Laser engraving device for plastic spectacle frame

A laser engraving and spectacle frame technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy contamination, scraping, poor printing effect, large labor consumption, etc., to avoid wear and tear The effect of material, material clamping is convenient and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

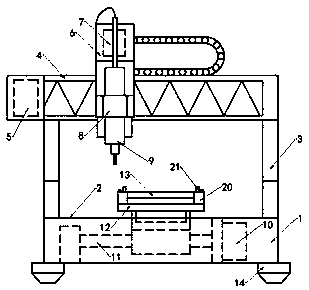

[0010] Depend on figure 1 Known, a kind of laser engraving device for plastic spectacle frame, comprises machine box 1, and described machine box 1 is provided with workbench 2, and workbench 2 two sides are provided with support block 3, is connected with crossbeam between two support blocks 3 4. The left end of the crossbeam 4 is provided with a driving device I5, and the inside of the crossbeam 4 is provided with a screw rod I connected with the driving device I5; the screw rod I is movably connected with a longitudinal moving part 6, and the longitudinal moving part 6 is controlled by the driving device I5 Carry out left and right movement; the top of the longitudinal moving part 6 is provided with a driving device II7, and the inside of the longitudinal moving part 6 is provided with a screw rod II connected with the driving device II7; the screw rod II is movably connected with a moving seat 8, and the moving seat 8 is fixed with a laser engraving part 9, and the laser e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com