A test device for detecting the comprehensive performance of denitrification catalyst and its application method

The technology of a denitration catalyst and a test device is applied in the field of test devices for detecting the comprehensive performance of the denitration catalyst, which can solve the problems of time-consuming, labor-intensive, manpower and material consumption, etc., and achieve the effects of convenient use, simple debugging and comprehensive detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

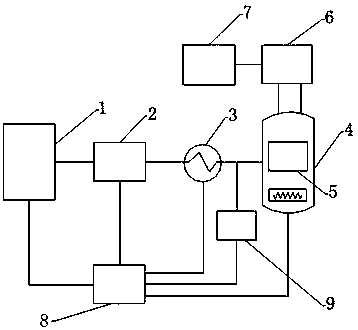

[0070] Such as figure 1 , 2 As shown, the present invention provides a test device for detecting the comprehensive performance of a denitrification catalyst, which includes a multi-channel gas introduction device 1, a mixer 2, a heater 3, a reaction vessel 4, a measurement system 6, a data acquisition system 7, and a control system 8 and auxiliary reaction device 9.

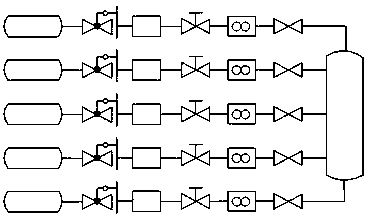

[0071] The multi-channel gas introduction device 1 is used to feed a variety of gases into the mixer 2 for mixing, and it includes gas cylinders, pressure reducing valves, pressure gauges, flow valves, flow meters and check valves connected in sequence; The check valve is connected with the mixer 2, such as figure 2 As shown, from left to right are cylinders, pressure reducing valves, pressure ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com