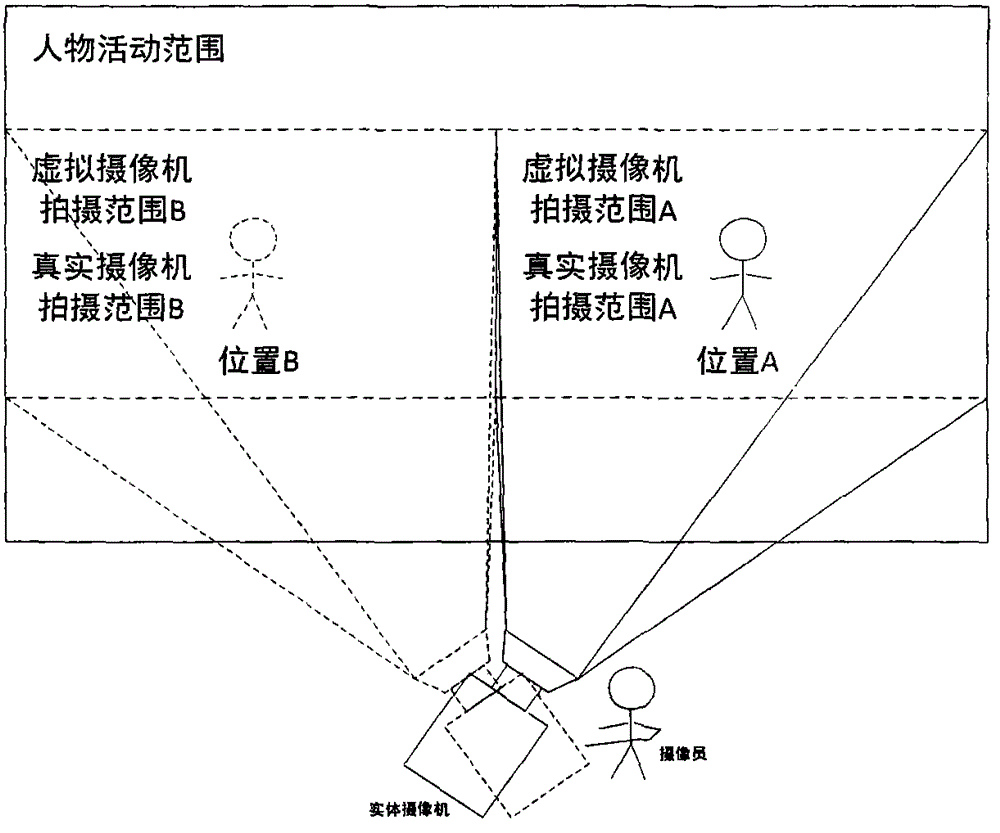

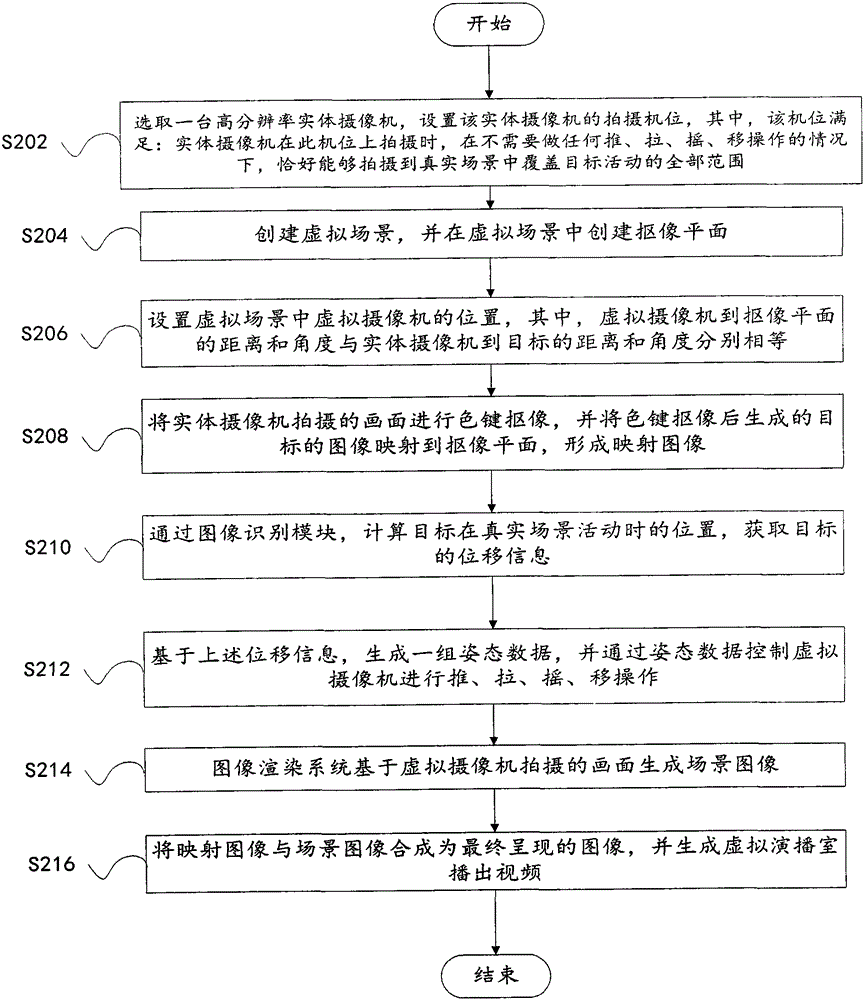

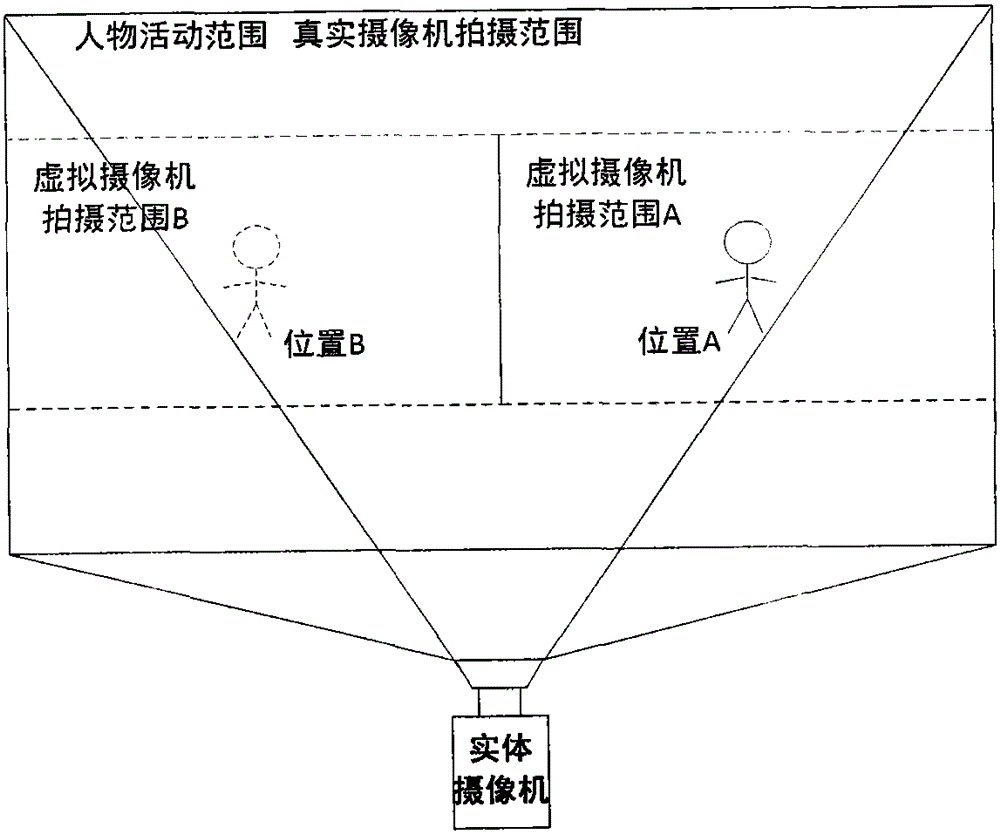

Virtual studio implementation method capable of automatically tracking objects

InactiveCN105072314AQuick installationGuaranteed image qualityTelevision system detailsColor television detailsData controlVirtual camera

The invention discloses a virtual studio implementation method capable of automatically tracking objects. The virtual studio implementation method comprises the following steps: selecting a high-resolution real camera and setting a camera position so that the real camera is capable of getting a comprehensive shot of the whole range of the activities of objects without any operation; creating a virtual scene and an image matting plane; setting the position of a virtual camera; performing chroma key image matting on a picture picked up by the real camera and mapping the images of the objects into the image matting plane to form mapped images; calculating the positions of the objects during activities in a real scene by use of an image identification module; generating a group of attitude data based on the position information and controlling the operation of the virtual camera through the attitude data; generating a scene image by an image rendering system based on the picture picked up by the virtual camera; and synchronizing the mapped images and the scene image into an image for final presentation and generating a virtual studio to play videos. The virtual studio implementation method capable of automatically tracking the objects is capable of enabling the installation and debugging of the virtual studio to be simple and fast, and also capable of greatly saving cost.

Owner:黄喜荣

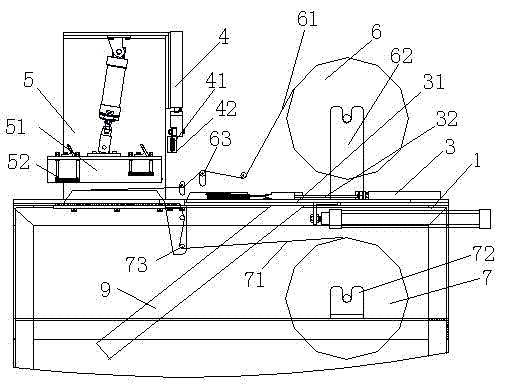

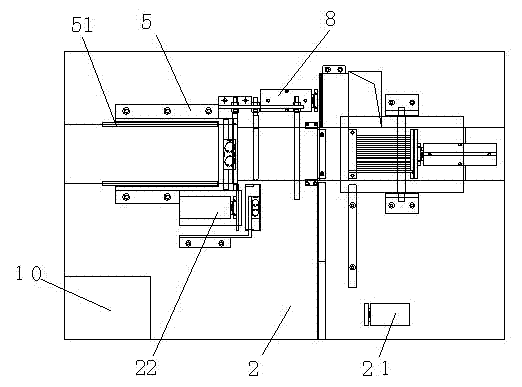

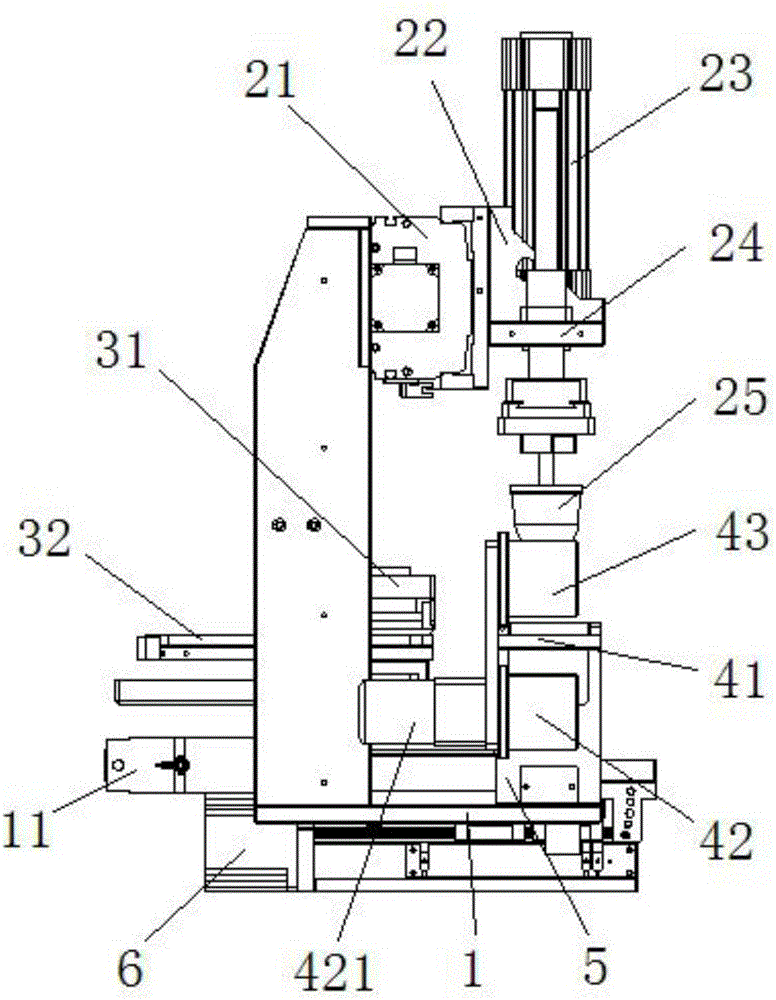

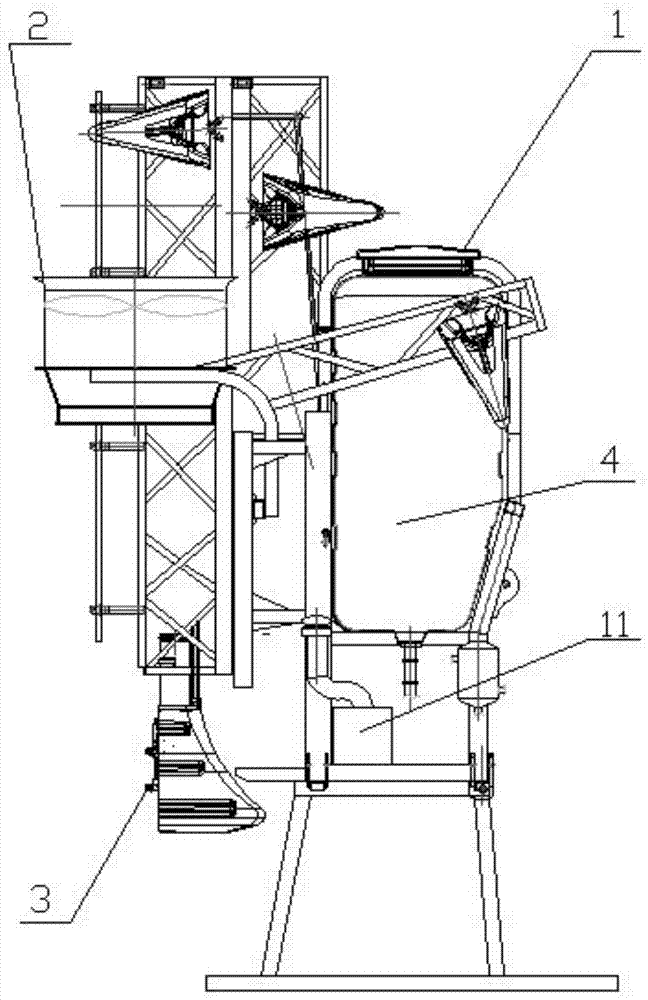

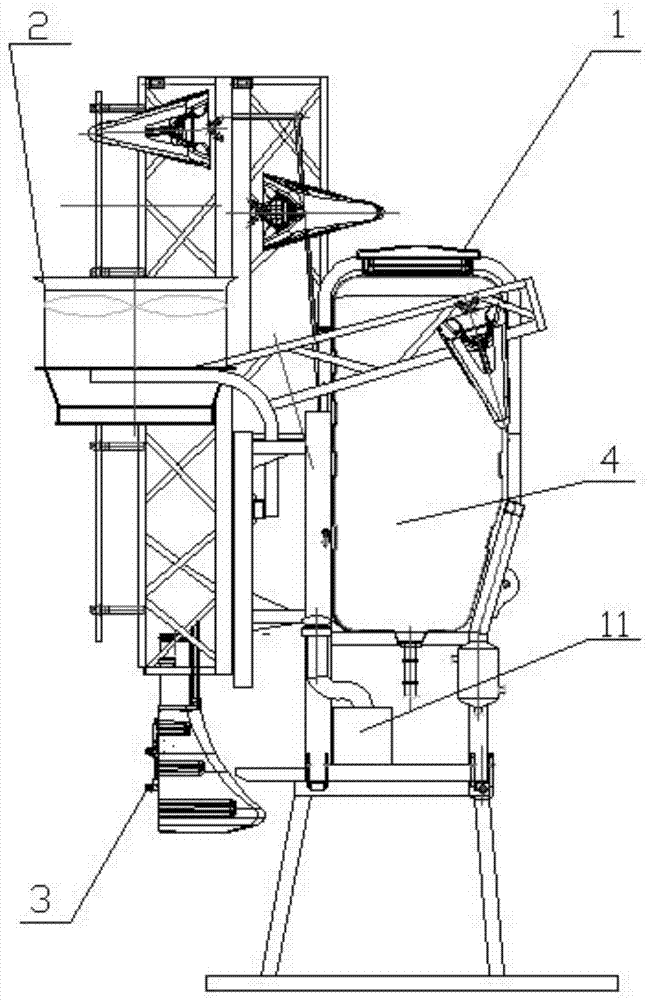

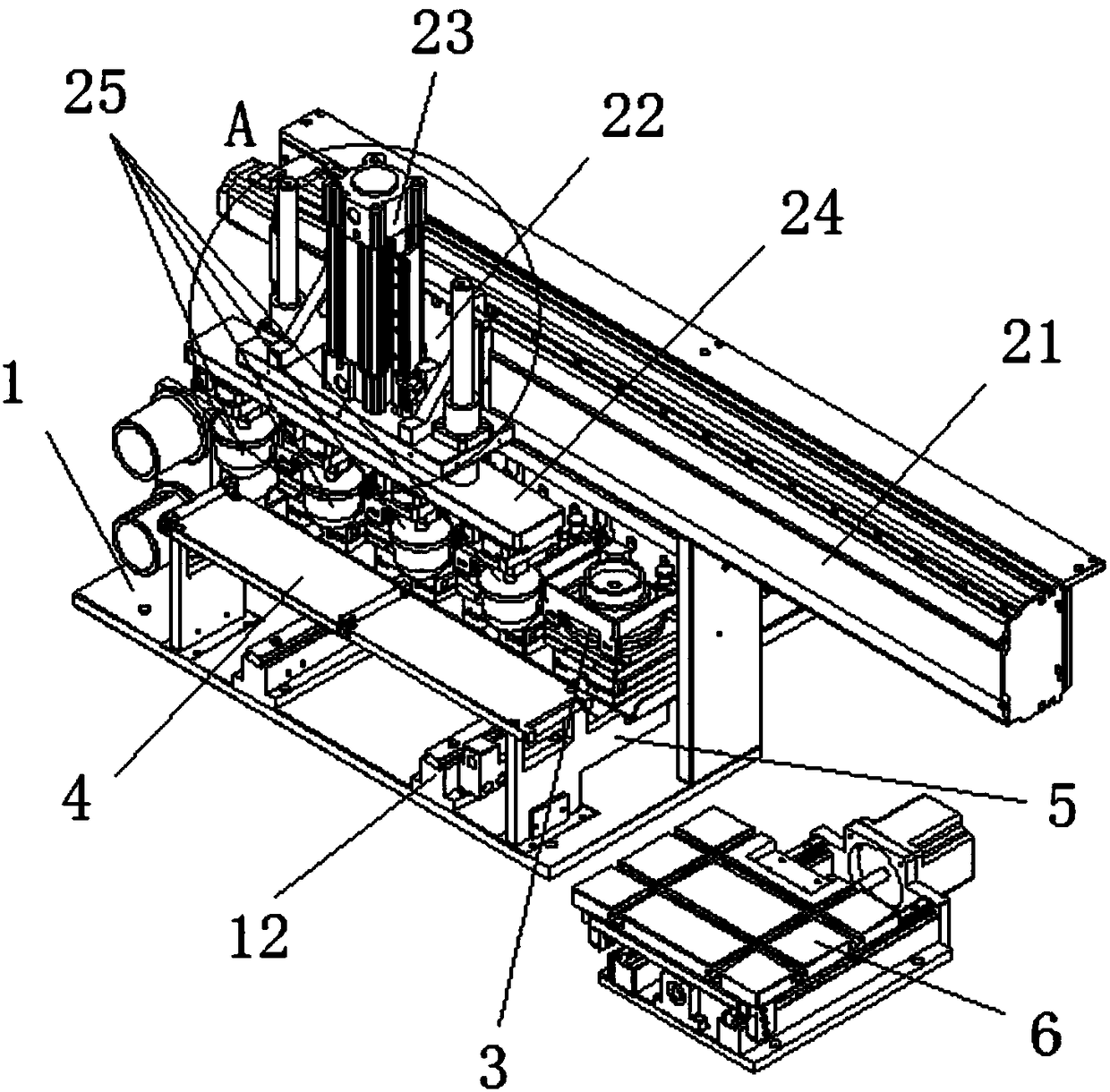

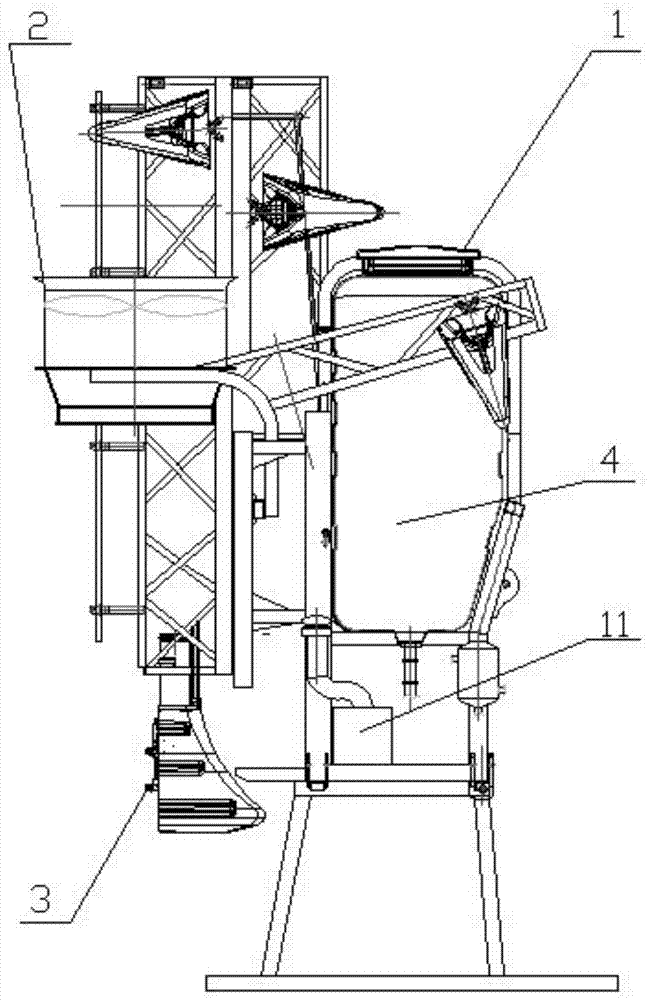

Automatic electric detonator packaging machine

ActiveCN102897334APrecise and reliable controlImprove intrinsic safetyPackaging by pressurising/gasifyingWrappingProgrammable logic controllerElectricity

The invention relates to an automatic electric detonator packaging machine which relates to an automatic packaging machine capable of automatically taking electric detonators out, reshaping the electric detonators and packing the electric detonators with a thermal sealing mode in the electric detonator production process. The automatic electric detonator packaging machine aims to solve the problems that in the prior art, the full-manual operation is low in efficiency and the safety can not be ensured. The technical scheme of the automatic electric detonator packaging machine is as follows: the operation of the automatic electric detonator packaging machine is entirely controlled by a PLC (programmable logic controller) control system, and comprises a mould conveying device, a pipe bagging device, a device for cutting two sealed ends, a side sealing device, a upper film feeding device and a lower film feeding device, wherein the mould conveying device, the pipe bagging device, the device for cutting two sealed ends and the side sealing device are positioned on a workbench according to the order of stations, the upper film feeding device is positioned above the workbench, and the lower film feeding device is positioned under the workbench. The automatic electric detonator packaging machine can prevent operators from directly contacting the dangerous electric detonators, enhances the internal safety, meets the automatic and isolate production requirements on the functions of the stations, and enhances the production efficiency. The automatic electric detonator packaging machine is mainly applied to the automatic packaging of the electric detonator and other objects of the similar structures.

