Automatic bottle feeding machine

A bottle machine and automatic technology, applied in the direction of packaging bottles, conveyors, conveyor objects, etc., can solve the problems of difficult adjustment and maintenance, cumbersome mechanism, and high cost, and achieve the effects of simple and convenient debugging, improved production efficiency, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

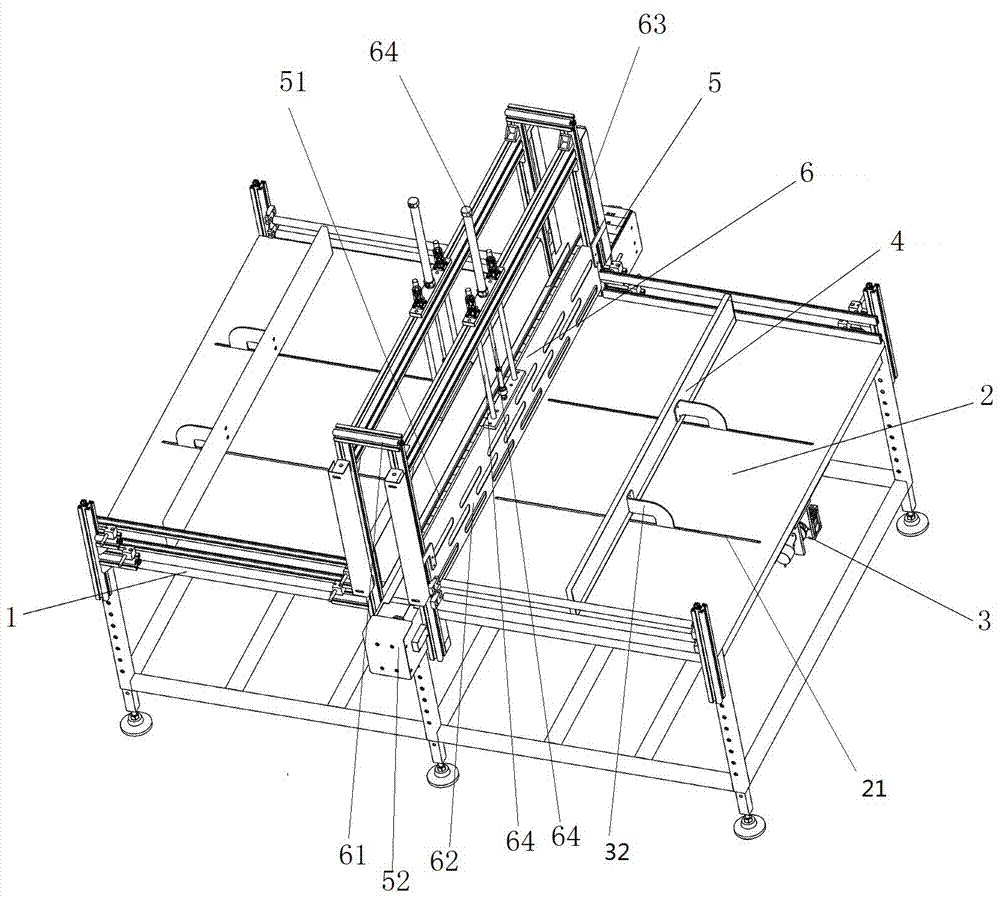

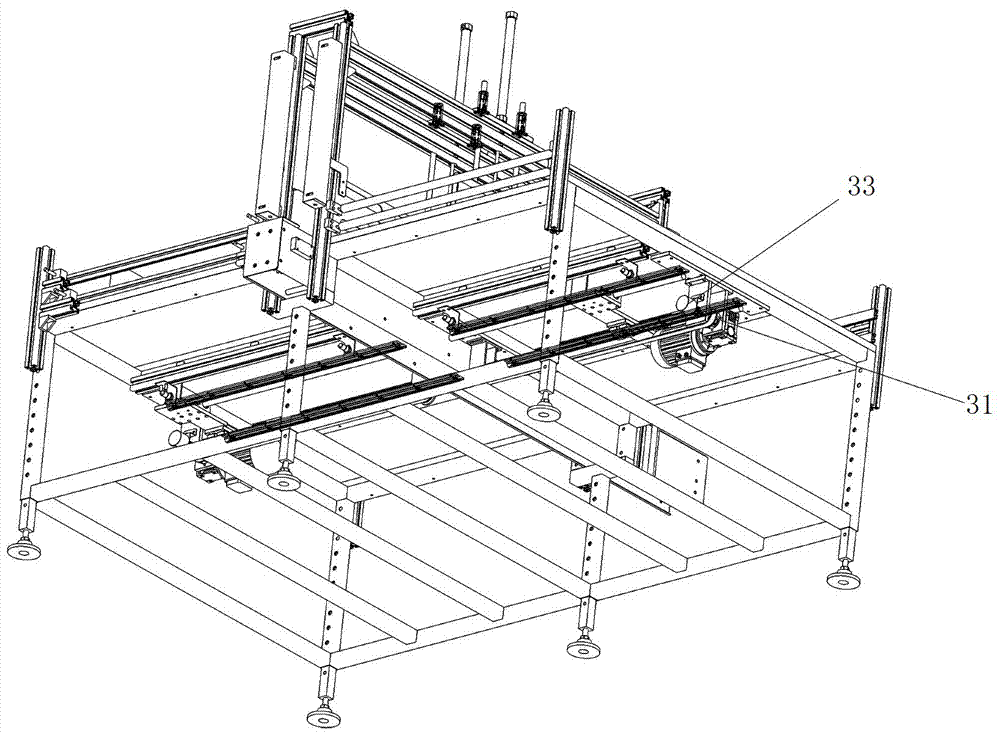

[0015] Such as Figure 1-2 As shown, an automatic bottle loading machine includes a frame 1 and a bottle storage platform 2 arranged on the frame 1, the bottle storage platform 2 is provided with a bottle pushing power device 3, a bottle pushing device 4, and a bottle conveying device 5; The bottle pushing power unit 3 is arranged below the bottle storage platform 2, and is used to drive the bottle pushing device 4 to advance the bottle to the bottle delivery device 5; the bottle pushing device 4 is arranged above the bottle storage platform 2, and is used to push the bottle toward The bottle conveying device 5 is advanced; the bottle conveying device 5 is arranged in the middle of the bottle storage platform 2, and is used for conveying the bottle to the next packaging process.

[0016] Specifically, a chute 21 is provided on the bottle storage platform 2, and the groove length direction of the chute 21 is arranged perpendicular to the bottle conveying direction. More specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com