Patents

Literature

71results about How to "Improve code quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of acrylic resin code spray ink

An acrylic resin ink for ink-jet printing on the surface of glass and polypropene plastics is prepared from acrylic resin, oil-soluble dye, electric conducting salt, adhesion improver EP2323, ethanediol ether, butanone and acetate. Its advantages are high adhesion and high resistance to rubbing.

Owner:SHANGHAI LELI SPATTER PRINTING TECH

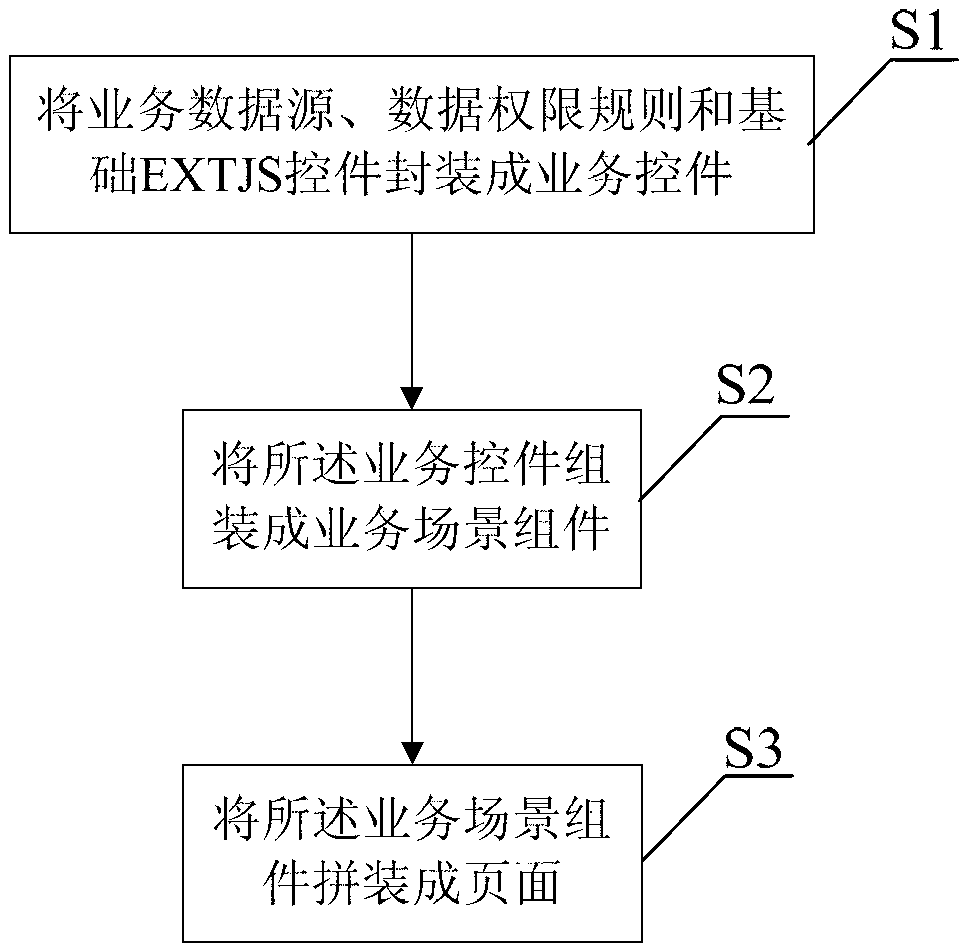

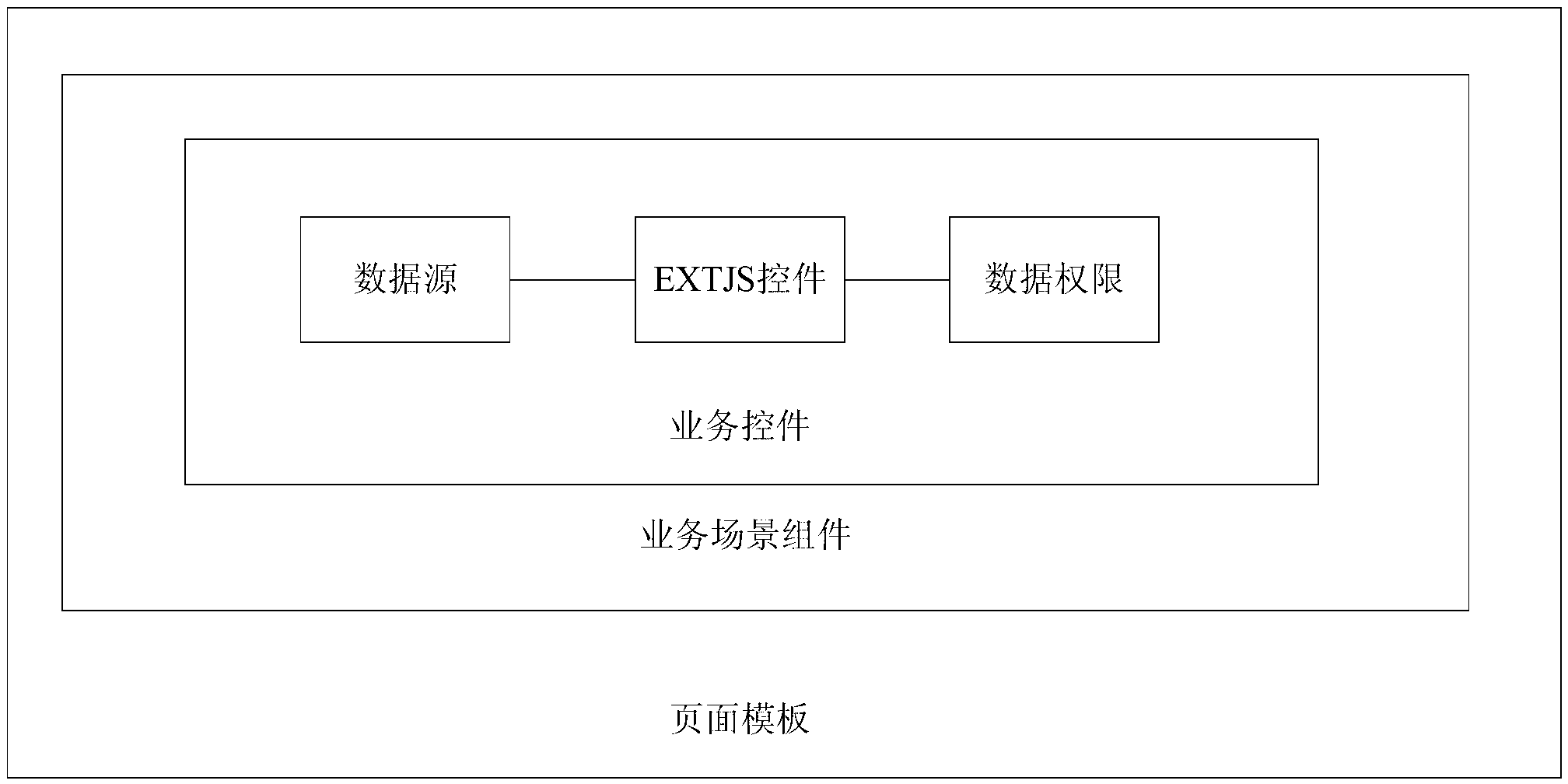

Method for rapidly developing BI platform based on EXTJS

InactiveCN103268227AImprove code qualityReduce labor costsSpecific program execution arrangementsService controlDEVS

The invention provides a method for rapidly developing a BI platform based on an EXTJS. The method for rapidly developing the BI platform based on the EXTJS is characterized by comprising the steps of packaging a service data source, data authority rules and an EXTJS control into a service control, assembling the service control into a service scene assembly, and assembling the service scene assembly into a page. According to the adoption of the method for rapidly developing the BI platform based on the EXTJS, due to the fact that most page codes are reused during development, the quality of the codes is high. Due to the adoption of the method for rapidly developing the BI platform based on the EXTJS, labor cost is also greatly reduced. Due to the fact that a learning curve of the EXTJS is long, workers who can skillfully use the EXTJS basically need long years of working, and middle and high ranking workers with high salaries are often brought. After the method for rapidly developing the BI platform based on the EXTJS is applied, only a proper service control is required to be selected on a proper scene, too many high-ranking development workers who are skilled at the EXTJS are not required, and only junior programmers are required.

Owner:上海吉贝克信息技术有限公司

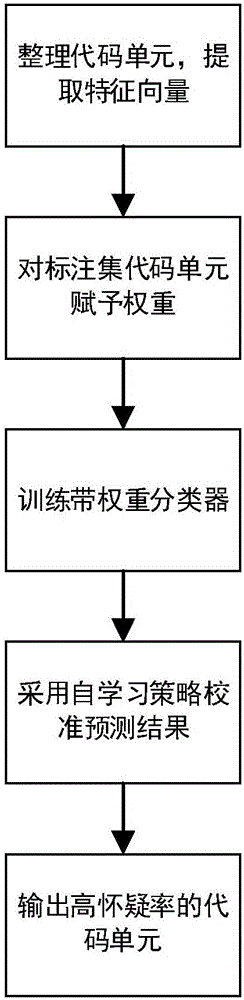

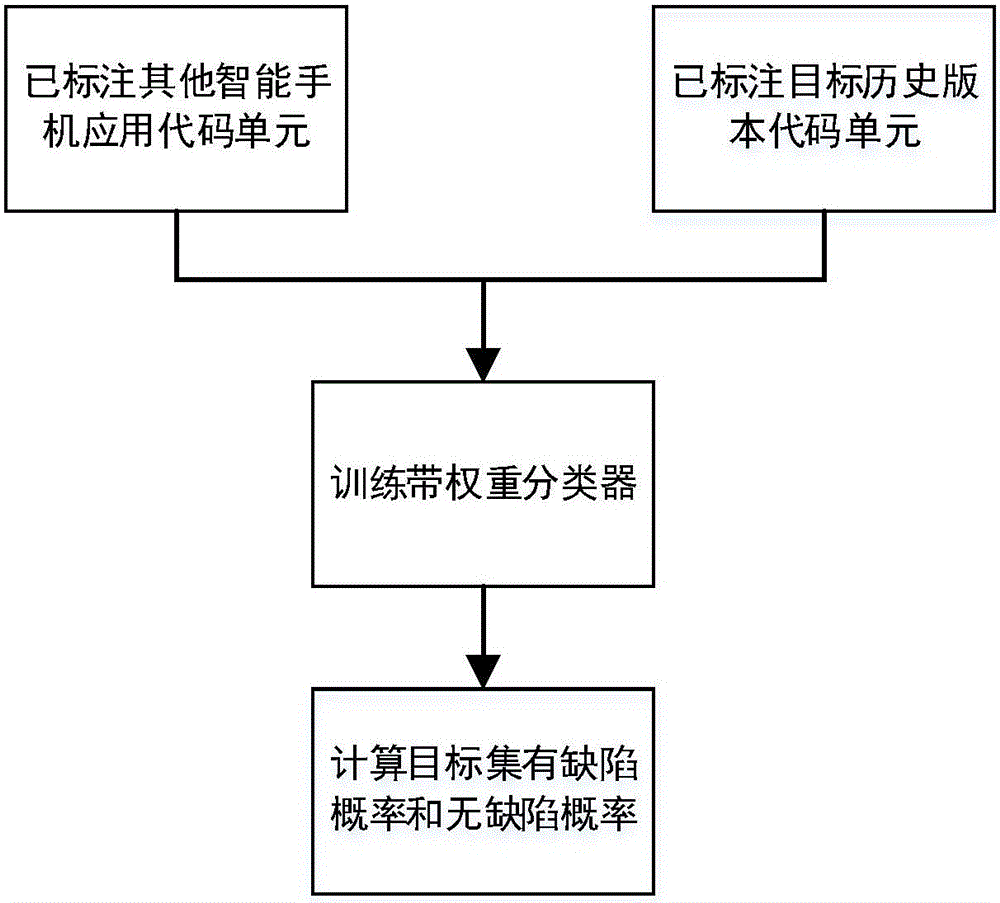

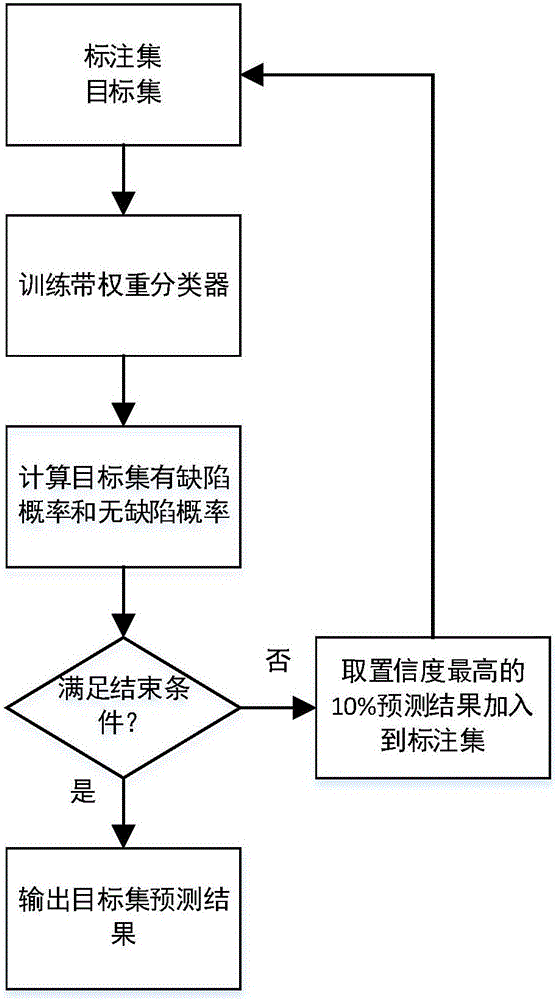

Method for code failure prediction in smartphone application and development

ActiveCN106502909AImprove efficiencyImprove code qualitySoftware testing/debuggingFeature vectorTheoretical computer science

The invention discloses a method for code failure prediction in smartphone application and development. The method comprises a step 1) of tidying code units, distinguishing a label set and a target set, defining characteristic indexes, and extracting characteristic vectors; a step 2) of endowing weights to the code units of the label set based on the characteristic vectors; a step 3) of training a weighted classifier, and calculating the defectiveness probability and no-defect probability of the code units of the target set; a step 4) of adopting a self-learning strategy to correct predicted results, and repeating the steps until prediction results calculated in a preceding time and a subsequent time are similar to or reach given iteration times; and a step 5) of outputting the code units with a high suspiciousness ratio in the target set. According to the method, data of historical versions of target smartphone applications and other smartphone applications is used, the characteristic indexes are defined in the code unit level, a machining learning technology is applied, the code units which possibly contain defects are predicted, and defective code units in the smartphone applications are positioned quickly and accurately. The method has simplicity in calculation, defective codes can be positioned quickly and effectively, and the method is suitable for development and maintenance of the smartphone applications.