Owner:YAHUA GROUP MIANYANG INDAL

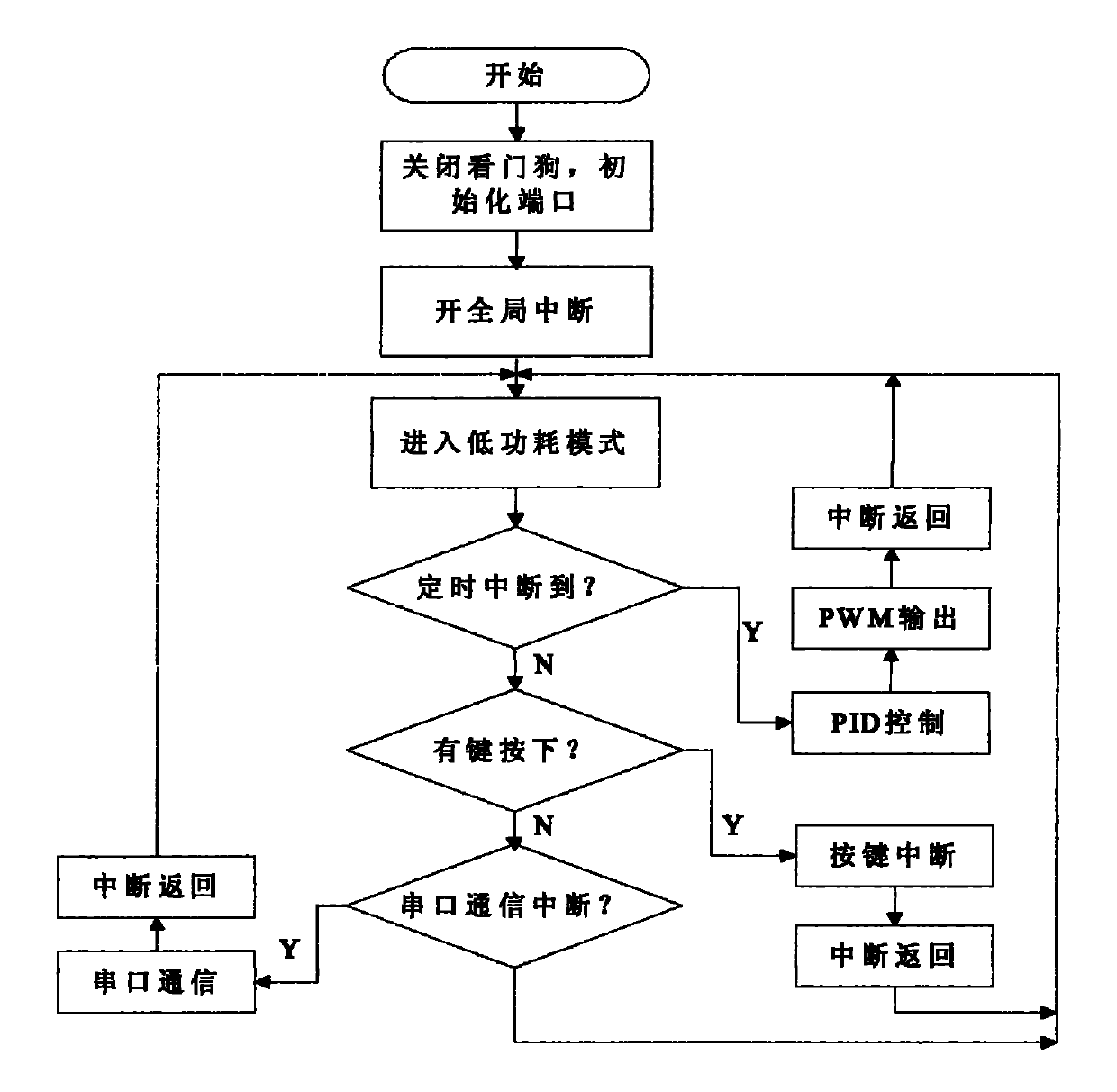

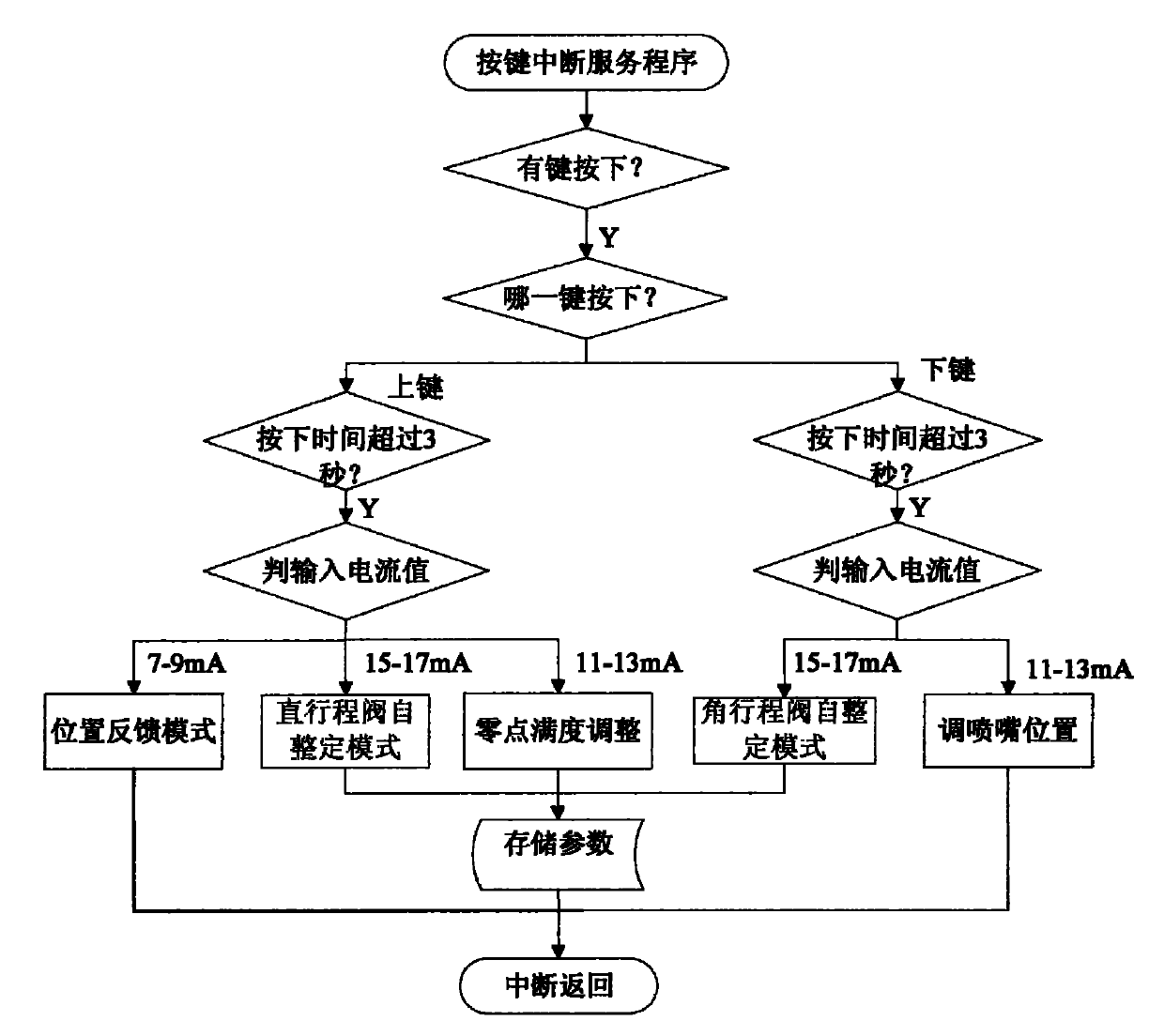

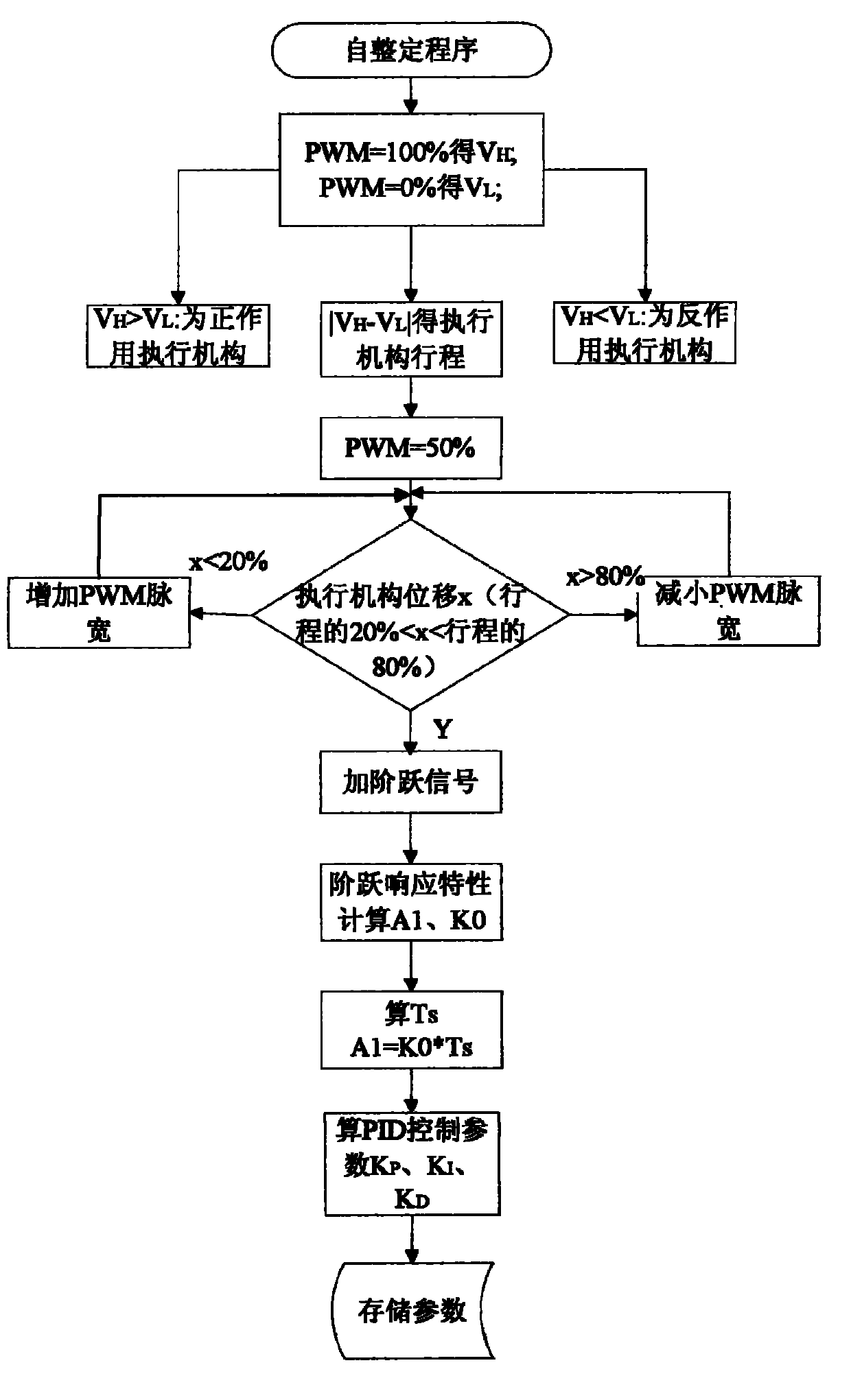

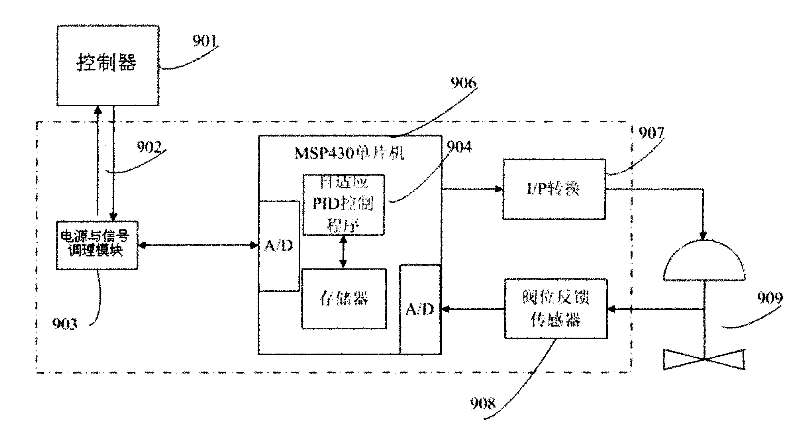

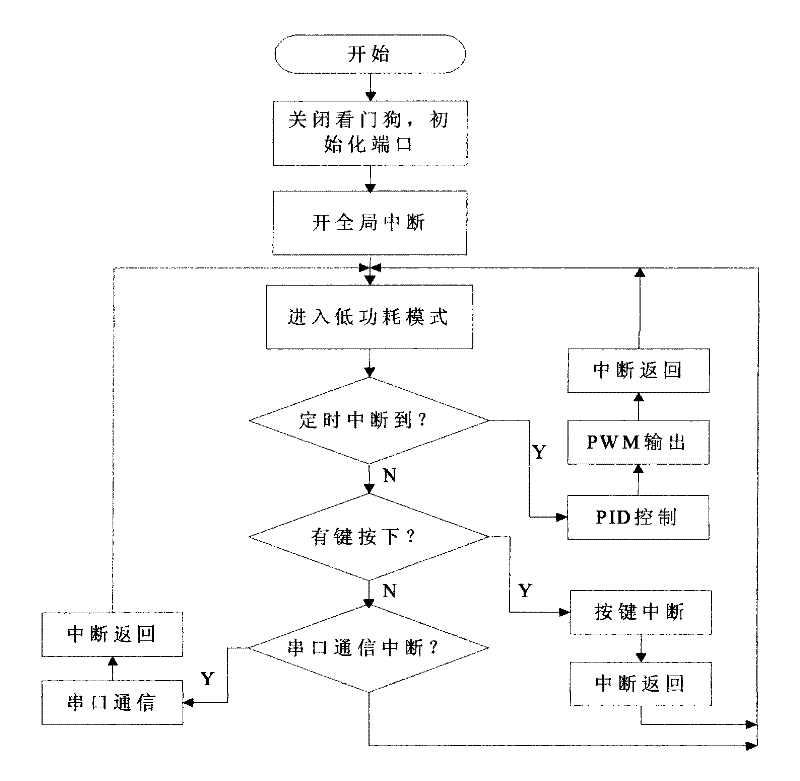

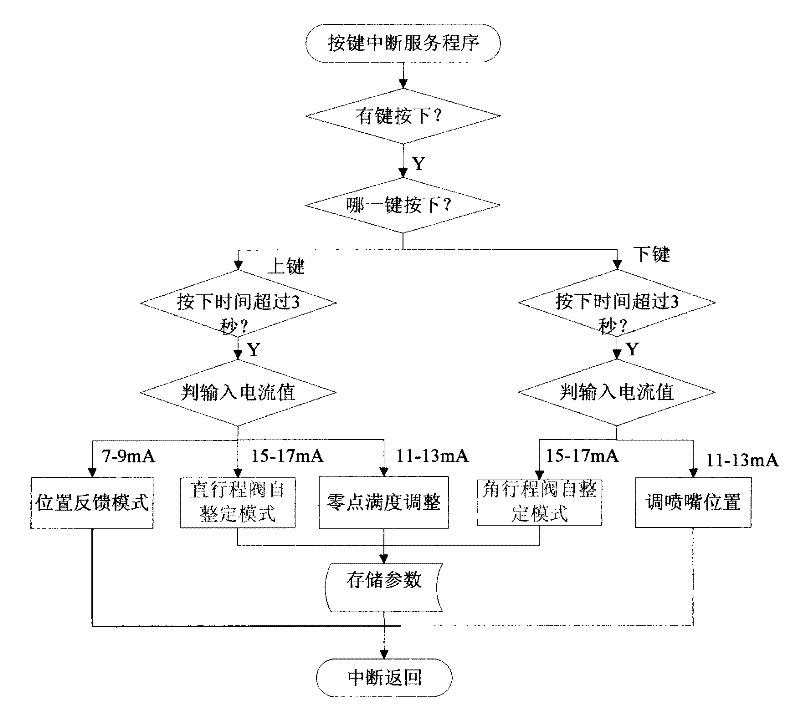

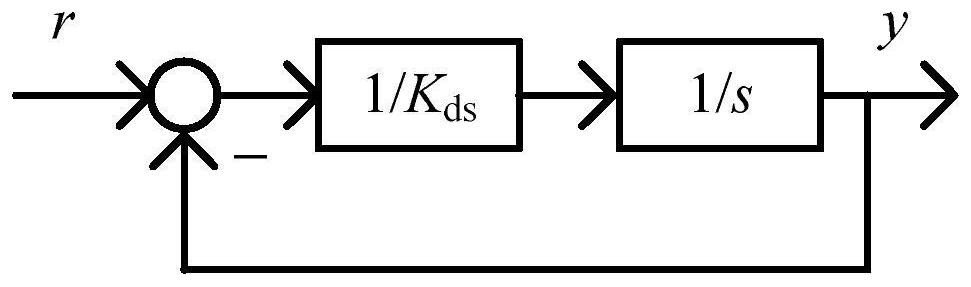

Control method for intelligent valve positioner

ActiveCN101770240AStable and reliable outputEasy and fast commissioningControl using feedbackSelf adaptivePosition sensor

The invention relates to a control method for an intelligent valve positioner, which has simple and rapid debugging. The technical scheme is that a singlechip receives a set signal sent by a controller and a feedback signal transmitted by a valve position sensor; the set signal is compared with the feedback signal; a bias is subjected to adaptive PID control; a corresponding PWM signal is output to drive an I / P converting unit; and an executing mechanism is driven by a pneumatic power amplifier.

Owner:衡阳北方光电信息技术有限公司

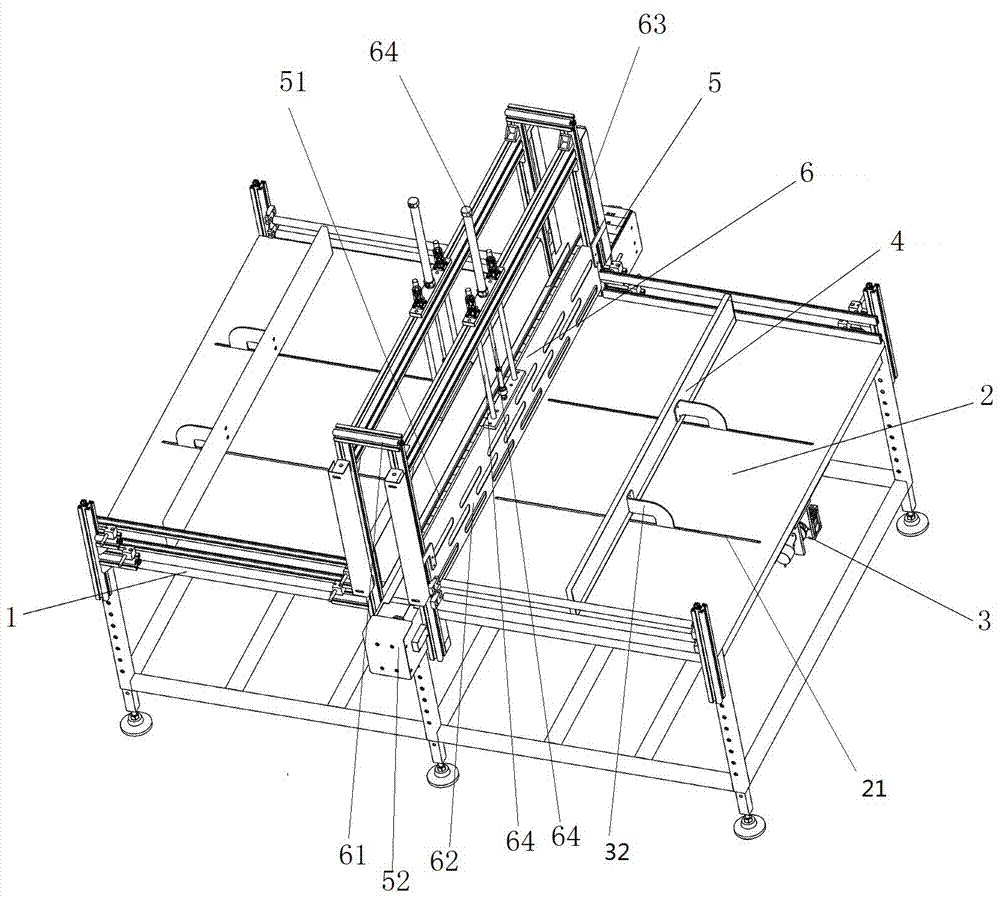

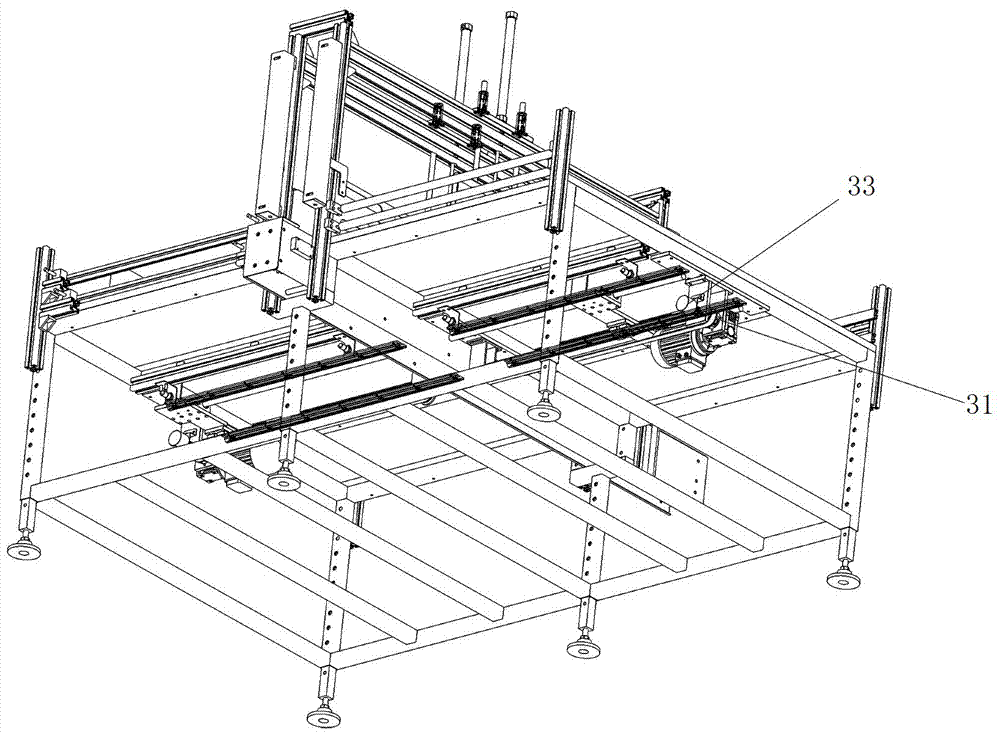

Multi-color and multi-position pad printing machine

The invention belongs to the technical field of pad printing and discloses a multi-color and multi-position pad printing machine. The multi-color and multi-position pad printing machine comprises a base, a pad printing assembly arranged on the base in a straddling manner, a plurality of ink feeding assemblies located below the pad printing assembly, a cleaning assembly located in front of the ink feeding assemblies and a material supporting assembly located beside the ink feeding assemblies; the pad printing assembly comprises a horizontally-arranged servo module which is provided with an X movement module capable of moving in the X direction; the X movement module is provided with a first cylinder which drives an adhesive head assembly to move up and down in the Z direction; the adhesive head assembly is provided with pad printing adhesive heads side by side in the X direction, and the number of the pad printing adhesive heads corresponds to that of the ink feeding assemblies; and the material supporting assembly comprises a base, a carrying table located above the base and a third cylinder fixed to the base and driving the carrying table to move in the X direction. The multi-color and multi-position pad printing machine can print colorful patterns formed by combining different color blocks on products, cost is saved compared with a common multi-color pad printing machine, and besides, debugging is easy and fast.

