Method for fast repositioning linear guides with high precision

A linear guide, high-precision technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems affecting the movement speed of the machining center, the large error of the width of the linear guide, and the difficulty in ensuring the installation accuracy. Not easy, high installation precision, convenient precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

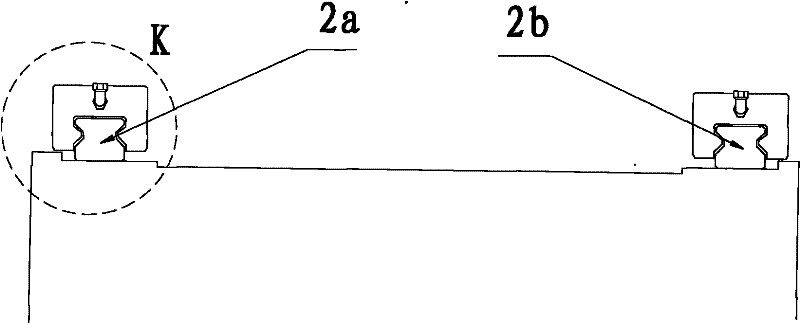

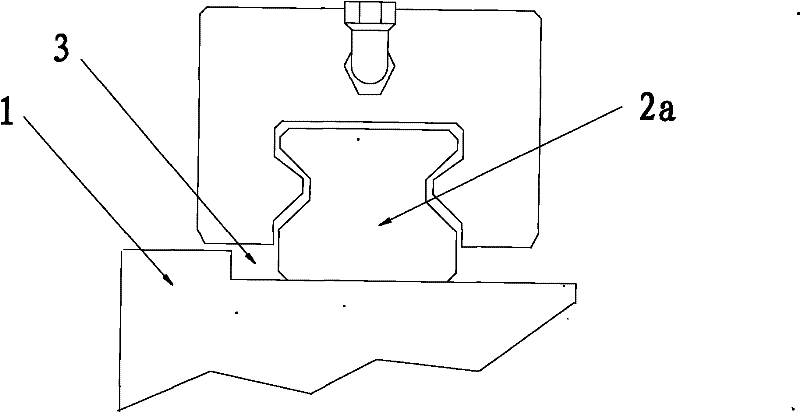

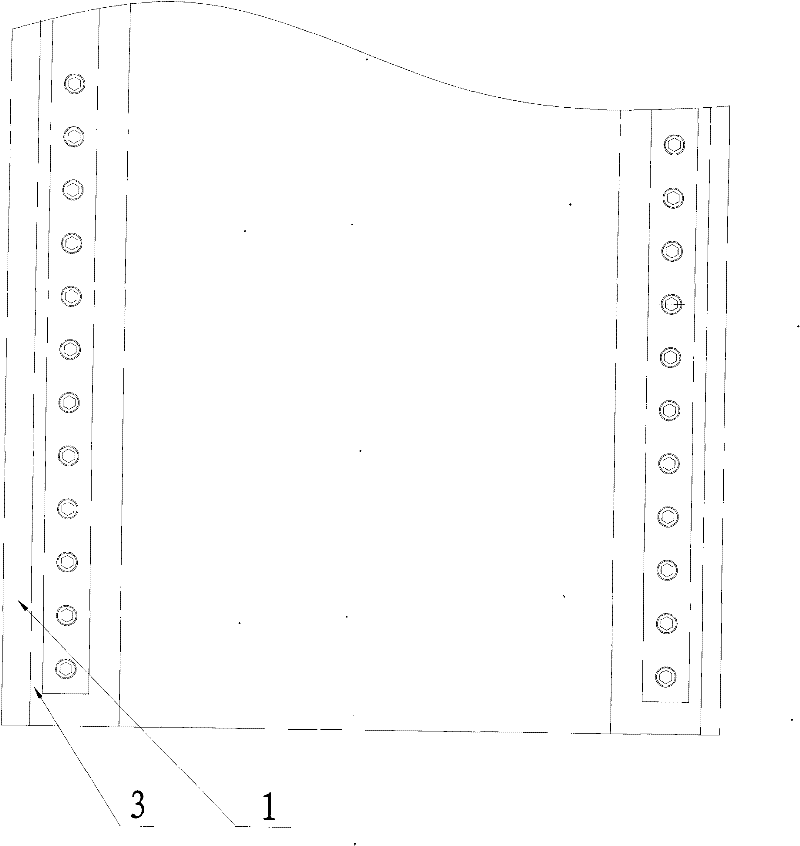

[0013] see figure 1 , 2 3. Take the positioning of the linear guide rail on the large guide rail of the machining center as an example: leave a gap of about 2 mm between the side 1 of the large guide rail body and the installation surface of the linear guide rail 2a, and adjust the accuracy of the linear guide rail 2a with a laser interferometer ( The horizontal plane and the vertical plane are adjusted separately), during the debugging process, the calculation of the straightness error adopts the least square method; after tightening the bolts, fill the gap 3 between the linear guide rail 2a and the large guide rail body 1 with high-precision positioning glue, After the positioning adhesive is cured, use the side of the positioning adhesive strip as the reference plane ("backing") to ensure the position accuracy of the linear guide rail replacement in the future. The other linear guide rail 2b uses the linear guide rail 2a as the reference guide rail, and the meter is calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com