Owner:NANJING UNIV

Laser engraving machine

The invention aims to provide a laser engraving machine which is high in code printing efficiency, good in quality and wide in application range. The laser engraving machine comprises a machine frame, a laser engraving unit and a feeding unit, wherein the laser engraving unit is arranged on the machine frame, and the feeding unit right faces the laser engraving unit. The laser engraving unit comprises a laser device and a scanning camera which horizontally move along the machine frame. The feeding unit comprises a feeding belt which right faces the laser device and the scanning camera. The feeding belt is driven by a transmission mechanism on the machine frame. According to the laser engraving machine, using of wastage materials is avoided, and the using cost is greatly reduced; and the code printing quality is high, and compared with label printing or pasting, the phenomena of defacing, scraping, disengagement and the like are avoided.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

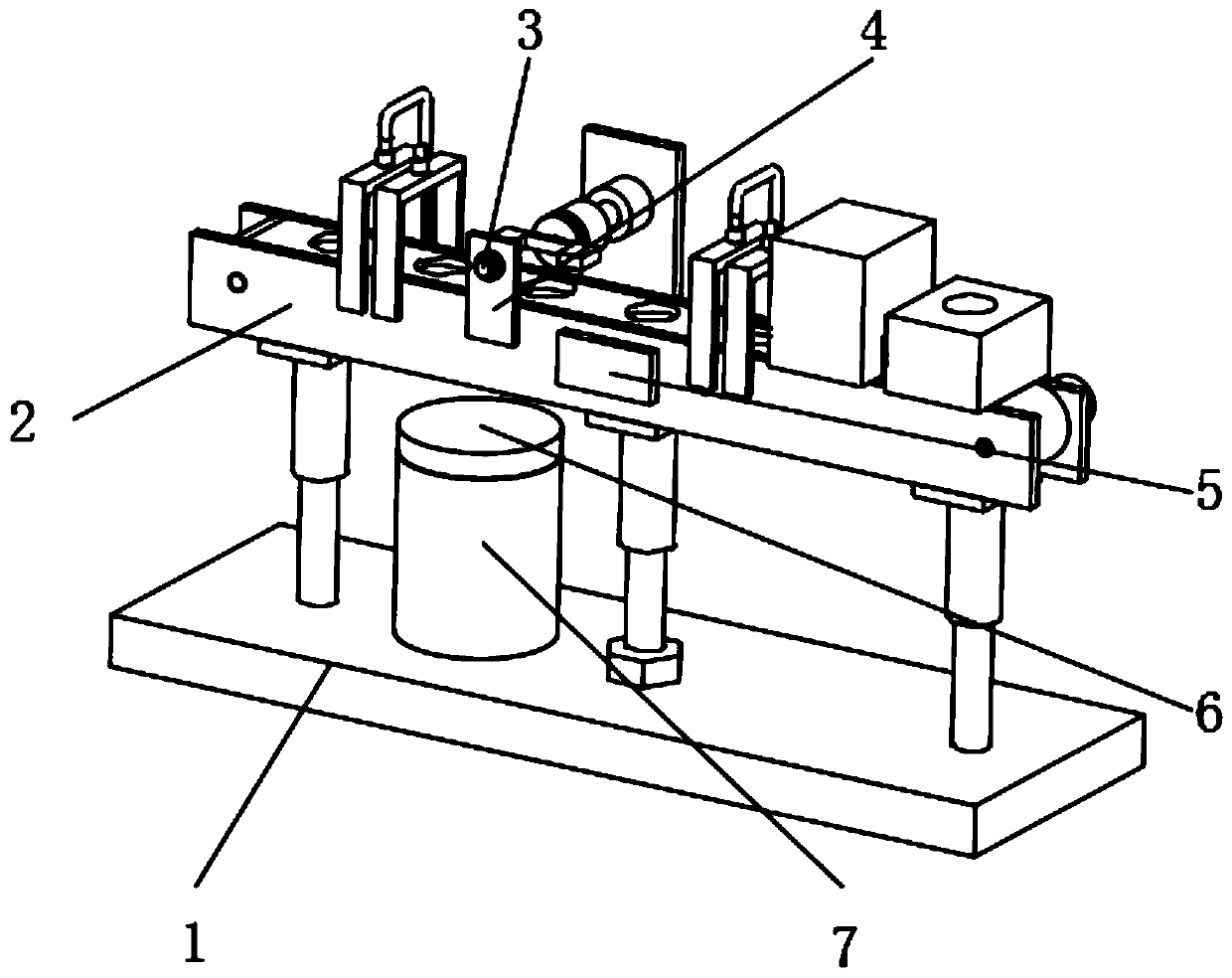

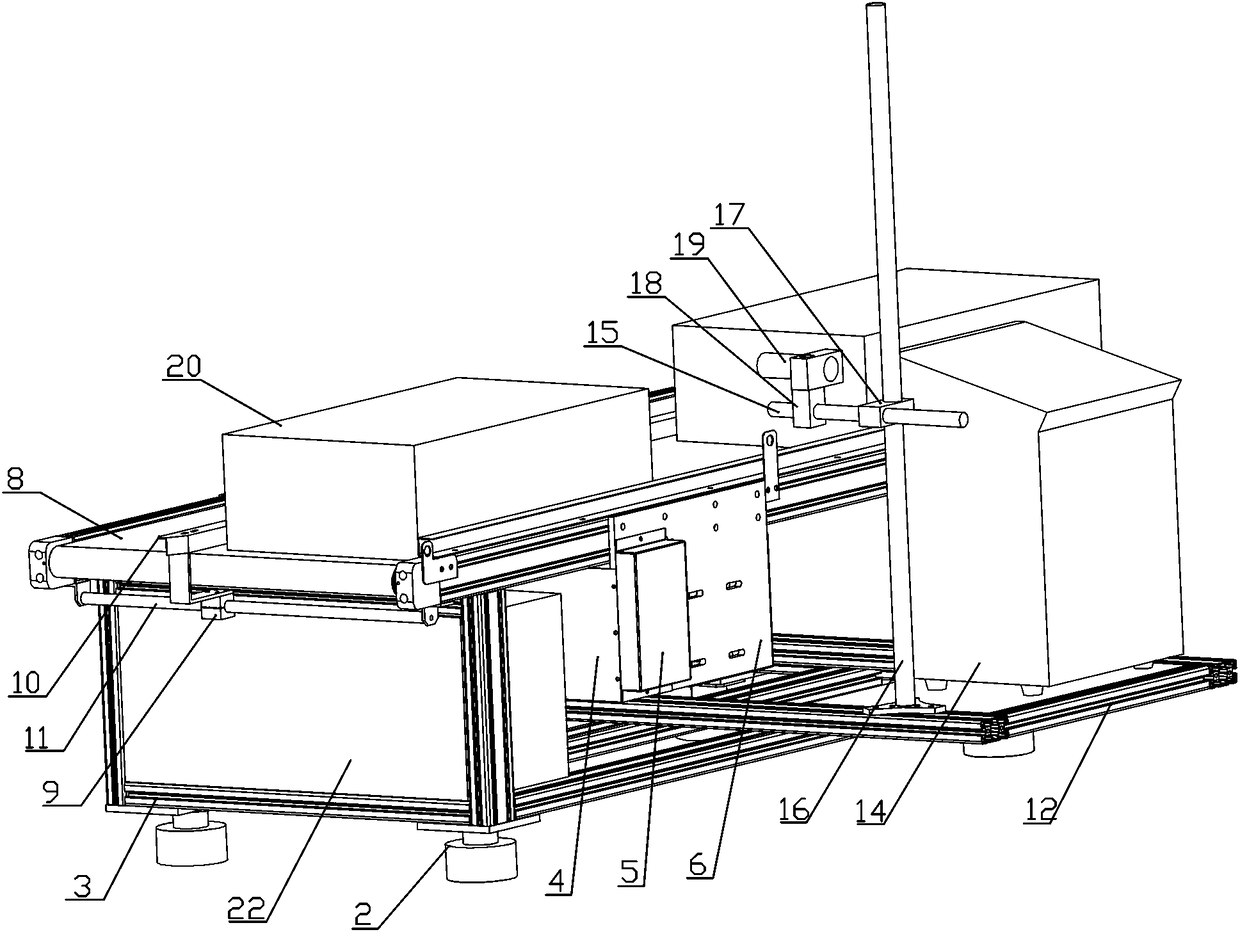

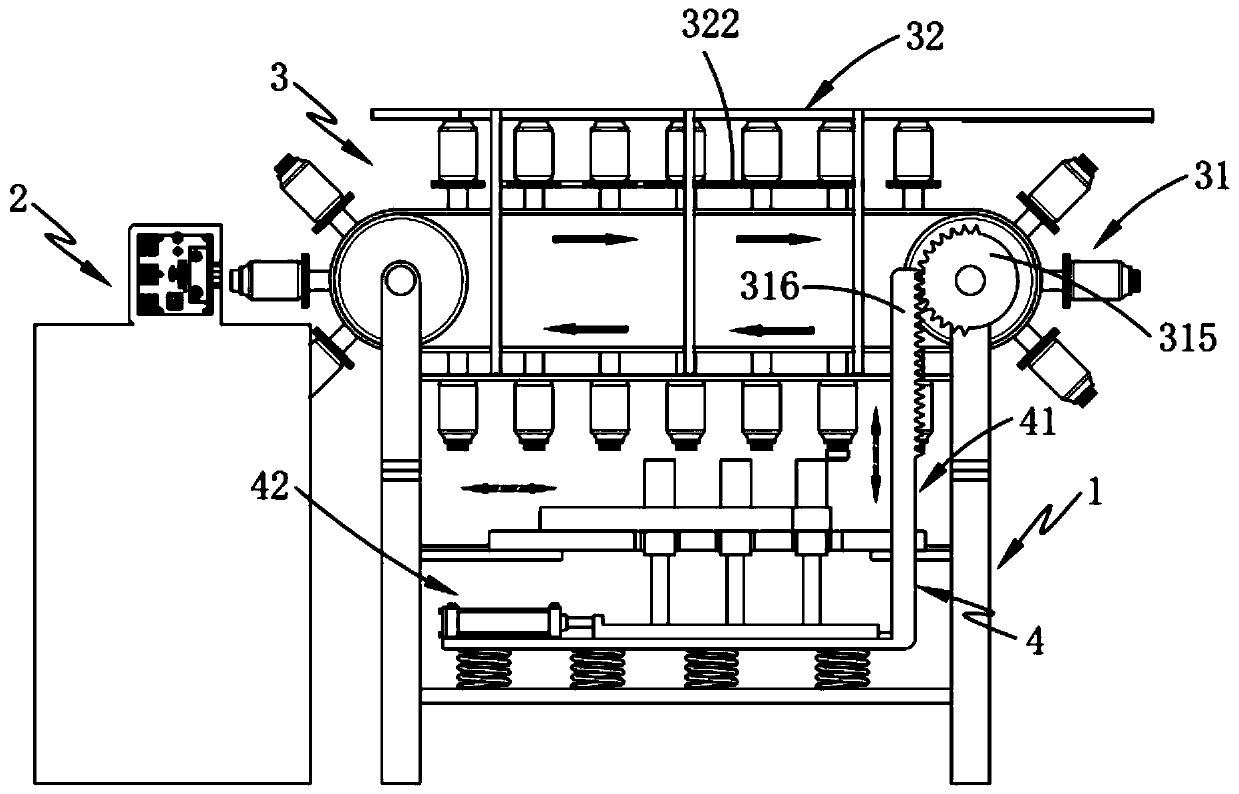

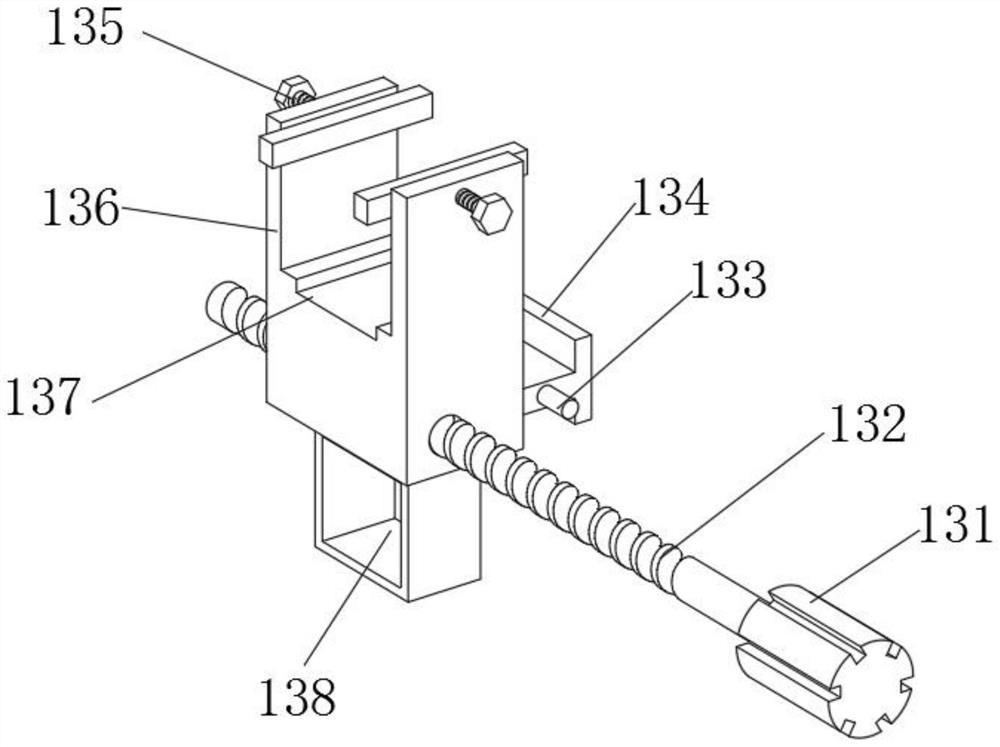

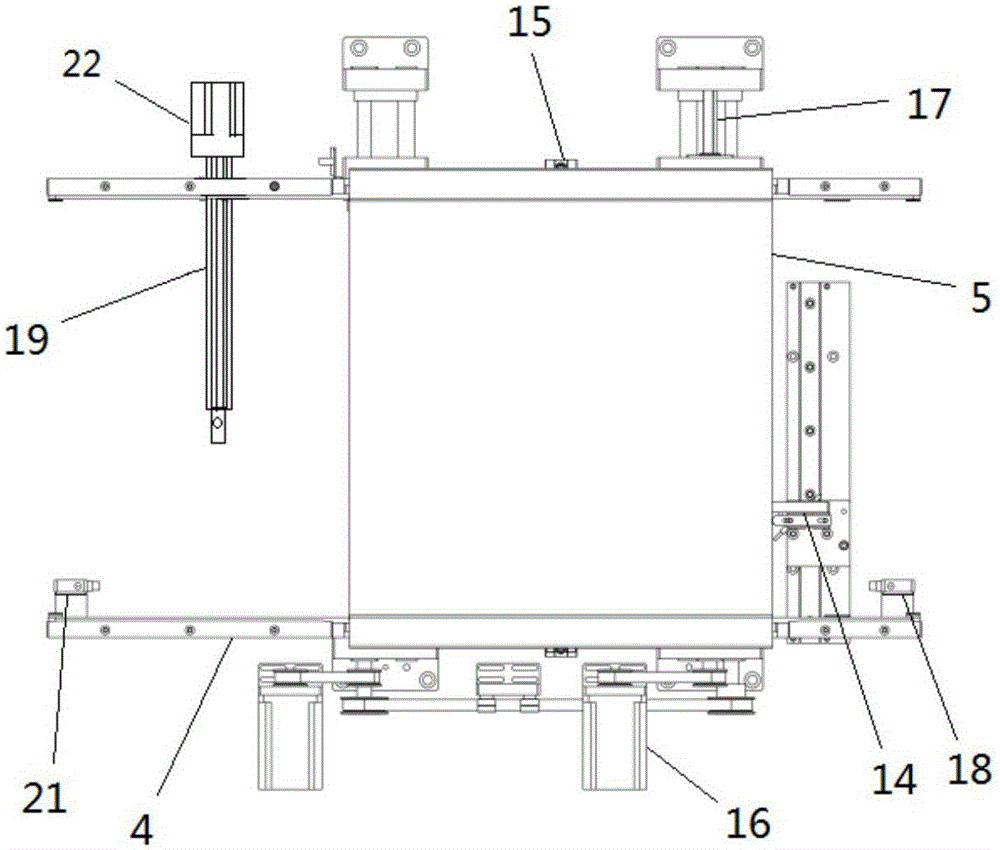

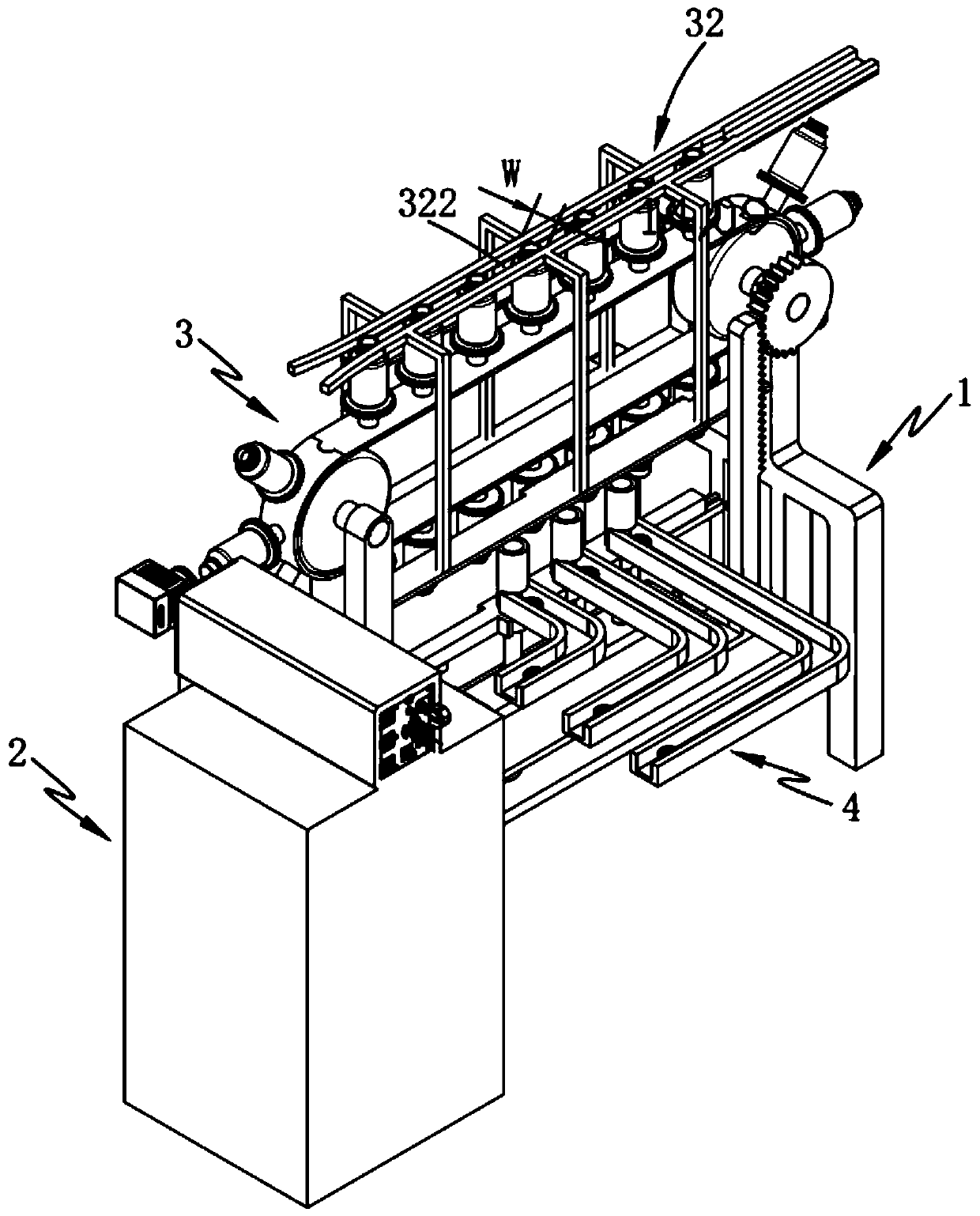

Code spraying printer for plastic packaging box and capable of facilitating ink adding

InactiveCN111391518AReduce process stepsImprove coding efficiencyTypewritersOther printing apparatusPlastic packagingComputer printing

The invention discloses a code spraying printer for a plastic packaging box and capable of facilitating ink adding, and relates to the technical field of packaging box code spraying. In order to solvethe problem that dual faces cannot be subjected to one-time code spraying, the code spraying printer is specifically characterized in that a height adjusting mechanism is mounted on the outer wall ofthe top of a base, two parallel side plates are mounted on the top of the height adjusting mechanism, conveying mechanisms are arranged on the inner walls of the two side plates, two induction code spraying mechanisms, turnover mechanisms and positioning mechanisms are mounted on the tops of the side plates, an ink bucket is fixed to the outer wall of the top of the base through a bolt, the outerwall of the top of the ink bucket is fixedly provided with a bucket cover through a bolt, the outer wall of one side of one side plate is fixedly provided with a control main board through a bolt, each conveying mechanism comprises a conveying motor and a conveying belt, the two induction code spraying mechanisms and the turnover mechanisms are mounted, the two induction code spraying mechanismscan carry out self-induction code spraying, in cooperation with the turnover mechanisms, one-time dual-face code spraying can be achieved, the process procedure can be saved, and the code spraying efficiency can be improved.