Owner:YINGTUO ELECTRONICS APP KUSN

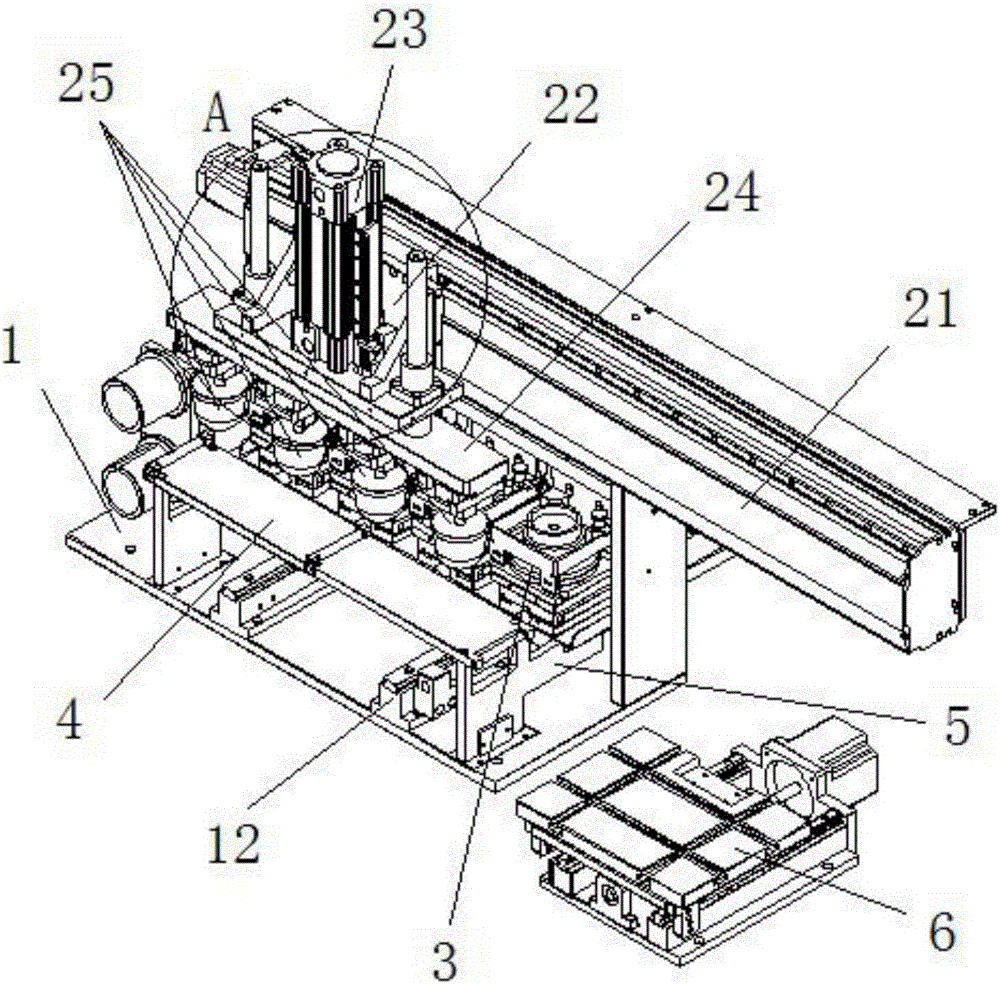

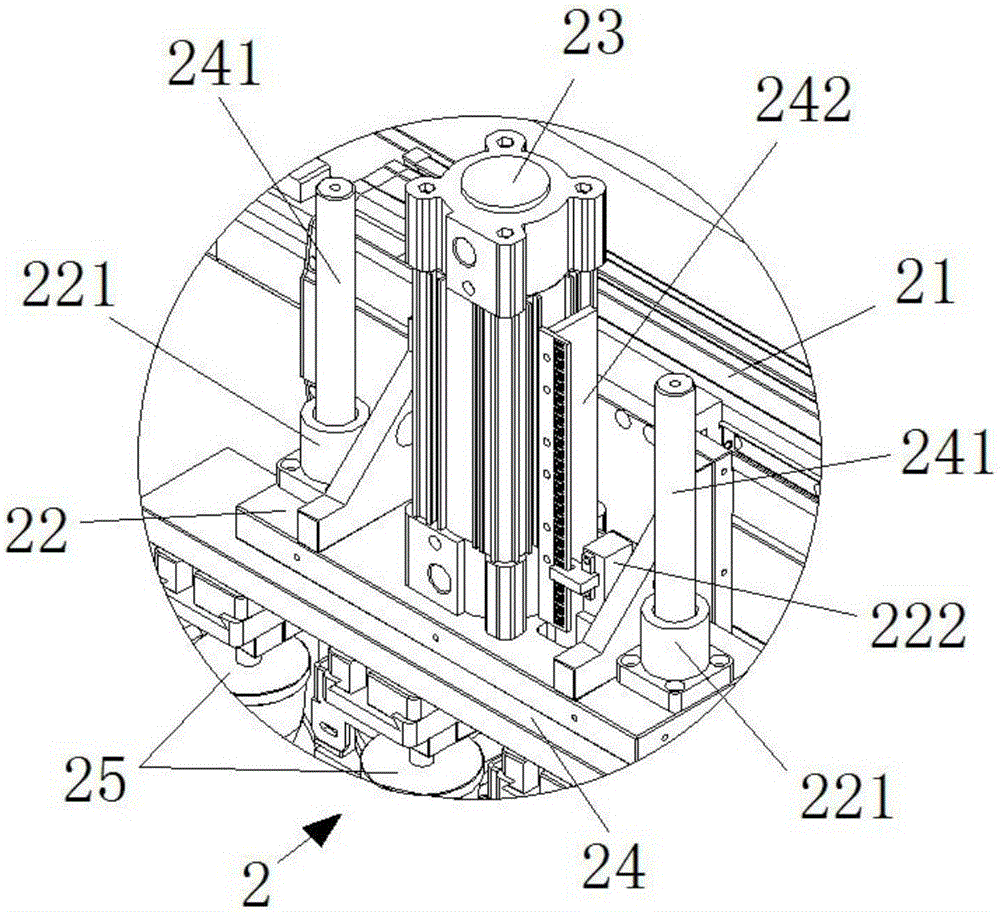

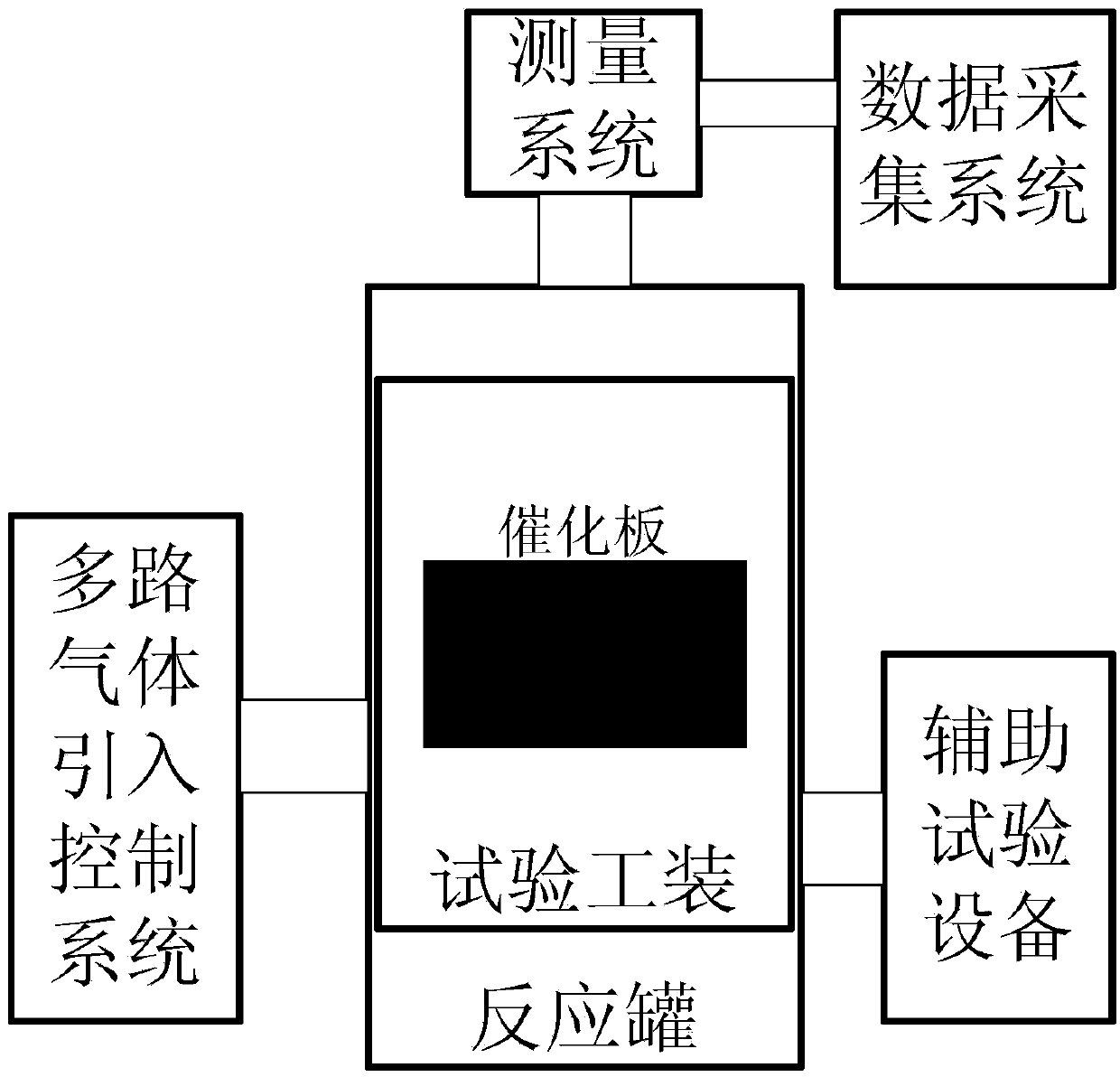

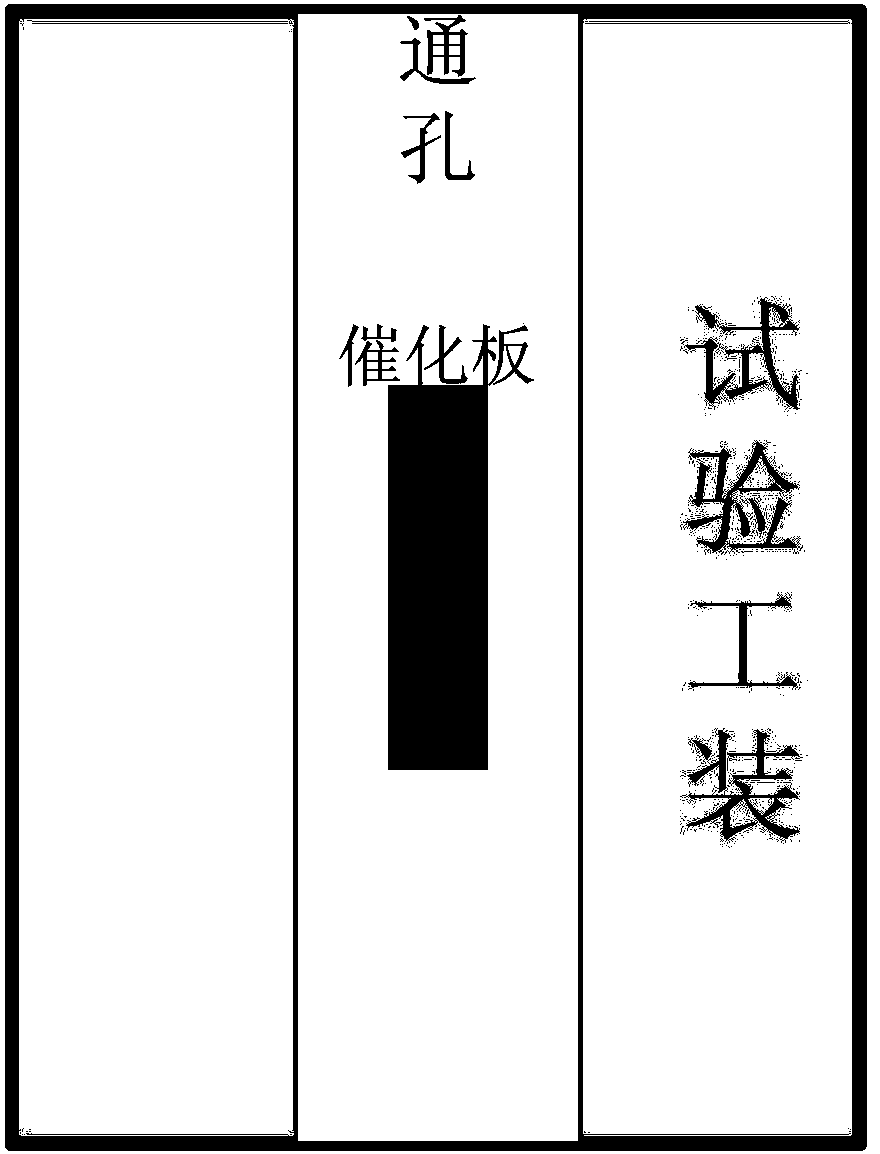

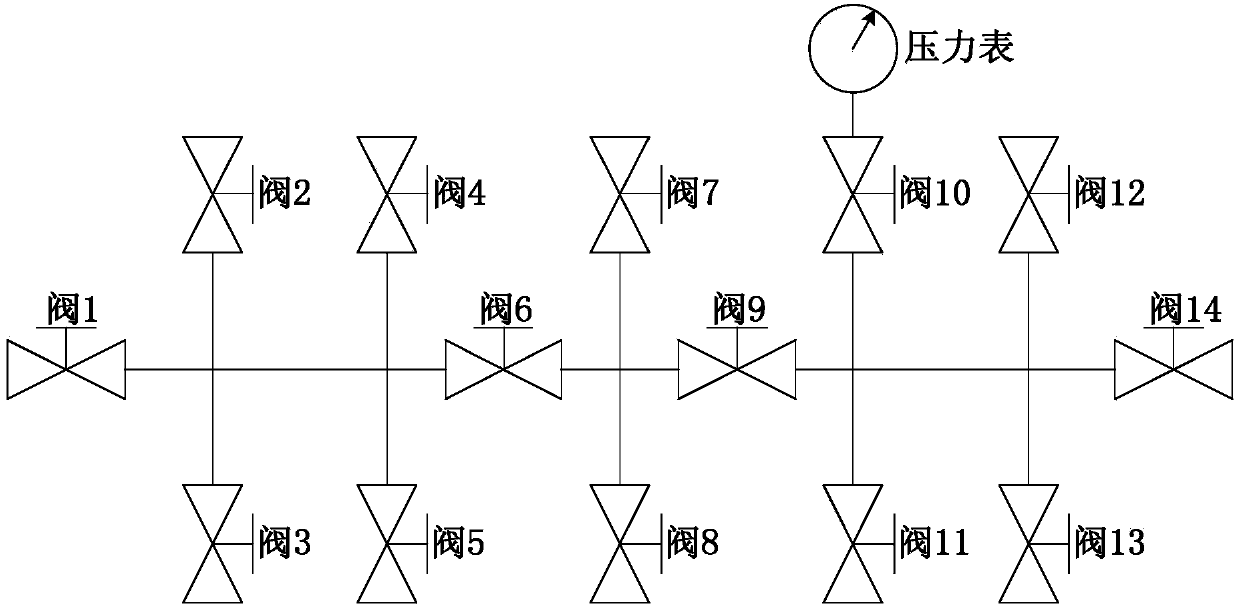

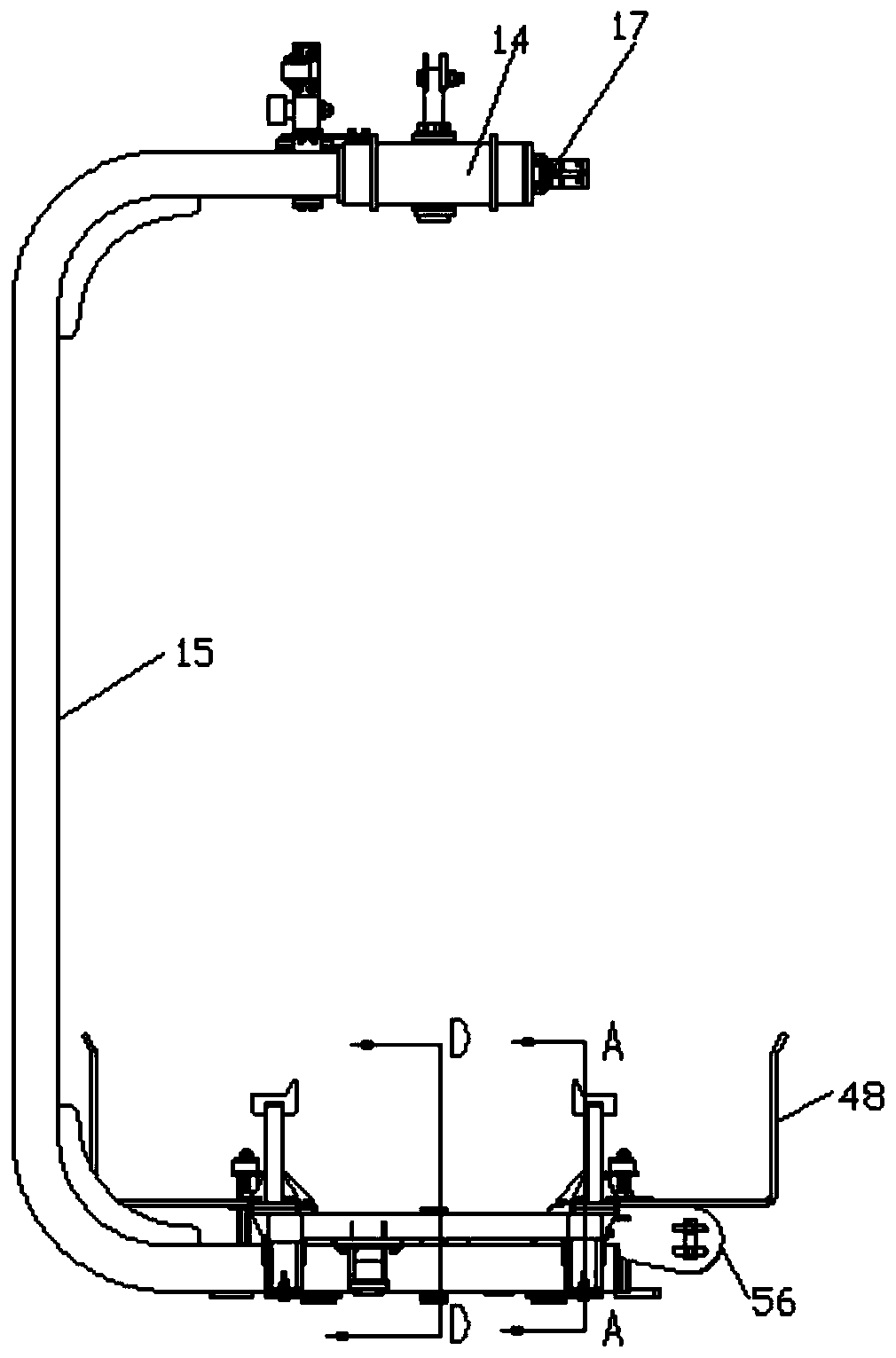

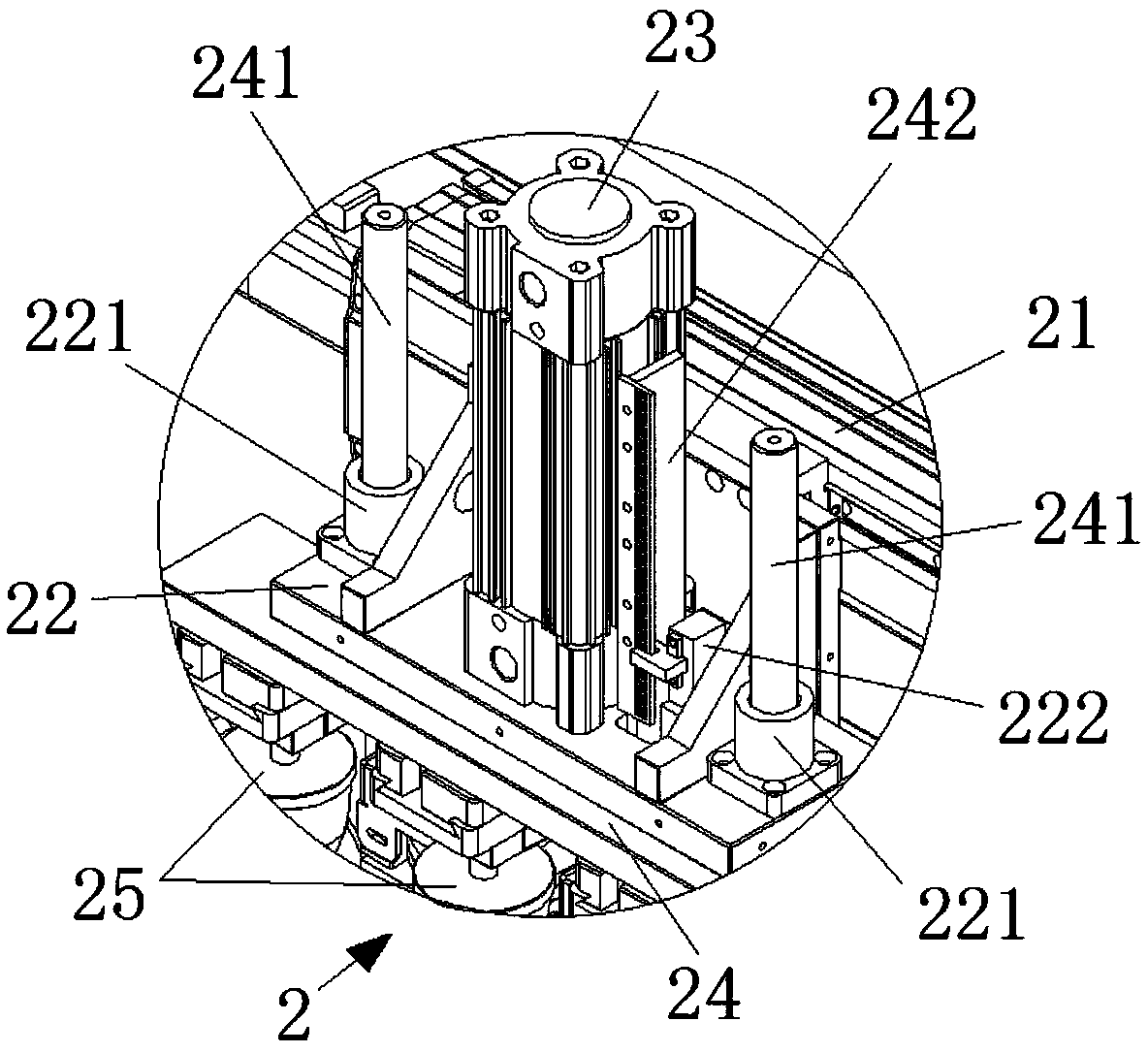

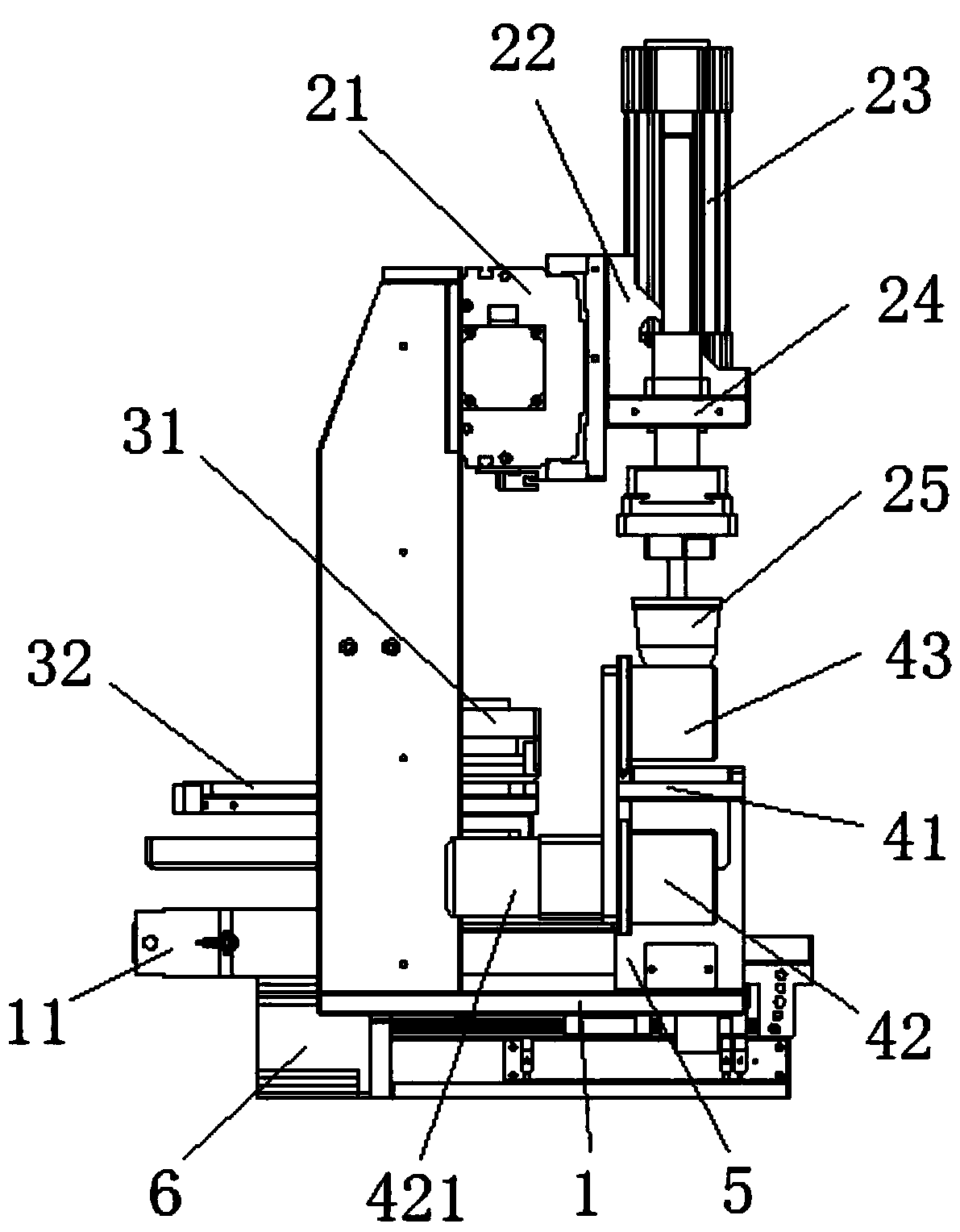

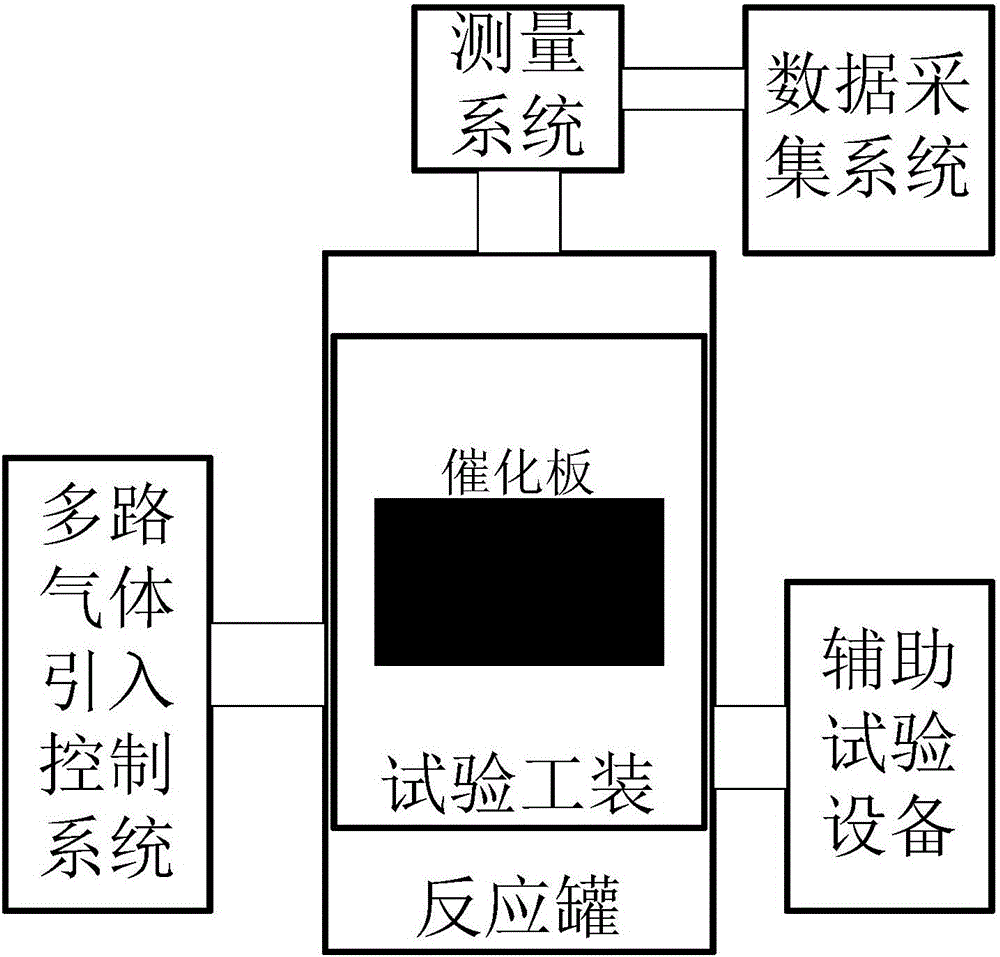

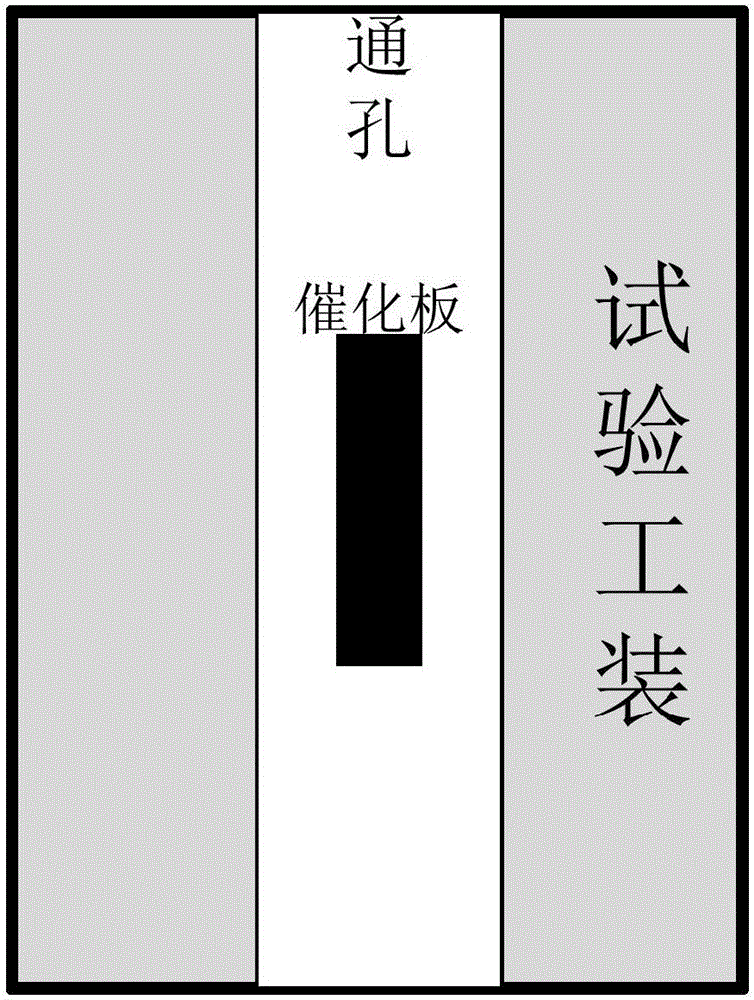

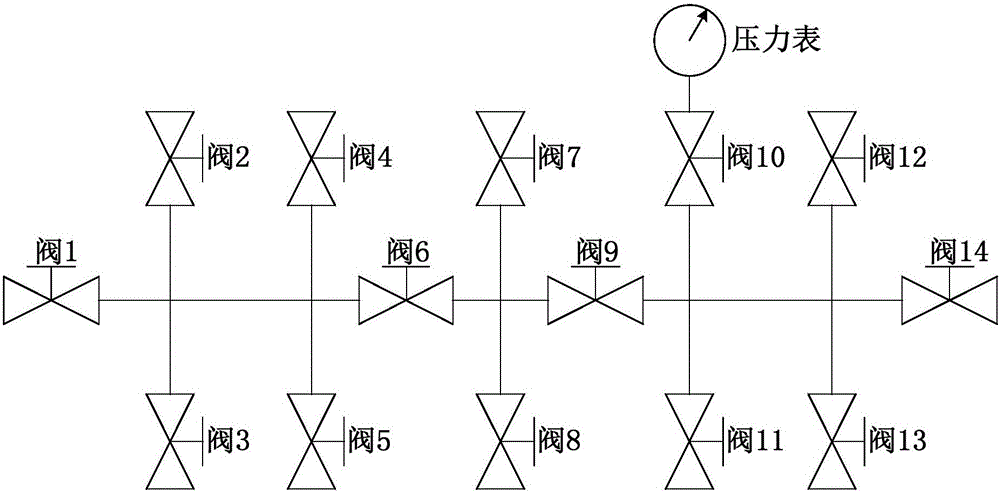

Comprehensive performance testing device for oxyhydrogen composite catalyst and application method thereof

InactiveCN104200856AAdjust environmental parameters at any timeIngenious designNuclear energy generationNuclear monitoringNuclear powerControl system

The invention discloses a comprehensive performance testing device for an oxyhydrogen composite catalyst and an application method thereof. The comprehensive performance testing device comprises a reaction tank, a test tooling, a measuring system, a data acquisition system, a multipath gas introduction control system and auxiliary testing equipment, wherein the test tooling is mounted in the reaction tank and is used for placing a catalytic board; the measuring system is mounted on the reaction tank and is used for detecting the concentration, the temperature, the pressure and other parameters of gas in the reaction tank; the data acquisition system is connected with the measuring system; the multipath gas introduction control system provides exogenous gas required by the test; the auxiliary testing equipment is connected with the reaction tank. According to the comprehensive performance testing device disclosed by the invention, the design is ingenious; the complex environment of a nuclear power station under the working condition of serious accidents is simulated by an oxyhydrogen composite catalytic board through special equipment, so that environment parameters of the catalyst can be adjusted at any time; all required data is accurately detected by the measuring system and various performance tests of the catalyst are realized; the transfer and the assembly of the catalytic board are eliminated, so that great human and material resources are saved; the time and the labor are saved; the comprehensive performance testing device is convenient and safe in use, simple and quick in debugging and comprehensive and sufficient in detection, and has high popularization and application values in the field.

