A kind of comprehensive performance test device of hydrogen-oxygen composite catalyst and application method thereof

A composite catalyst and comprehensive performance technology, applied in the field of performance testing of hydrogen-oxygen composite catalysts, can solve the problems of time-consuming, labor-intensive, labor-intensive and material-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

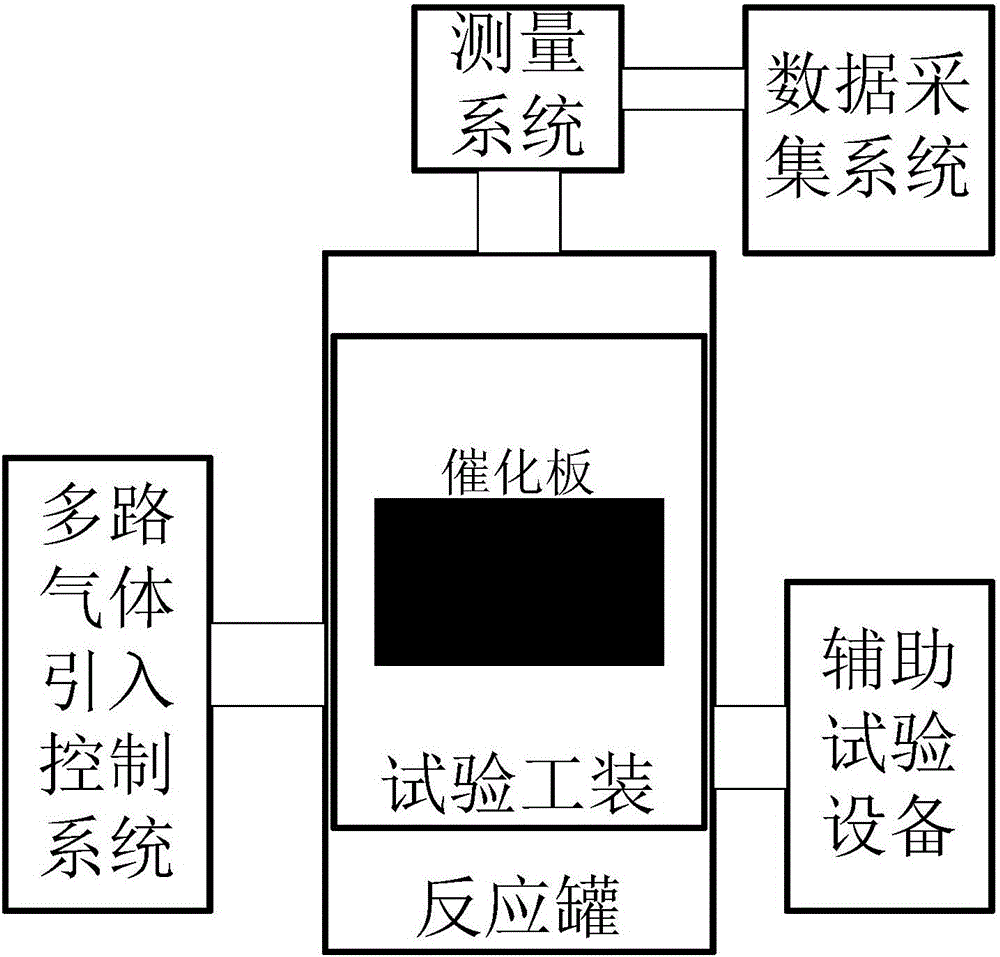

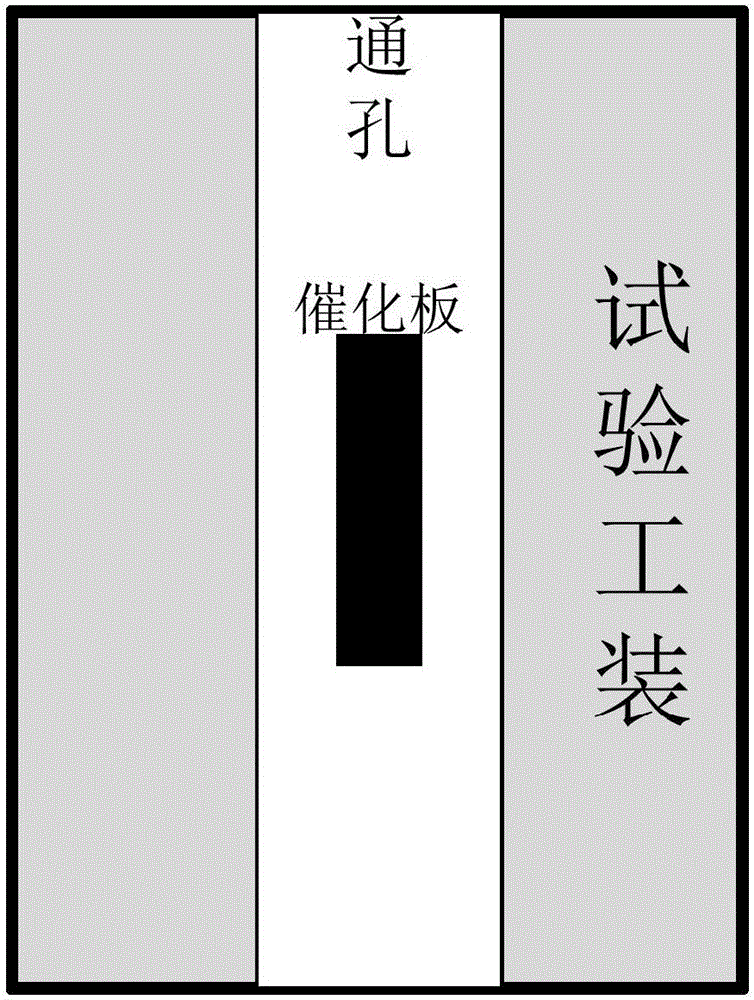

[0071] Such as Figure 1 to Figure 3 As shown, the comprehensive performance test device of the hydrogen-oxygen composite catalyst is mainly used for various tests on the performance of the catalyst catalytic plate in the passive hydrogen-oxygen recombiner of the nuclear power plant. Compared with the existing various detection and test devices, it can only test a certain As far as this performance is concerned, the feature of this device that can quickly deploy and switch test parameters is a highlight. Another highlight of this device is that it can simulate various complex processes in the event of a serious accident in a nuclear power plant to the greatest extent through various settings. This provides an effective guarantee for obtaining reliable and accurate test data. Specifically, the comprehensive performance test device mainly includes six parts: reaction tank, test tooling, measurement system, data acquisition system, multi-channel gas introduction control system an...

Embodiment 2

[0077] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the above-mentioned device structure is used in a specific performance test, and the required equipment has a corresponding change. omitted.