Owner:金元萍

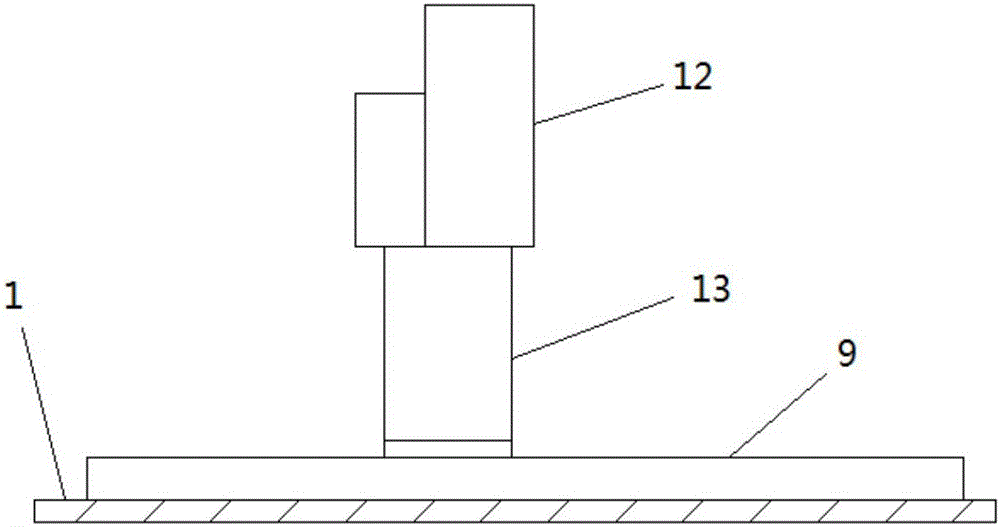

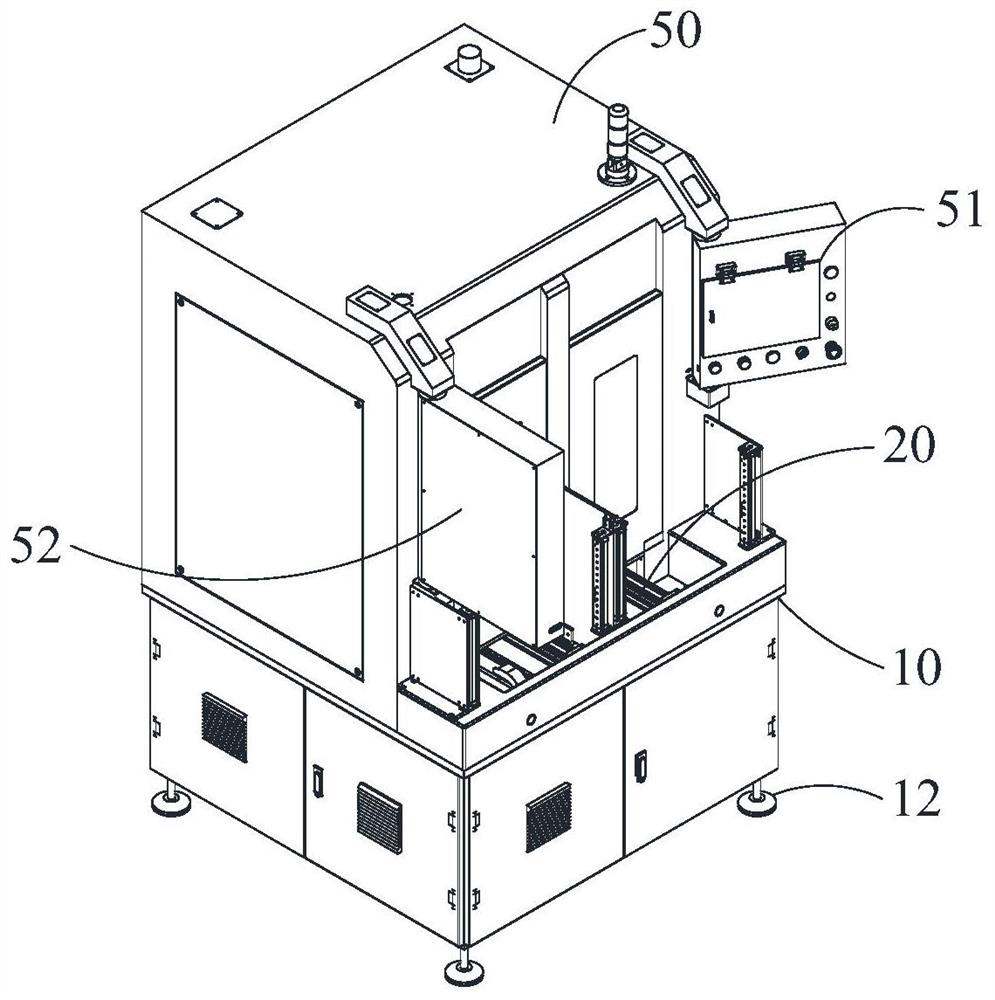

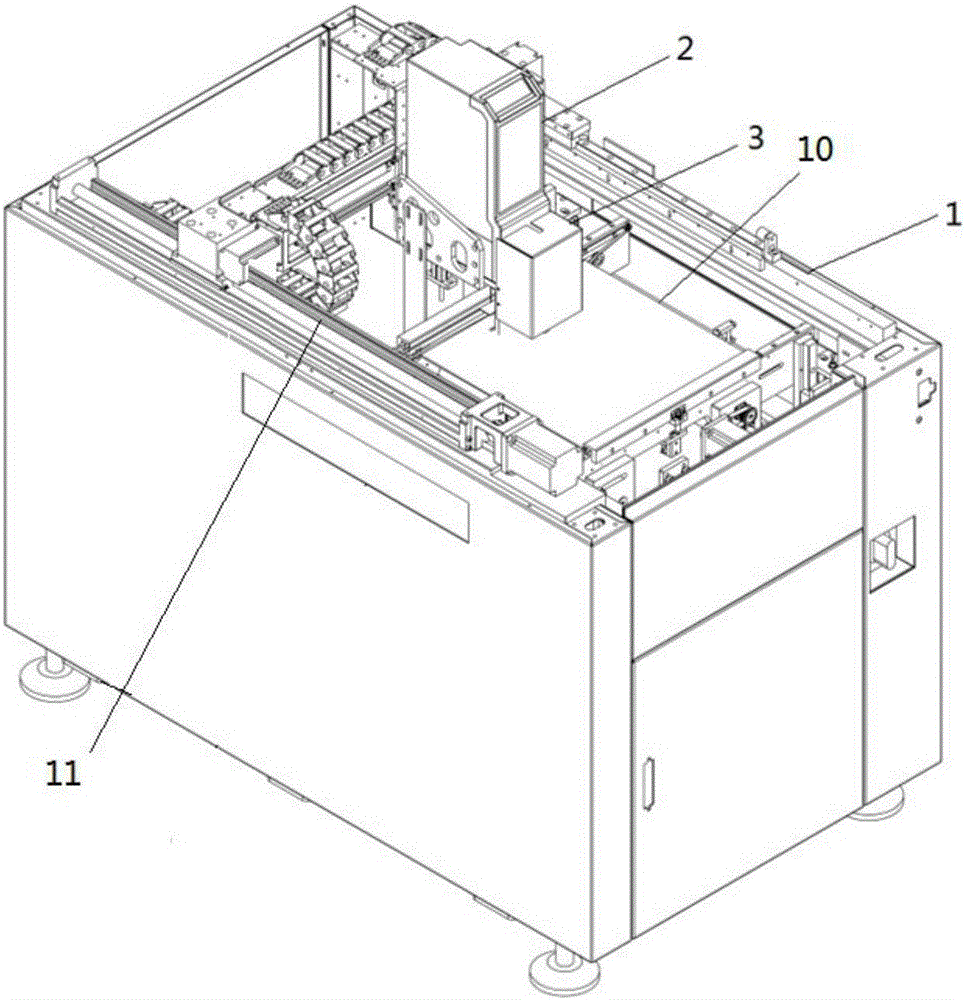

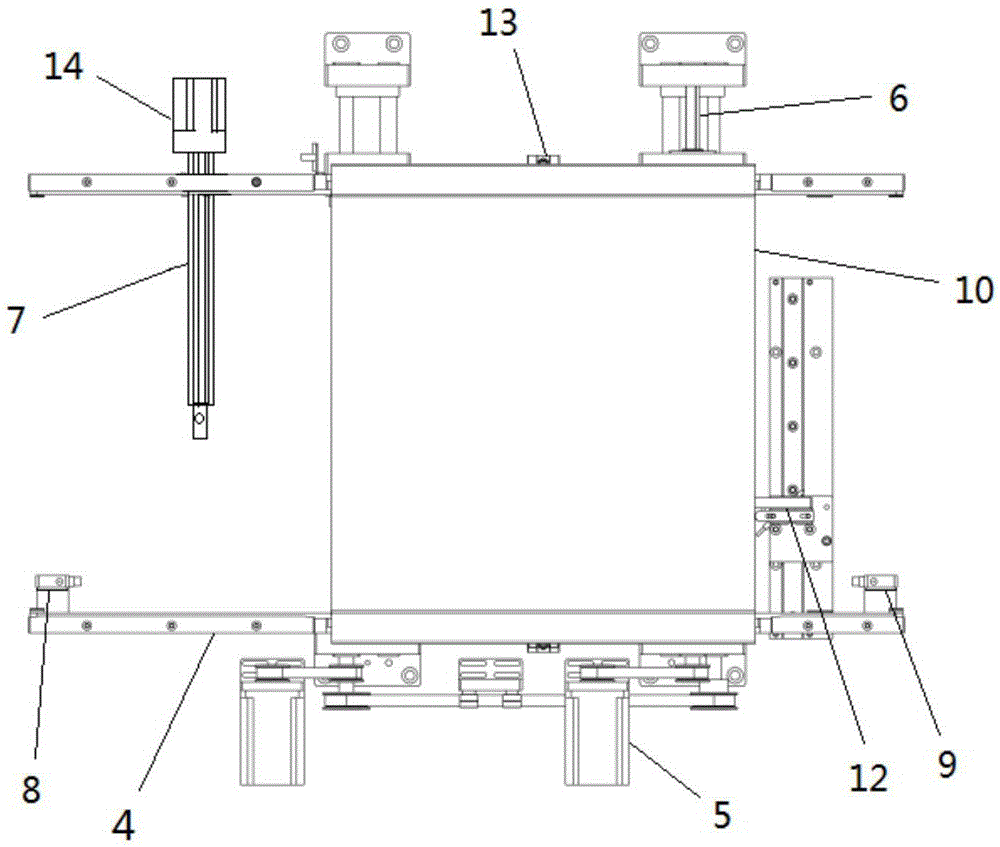

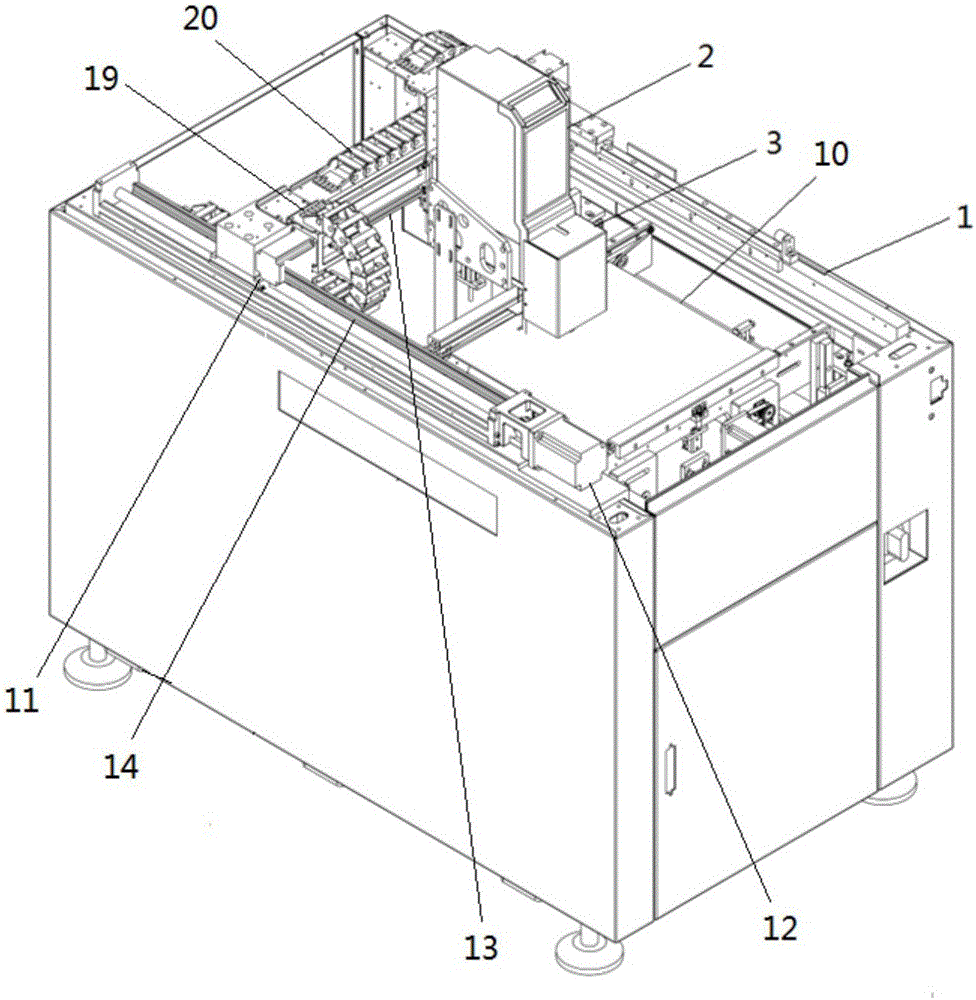

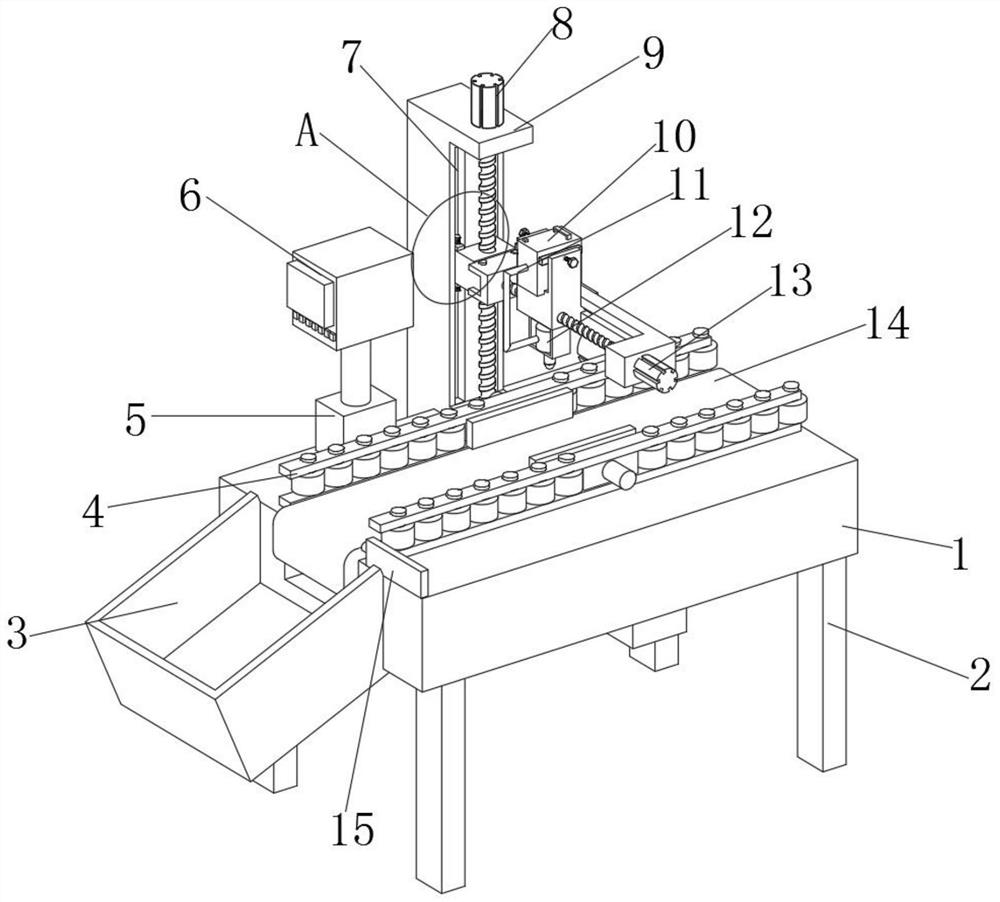

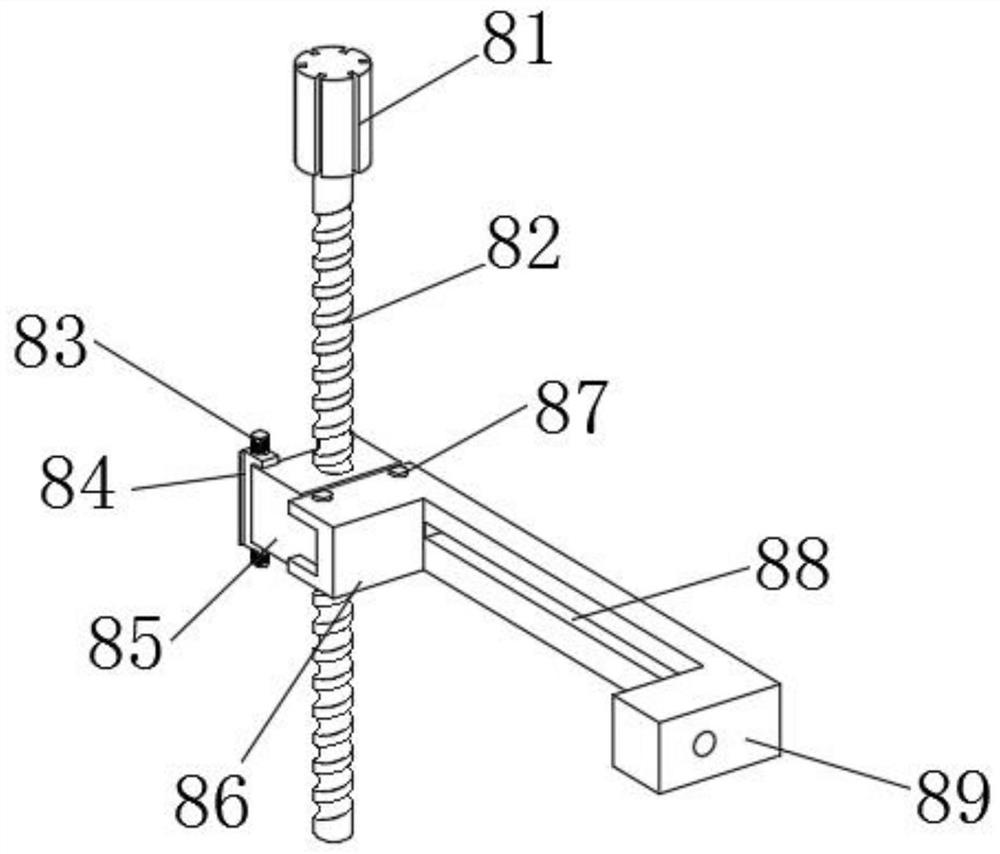

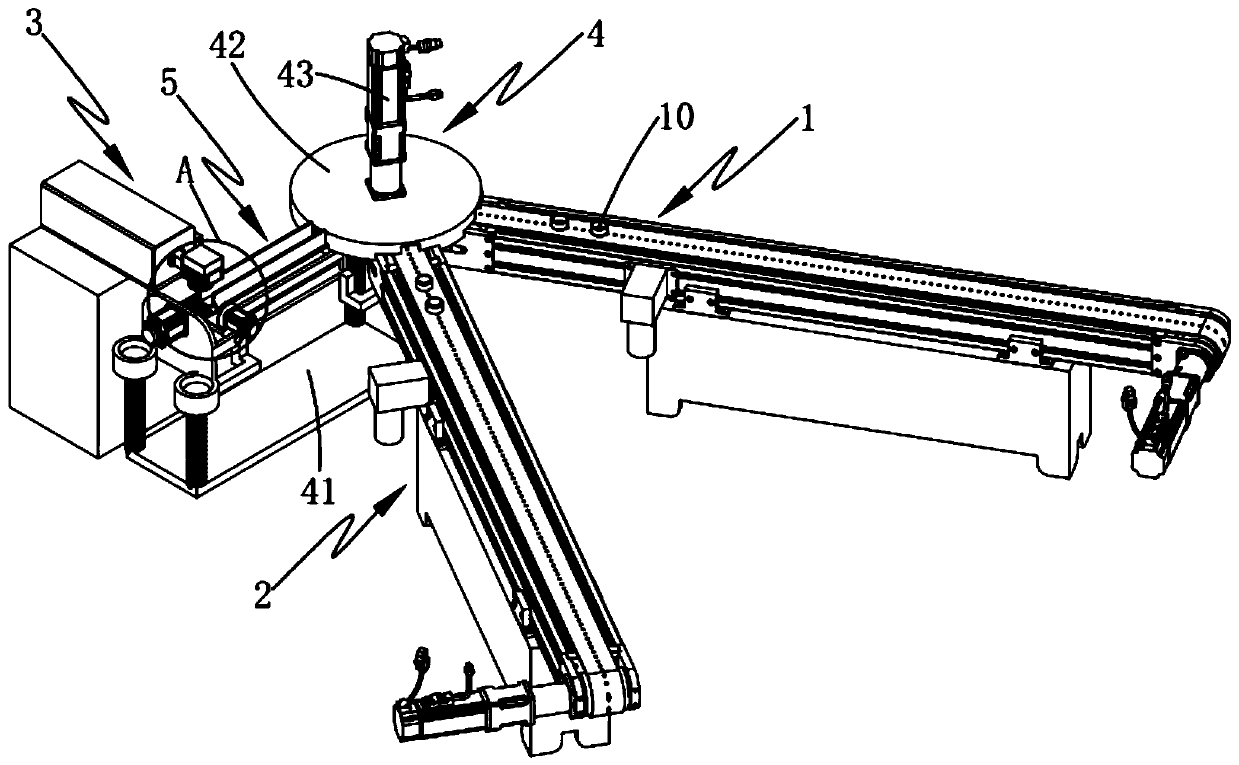

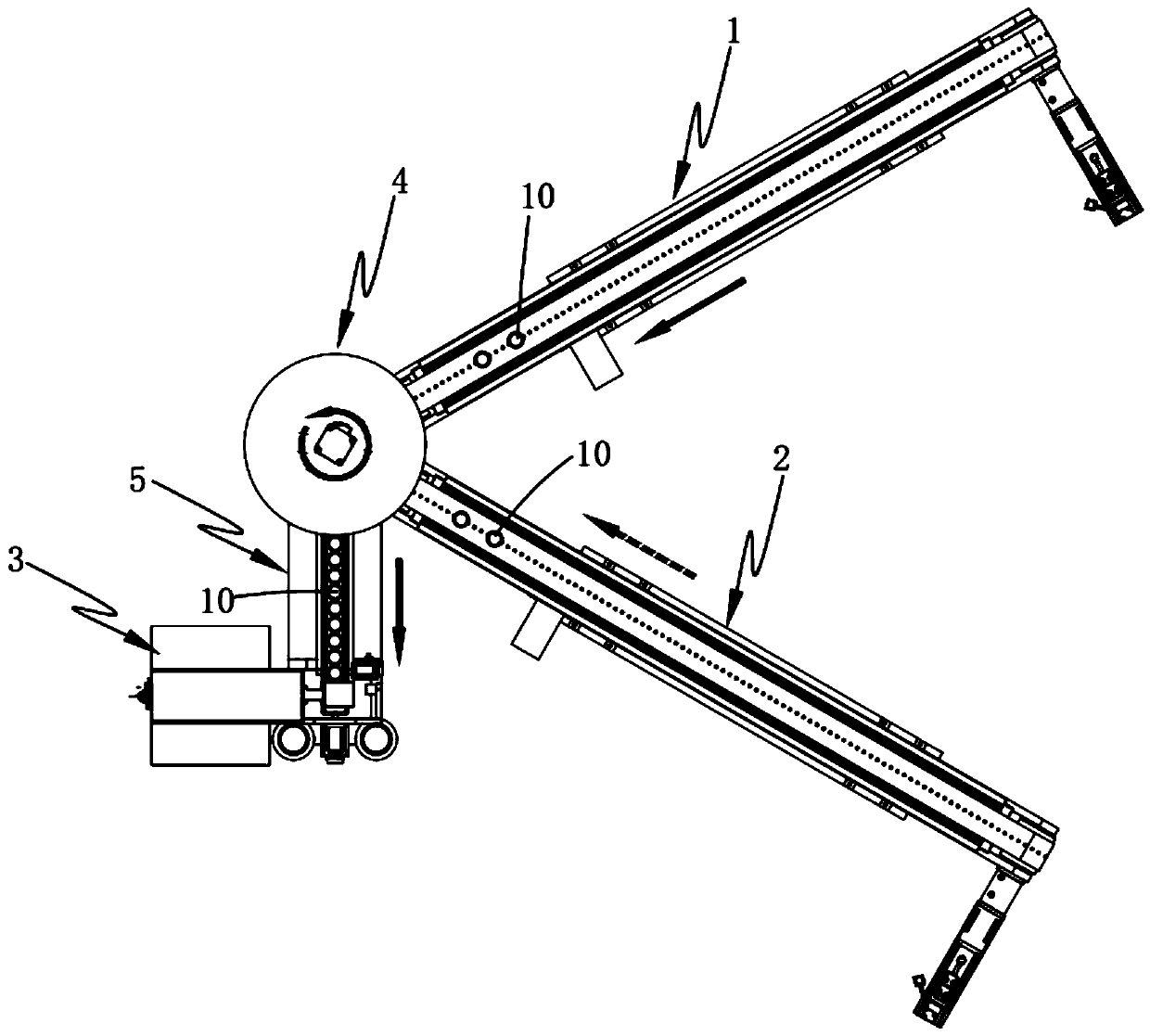

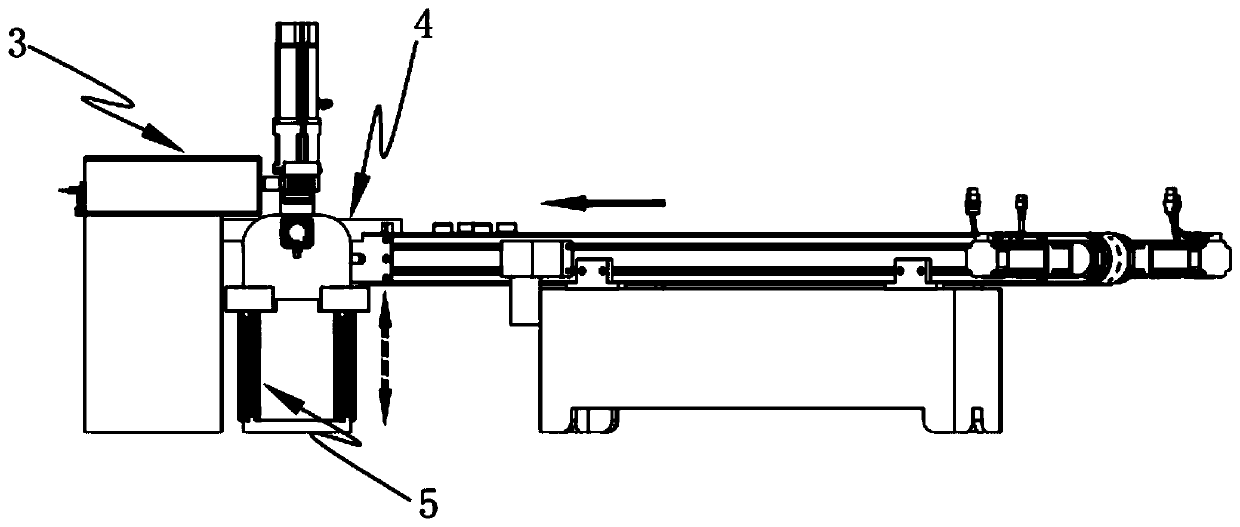

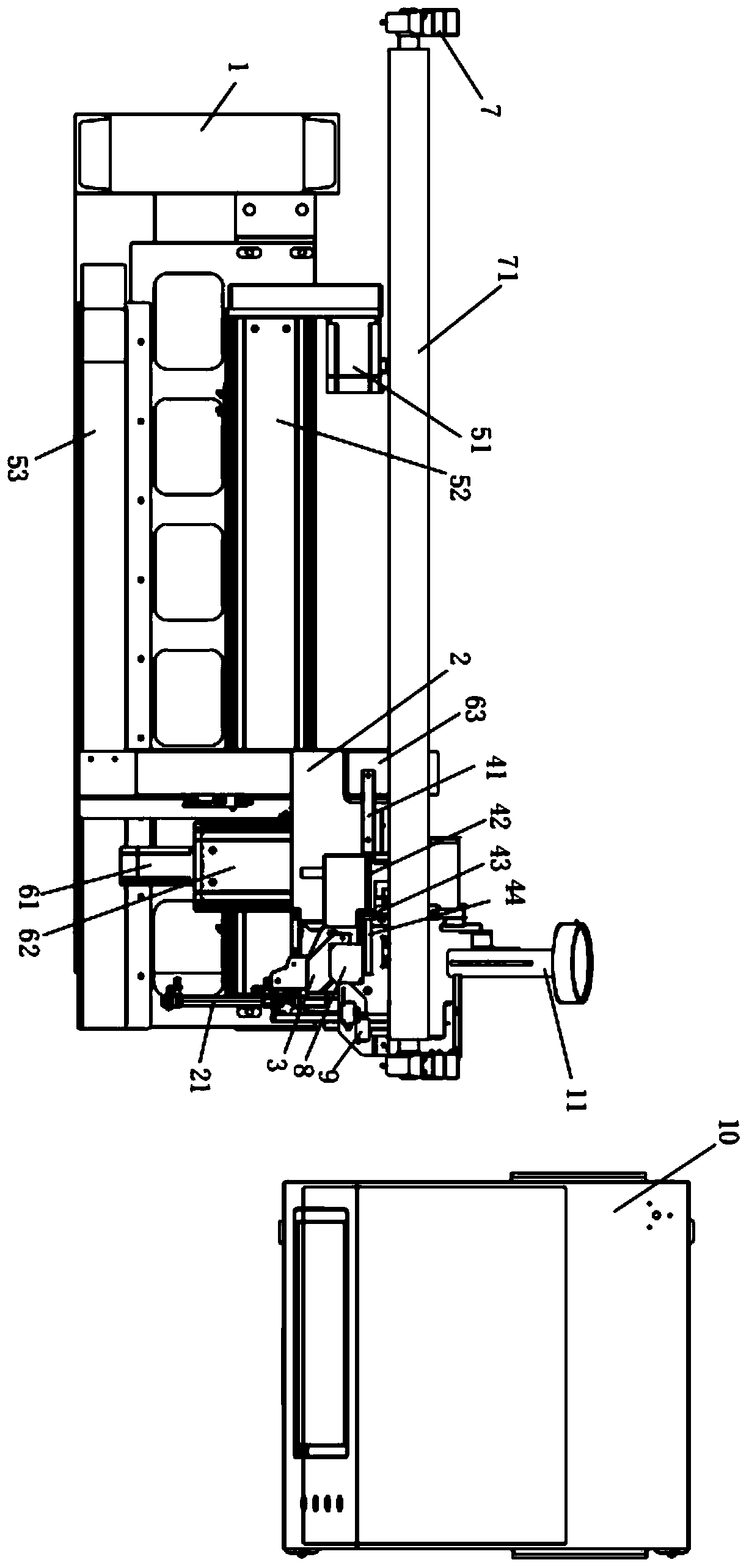

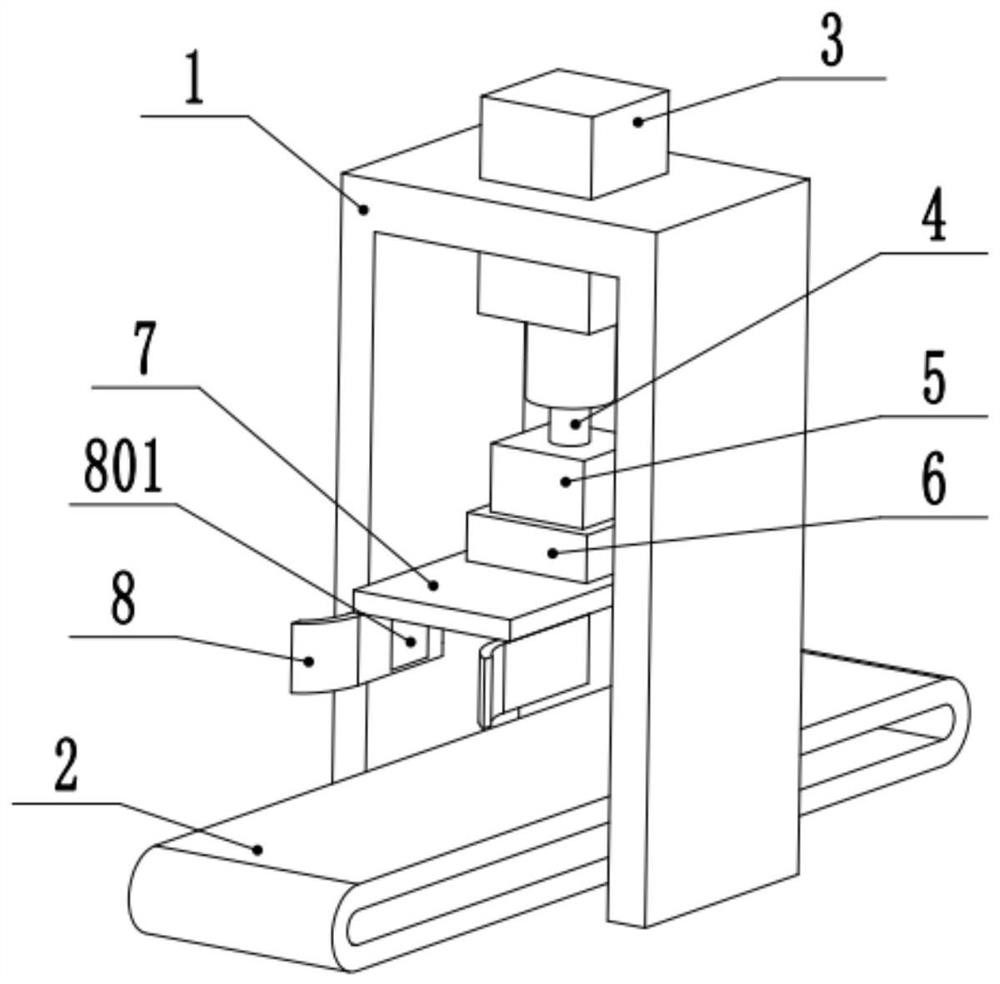

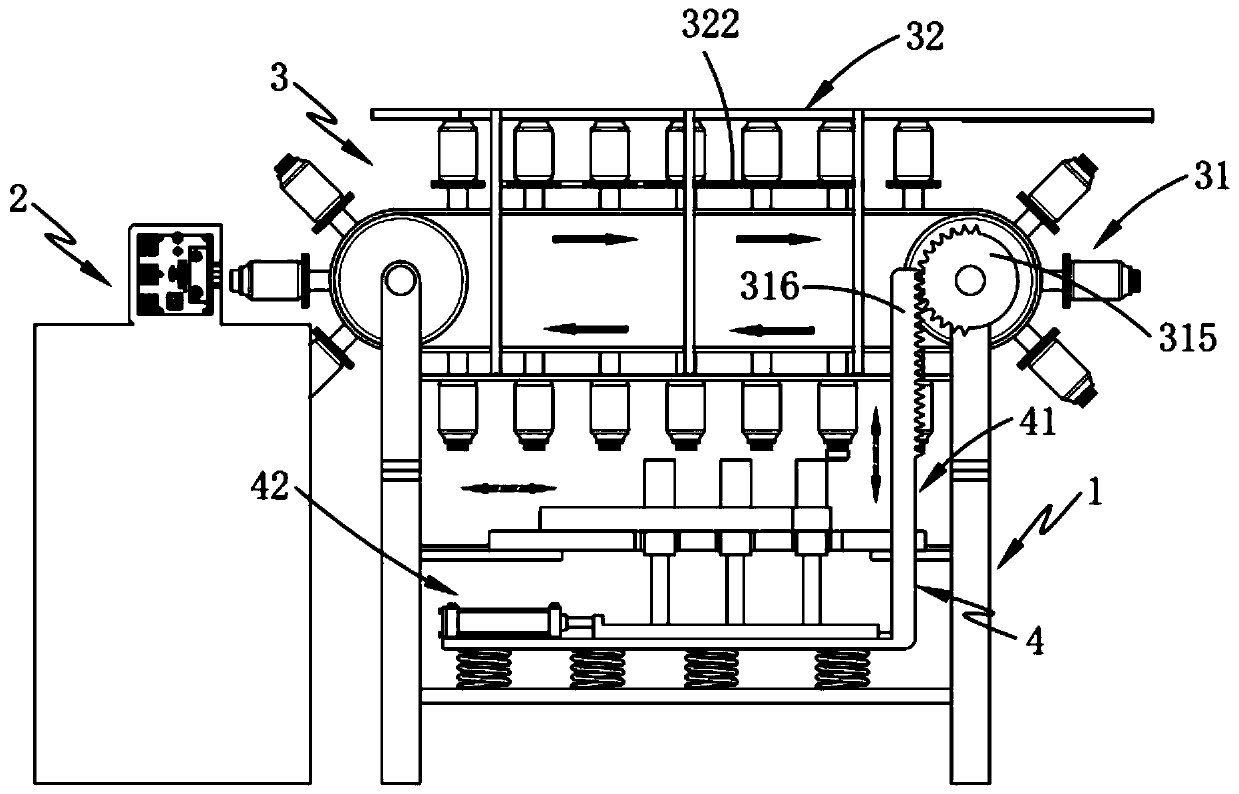

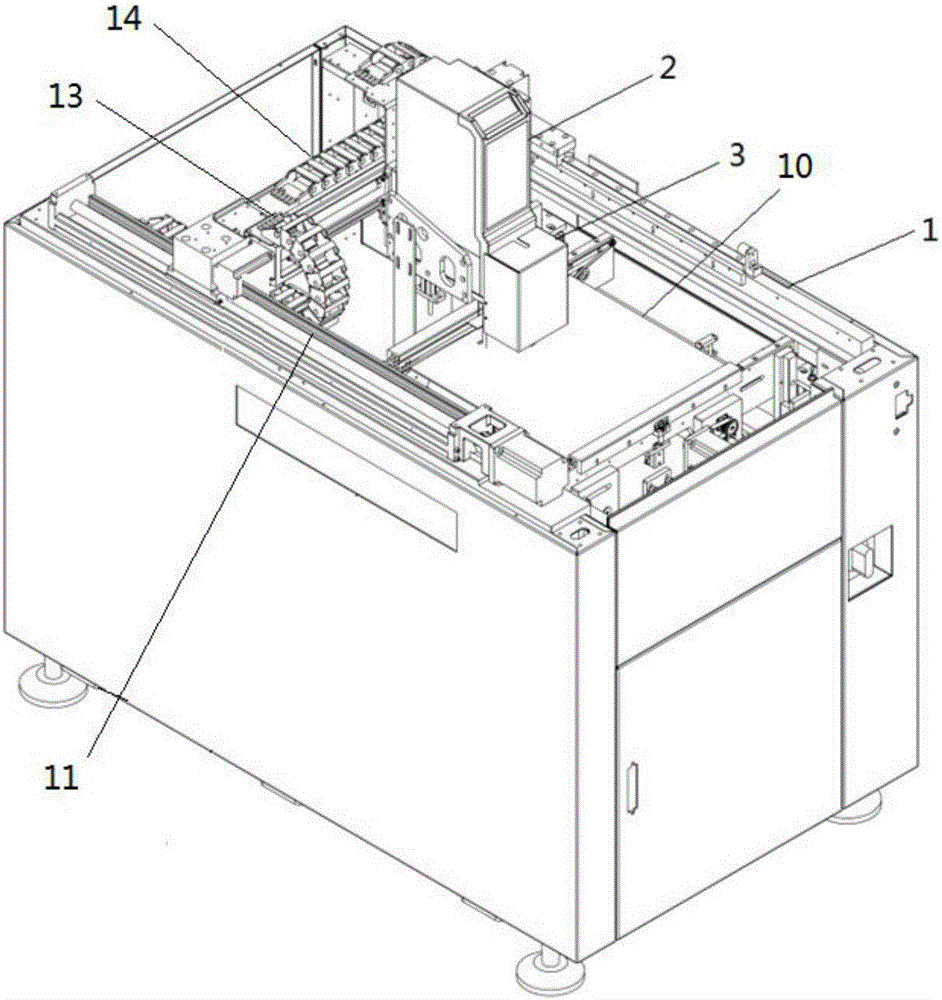

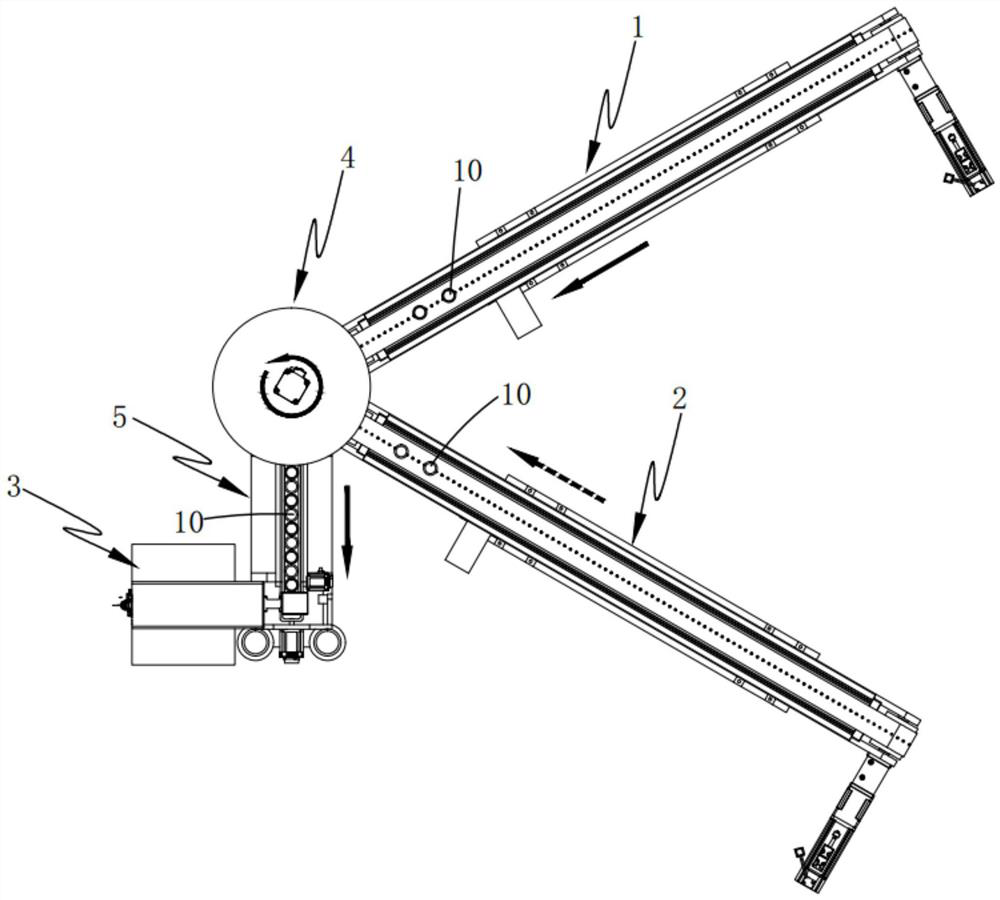

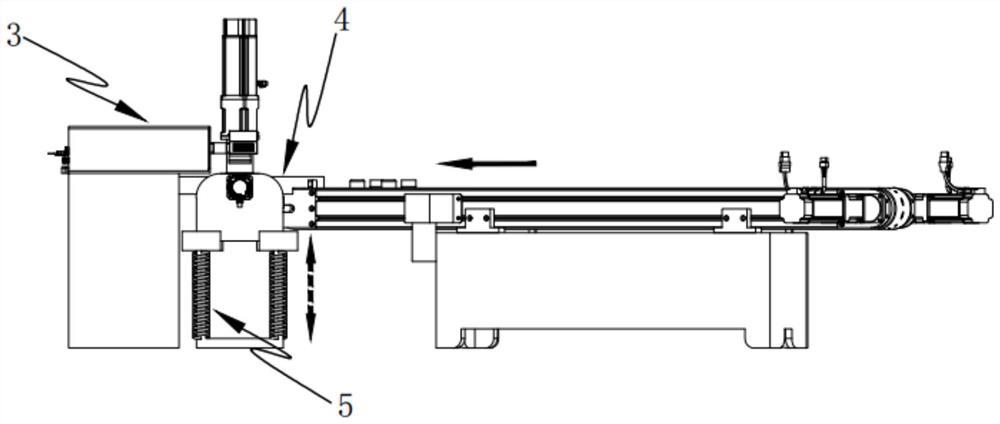

Automatic battery coding device

PendingCN112497931AImprove coding efficiencyReduce manual involvementFinal product manufactureCylindrical casing cells/batteryControl engineeringComputer science

The embodiment of the invention provides an automatic battery coding device, and relates to the technical field of battery cell production and manufacturing equipment. The automatic battery coding device comprises