Owner:SICHUAN INST OF MATERIALS & TECH +2

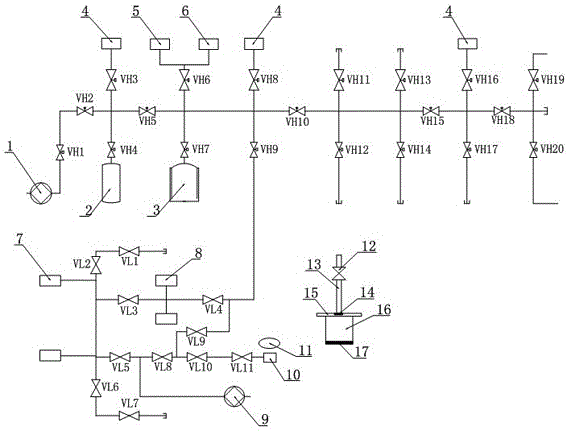

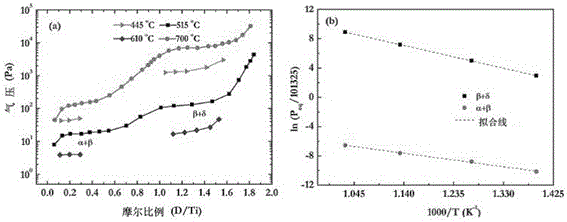

High vacuum-high pressure combined hydrogen storage property testing device for low hydrogen absorption equilibrium pressure material

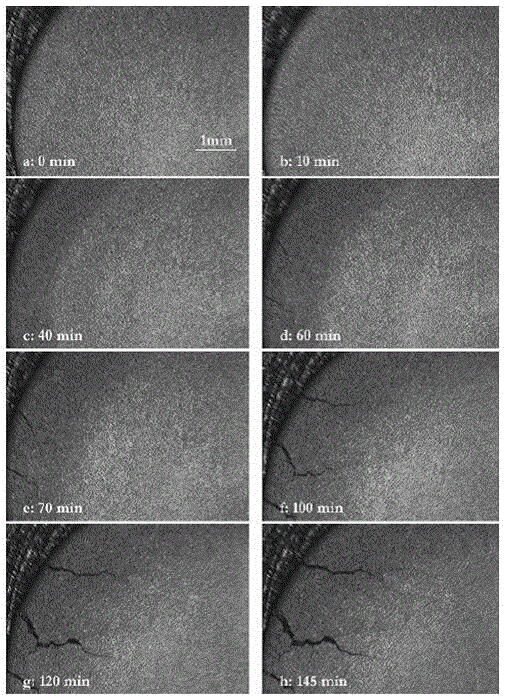

InactiveCN105606767AIngenious designSave manpower and material resourcesMaterial analysisGas solidUltra high pressure

The invention discloses a high vacuum-high pressure combined hydrogen storage property testing device for a low hydrogen absorption equilibrium pressure material. The device comprises a high pressure gas introduction system, a high vacuum gas reaction and hydrogen storage sample real-time observation system, a measurement system, a data acquisition system and an auxiliary testing device. The device disclosed by the invention has the advantages that the design is smart; the device can be used for acquiring kinetic data and thermodynamic data of a gas-solid reaction of a hydrogen storage material, especially the low hydrogen absorption equilibrium pressure material, in hydrogen absorption and desorption processes, and further observing the change of the sample surface appearance in situ in the reaction process at the same time, therefore the hydrogen storage properties of these materials are overall obtained, and the research demands on the fields of fusion energy and hydrogen energy are met.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

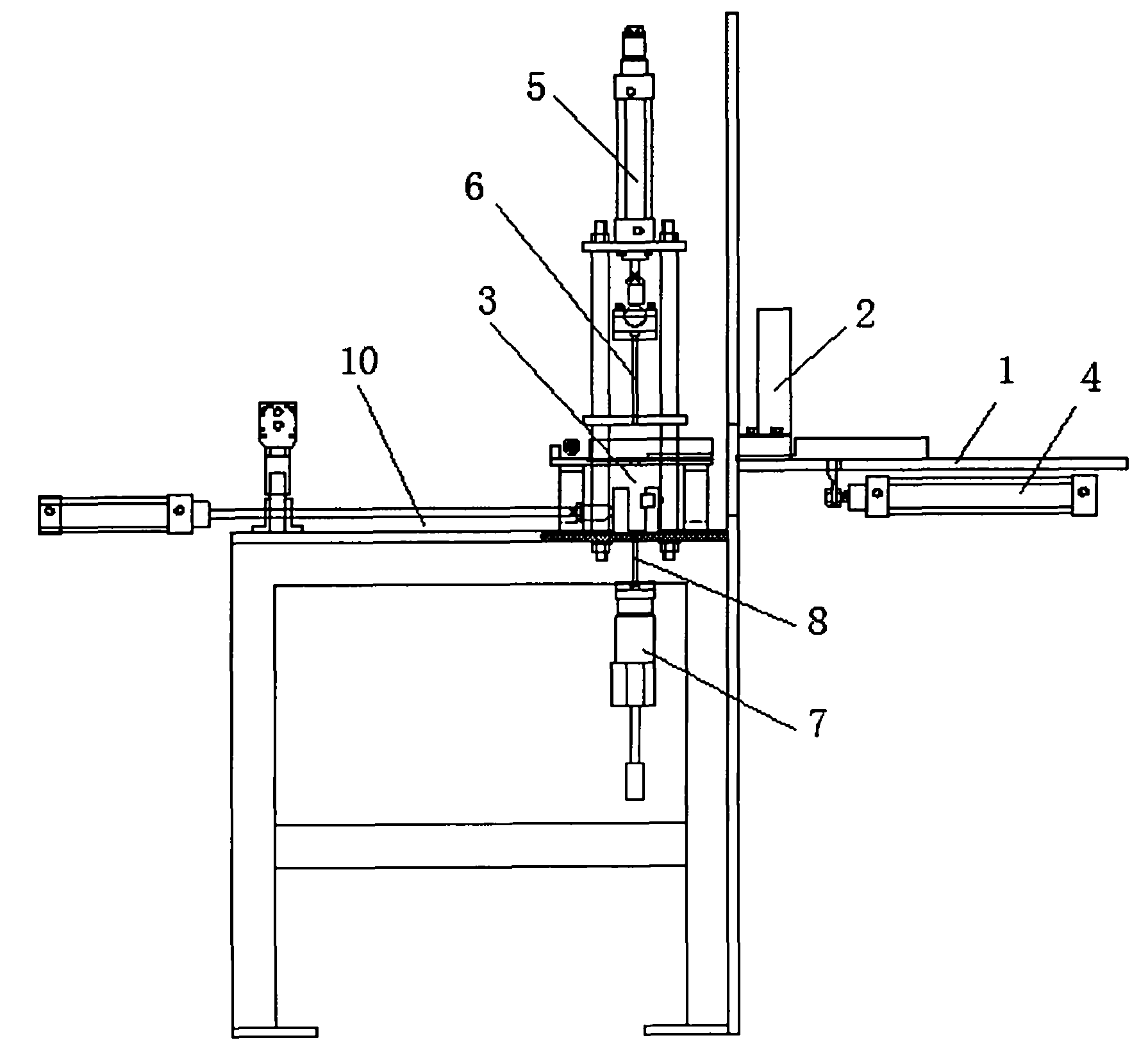

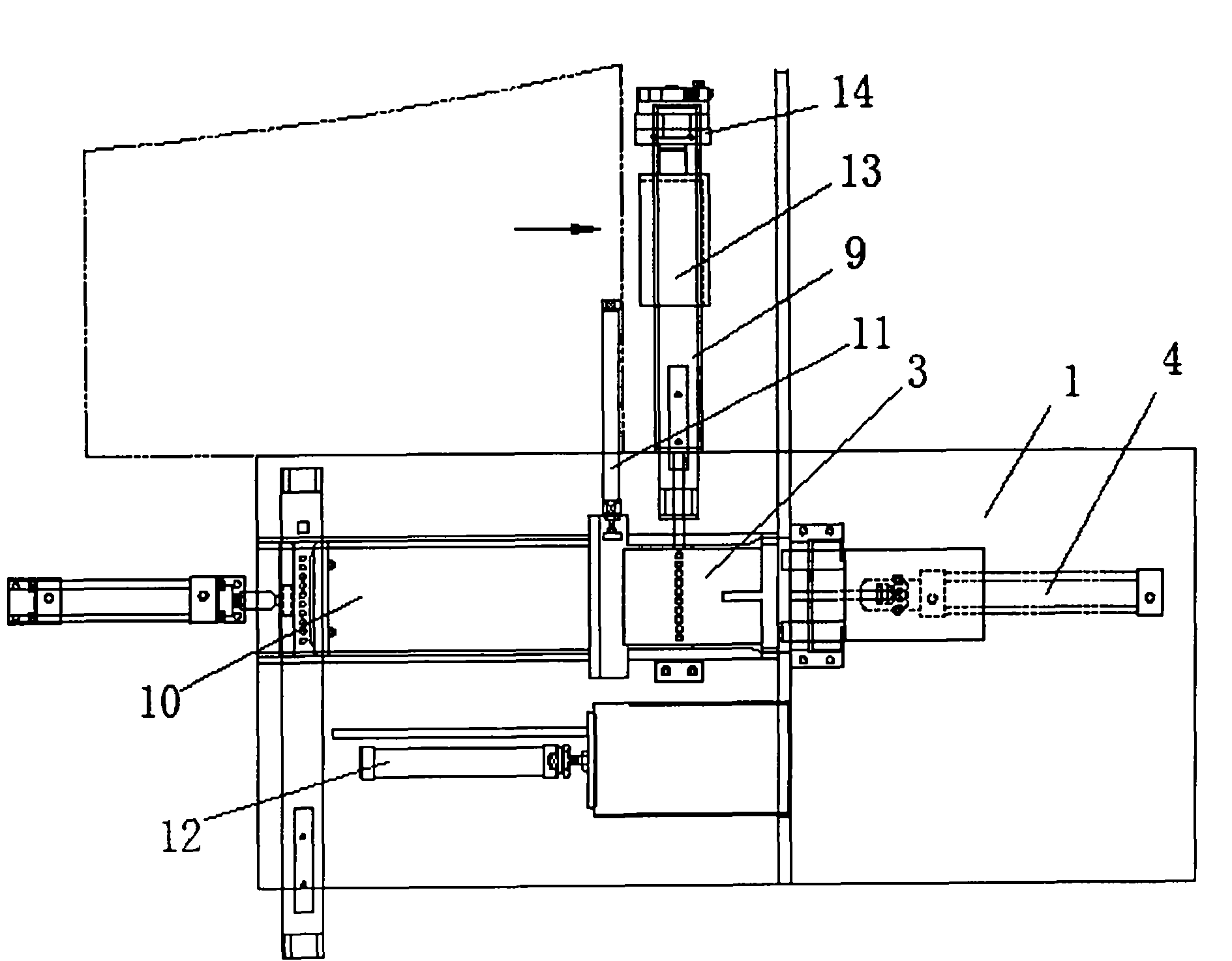

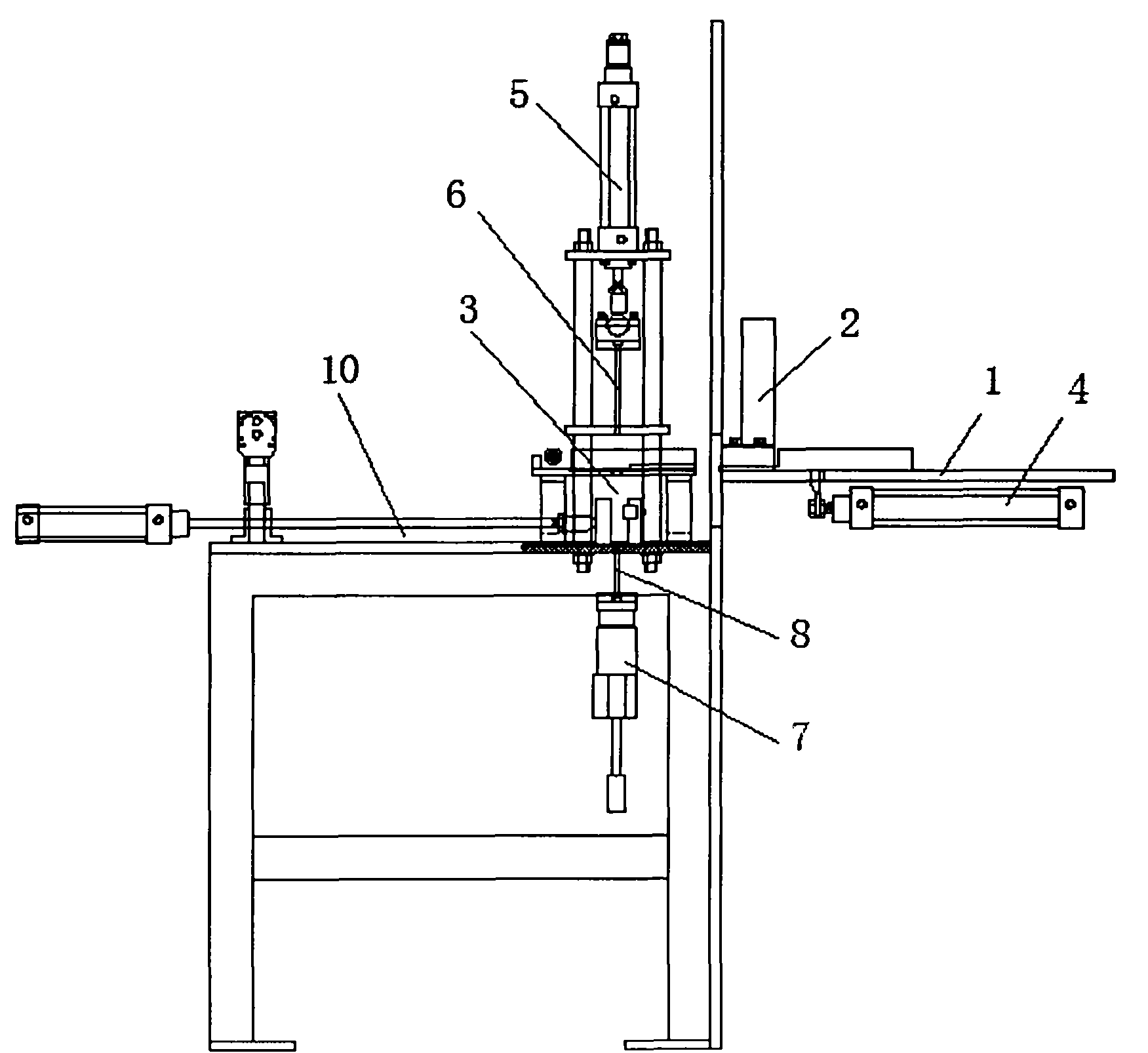

Automatic lead removing press

The invention discloses an automatic lead removing press, and relates to a detonator lead delay body assembly device. In order to solve the problems that the efficiency of manually assembling and pressing a delay body is low and the safety cannot be guaranteed, the invention provides the automatic lead removing press capable of effectively realizing safe operation of human-machine separation and greatly improving the production efficiency. In odor to achieve the purposes, the invention adopts the technical scheme that: the automatic lead removing press comprises a lead core die delivery cylinder for pushing a lead core connecting die on an outer mesa into a pressing station; a lead pressing punch strip controlled by a lead pressing cylinder is arranged above the pressing station, and a pipe jacking punch strip controlled by a pipe jacking cylinder is arranged below the pressing station, wherein the lead pressing punch strip and the pipe jacking punch strip can move up and down; and the lateral surface of the pressing station is provided with a die delivery cylinder for delivering a detonator die into the pressing station. The automatic lead removing press is mainly applied to automatic assembly of the detonator lead delay body.

Owner:YAHUA GROUP MIANYANG INDAL

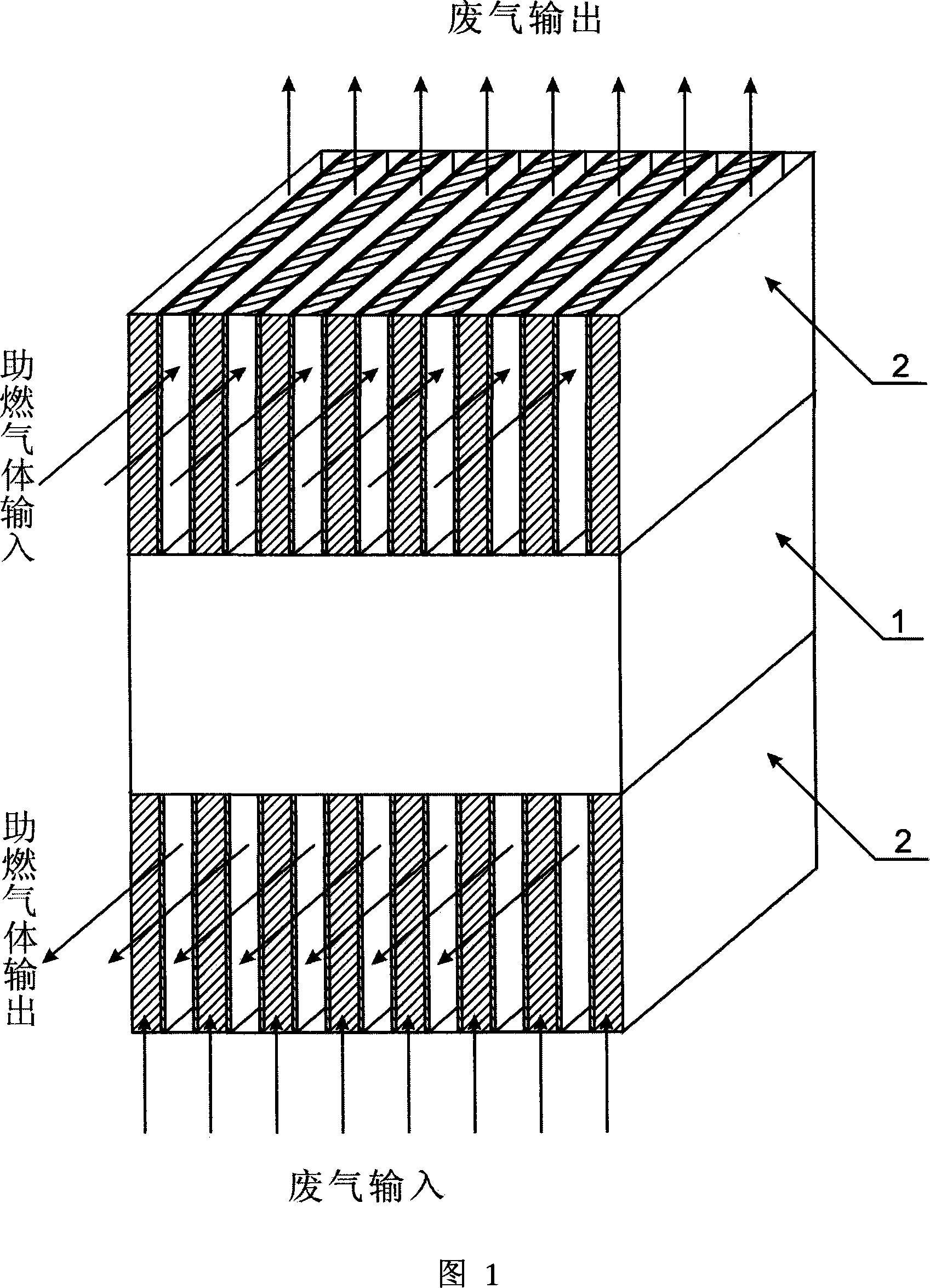

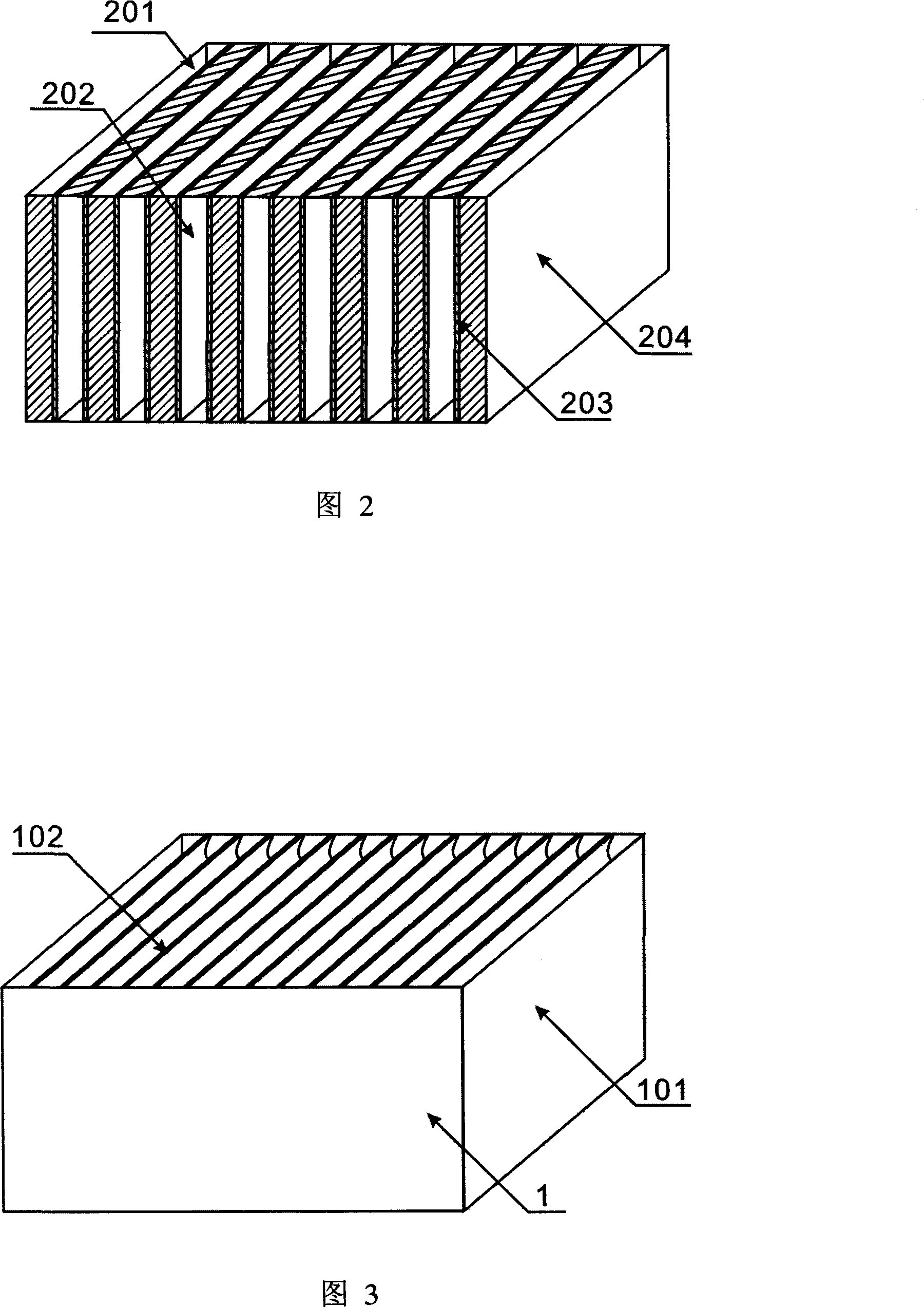

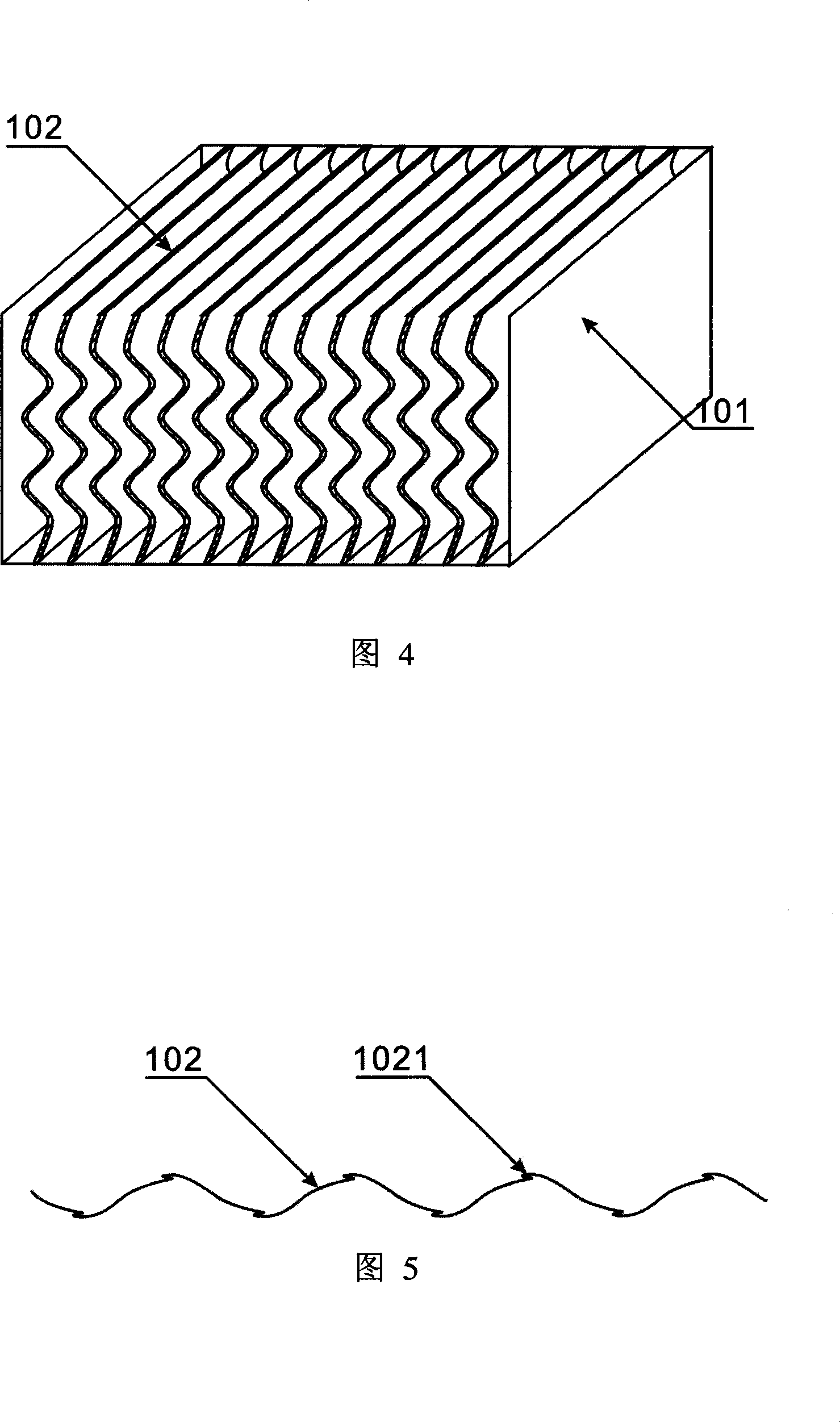

Discharge gas and waste heat recovery heat converter

ActiveCN101216266AShort construction periodIncrease profitStationary plate conduit assembliesCombustionExhaust fumes

The invention discloses a heat exchanger for recovering exhaust gas and waste heat, which comprises a heat exchanger and a fluid diverter. The heat exchanger comprises a case body and corrugated heat exchange plates. The case body has a cuboid structure with opened up and down end surfaces; the corrugated heat exchange plates are laminated together and fixed inside the case body; and a gas passage is provided between adjacent corrugated heat exchange plates, and the inlet and outlet of the gas passage are provided on one of the opened end surfaces. The fluid diverter comprises a case body and passage partitioning plates; the partitioning plates are parallelly disposed and fixed inside the case body of the fluid diverter to divide the space of case body into an exhaust gas passage and a combustion supporting gas passage; the fluid diverter is installed at the inlet and outlet of the heat exchanger; and the exhaust gas passage and the combustion supporting gas passage are separated from each other. The inventive heat exchanger can recover exhaust gas and waste heat on site; and has the advantages of small volume, light weight, simple structure, remarkably improved unit volume heat exchange efficiency, good reliability, saved energy consumption and environmental friendliness.

