Control method for intelligent valve positioner

A control method and technology of intelligent valve, applied in the direction of using feedback control, etc., can solve the problems of increasing the work difficulty of on-site operators, prone to human error, poor adaptability, etc., to achieve simple and fast debugging, convenient debugging operation, and fast positioning speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

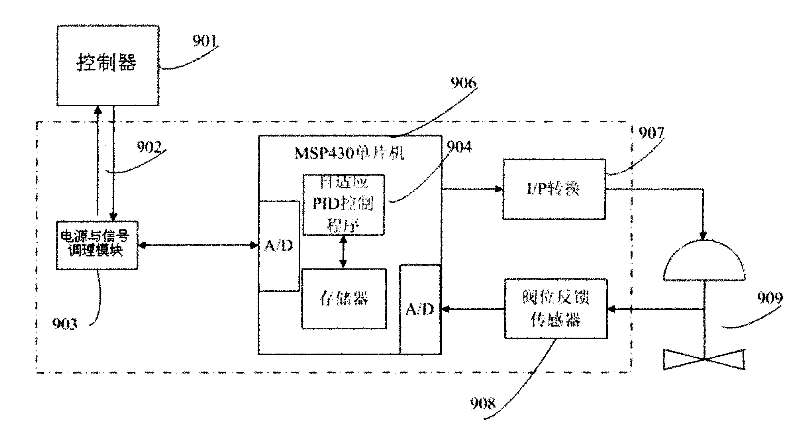

[0036] like figure 1 As shown, the controller 901 outputs the setting signal, enters the power supply and signal conditioning module 903 through the two wires 902, provides the working power of the whole machine, extracts the control signal and sends it to the MSP430 microcontroller 906, and the current valve position of the actuator 909 is sent through the valve position sensor 908. to the MSP430 single-chip microcomputer; the adaptive PID control program 904 compares the setting signal with the feedback signal, performs adaptive PID processing on the deviation, and sends the PWM signal at the next moment, and the PWM signal drives the I / P conversion unit 907, which is driven by the pneumatic power amplifier. The actuator is adjusted.

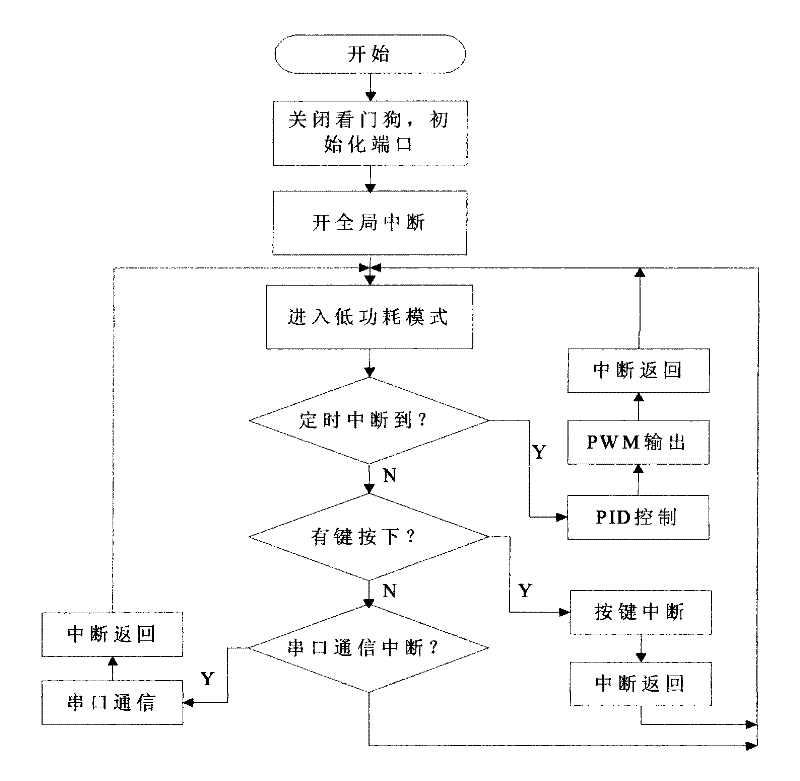

[0037] (1) Main program

[0038] The microcontroller MSP430 works in a low power consumption mode, and its low power consumption is mainly realized by working in an idle mode or a power-down mode. Except for the ACLK activity, the CPU and va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com