an operation table, a conveying mechanism, a tool clamp and a coding mechanism. The tool clamp is used for clamping a product to be coded. The tool clamp is installed on the conveying mechanism. Under the effect of the conveying mechanism, the tool clamp operates back and forth between a feeding station and a coding station. The coding mechanism is installed on the operation table and used for carrying out coding operation on the product to be coded, wherein the product is clamped by the tool clamp. According to the automatic battery coding device in the embodiment, with the helpof the conveying mechanism, the position of the tool clamp is switched, and thus the coding mechanism conveniently carries out coding operation on the product which is clamped by the tool clamp and is to be coded. The whole device is totally operated automatically except manual feeding and discharging, coding efficiency is high, labor participation is reduced, the influence on the coding qualityby labor operation is avoided, and the coding quality is improved beneficially.

Owner:江苏逸飞激光设备有限公司

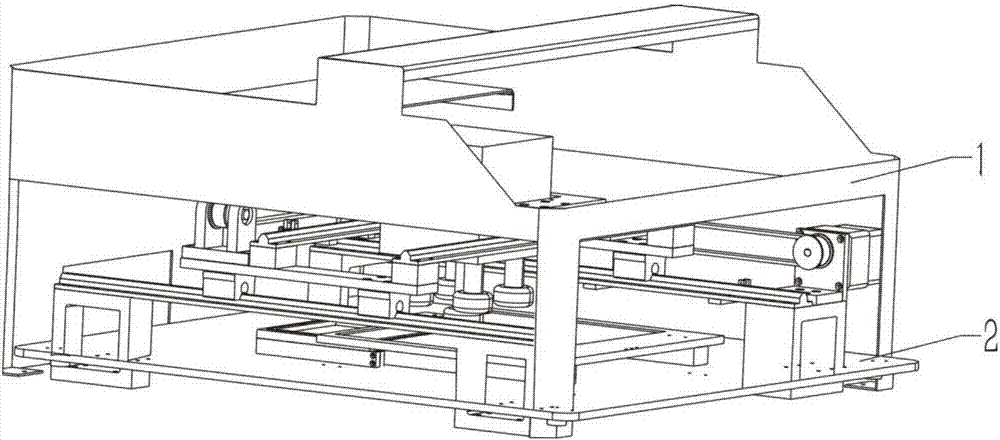

Laser engraving machine

InactiveCN105750733ARun fastEffective width adjustmentLaser beam welding apparatusLaser engravingEngineering

The invention aims to provide a laser engraving machine high in marking efficiency and marking quality and wide in use range. The laser engraving machine comprises a frame, a laser engraving unit and a feeding unit, wherein the laser engraving unit is arranged on the frame and comprises a laser device and a scanning camera, the laser device moves horizontally along the frame, the feeding unit directly facing the laser engraving unit comprises a feeding belt directly facing the laser device and the scanning camera, and the feeding belt is driven by a drive mechanism on the frame. The laser engraving machine has the advantages that consumable material use is avoided, and use cost is reduced greatly; the laser engraving machine is high in marking quality and avoids contamination, scraping and shedding the like as compared with printing or labeling.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