Owner:刘启端

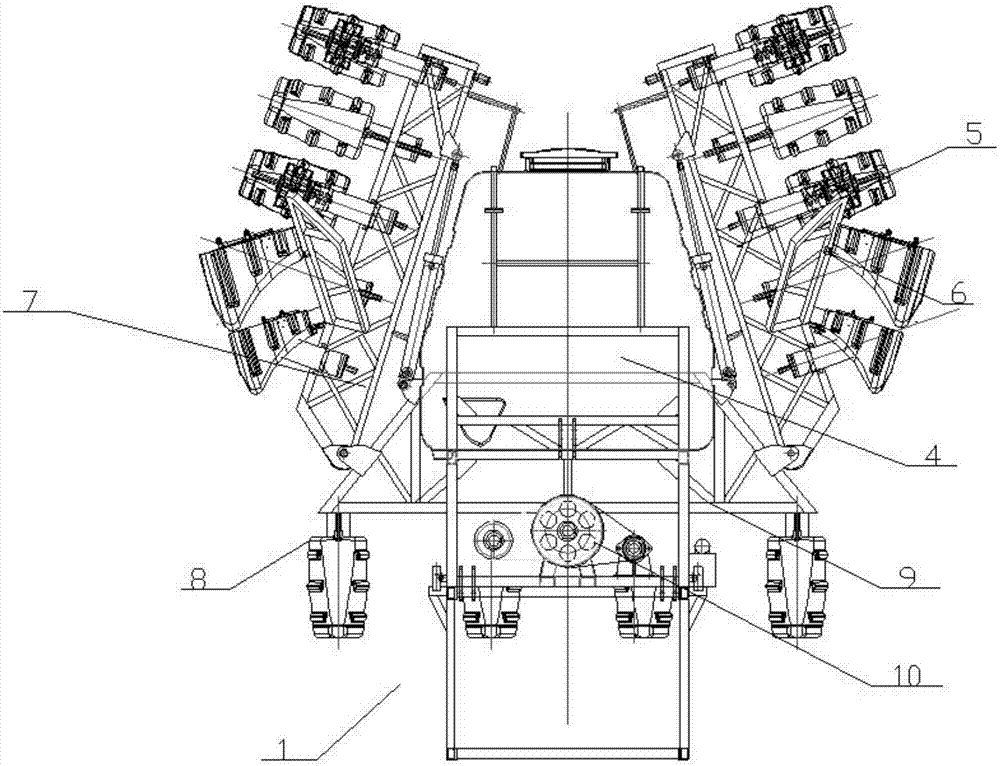

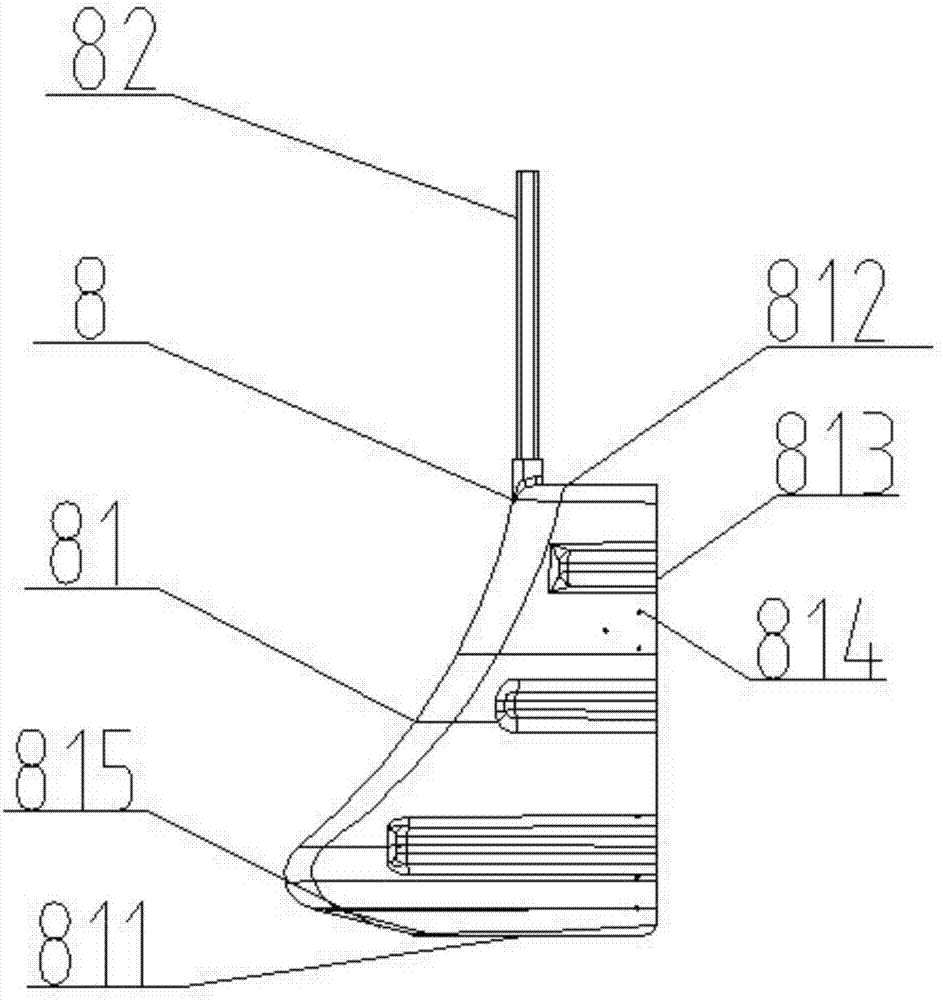

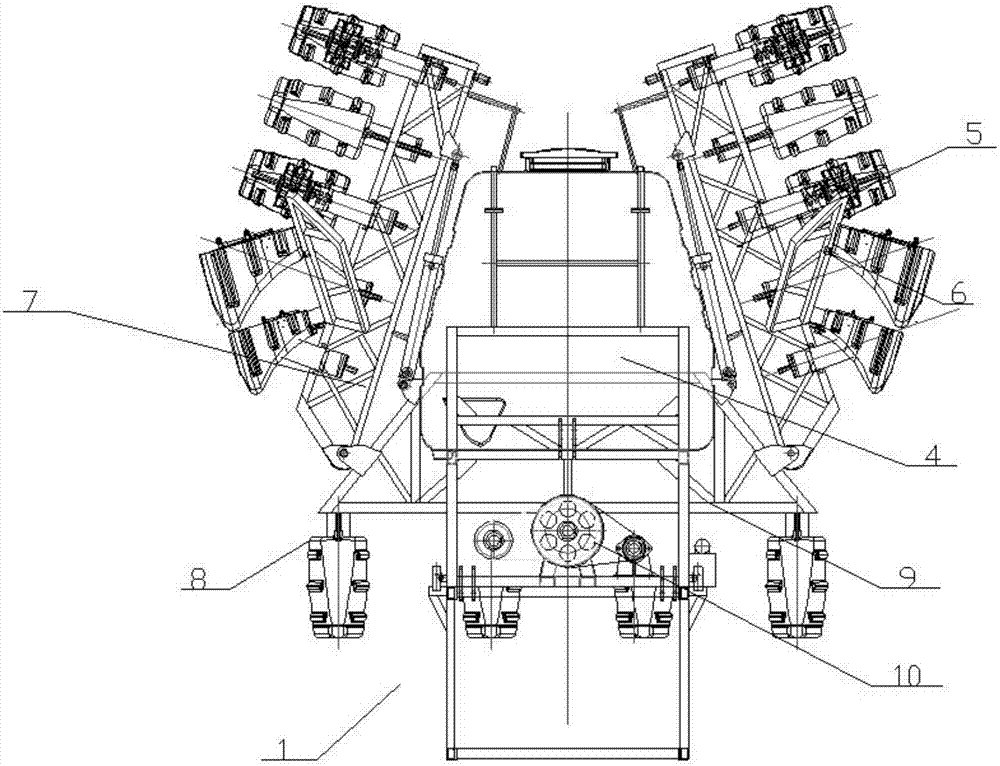

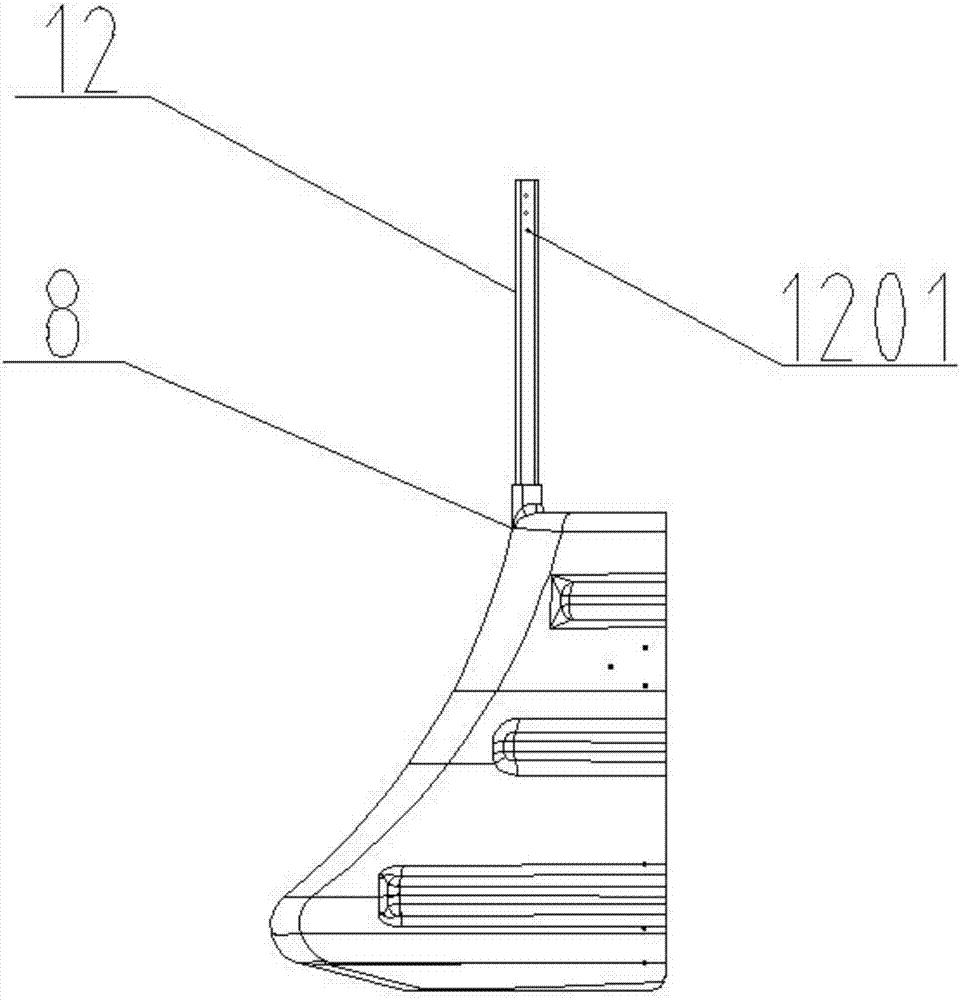

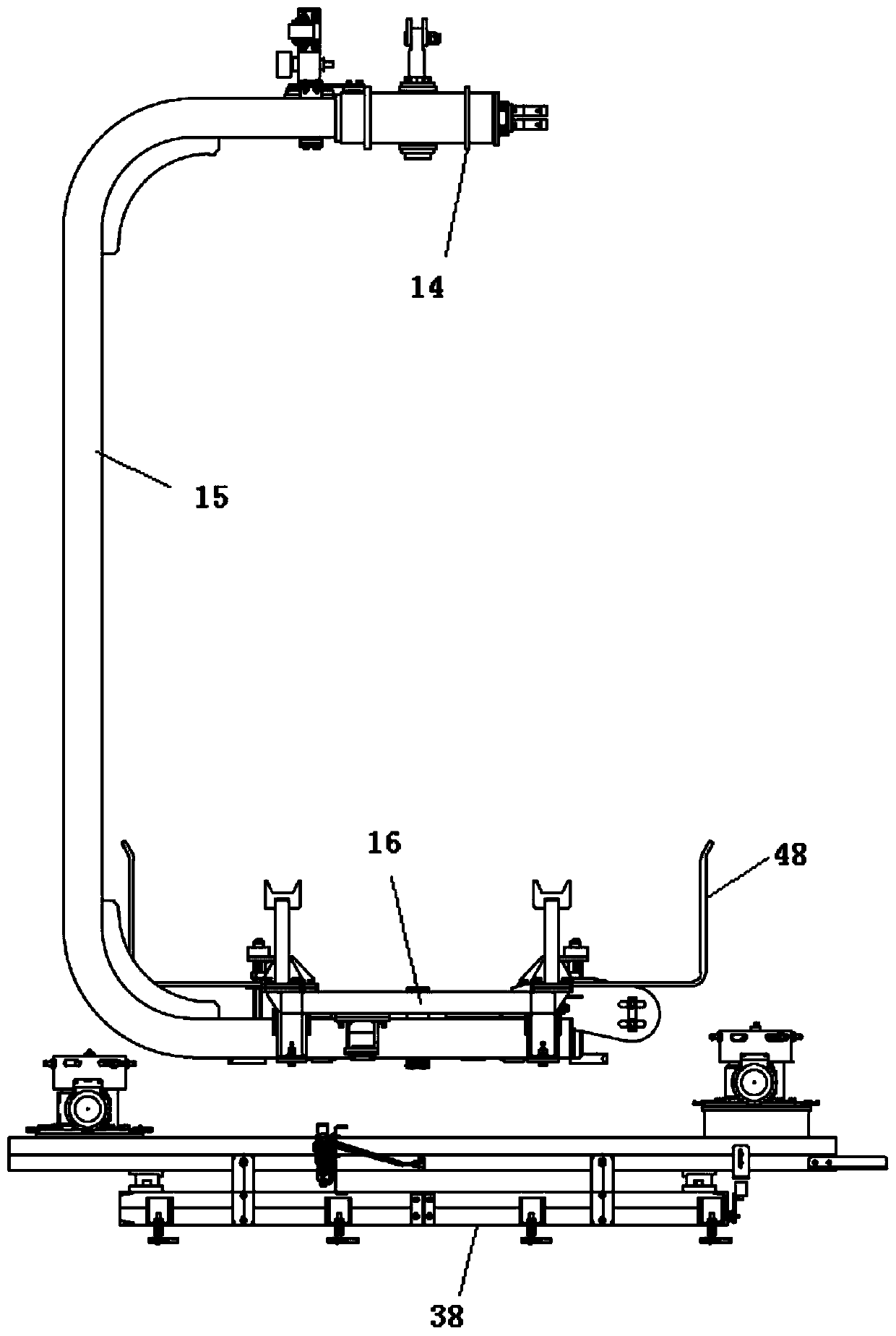

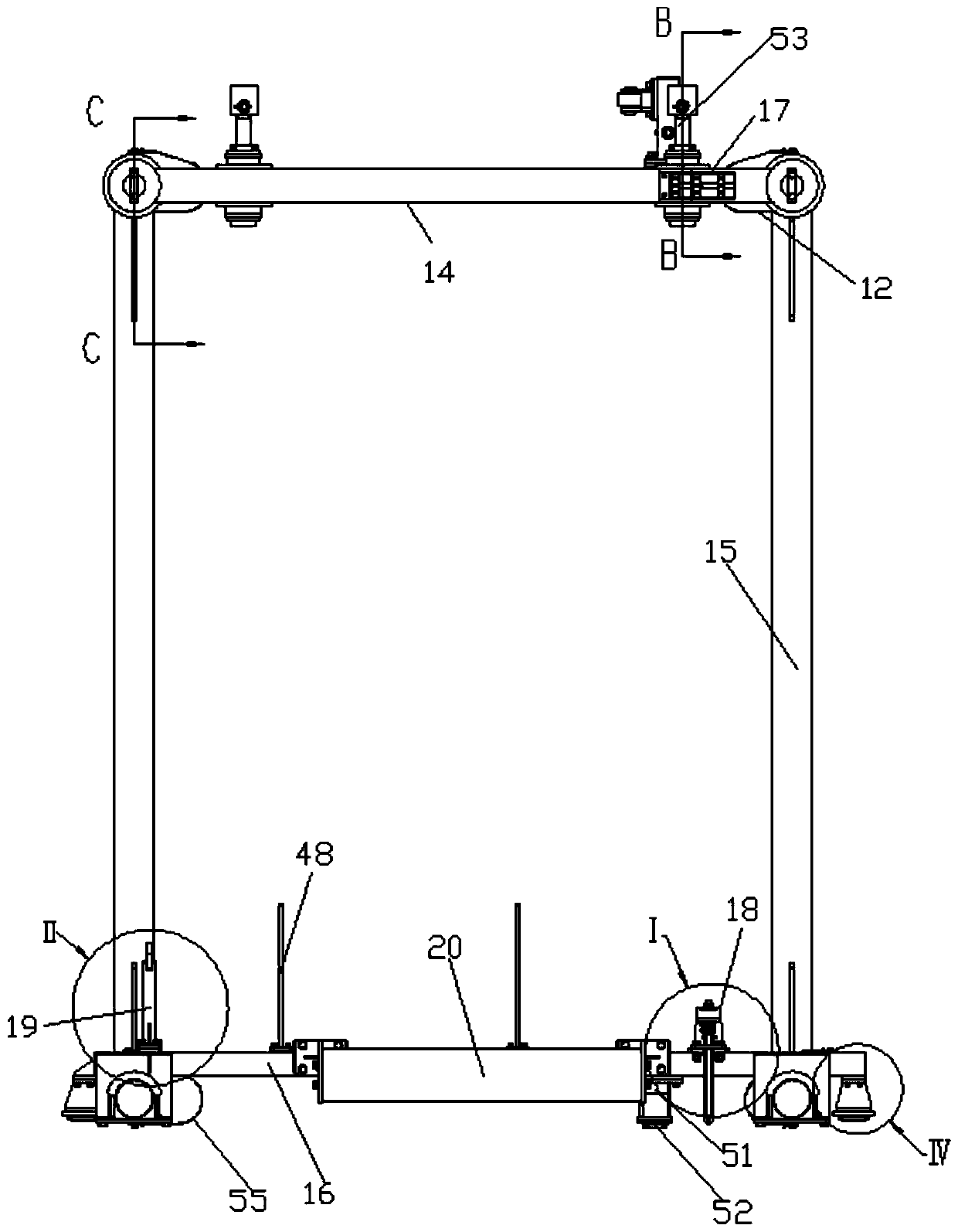

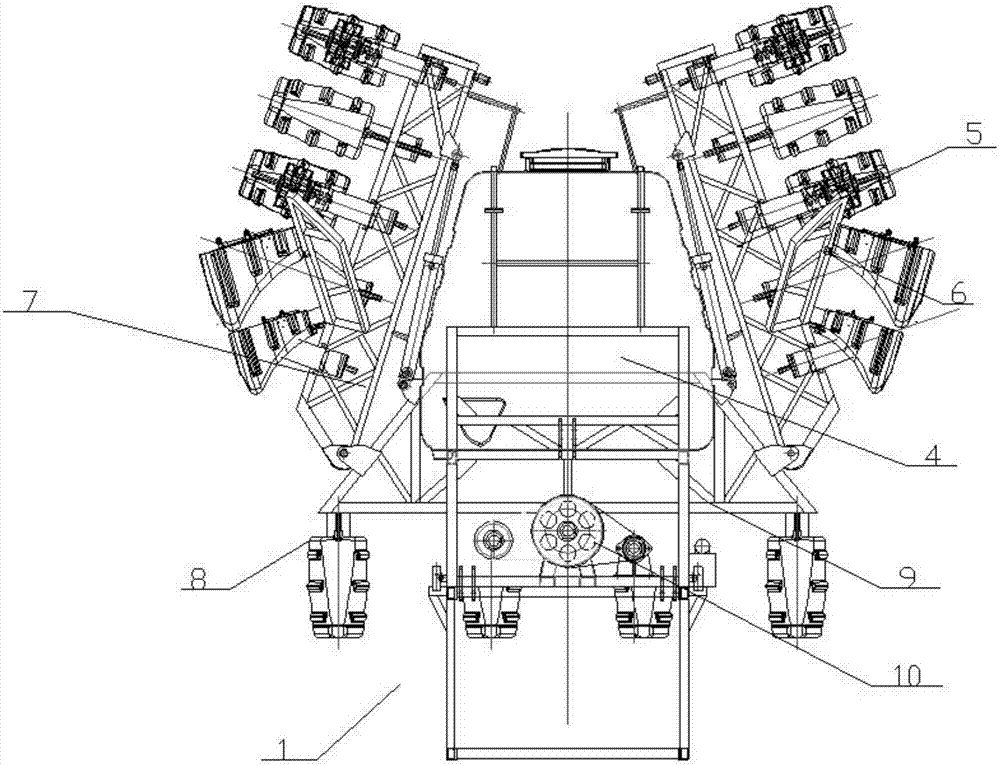

Branch device and pesticide application machine special for cotton applying same

PendingCN107347854AAffect efficiencyAffect qualityInsect catchers and killersVertical edgeEngineering

The invention provides a branch device and a pesticide application machine special for cotton applying the same. The branch device comprises a boot-shaped guiding assembly and a connecting rod connected with the guiding assembly. The connecting rod is connected to the upper portion face of the guiding assembly. The connecting rod is vertically arranged. The cross section of the guiding assembly is in a V shape with the circular arc transition tip, an upward bent arc is arranged on the bottom face, close to one side of the V-shaped arc end, of the guiding assembly, the edge of the side, close to the V-shaped opening in the circular arc transition, of the guiding assembly is a vertical edge, the branch device is fixedly arranged on one side of a spraying device, and the spraying device is fixedly connected with the branch device through a through hole. The branch device is easy to install, convenient to use, capable of achieving pesticide application to cotton seedlings of different stages at the same time, capable of sensitively changing the length and height of a spraying cantilever, capable of rapidly adapting to different pesticide application areas, easy and rapid to adjust and operate, capable of achieving efficient branching, large in pesticide application area, low in cost and high in efficiency.

Owner:NANTONG HUANGHAI CHEM MACHINERY

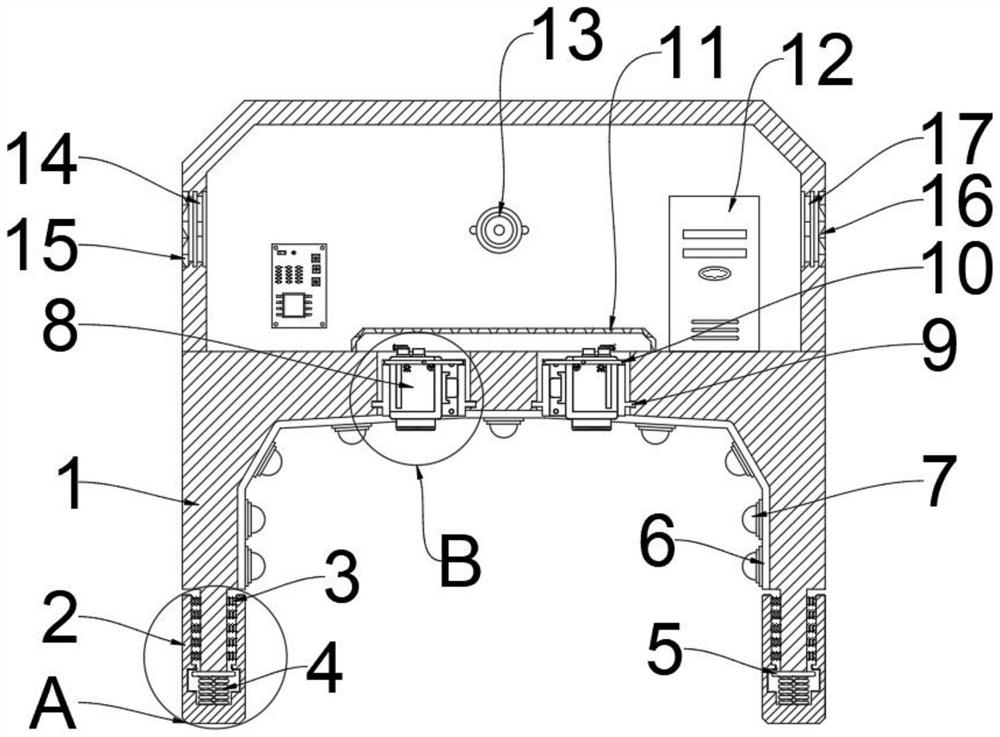

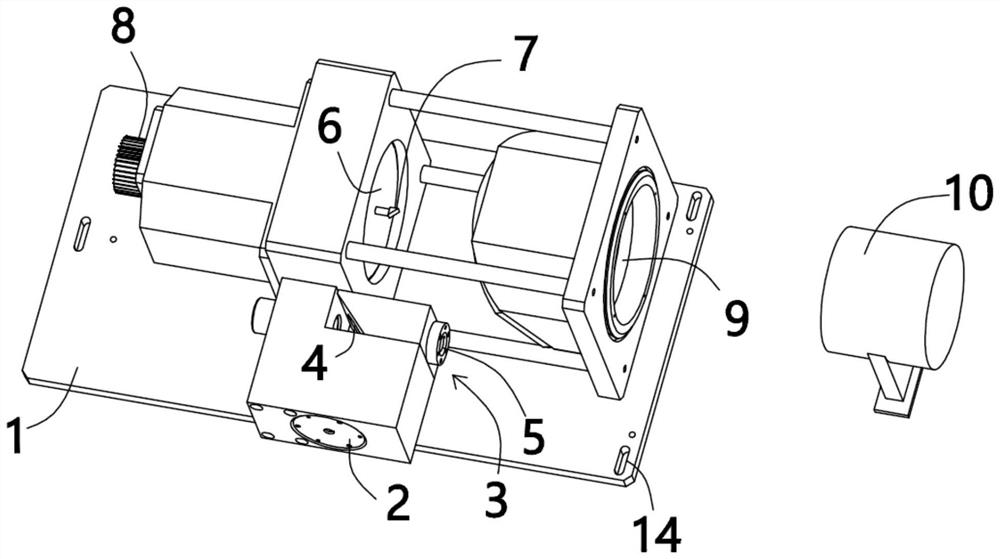

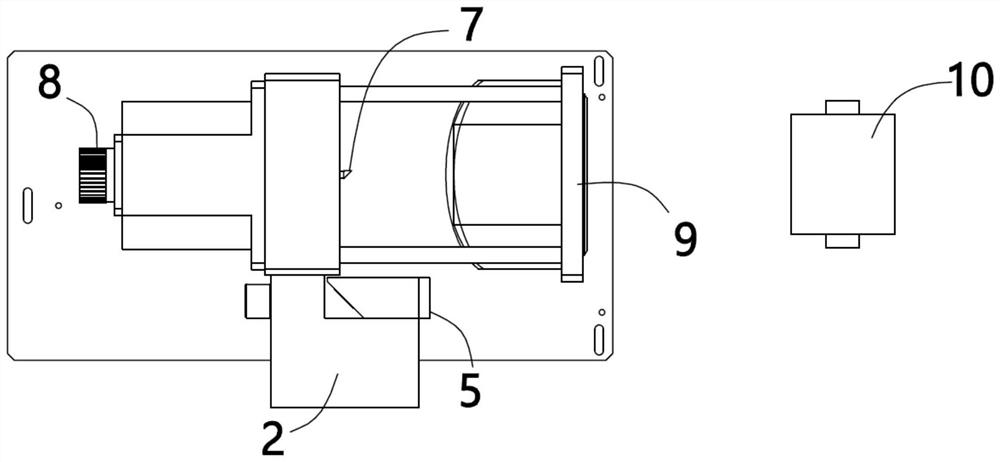

Embedded high-speed online machine vision detection method and device

InactiveCN111957584AReduce longitudinal vibrationAvoid image blurDispersed particle filtrationSortingMachine visionEngineering

The invention discloses an embedded high-speed online machine vision detection method and device, and relates to the technical field of vision detection, in order to solve the problem that the existing embedded high-speed online machine vision detection device has weak shock resistance capability, is easily subjected to vibration to make the internal precision parts damaged to affect its use, willresult in blurred imaging caused by vibration to affect the precision of the device detection, and will be easily affected by the unstable light from the outside, causing the device to have the problem of false detection. A support bracket is installed under a main body bracket, an anti-dropping chuck is installed at the lower end of the main body bracket, the anti-dropping chuck is welded and connected to the main body bracket, a bottom shock-absorbing spring is installed at the lower end of the support bracket, the bottom shock-absorbing spring is welded to the support bracket and the anti-dropping chuck, both sides in the support bracket are installed with lateral damping springs, and the lateral damping springs are welded and connected to the support bracket and the main body bracket.

