Multi-color and multi-position pad printing machine

A pad printing machine and pad printing technology, applied in printing machines, rotary printing machines, printing and other directions, can solve the problem that the position of ink taking and printing cannot be changed randomly according to requirements, rigid and other problems, and achieves simple debugging, convenient use, structure and so on. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

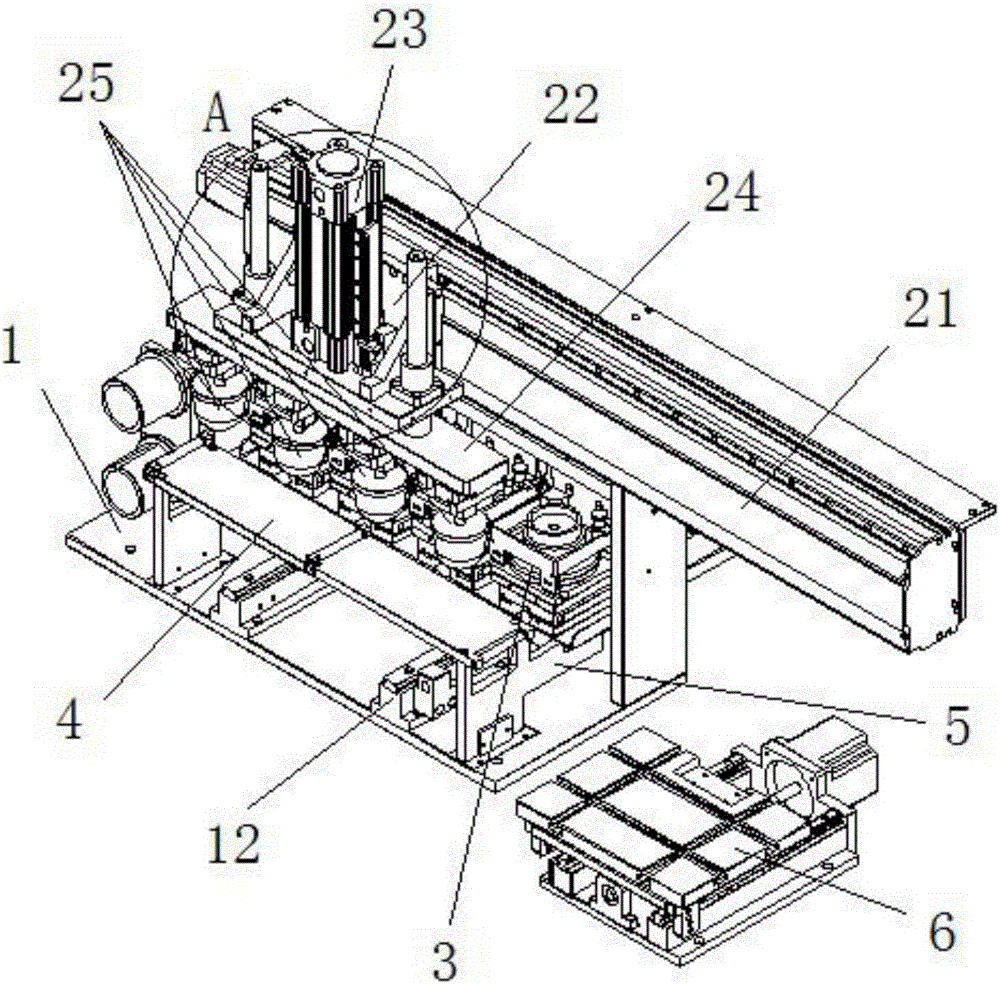

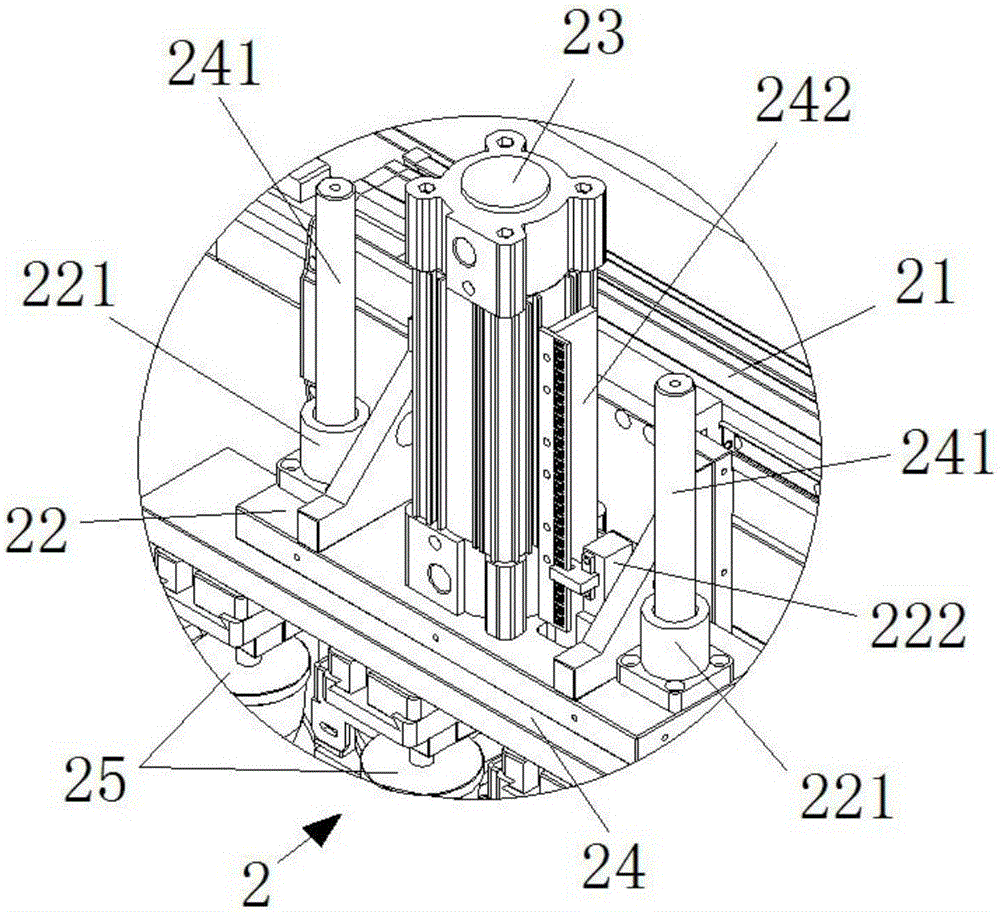

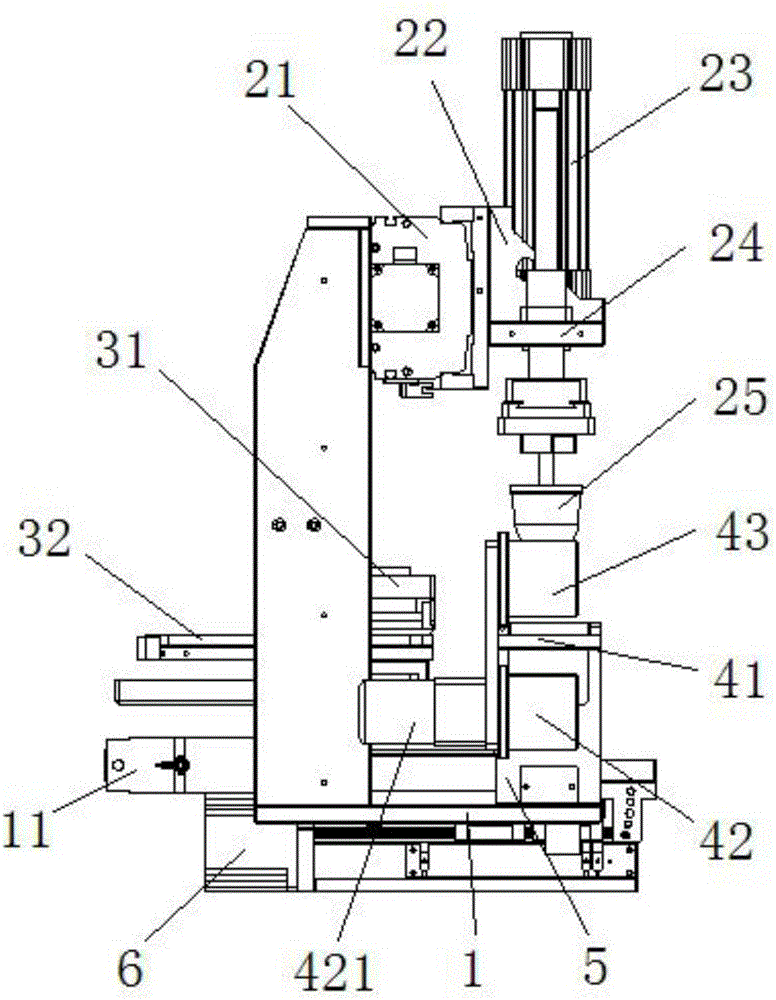

[0065] like figure 1 , Figure 4 , Image 6 and Figure 8 As shown, a multi-color multi-displacement printing machine of the present invention includes a base 1, a pad printing assembly 2 straddling the base 1, a number of inking assemblies 3 located below the pad printing assembly 2, and a plurality of inking assemblies 3 located in front of the pad printing assembly 3. The cleaning assembly 4 and the material holding assembly 6 located on the side of the inking assembly 3 . The inking unit 3 can contain inks of various colors, and one or two patterns can be engraved on one printing plate, so that this pad printing machine can not only complete the simple printing work of single color and single position, but also can print on the product. Print a color pattern composed of different color blocks, even by changing the position of the ink, the pattern can be printed on the position with double the number of printing plates; that is, the two-color machine can print at least 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com