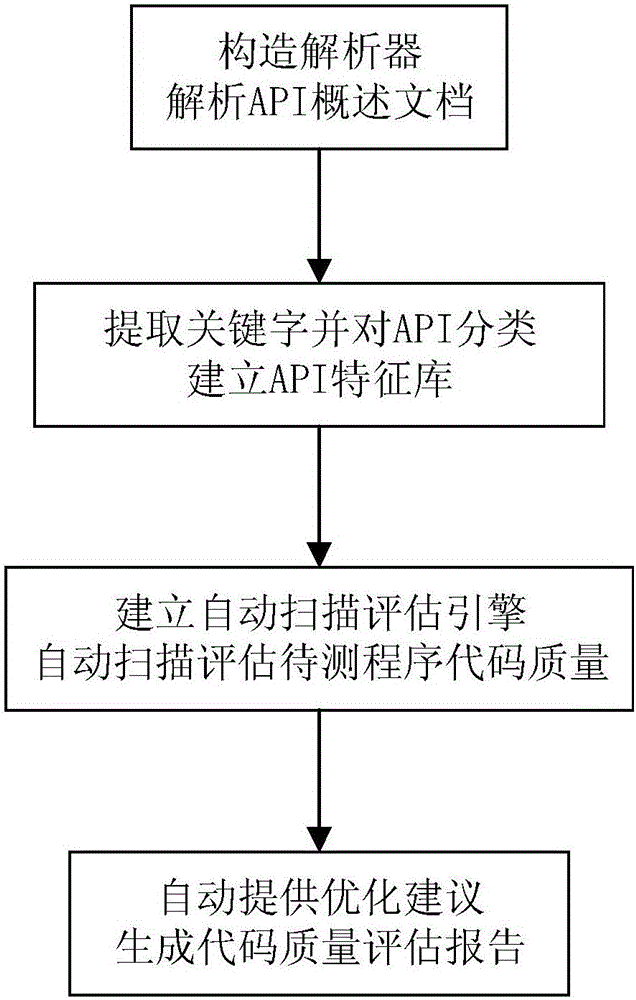

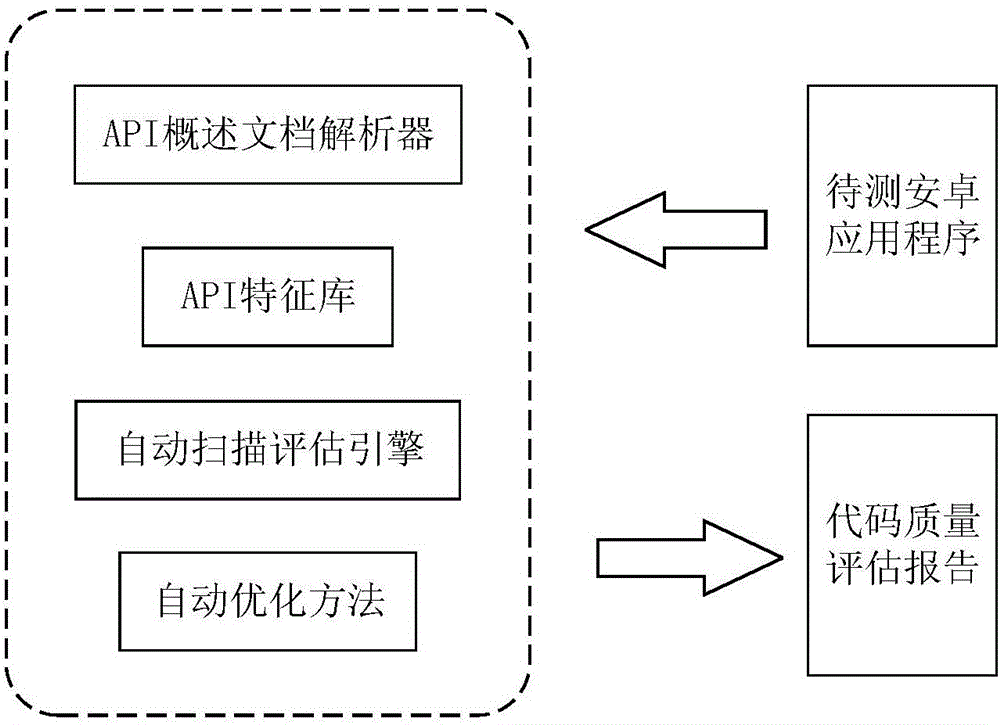

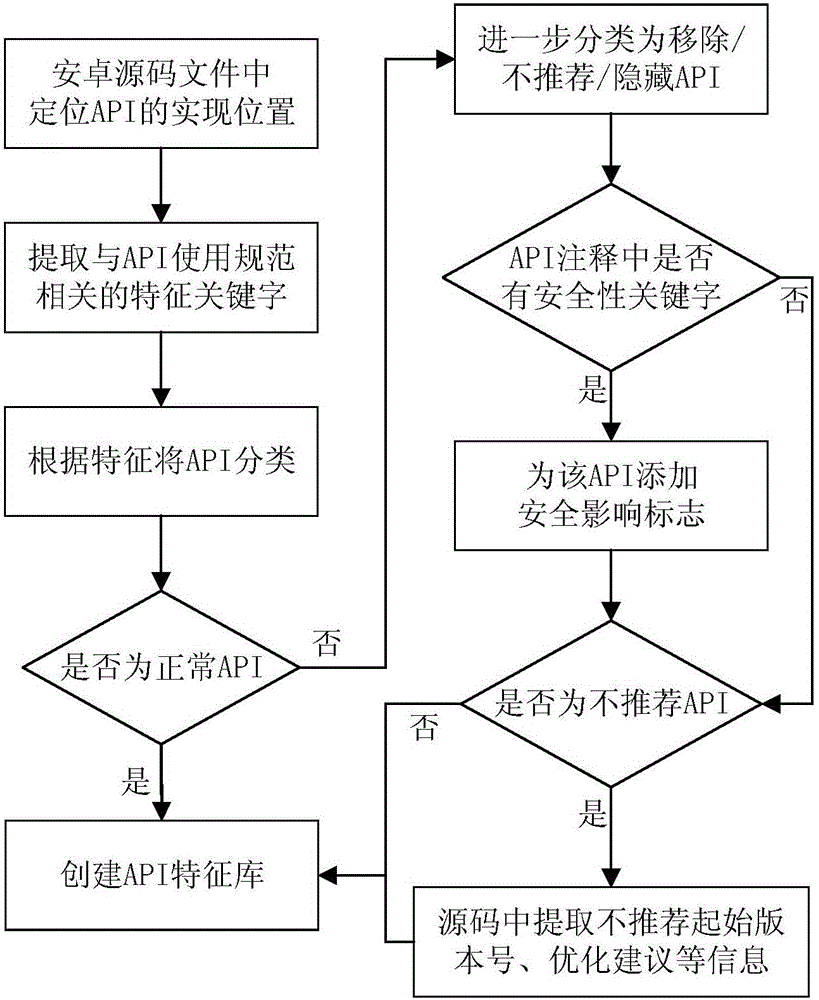

Android API application specification-based automatic code quality evaluation and optimization method

ActiveCN106126412AReduce misuse and misuseImprove code qualitySoftware testing/debuggingApplication softwareQuality assessment

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

Electronic product production code spraying device with dust removal function

InactiveCN108790426AEasy to replaceEasy to adjustTypewritersOther printing apparatusWorking environmentEngineering

The invention discloses an electronic product production code spraying device with a dust removal function. The code spraying device comprises a workbench; hydraulic supporting rods are welded to thefour corners of the outer wall of the bottom of the workbench; a blower box is welded to one side of the outer wall of the top of the workbench, and one side of the blower box is provided with a firstthrough hole; a blower box cover is connected to the inner wall of the side surface of the blower box through a hinge, and the middle of the blower box cover is provided with a second through hole; an air feeding pipe is inserted and connected to the inner wall of the second through hole; a blower is connected to the inner wall of the bottom of the blower box through screws, and the outer wall ofan air outlet of the blower is sleeved with an air blowing pipe; and the outer wall of the air blowing pipe is inserted and connected to the inner wall of the first through hole. The code spraying device can adapt to assembly line conveying platforms with different heights, the working environment can be conveniently changed, dust on the surfaces of electronic products can be removed, ink can adhere to the electronic products better, codes can be accurately sprayed onto the assigned positions of the electronic products, and thus, code spraying is normalized.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

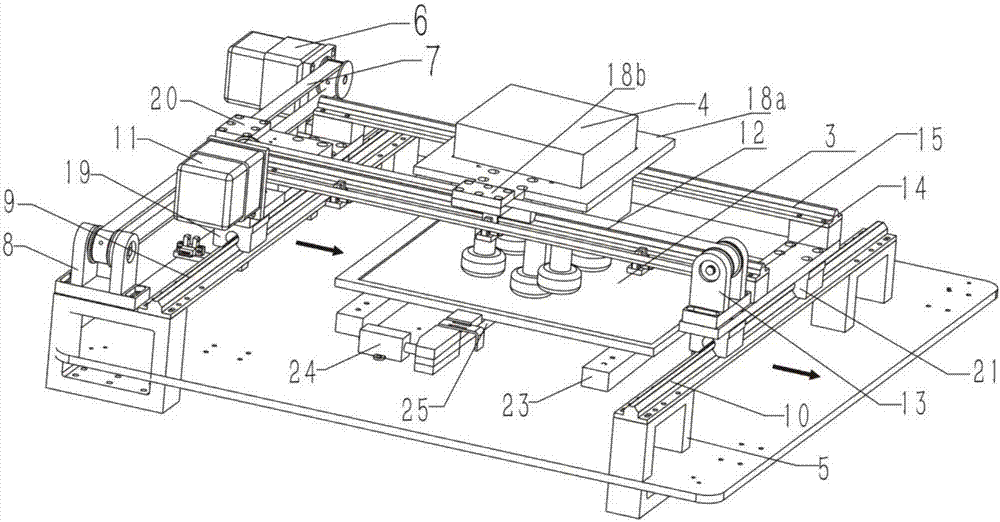

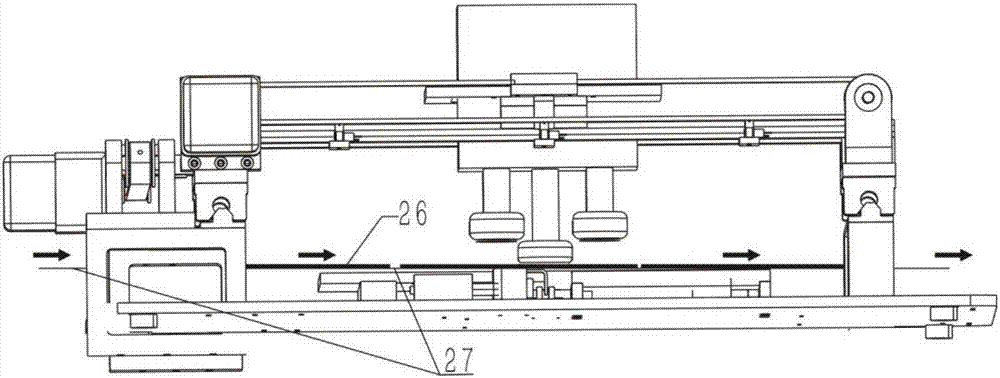

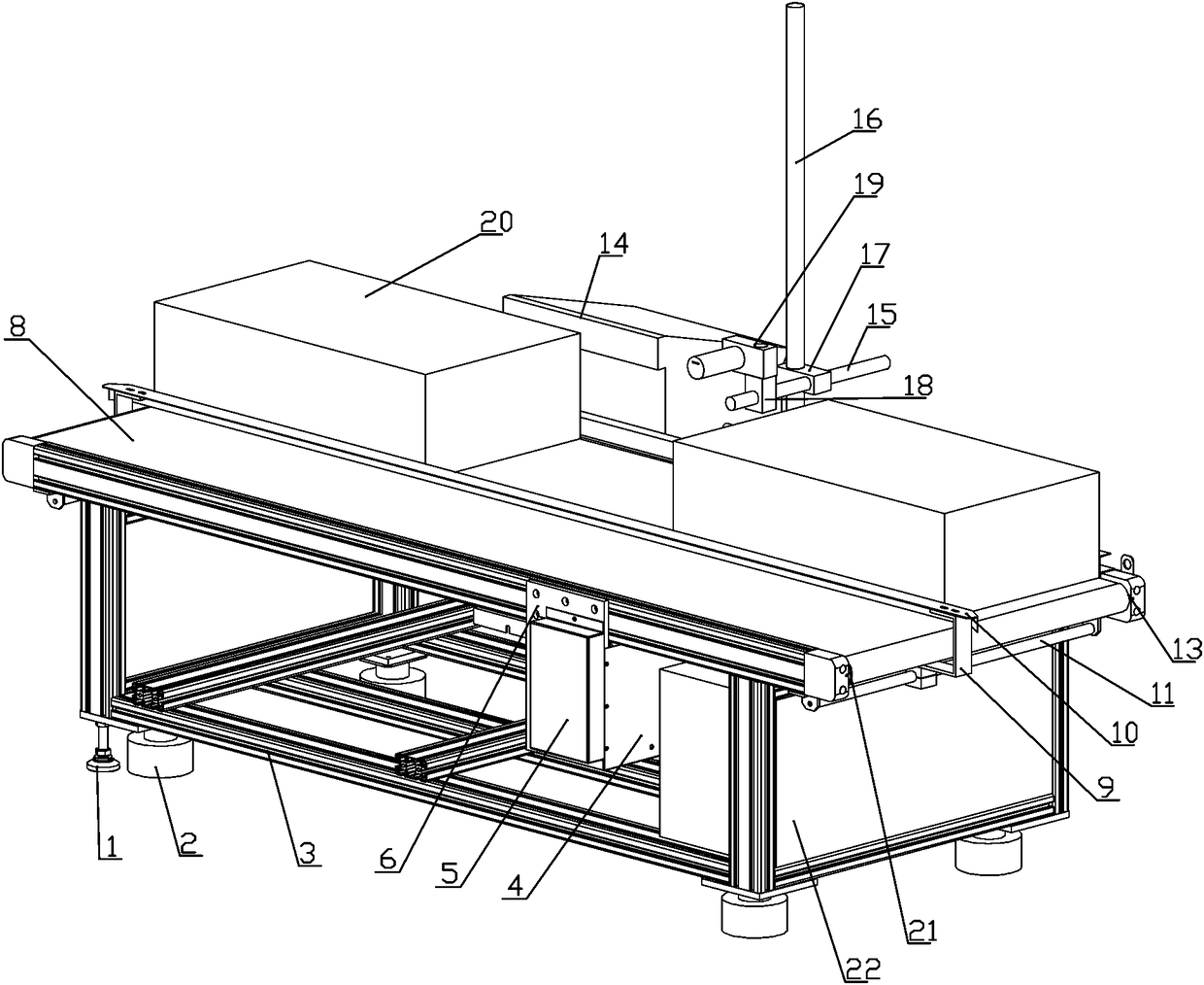

Device for marking information on surface of feed packaging bag

The invention discloses a device for marking information on the surface of a feed packaging bag. During operation, a to-be-marked package bag driven by an external conveyor belt is fed from one side of a front-back driving motor; a marking executing unit left-right driving system and a marking executing unit front-back driving system adjust the position of a marking executing unit; during markingoperation, an air blowing purging nozzle arranged below a marking executor purges the surface of the package bag and then a marking and spraying device marks the packaging bag below; after the operation, the marking executing unit is driven to retreat; and then the external conveyor belt drives the marked package bag to move out and meanwhile, the next package bag is fed in. The device disclosed by the invention is specially used for marking dates of the feed package bag (without feeds). The device has the advantages of being simple in structure, convenient to operate, quick and convenient tomark and the like, and the production efficiency is increased greatly and the labor cost can be lowered if being applied to feed industry.

Owner:沛县科达工贸有限公司

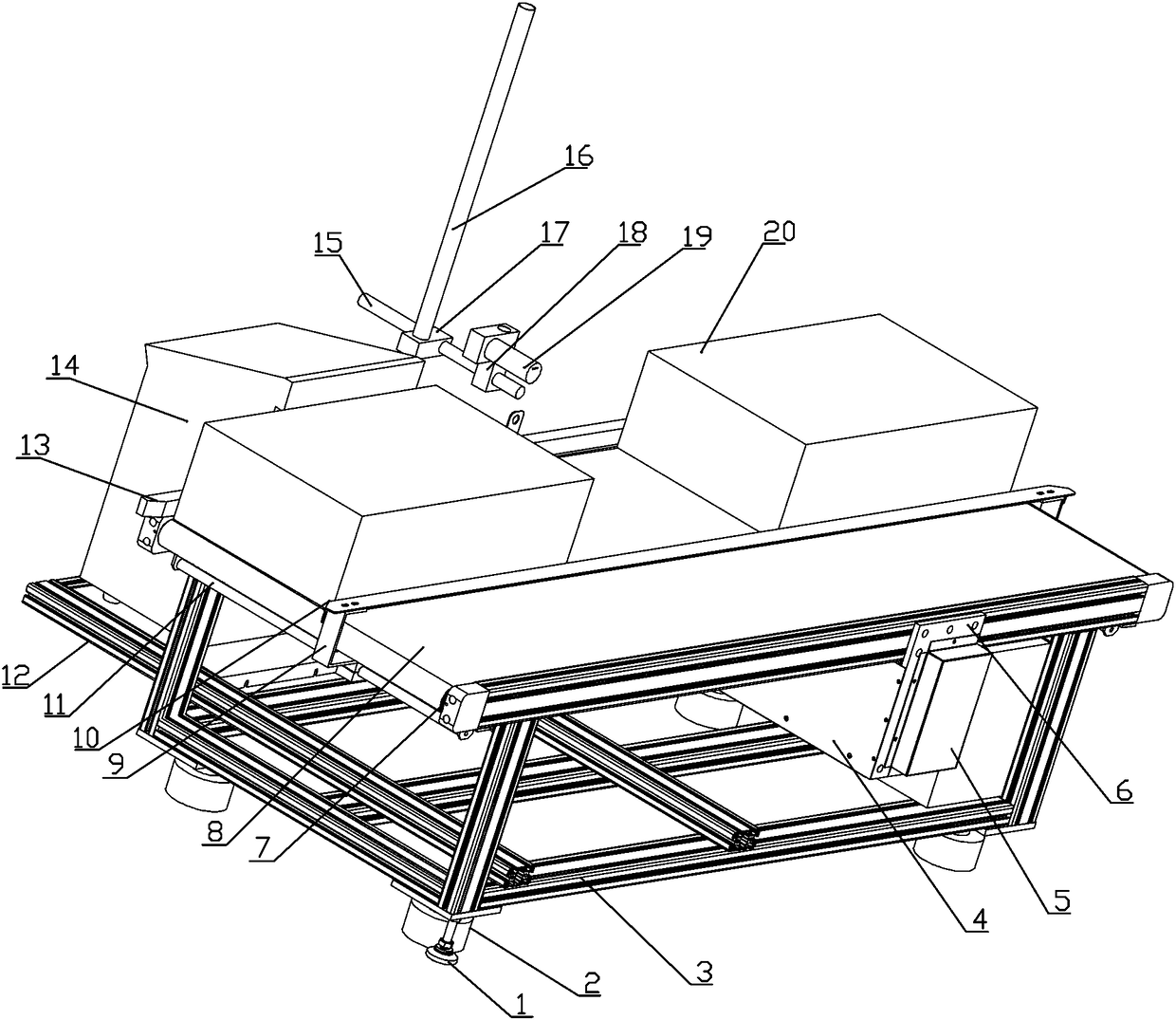

Movable type code spraying flow line used for code spraying of packing boxes

The invention provides a movable type code spraying flow line used for code spraying of packing boxes. The flow line includes a machine frame. A top framework is disposed on the top of the machine frame; an active carrying idler and a driven carrying idler are respectively disposed at two ends of the top framework; a conveyor belt is installed between the active carrying idler and the driven carrying idler; the conveyor belt is provided with a width adjusting mechanism adapting to packing boxes of different width; a code spraying machine is disposed on one side surface of the machine frame; acode spraying head of the code spraying machine is disposed on a top side surface of the conveyor belt through an adjustable bracket; the code spraying machine is connected to an electronic control device; and the active carrying idler is connected to a transmission device and drives the conveyor belt to transmit. The movable type code spraying flow line can be easily connected with a production line for the packing boxes in a butt joint manner, automatically achieves movement of the packing boxes, and automatically achieves code spraying operation of the packaging boxes, and so, the work efficiency is improved, and the labor intensity of work personnel is reduced.