Owner:杭州蒲丰视觉检测科技有限公司

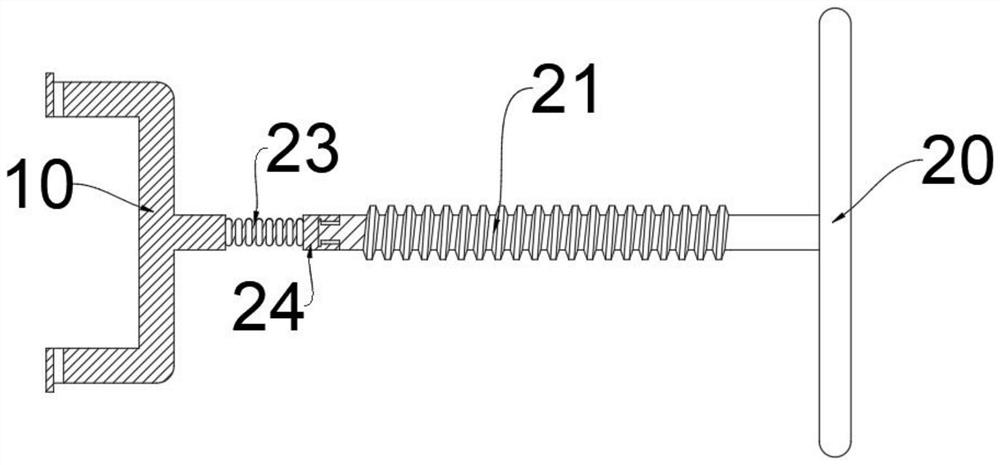

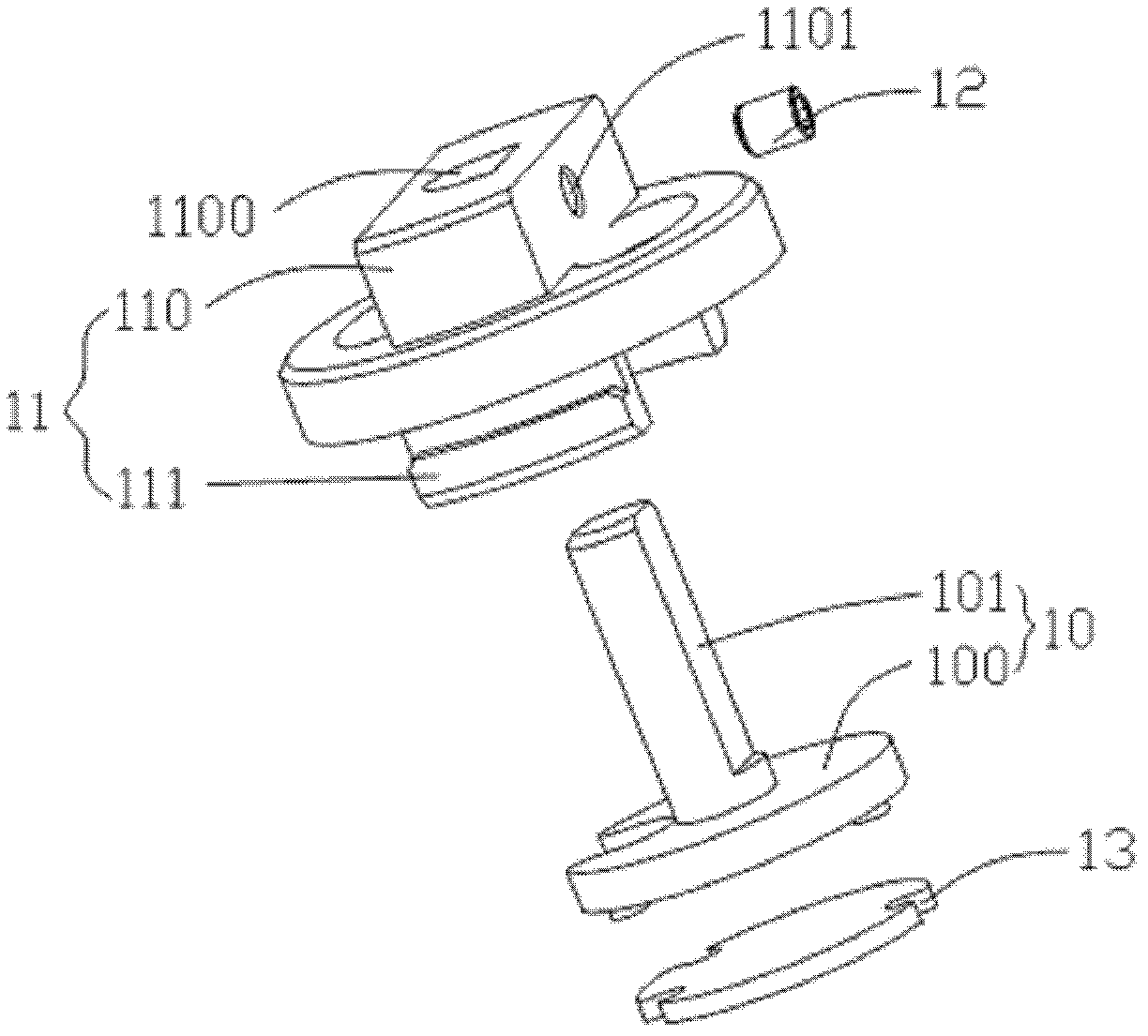

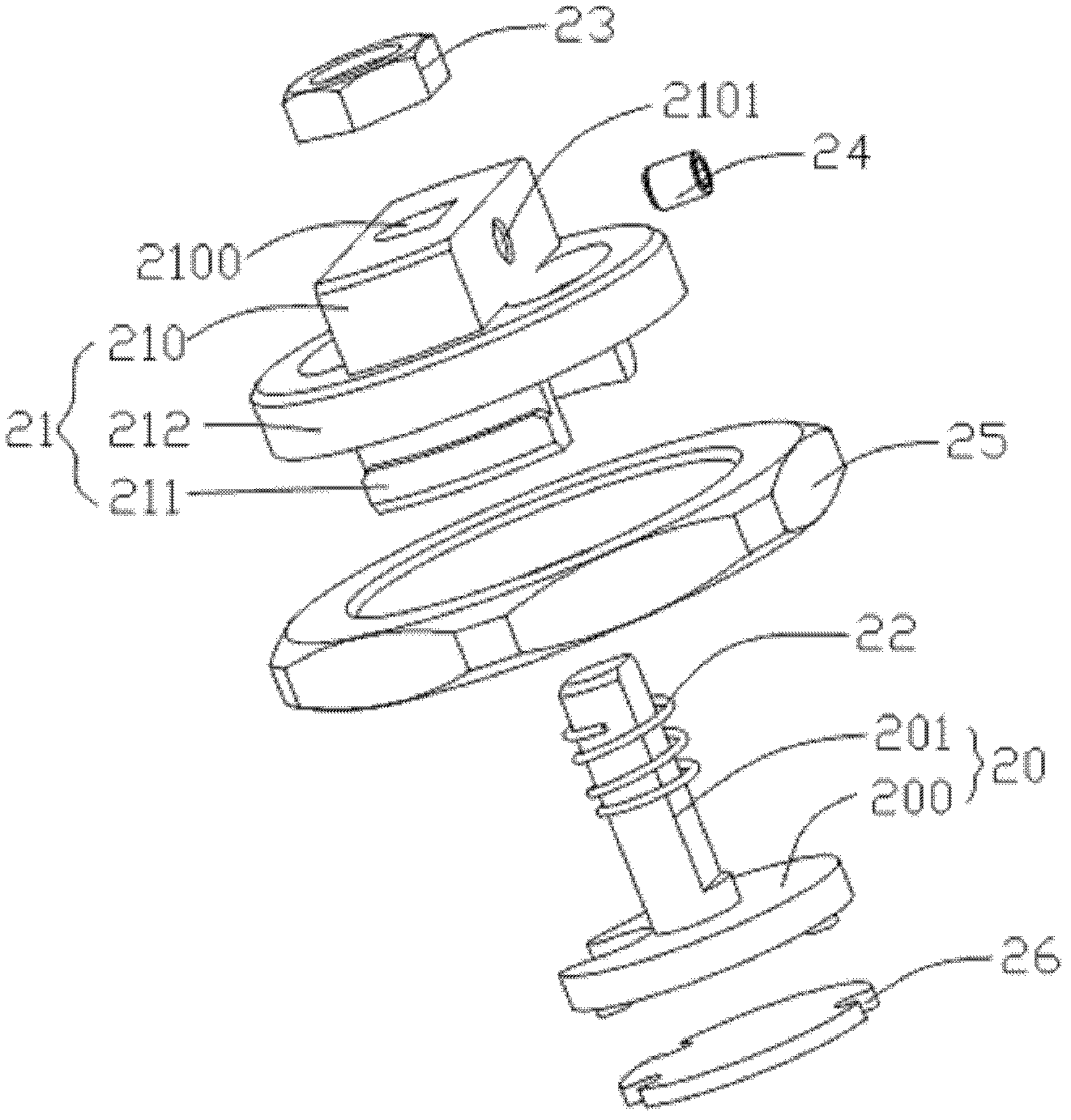

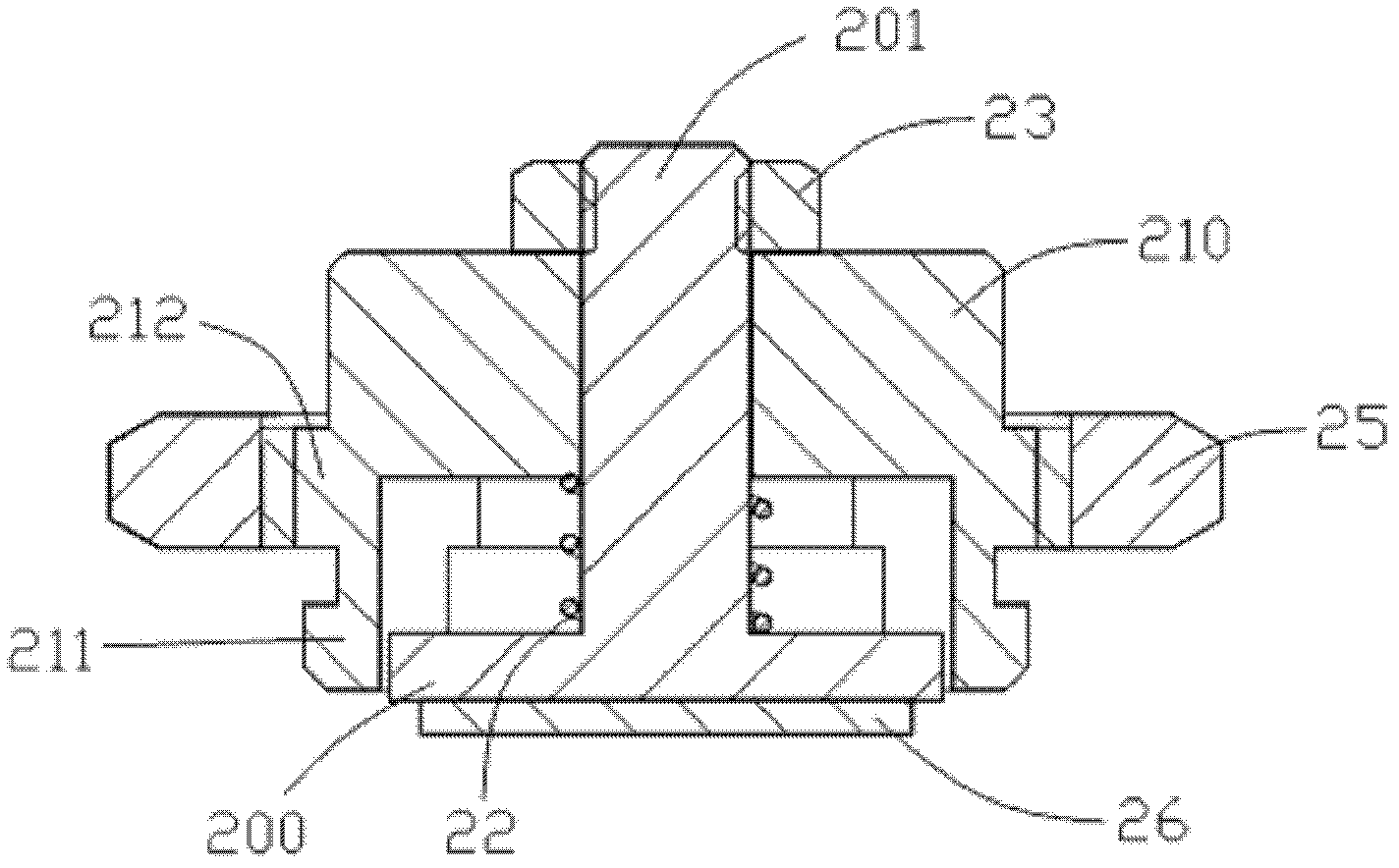

Quick-change lock and agent applying machine specially for cotton by means of quick-change lock

ActiveCN107318818AIncrease rebound strengthEasy to fixInsect catchers and killersEngineeringCantilever

The invention provides a quick-change lock and an agent applying machine specially for cotton by means of the quick-change lock. The quick-change lock comprises a connecting base, a movable pin, an elastic part and a tube sleeve; the connecting base is fixedly connected with the tube sleeve, the elastic part is arranged in the tube sleeve, and the movable pin penetrates the tube sleeve in the axial direction and extends into the connecting base; the end, away from the connecting base, of the elastic part is fixedly connected with the tube sleeve, and the end, close to the connecting base, of the elastic part is fixedly connected with the movable pin; the movable pin can move in the axial direction in the tube sleeve, and a spraying device is fixedly connected to the lower portion of a spraying cantilever through the quick-change lock; a connecting column is arranged on a branch device, the cross section of the connecting column is in the same shape and size as a running hole in the connecting base, multiple through holes are formed in the upper end of the connecting column, and the diameters of the through holes are equal to the diameter of the movable pin. The quick-change lock and the agent applying machine specially for the cotton by means of the quick-change lock have the advantages that installation is easy, operation is convenient, a spraying mechanism can be quickly changed, adjusting operation is easy and fast, the agent applying area is broad, the cost is low and the efficiency is high.

Owner:NANTONG HUANGHAI CHEM MACHINERY

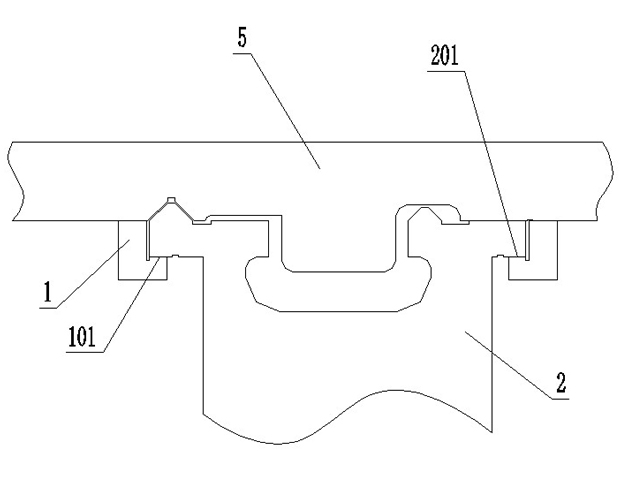

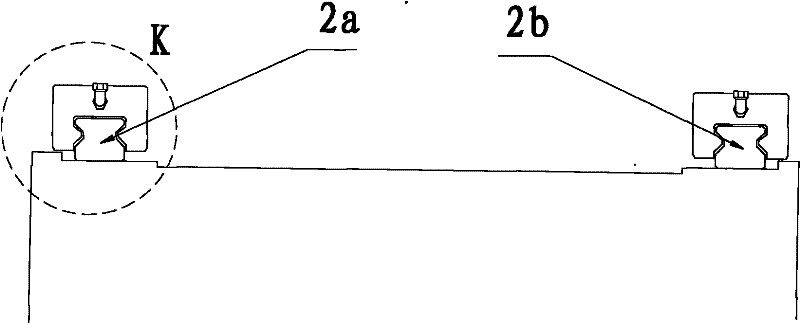

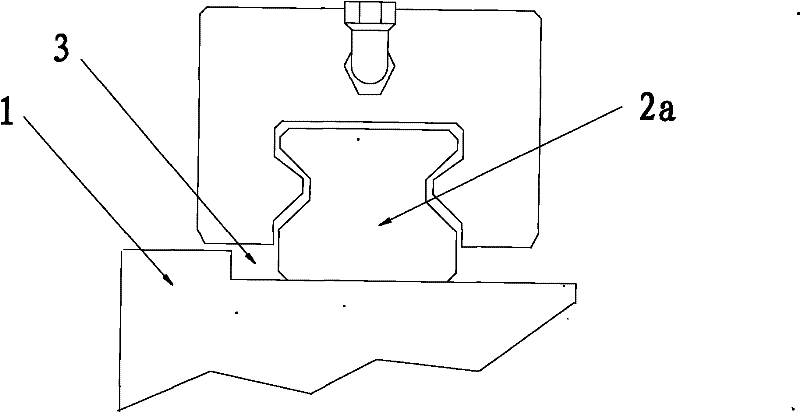

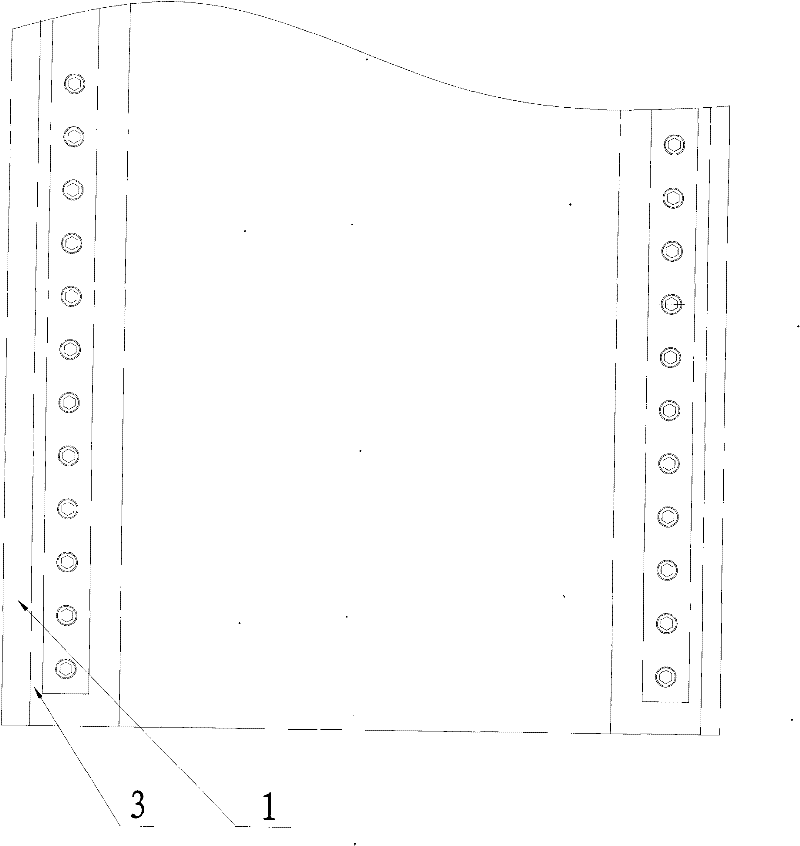

Lower press plate used by flat bed guide rail of machine tool

InactiveCN102069390AExtended service lifeEasy and fast commissioningLarge fixed membersEngineeringCam

The invention relates to a lower press plate used by a machine tool bed in a mechanical manufacturing device, and in particular relates to a lower press plate used by a flat bed guide rail of a machine tool, comprising a press plate seat and a press plate surface which is arranged on the press plate seat and matched with a downslide surface of the machine tool bed, wherein an oblique cam is arranged on the press plate surface, and the oblique cam is connected to the press plate seat by stud adjusting bolts passing through the press plate seat. The lower press plate provided by the invention has the following advantages: the service life is prolonged, the disabled machine tool can be adjusted to the delivery precision simply and rapidly, and the cost is reduced.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