[0078] Specifically, this embodiment is mainly applied to the hydrogen elimination performance test of the catalytic plate under different hydrogen concentrations and different temperatures.

[0079] (S100) The structure configured to test the hydrogen elimination performance of the catalytic plate under different hydrogen concentrations:

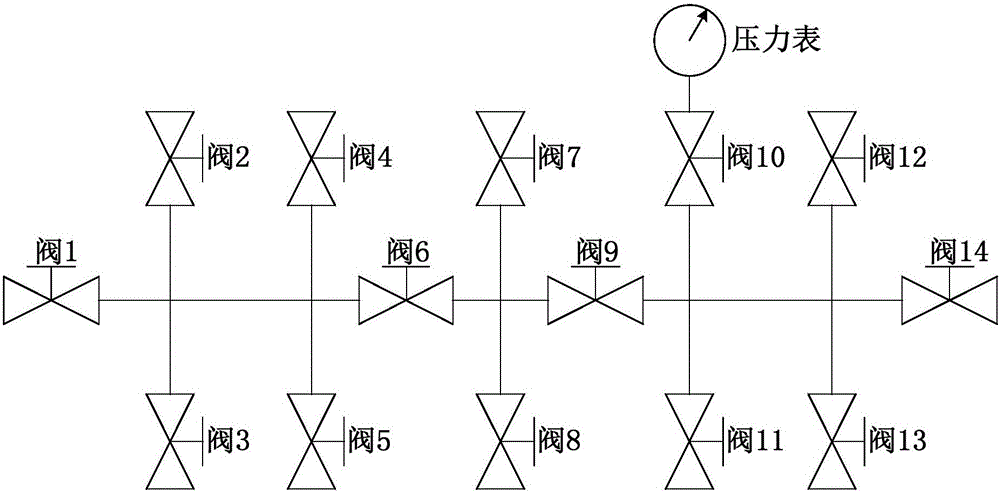

[0080] The valve 8 branch of the multi-channel gas introduction control system is connected with the reaction tank, the flow controller is set on the valve 7 branch and communicated with the external air source, the flow controller is set on the valve 12 branch and communicated with the external hydrogen source, and the pressure gauge is set at On the valve 10 branch road, the valve 1 branch is connec...

Embodiment 3

[0090] Such as Figure 5 As shown, the difference between this embodiment and embodiment 1 is that the device structure is used in a specific performance test, and the required equipment has a corresponding change. In order to make the illustration clear and obvious, the equipment not involved is shown omitted. Specifically, this embodiment is mainly applied to the hydrogen elimination performance test of the catalytic plate under different oxygen concentrations.

[0091] (S200) The structure configured to test the hydrogen elimination performance of the catalytic plate under different oxygen concentrations:

[0092] The valve 8 branch of the multi-channel gas introduction control system is connected to the mixing tank, and the mixing tank is connected to the reaction tank. An oxygen meter is installed on the pipeline between the two, and the valve 2 branch, valve 4 branch, and valve 12 branch are sequentially connected. Connect with the external nitrogen source, oxygen sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com