Active load reducing control system and method for large wind turbine blade

A technology for wind turbine blades and active load reduction, applied in the control of wind turbines, engine control, wind turbines, etc., can solve problems such as difficulty in meeting blade load reduction requirements, the influence of fan blade load cannot be ignored, and difficult mathematical models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

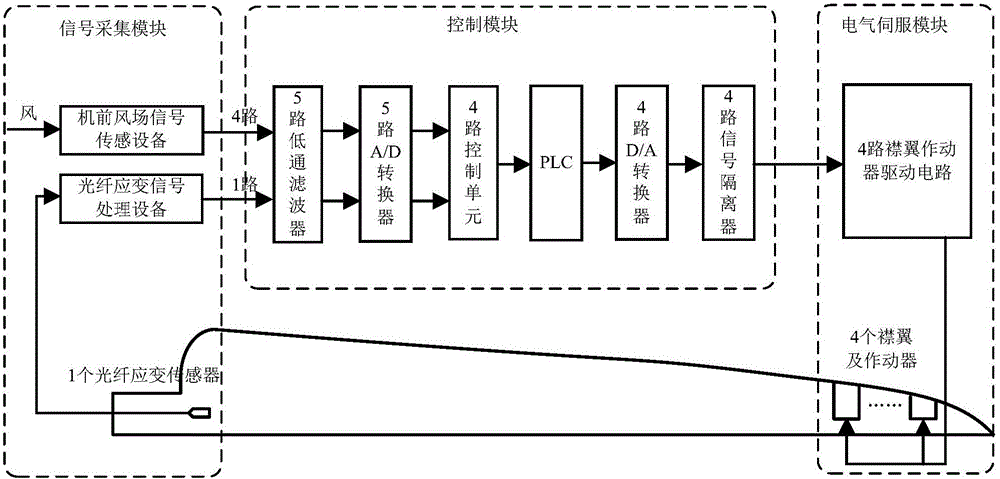

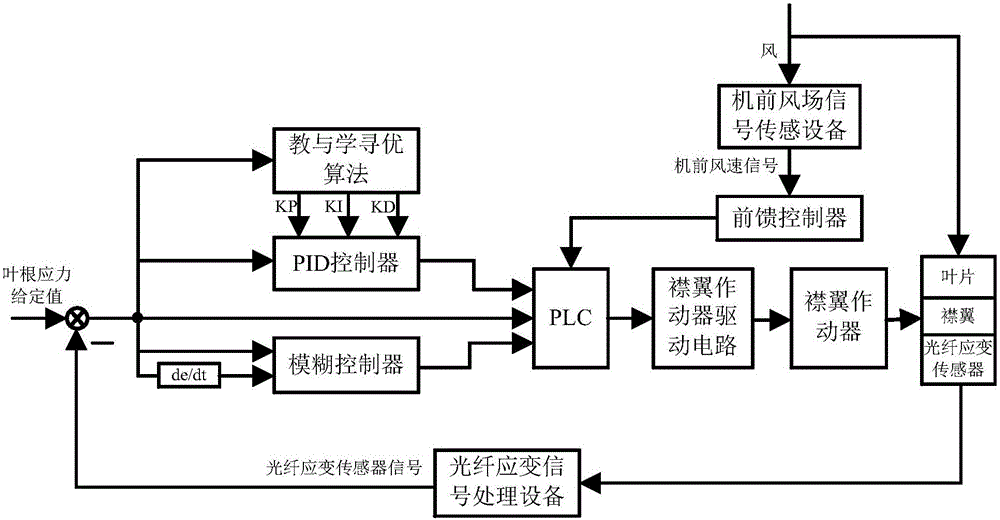

[0048] Such as figure 1 A large-scale wind turbine blade active load reduction control system is shown, the system includes a signal acquisition module, a control module and an electrical servo module;

[0049] The signal acquisition module includes an optical fiber strain sensor, a wind field signal sensing device in front of the machine, and an optical fiber strain signal processing device; the control module includes a 5-way low-pass filter, a 5-way analog-to-digital converter, a 4-way control unit, and a PLC , 4-way digital-to-analog converters and 4-way signal isolators; the electrical servo module includes 4-way flap actuator drive circuits and 4-way flap actuators;

[0050] The optical fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com