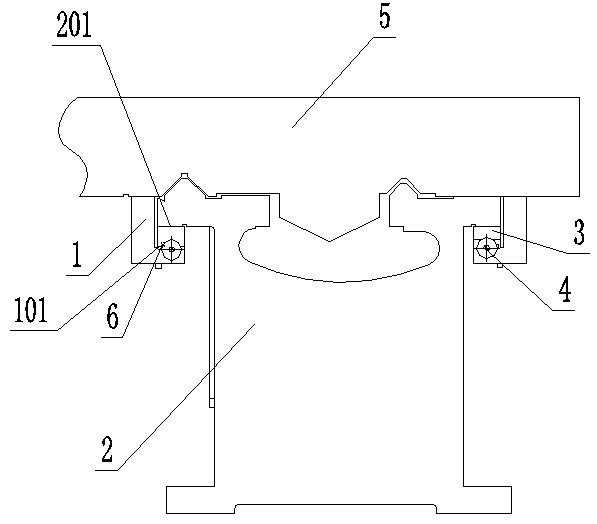

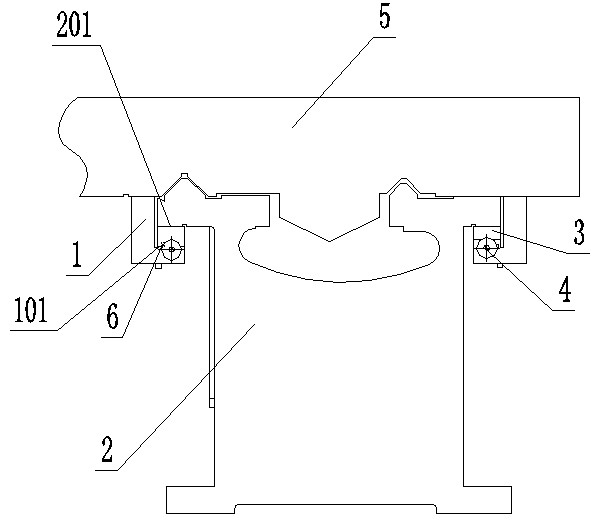

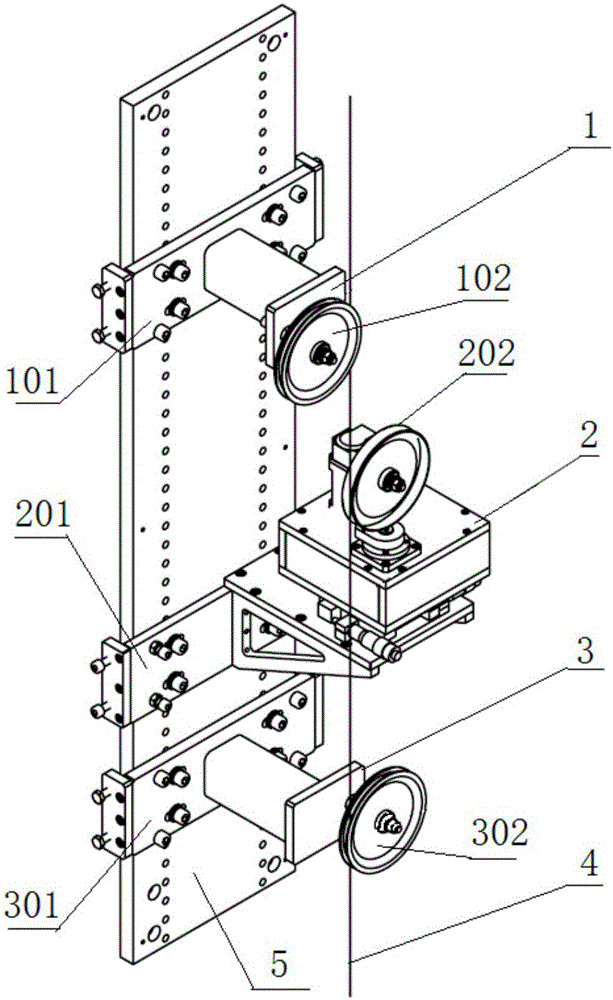

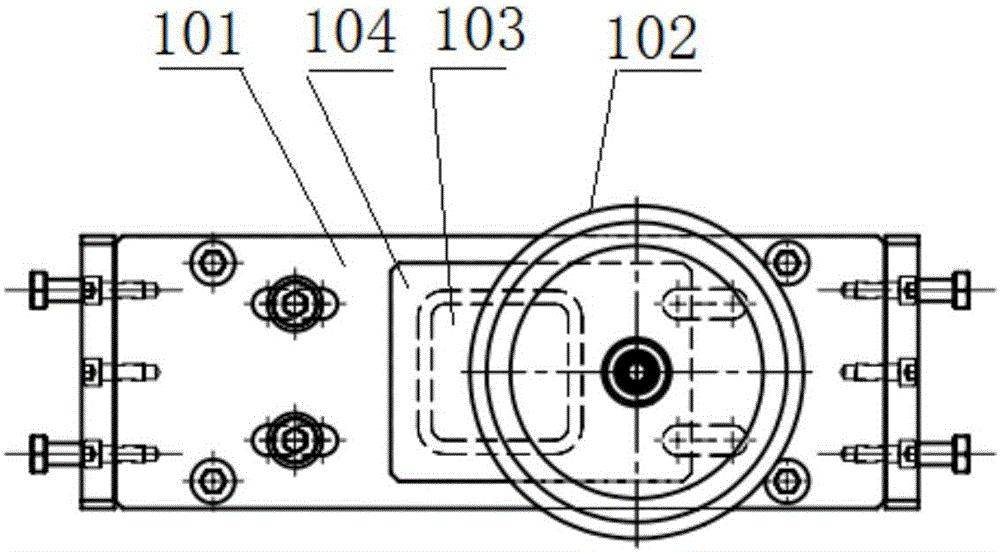

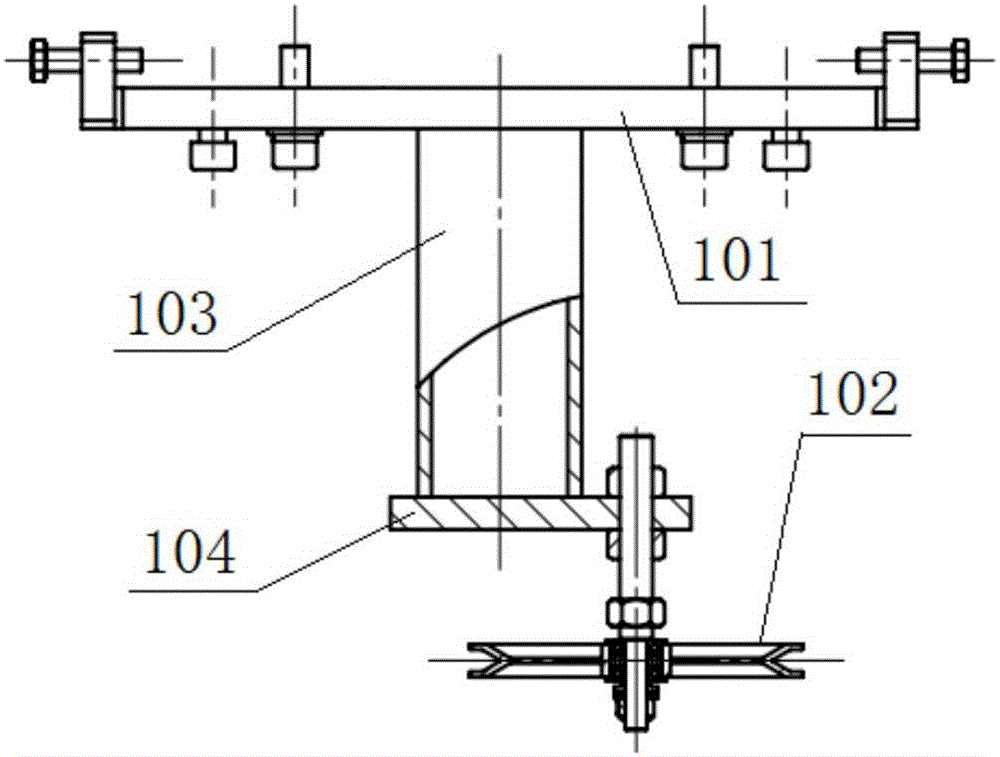

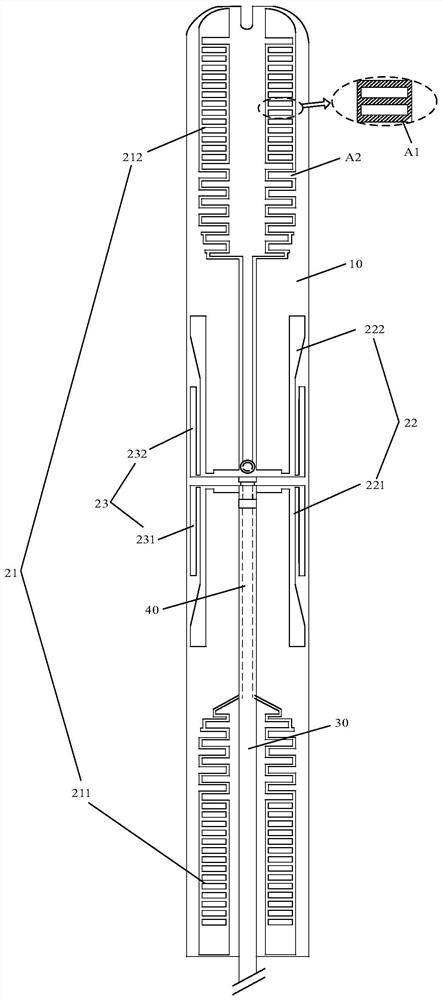

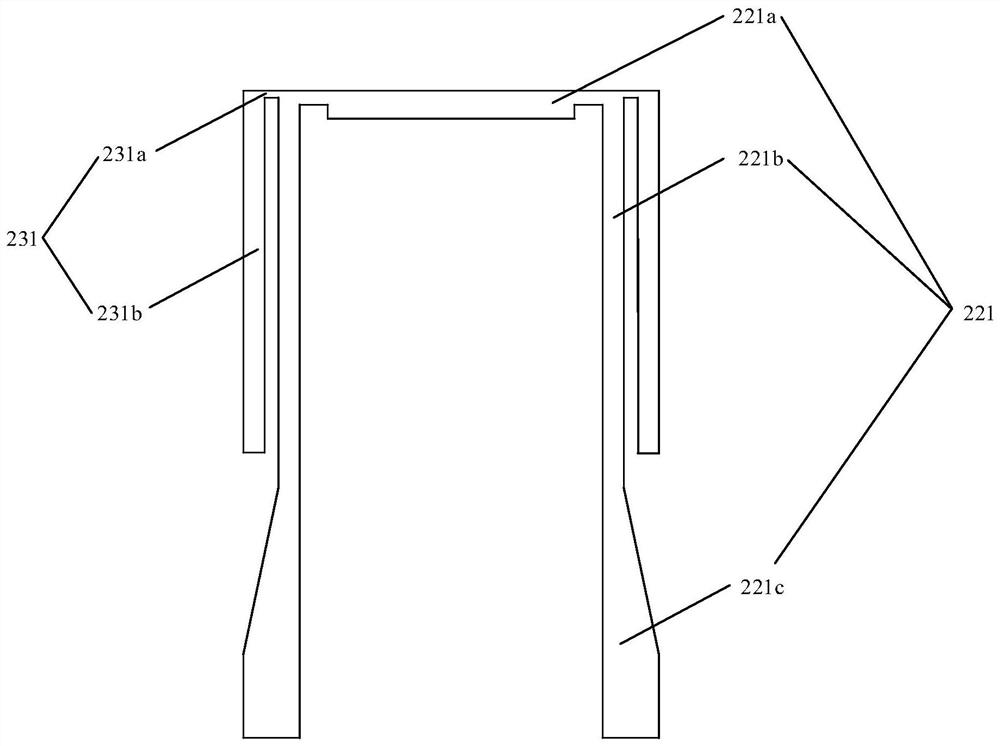

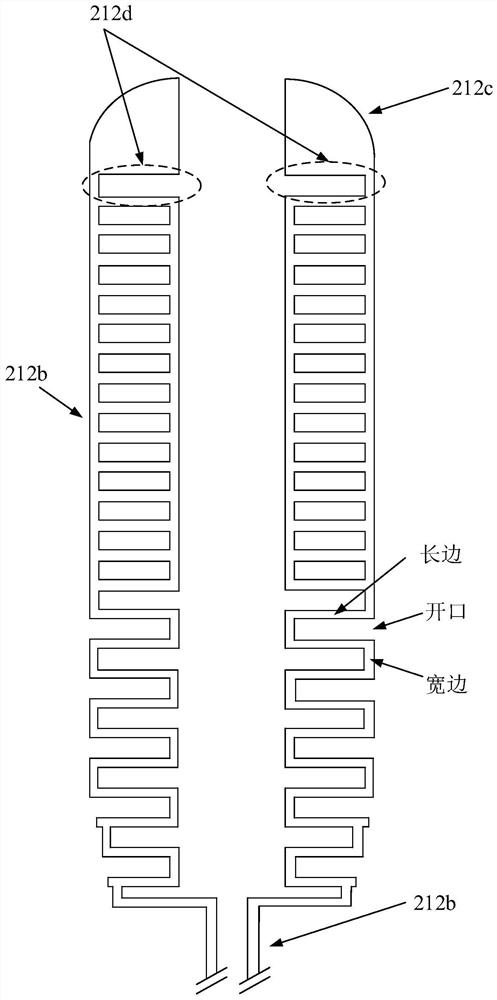

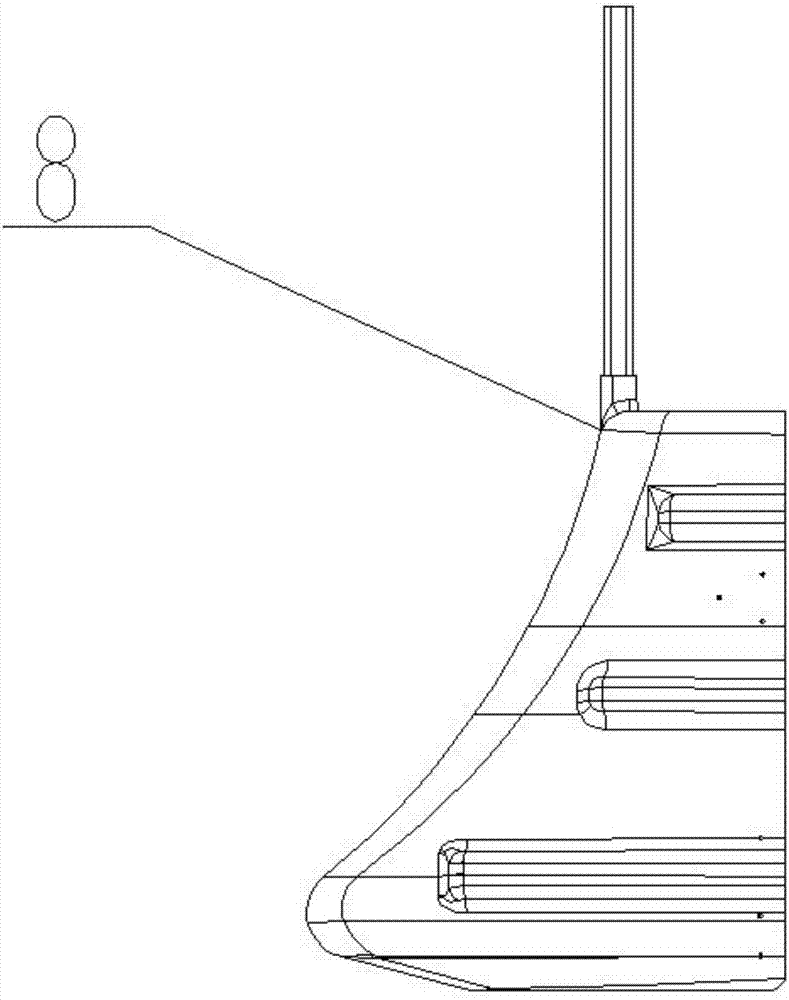

Single-wheel deflection optical fibre twisting equipment

ActiveCN106630589AReverse guaranteeMeet the technical requirements of the drawing processGlass making apparatusGlass productionElectric machineReciprocating motion

The invention discloses single-wheel deflection optical fibre twisting equipment. An upper positioning wheel set (1), a single wheel deflection mechanism (2) and a lower positioning wheel set (3) are mounted on a machine frame (5) in sequence from top to bottom; through centering adjustment of the upper positioning wheel set (1) and the lower positioning wheel set (3), two guide wheel grooves of an upper positioning guide wheel (102) and a lower positioning guide wheel (302) are simultaneously tangent to the surface of an optical fibre (4); optical fibre twisting movement is transferred upwards stably; the continuity of periodic deflection movement is realized by the single wheel deflection mechanism (2) adopting a continuous transmission mechanism; by adopting a single-wheel periodic deflection structure, the two side surfaces of a V-shaped wheel groove are in contact with the optical fibre alternately, so that periodic reciprocating twisting of the optical fibre is realized; a motor of the transmission mechanism operates continuously in a single direction, so that forward and backward reciprocating movement is not required. The positioning guide wheels are added above and below the deflection wheel so as to ensure that the optical fibre is only twisted, and the swinging of the optical fibre is avoided. The equipment is easy, quick and convenient to machine, assemble and debug; the manufacturing and maintenance cost is remarkably reduced; technical requirements on an optical fibre drawing process can be met practically and effectively.

Owner:SHANGHAI YUPIN COMM TECH

C-shaped lifting appliance with locking function

ActiveCN110436334ABig spaceReduce the amount of weldingLoad-engaging elementsElectricityWear resistant

The invention provides a C-shaped lifting appliance with a locking function. The C-shaped lifting appliance is characterized by comprising an upper frame, a lower frame, suspension arms and a lockingdevice; and the upper frame is connected to the suspension arms through bolts, the upper frame is connected to a trolley unit through a hanging shaft, and the middle of the upper frame is ensured to be insulated through a polytetrafluoroethylene spacer bush. The upper frame is provided with an electrifying device, and electricity is conducted through conductive copper plates on the outer side of aelectrophoresis station. The suspension arms are formed by welding tubes and plates, the suspension arms are formed by hot bending once by adopting steel tubes, are connected to the upper frame and the lower frame through bolts up and down, and the welding error is reduced while the welding amount is reduced. Special tool clamps are used for manufacturing the suspension arms, and the machining error of the suspension arms is within 2 mm. The lower frame is connected to the suspension arms through bolts, and the middle of the lower frame is ensured to be wear-resistant and corrosion-resistantthrough a polytetrafluoroethylene spacer bush. The locking device is arranged below the lifting appliance, and the locking device is used for automatically clamping parts which are hoisted and moved by the lifting appliance, so that the purpose of automatic production is achieved, and the purpose of improving the production efficiency is achieved.

Owner:江苏长虹机械设计院有限公司 +1

Compensation Topology for Wireless Power Transfer Systems

InactiveCN106533185BIncrease flexibilityEasy and fast commissioningEfficient power electronics conversionCircuit arrangementsCapacitanceLoose coupling

A compensation topology structure of a wireless power transmission system relates to a compensation topology structure of a wireless power transmission system. The invention solves the problems of a large number of compensation components, higher system cost and lower power density of the existing wireless power transmission system compensation topology structure. The S / CLC compensation topology includes primary series compensation capacitors, loosely coupled transformers, secondary parallel compensation capacitors, secondary series compensation inductors and phase-shifting capacitors; the primary series compensation capacitors are connected to the full-bridge inverter, and the primary series compensation capacitors are connected The self-inductance of the primary side of the loosely coupled transformer, the self-inductance of the primary side of the loosely coupled transformer is connected to the full-bridge inverter, the self-inductance of the secondary side of the loosely coupled transformer is connected to the parallel compensation capacitor of the secondary side and the series compensation inductance of the secondary side, and the self-inductance of the secondary side of the loosely coupled transformer is connected. The secondary side is connected in parallel with the compensating capacitor, the phase-shifting capacitor and the full-wave rectifier, and the secondary side is connected in series with the compensating capacitor and the phase-shifting capacitor and the full-wave rectifier. The present invention is used for wireless power transfer.

Owner:HARBIN INST OF TECH

Control method for intelligent valve positioner

ActiveCN101770240BStable and reliable outputEasy and fast commissioningControl using feedbackMicrocontrollerPwm signals

The invention relates to a control method for an intelligent valve positioner, which has simple and rapid debugging. The technical scheme is that a singlechip receives a set signal sent by a controller and a feedback signal transmitted by a valve position sensor; the set signal is compared with the feedback signal; a bias is subjected to adaptive PID control; a corresponding PWM signal is output to drive an I / P converting unit; and an executing mechanism is driven by a pneumatic power amplifier.

Owner:衡阳北方光电信息技术有限公司

Multi-color multi-displacement printer

The invention belongs to the technical field of pad printing and discloses a multi-color and multi-position pad printing machine. The multi-color and multi-position pad printing machine comprises a base, a pad printing assembly arranged on the base in a straddling manner, a plurality of ink feeding assemblies located below the pad printing assembly, a cleaning assembly located in front of the ink feeding assemblies and a material supporting assembly located beside the ink feeding assemblies; the pad printing assembly comprises a horizontally-arranged servo module which is provided with an X movement module capable of moving in the X direction; the X movement module is provided with a first cylinder which drives an adhesive head assembly to move up and down in the Z direction; the adhesive head assembly is provided with pad printing adhesive heads side by side in the X direction, and the number of the pad printing adhesive heads corresponds to that of the ink feeding assemblies; and the material supporting assembly comprises a base, a carrying table located above the base and a third cylinder fixed to the base and driving the carrying table to move in the X direction. The multi-color and multi-position pad printing machine can print colorful patterns formed by combining different color blocks on products, cost is saved compared with a common multi-color pad printing machine, and besides, debugging is easy and fast.

Owner:YINGTUO ELECTRONICS APP KUSN

A kind of comprehensive performance test device of hydrogen-oxygen composite catalyst and application method thereof

InactiveCN104200856BAdjust environmental parameters at any timeIngenious designNuclear energy generationNuclear monitoringHydrogenControl system

The invention discloses a comprehensive performance testing device for an oxyhydrogen composite catalyst and an application method thereof. The comprehensive performance testing device comprises a reaction tank, a test tooling, a measuring system, a data acquisition system, a multipath gas introduction control system and auxiliary testing equipment, wherein the test tooling is mounted in the reaction tank and is used for placing a catalytic board; the measuring system is mounted on the reaction tank and is used for detecting the concentration, the temperature, the pressure and other parameters of gas in the reaction tank; the data acquisition system is connected with the measuring system; the multipath gas introduction control system provides exogenous gas required by the test; the auxiliary testing equipment is connected with the reaction tank. According to the comprehensive performance testing device disclosed by the invention, the design is ingenious; the complex environment of a nuclear power station under the working condition of serious accidents is simulated by an oxyhydrogen composite catalytic board through special equipment, so that environment parameters of the catalyst can be adjusted at any time; all required data is accurately detected by the measuring system and various performance tests of the catalyst are realized; the transfer and the assembly of the catalytic board are eliminated, so that great human and material resources are saved; the time and the labor are saved; the comprehensive performance testing device is convenient and safe in use, simple and quick in debugging and comprehensive and sufficient in detection, and has high popularization and application values in the field.

Owner:SICHUAN INST OF MATERIALS & TECH +2

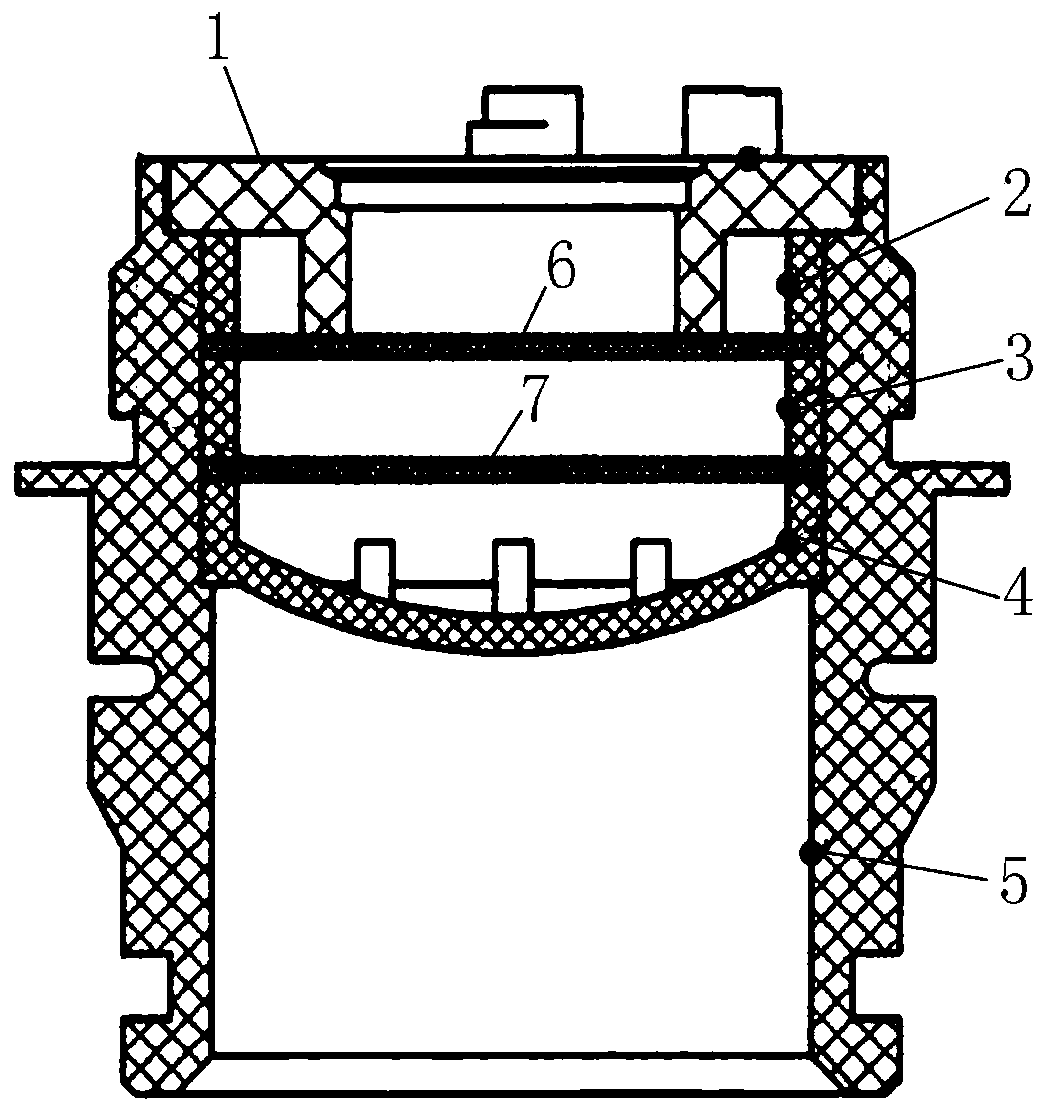

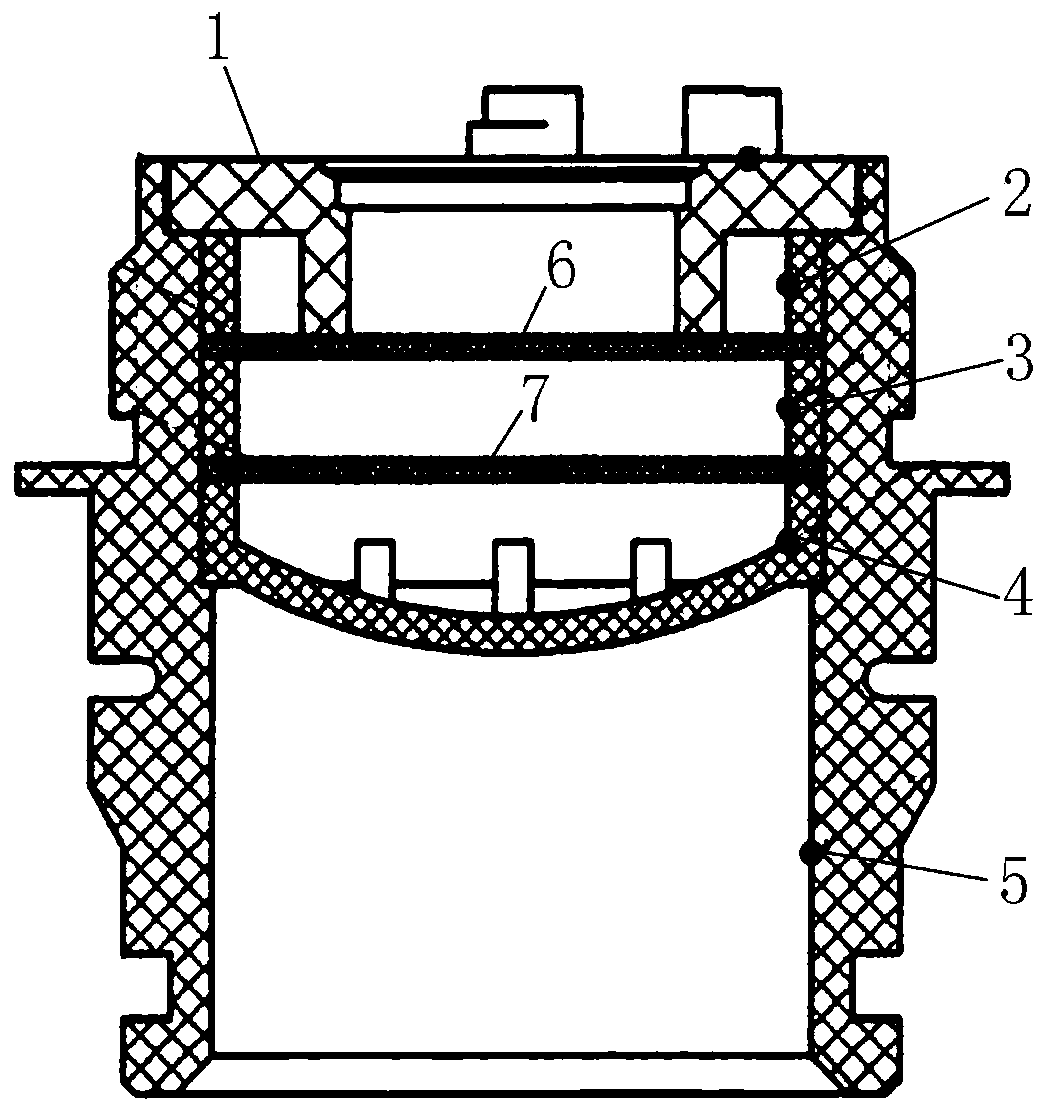

Joint of air supply valve of air breathing apparatus

The invention relates to the technical field of safety protection, in particular to a joint of an air supply valve of an air breathing apparatus.The joint comprises a joint body, a lower valve rack, adamping assembly and a grizzly. The joint body is of a hollow structure, two ends of which penetrate; the lower valve rack is fixed to the lower end of the joint body; the lower valve rack is of a hollow structure, two ends of which penetrate; the lower valve rack communicates to the joint body; the grizzly is fixed below the lower valve rack on the inner side of the joint body; a plurality of through holes for oxygen circulation are formed in the grizzly; and the damping assembly is fixed between the lower valve rack on the inner side of the joint body and the grizzly. According to the air supply valve of the air breathing apparatus provided by the invention, noise is reduced obviously by means of mild damping action of the damping assembly and the grizzly to a breathing air flow, so that a good noise-reducing effect is achieved. The air demand is great and the joint is simple and convenient to debug.

Owner:辽宁思科安全装备制造有限公司

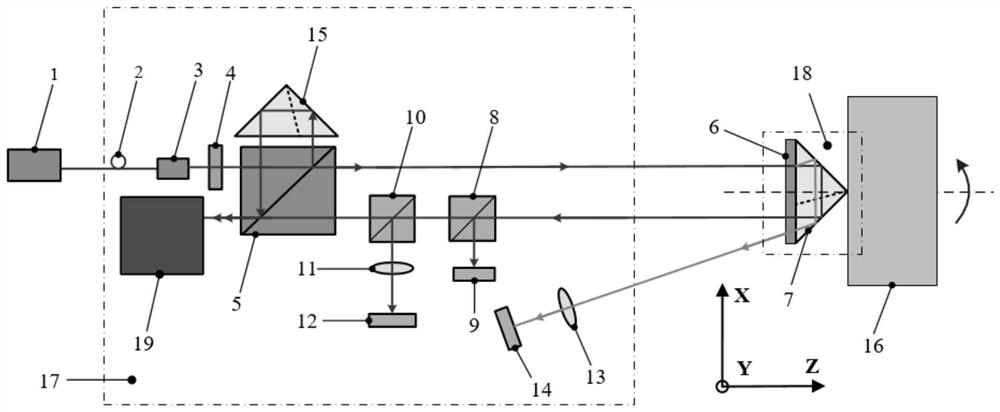

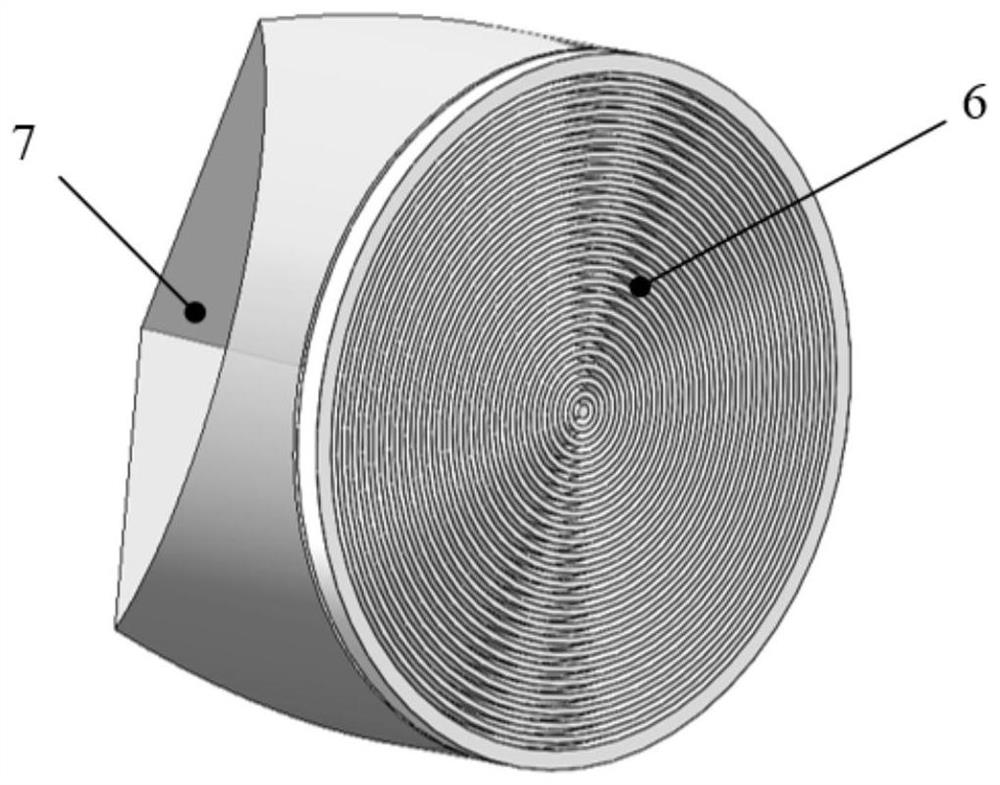

System for simultaneously measuring five-degree-of-freedom motion errors of rotating shaft

PendingCN113865482AImprove detection efficiencyAvoid introducingUsing optical meansRotational axisGrating

The invention provides a system for simultaneously measuring five-degree-of-freedom motion errors of a rotating shaft. The system comprises a light source, a measuring unit and an error sensing unit which are in light path connection. The light source is a laser for emitting laser; the measuring unit is used for processing the laser emitted by the light source, transmitting the laser to the error sensing unit and measuring the five-degree-of-freedom motion error of the rotating shaft according to the diffracted light returned by the error sensing unit; the error sensing unit comprises an annular grating and a first cube-corner prism, the annular grating is fixed to the center position of the inclined face of the first cube-corner prism, the cone center end of the first cube-corner prism is fixed to the center position of the end face of the rotating shaft, and the rotating center axes of the annular grating, the first cube-corner prism and the rotating shaft coincide. And the error sensing unit is used for diffracting and retroreflecting the incident light of the measuring unit. According to the system, simultaneous measurement of five-degree-of-freedom motion errors of the rotating shaft can be realized, and the detection efficiency is greatly improved.

