Single-wheel deflection optical fibre twisting equipment

A yaw, optical fiber technology, applied in glass manufacturing equipment, manufacturing tools, glass production and other directions, can solve the problems of complex transmission chain of the yaw mechanism, difficult assembly and debugging, complex structure, etc., to achieve simple and convenient debugging and continuous transmission. Stable and reliable, the effect of avoiding fiber swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

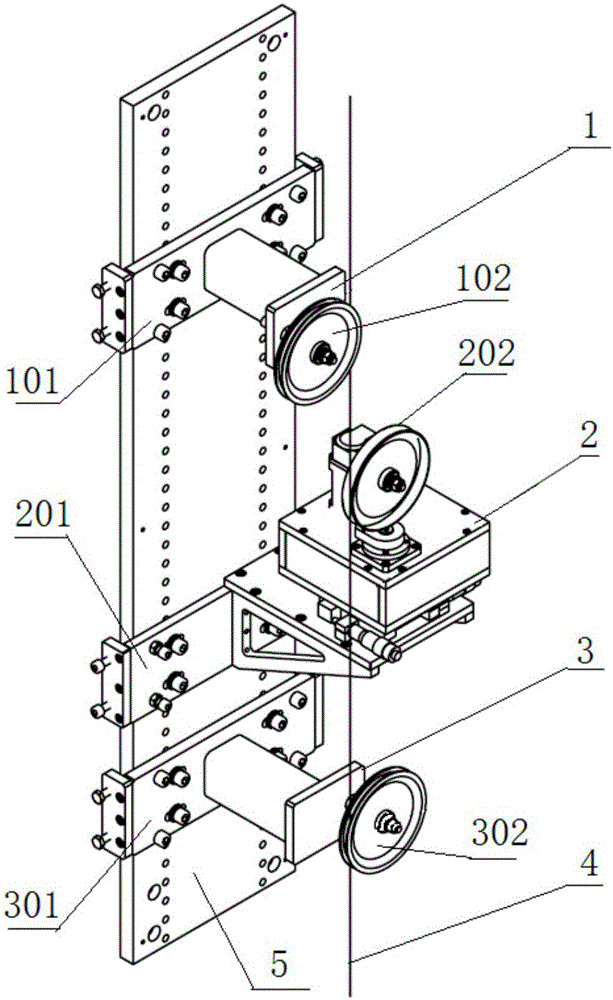

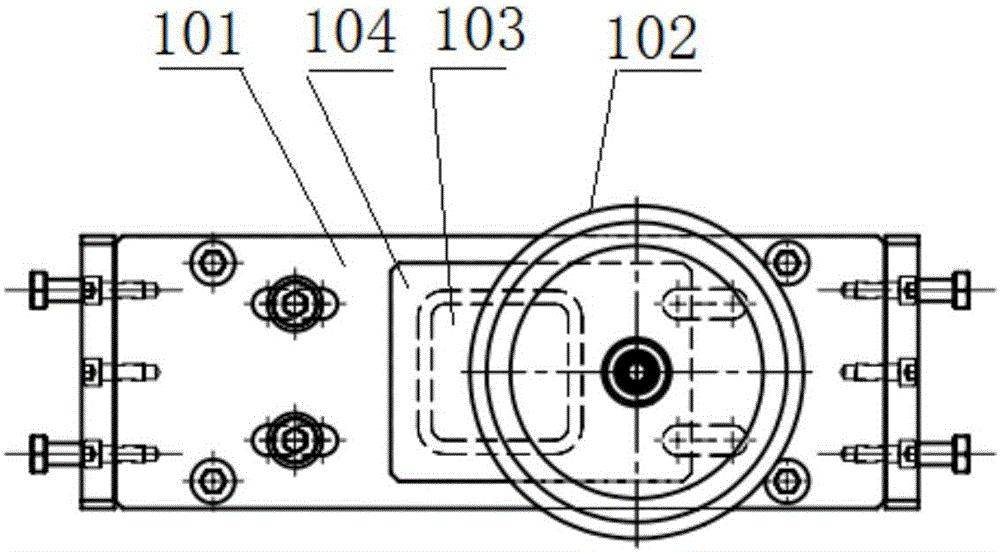

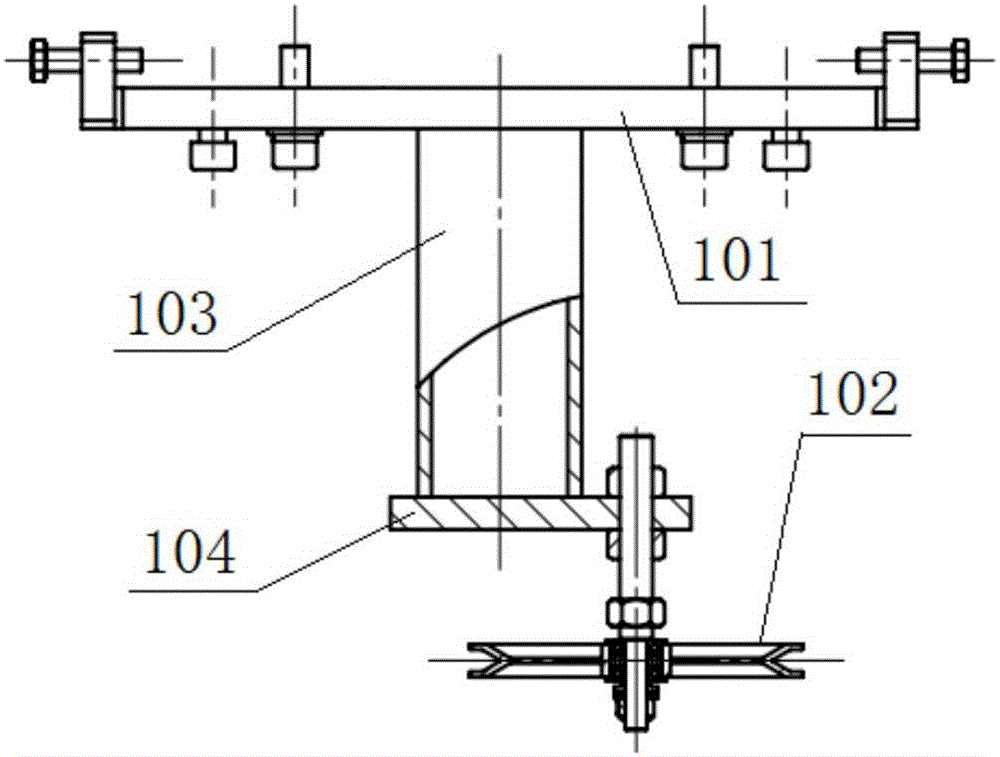

[0023] Embodiment 1: as attached figure 1 As shown, the frame 5 is erected and fixed, and the upper positioning wheel set 1, the single wheel yaw mechanism 2 and the lower positioning wheel set 3 are installed sequentially on the frame 5 from top to bottom, wherein, the rear portion of the upper positioning wheel set 1 passes through the upper The positioning seat 101 is installed on the frame 5, and the upper positioning guide wheel 102 is installed on the front side of the upper positioning seat 101. The yaw wheel 202 is installed on the side, the rear part of the lower positioning wheel group 3 is installed on the frame 5 through the lower positioning seat 301, the lower positioning guide wheel 302 is installed on the front side of the lower positioning seat 301, the upper positioning guide wheel 102 and the lower positioning guide wheel 302 There are respectively guide wheel grooves on the outer edge of the yaw wheel 202, and the optical fiber 4 is vertically embedded in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com