System for simultaneously measuring five-degree-of-freedom motion errors of rotating shaft

A motion error and rotary axis technology, applied in the system field of simultaneous measurement of the motion error of the rotary axis with five degrees of freedom, can solve the problems of servo rotation error, unfavorable error compensation, large environmental impact, etc., to avoid the introduction of related errors and applicability Strong, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

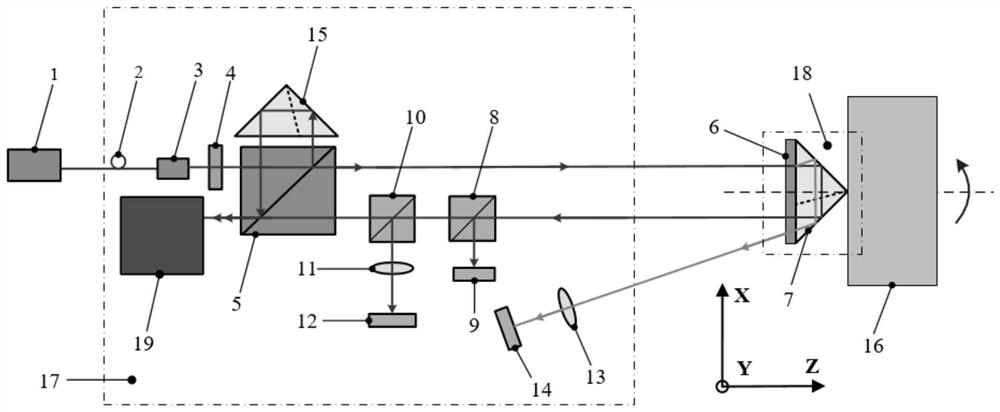

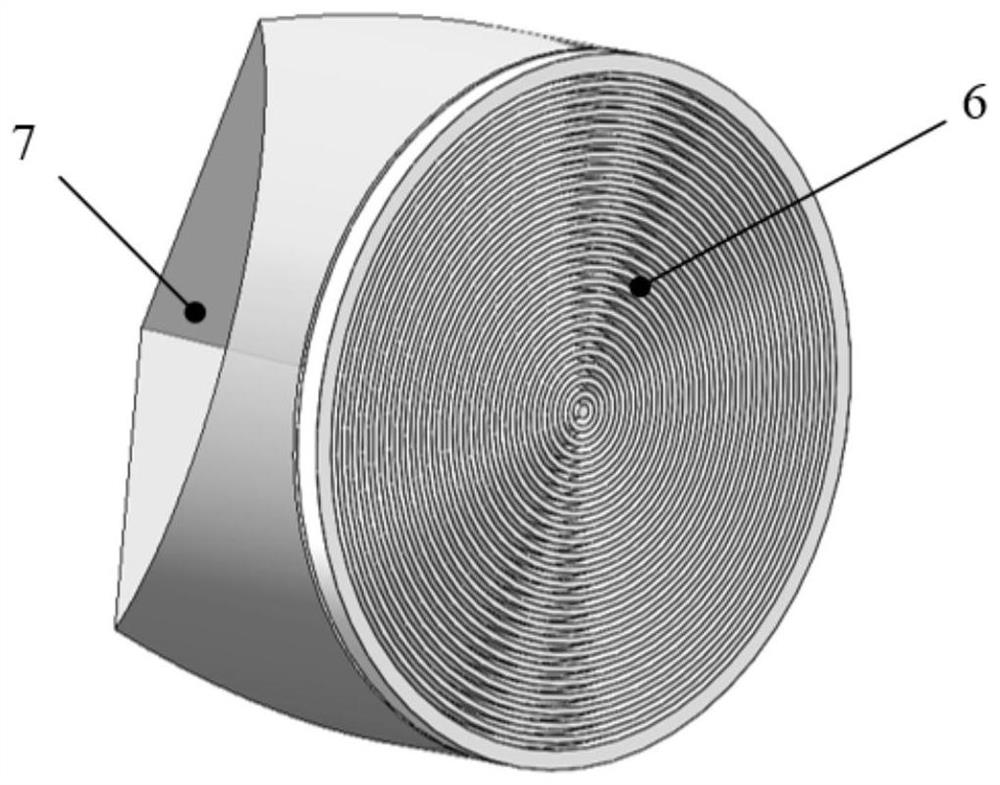

[0054] figure 1 Provided by the present embodiment for a system structure diagram five degrees of freedom movement of the rotary shaft while measuring the error in order to more clearly illustrate the five degrees of freedom to establish a coordinate system O-XYZ embodiment of the present embodiment; measured rotating rotation center axis and Z axis is parallel to the axis, and an annular corner cube circle grating rotationally symmetrical axis is also parallel to the Z-axis, and coincides with the central axis of rotation of the rotating shaft to be measured; five degrees of freedom of the rotating shaft to be measured at this time errors were: translation along the X, Y, Z three directions of the three straightness errors δ X ,δ Y ,δ Z Around the X, Y two inclination angle of rotation of the two coordinate axes error ε X Ε Y .

[0055] Refer figure 1 , The system comprising: an optical path connecting a light source 1, the measuring unit 17 and unit 18 is sensitive to errors.

...

Embodiment 2

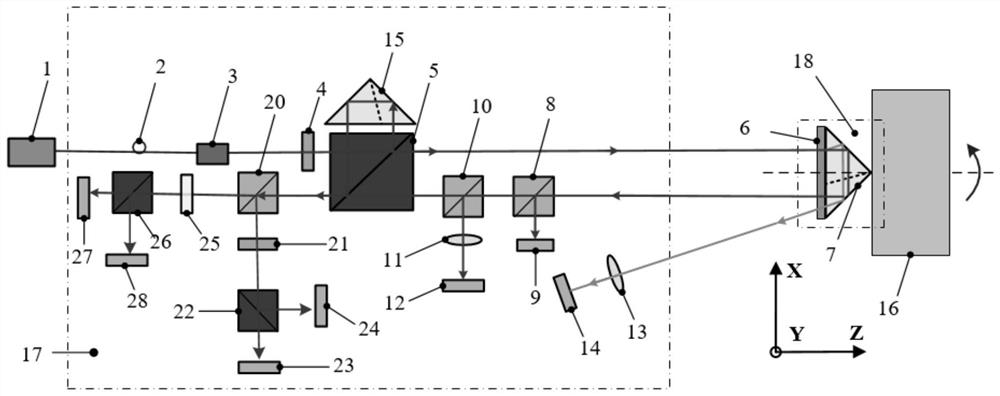

[0078] Figure 4 Provided by the present embodiment for a system structure diagram five degrees of freedom movement of the rotary shaft while measuring the error in order to more clearly illustrate the five degrees of freedom to establish a coordinate system O-XYZ embodiment of the present embodiment; measured rotating rotation center axis and Z axis is parallel to the axis, and an annular corner cube circle grating rotationally symmetrical axis is also parallel to the Z-axis, and coincides with the central axis of rotation of the rotating shaft to be measured; five degrees of freedom of the rotating shaft to be measured at this time errors were: translation along the X, Y, Z three directions of the three straightness errors δ X ,δ Y ,δ Z Around the X, Y two inclination angle of rotation of the two coordinate axes error ε X Ε Y .

[0079] Refer Figure 4 , The system comprising: an optical path connecting a light source 1, the measuring unit 17 and unit 18 is sensitive to errors.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com