Owner:BEIJING JIAOTONG UNIV

Automatic bottle feeding machine

PendingCN107399450AImprove performanceLabor savingConveyorsPackaging bottlesComputer hardwareProcess engineering

The invention discloses an automatic bottle feeding machine. The automatic bottle feeding machine comprises a frame and a bottle storage platform arranged on the frame, wherein the bottle storage platform is provided with a bottle pushing power device, a bottle pushing device and a bottle conveying device; the bottle pushing power device is arranged below the bottle storage platform and is used for driving the bottle pushing device to push bottles towards the bottle conveying device; the bottle pushing device is arranged above the bottle storage platform and is used for pushing the bottles to the bottle conveying device; and the bottle conveying device is arranged in the middle of the bottle storage platform and is used for conveying the bottles to a next packaging procedure. The automatic bottle feeding machine is suitable for arranging and feeding plastic bottles of various types, is stable in performance, and is matched and used with an automatic packaging assembly line, so that labor is saved and production efficiency is improved. The functions of bottle storage, bottle sending, bottle driving and bottle conveying are integrated in the automatic bottle feeding machine. The automatic bottle feeding machine is small in occupied area, simple in mechanism, low in cost, simple and convenient to debug and easy to operate, the bottles are not stuck and not damaged, labels are not damaged, and the bottle arranging rate of 100% is achieved.

Owner:米多智能包装(昆山)有限公司

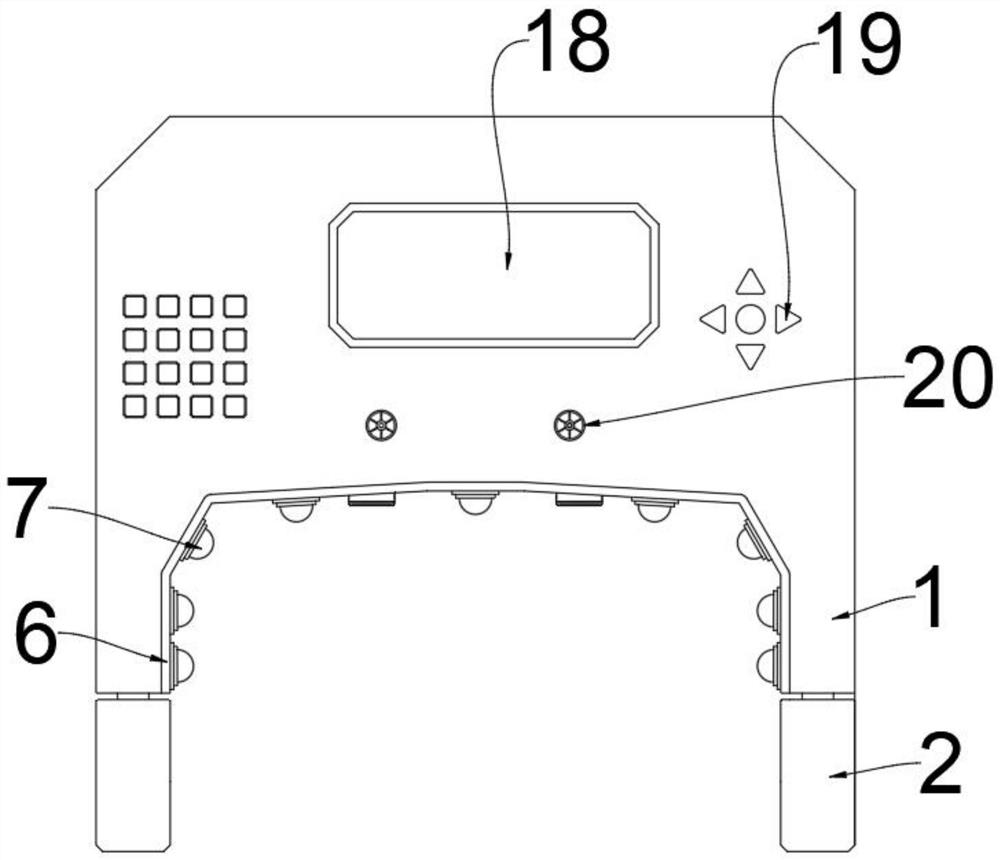

Antenna, debugging method thereof, external antenna structure and unmanned aerial vehicle

PendingCN112909504AEasy and fast commissioningShorten the timeAntenna adaptation in movable bodiesRadiating elements structural formsMulti bandUncrewed vehicle

The embodiment of the invention relates to the technical field of antennas, and in particular relates to an antenna, a debugging method thereof, an external antenna structure and an unmanned aerial vehicle. The antenna comprises: a substrate having at least one flat substrate surface, and a first radiation part which is arranged on the surface of the substrate and comprises a first vibrator and a second vibrator which face opposite directions; each of the first vibrator and the second vibrator comprises a vibrator main body formed by a plurality of enclosed structures; at least a part of the adjacent enclosing structures are overlapped to form a communicated oscillator main body; and one or more of the enclosing structures forming the oscillator main body are provided with openings, so that the oscillator main body forms a bent snake-shaped structure. According to the antenna, reasonable wiring and structural design are adopted, and the use requirement of a multi-band antenna can be met on the substrate with a small size. Moreover, the antenna debugging process is simpler, and the wiring mode is faster.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

Air curtain for special pesticide spraying machine for cotton and special pesticide spraying machine for cotton using air curtain

PendingCN107306930AEasy to fixAchieve circulationInsect catchers and killersAgricultural engineeringCantilever

The invention provides an air curtain for a special pesticide spraying machine for cotton and a special pesticide spraying machine for cotton using the air curtain. The air curtain for the special pesticide spraying machine comprises a straight air curtain body and an inclined air curtain body, wherein the straight air curtain body and the inclined air curtain body are formed integrally; a retractable seam is formed between the straight air curtain body and the inclined air curtain body; the inclined air curtain body can retract into the straight air curtain body through the retractable seam; a plurality of tapered air outlet tubes are equidistantly arranged on the lower part of the air curtain; the tapered air outlet tubes are fixedly connected with the air curtain; the two air curtain bodies are symmetrically arranged on two sides of a fan; the straight air curtain body is fixedly connected with the fan; a plurality of fixing straps are arranged on one side, which is close to a spraying cantilever, of each air curtain body; the air curtain bodies are connected with the spraying cantilever through the fixing straps; and the fixing straps are arranged equidistantly. The air curtain is easy to mount and convenient to operate; pesticide can be applied to cotton seedlings in different periods; the air curtain can rapidly adapt to different pesticide application areas; efficient ventilation can be realized; the pesticide application efficiency is high; debugging operation is simple and speedy; the cost is low; and the pesticide application area is large.

Owner:NANTONG HUANGHAI CHEM MACHINERY

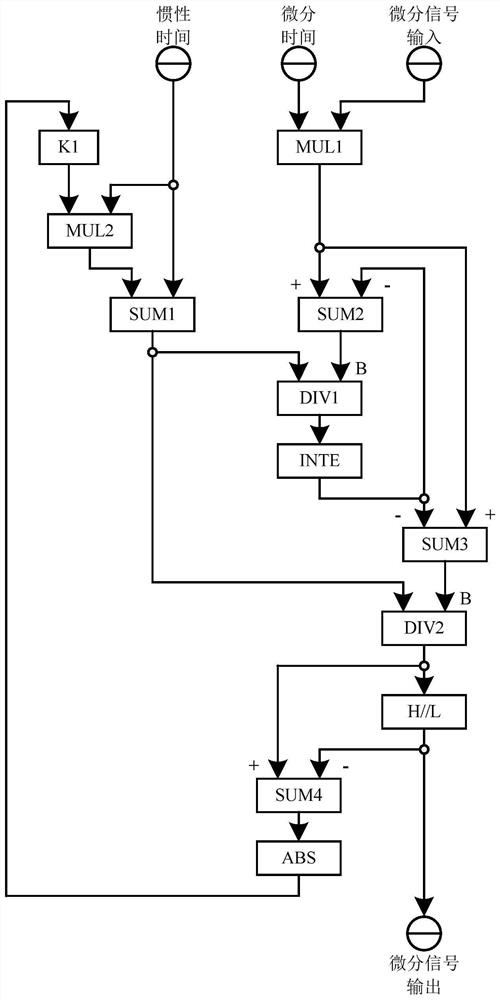

A Limiting Differential Control Method

InactiveCN109100933BImprove control effectImprove applicabilityControllers with particular characteristicsControl systemClosed loop

A limited differential control method, which is used to improve the control quality of a controlled object with large inertia, large lag, and its technical solution is that the method uses a limited differential controller to control the controlled object, when the limited differential controller When the output of the limiting differential controller is less than or equal to the limiting value, the output of the limiting differential controller is not limited; when the output of the limiting differential controller is greater than the limiting value, while limiting the output of the limiting differential controller, the The inertia time in the differential link is adjusted in a closed loop. By increasing the differential control inertia time, the differential output amplitude is reduced and the total differential control quantity remains unchanged. The present invention controls the differential output within a reasonable range under the condition of keeping the total differential control effect unchanged, and the control effect is obvious in the control system with large lag, large inertia object and dynamic compensation that requires large differential action It is superior to the traditional differential control method. The physical meaning of each parameter of the invention is clear, and the on-site debugging is simple and quick.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

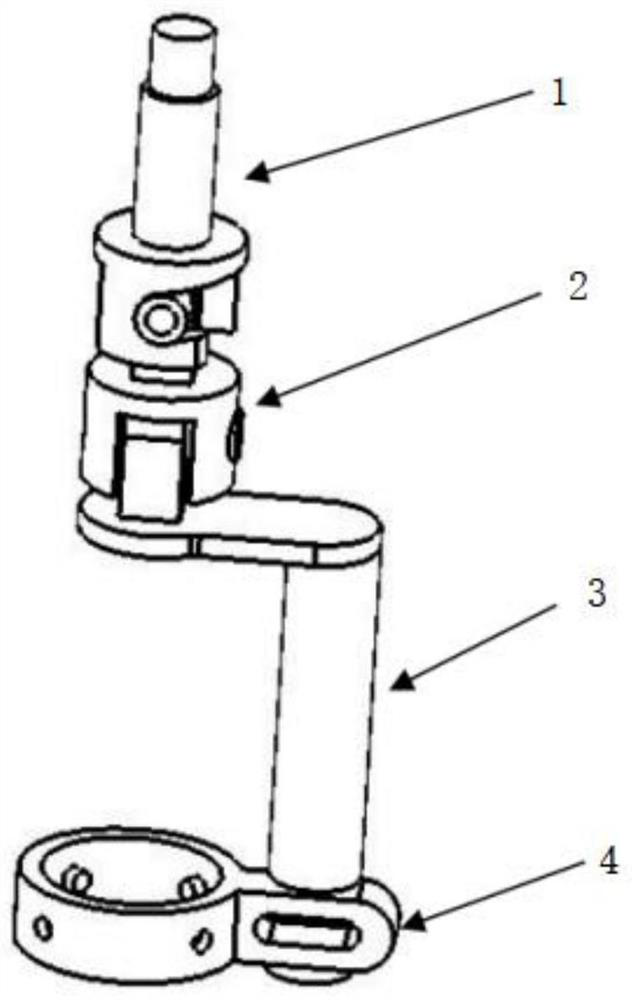

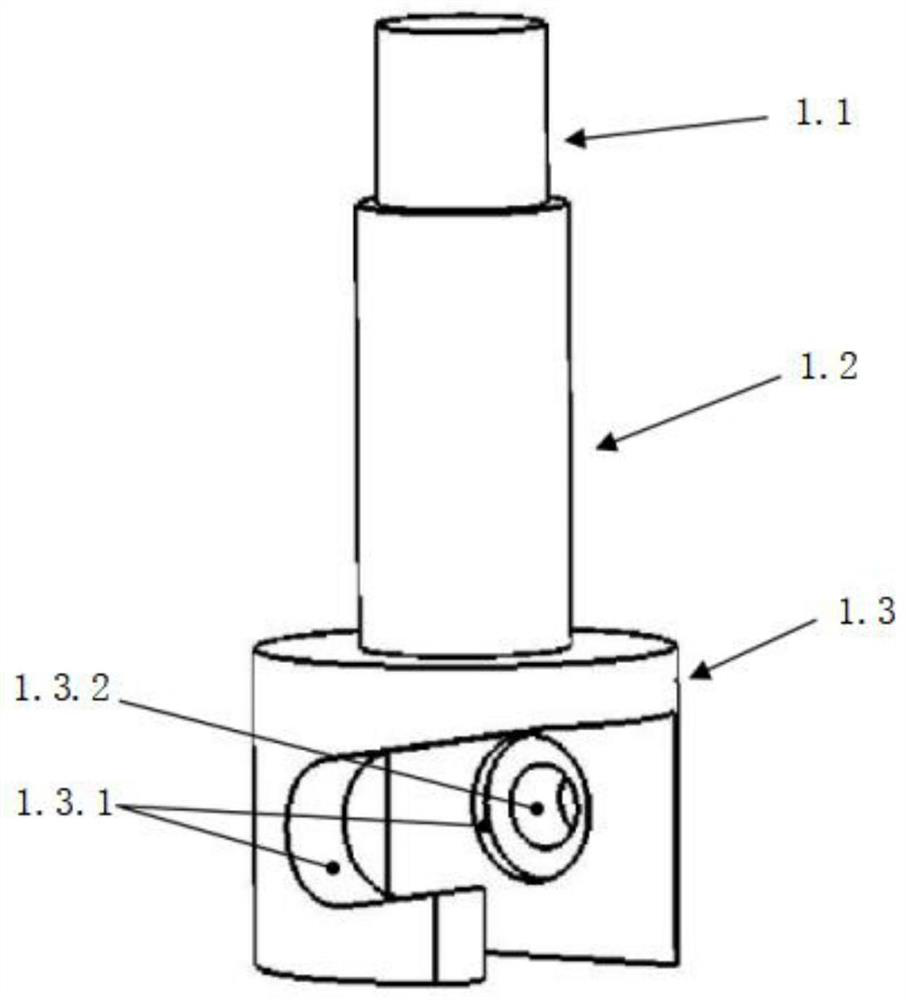

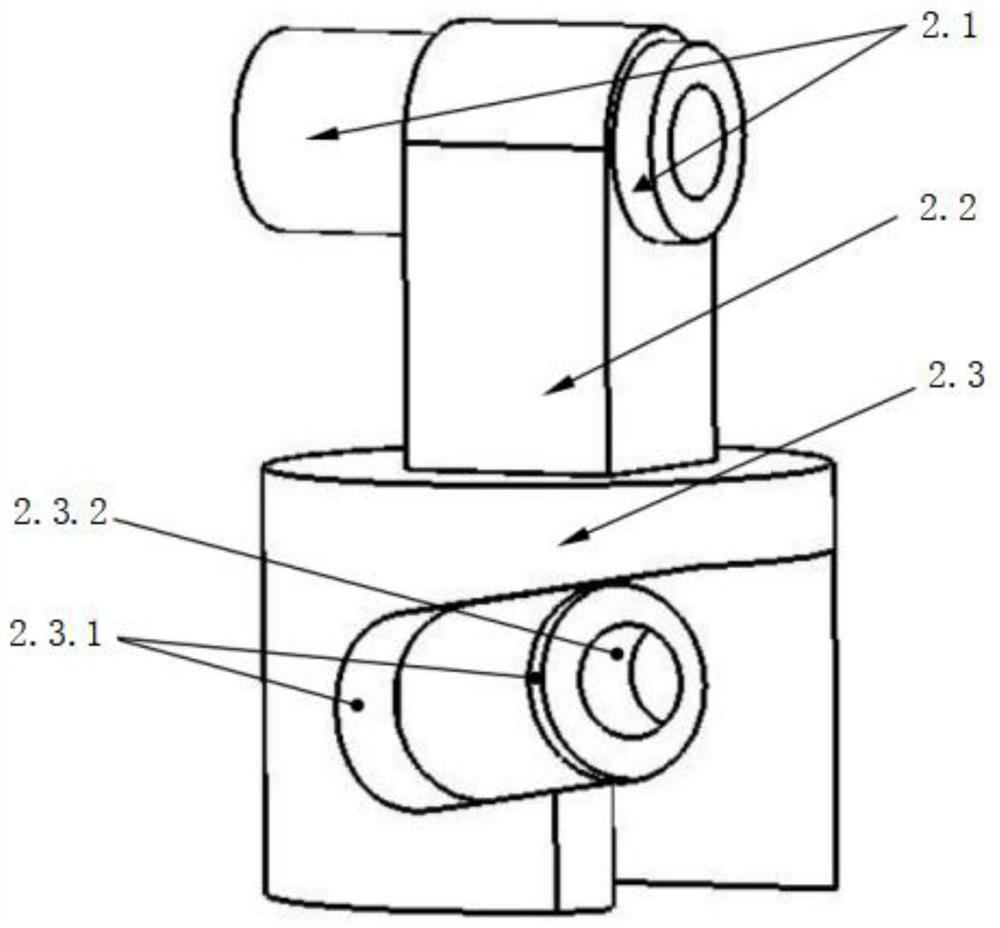

Optical probe mounting and debugging device for machining center and use method of optical probe mounting and debugging device

PendingCN114193233AReliable clampingNo position driftMeasurement/indication equipmentsJackscrewElectron microscope

The invention relates to an optical probe mounting and debugging device for a machining center and a using method, the device comprises a mounting head, and the mounting head is mounted on a general tool handle or a magnetic gauge stand of a machine tool and is used for positioning and fastening in the machine tool; comprising a rotary adjusting structure, the rotary adjusting structure is connected to the lower portion of the mounting head and comprises a first rotary adjusting piece and a second rotary adjusting piece, the first rotary adjusting piece is fixedly connected with the lower end of the mounting head in a rotary adjusting mode along the Y axis, and the upper end of the second rotary adjusting piece is fixedly connected with the lower end of the first rotary adjusting piece in a rotary adjusting mode along the X axis; comprising an optical probe fixing piece, the optical probe fixing piece is connected with the lower end of a second rotary adjusting piece in a transverse adjustable mode, a mounting ring is arranged at the end, away from the end connected with the second rotary adjusting piece, of the optical probe fixing piece, and a plurality of radial jackscrew holes are evenly distributed in the side wall of the mounting ring in the circumferential direction; a fine adjustment jackscrew is installed in each radial jackscrew hole, and the electron microscope is fastened in the installation ring through the fine adjustment jackscrews. The method is high in measurement precision and wide in application range.

Owner:TIANJIN NAVIGATION INSTR RES INST

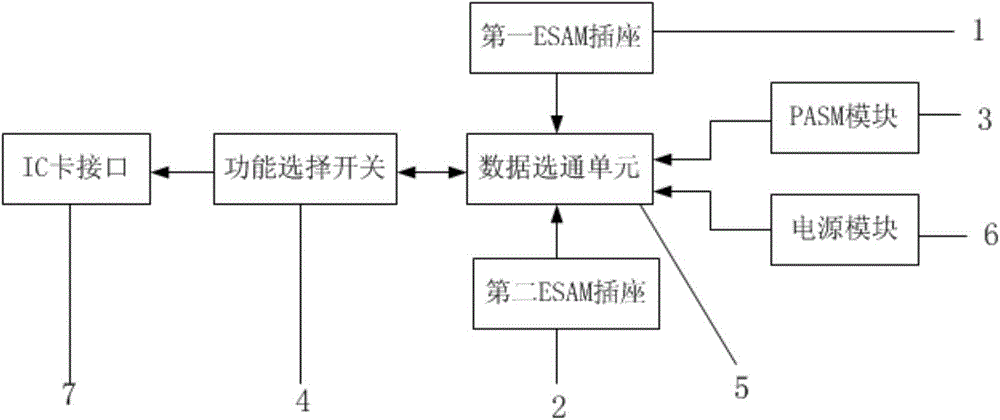

Novel debugging device for interface meeting ISO7816 protocol

InactiveCN104468271AEliminate cumbersome operationsEasy to debugData switching networksFunctional moduleWelding

The invention provides a novel debugging device for an interface meeting an ISO7816 protocol. The novel debugging device comprises a first ESAM socket, a second ESAM socket, a PSAM module, a function selection switch, a data strobe unit and a power source module. A device or card to be debugged is arranged at the corresponding position of the debugging device, strobe is conducted on the corresponding function module, the debugging device is inserted in an IC card socket of an active tag, debugging can be conducted conveniently and fast through a simulation tool of the active tag, the debugging device has the advantages of being capable of sharing the operation process, sharing codes and the like, and a debugged unit is replaced conveniently. Interfaces of all types of devices or cards meeting the ISO7816 protocol are debugged uniformly, size debugging is facilitated, the ESAM, a PSAM card, an SIM card and a UIM card are packaged, and welding and other redundant operations in the debugging process are omitted.

Owner:ZTE INTELLIGENT IOT TECH

Connectors and their couplings

The invention discloses a connector and a coupling device thereof. The connector comprises a connecting rod and an adjusting cavity, a signal input end is connected with a signal output end by the connecting rod, the adjusting cavity is arranged in the connector, the coupling device is disposed in the adjusting cavity and consists of a distance adjusting mechanism and an angle adjusting mechanism, the distance from a coupling circuit board to the connecting rod is adjusted by the distance adjusting mechanism, and the coupling circuit board is driven to rotate by the angle adjusting mechanism so that an included angle between the coupling circuit board and the axial direction of the connecting rod is changed. When the coupling degree and / or the isolation are adjusted, the connector and the coupling device thereof do not need to be frequently detached, welded and the like, the coupling circuit board and relevant devices are effectively protected, a debugging process is simple and speedy, and work efficiency is improved.

Owner:ANHUI TATFOOK TECH CO LTD

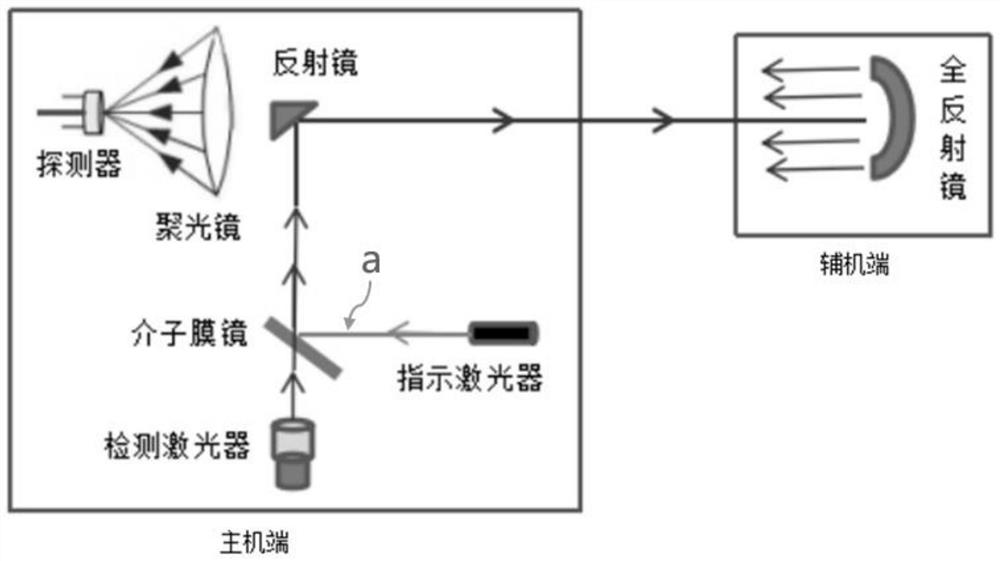

Light path debugging method and system for motor vehicle pollution detection equipment

PendingCN114200689ASave labor cost and time costSolve the difficulty of optical path calibrationMaterial analysis by optical meansOptical elementsOptical pathLaser light

The invention provides a light path debugging method and system for motor vehicle pollution detection equipment, and the method comprises the steps: transmitting a beam of infrared laser from one side to the other side after reflection, and forming a first light path; emitting a beam of visible light into a first light path; the incident angle of the visible light is adjusted, so that the visible light and the first light path are kept coaxial, and then the spectrum of the infrared laser is reflected back along the original path; the reflected infrared laser light signal is converted into an electric signal, and the pollutant concentration is calculated through processing. According to the invention, the defects that the light path debugging of the traditional equipment for detecting the pollution of the motor vehicle is limited by environmental conditions, the debugging time is long, the number of personnel is large, the process is complicated and the potential safety hazard is large during debugging are overcome, and when the infrared spectral line is debugged outdoors, a light beam quality analyzer, a spectrum color card and other equipment are not needed to search the light position; and optical path debugging can be carried out at any time in 24 hours all day, and the problem that the optical path is difficult to calibrate in the equipment installation and operation process is solved.

Owner:ANHUI QINGYU PHOTOELECTRIC TECH

Method for fast repositioning linear guides with high precision

InactiveCN101804567BImprove interchangeabilityHigh precisionLarge fixed membersEngineeringMachine tool

The invention belongs to the field of mechanical manufacture, in particular to a method for fast repositioning linear guides with high precision. The method comprises the steps of: firstly correcting each precision of one linear guide with a laser interferometer, and screwing and fixing the linear guide with a screw bolt; debugging correction table to the other linear guide by taking the former linear guide as a standard guide, and screwing and fixing the other linear guide with a screw bolt; arranging barrier materials along one sides of the two linear guides, wherein clearances are remainedbetween the barrier materials and the linear guides; and filling high-precision positioning glue into the clearances, wherein the positioning glue is solidified to be formed into a glue strip, so that the surface of the glue strip near the corresponding linear guides is the installation reference plane of the linear guides. The method assembles and debugs the straight line degree and the parallelism degree of the two linear guides to be both at 0.005mm, improves the fast motion and the assembly quality of a machine tool, and is convenient and simple for debugging a machining center by simplifying working procedures.

Owner:WUHU RUIJING MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com