Owner:湖北荣华彩色包装印务股份有限公司

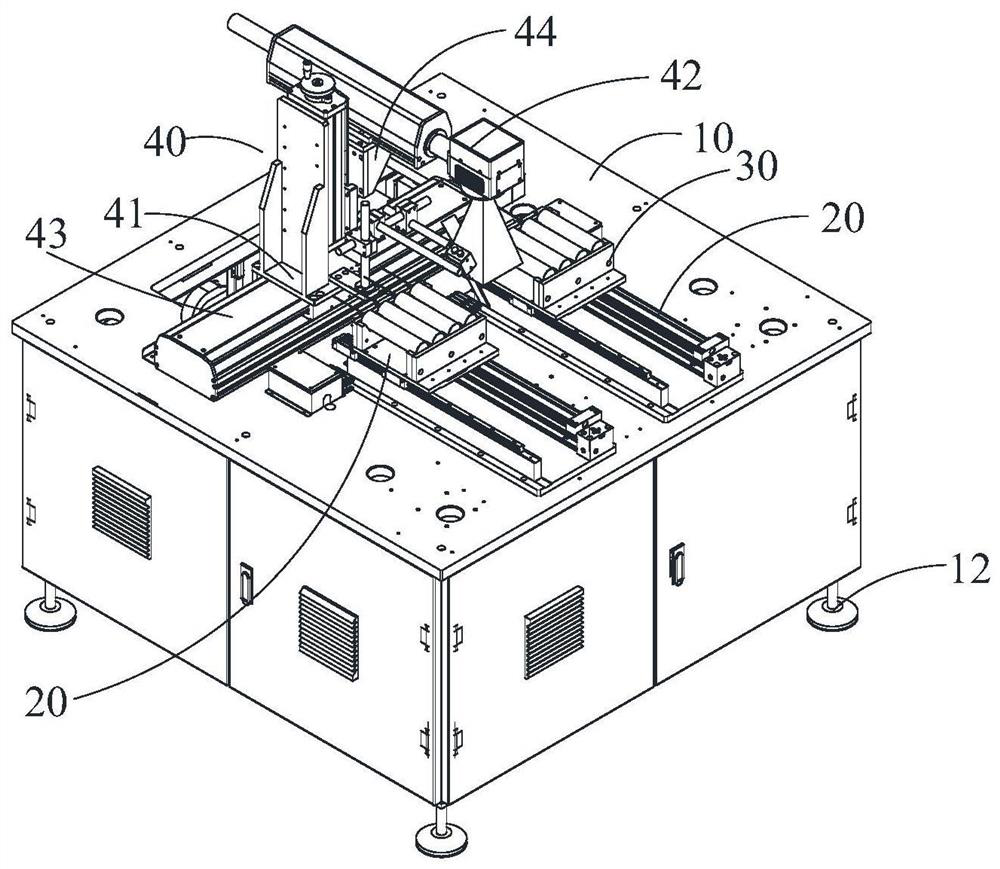

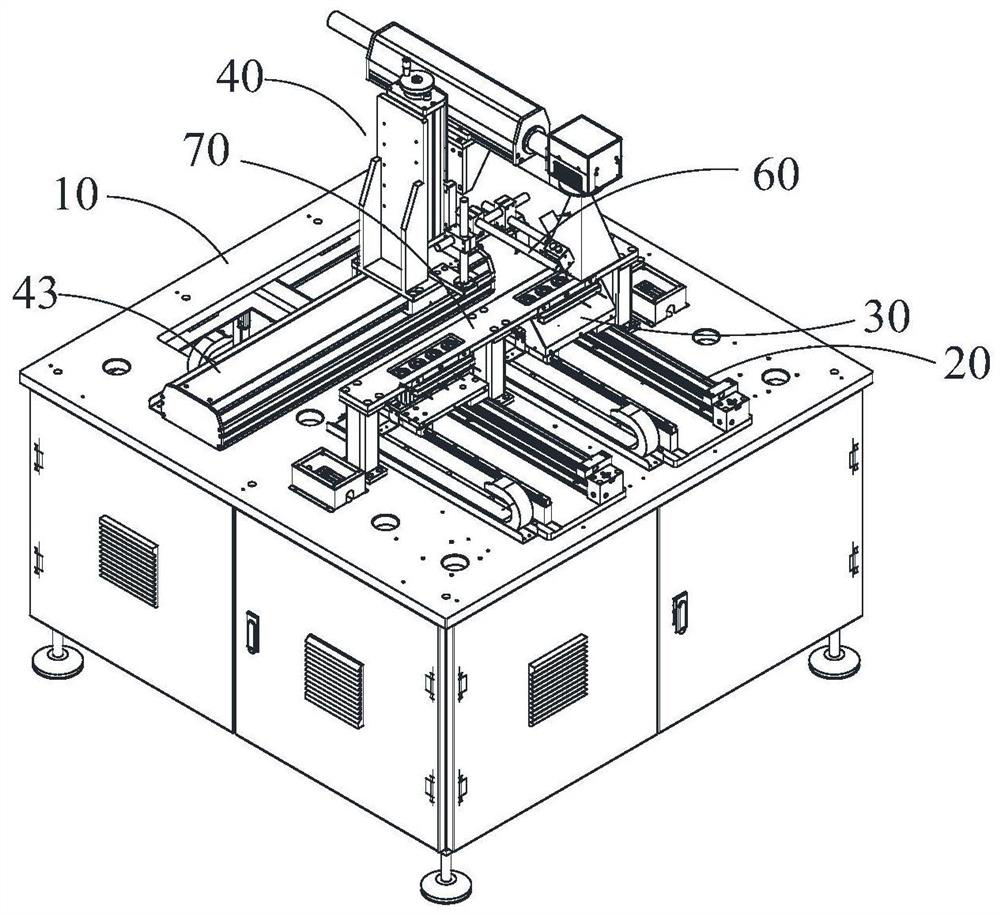

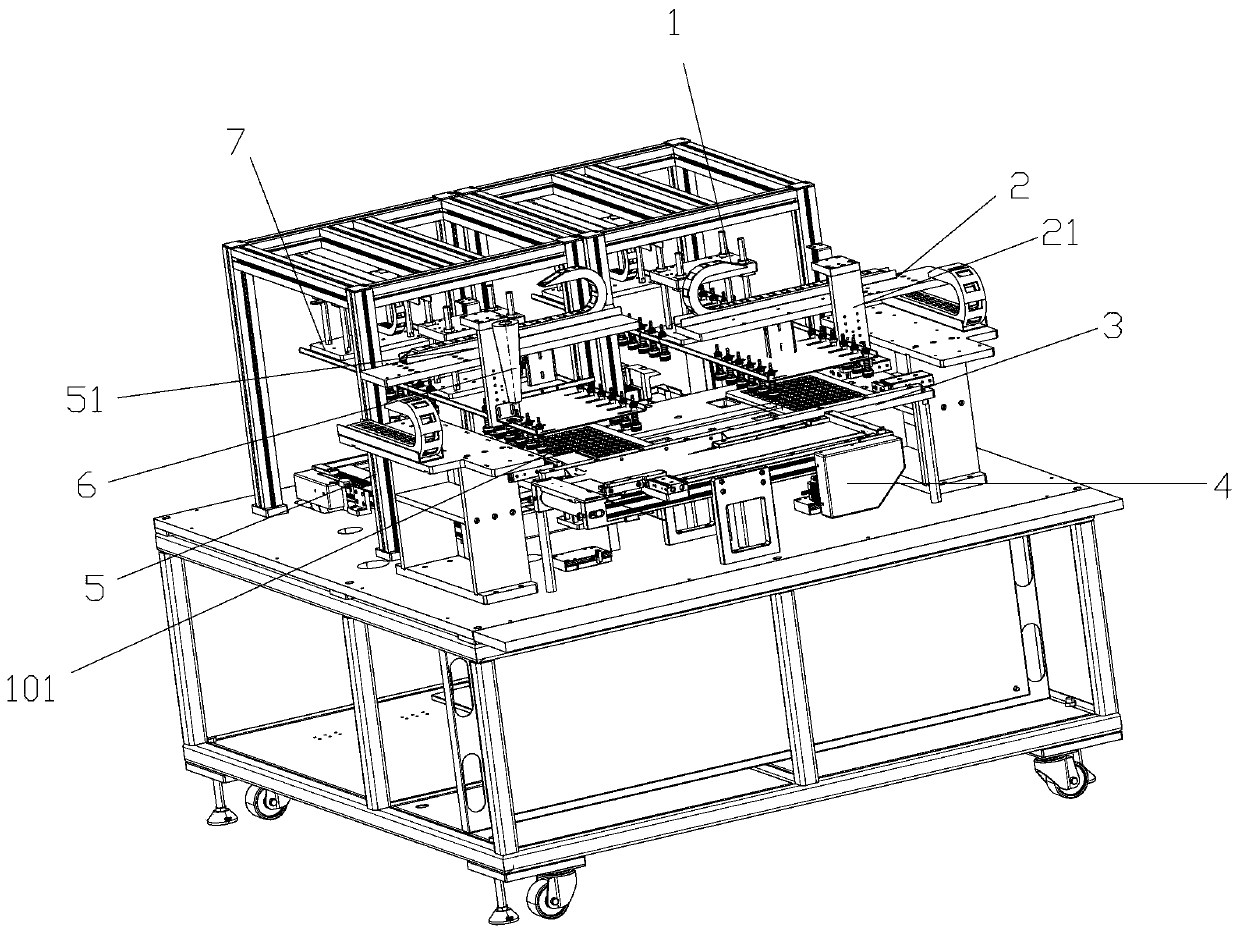

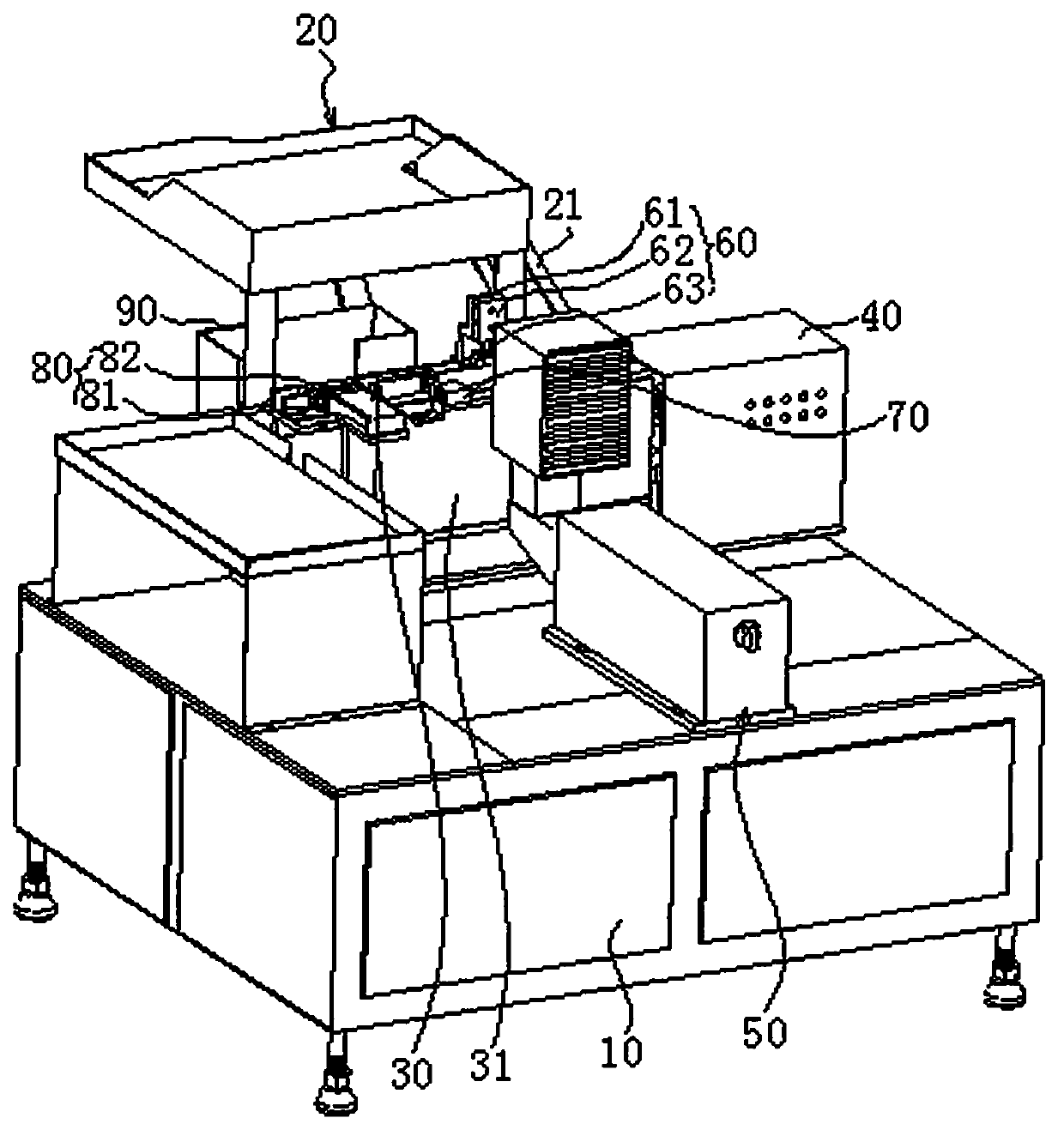

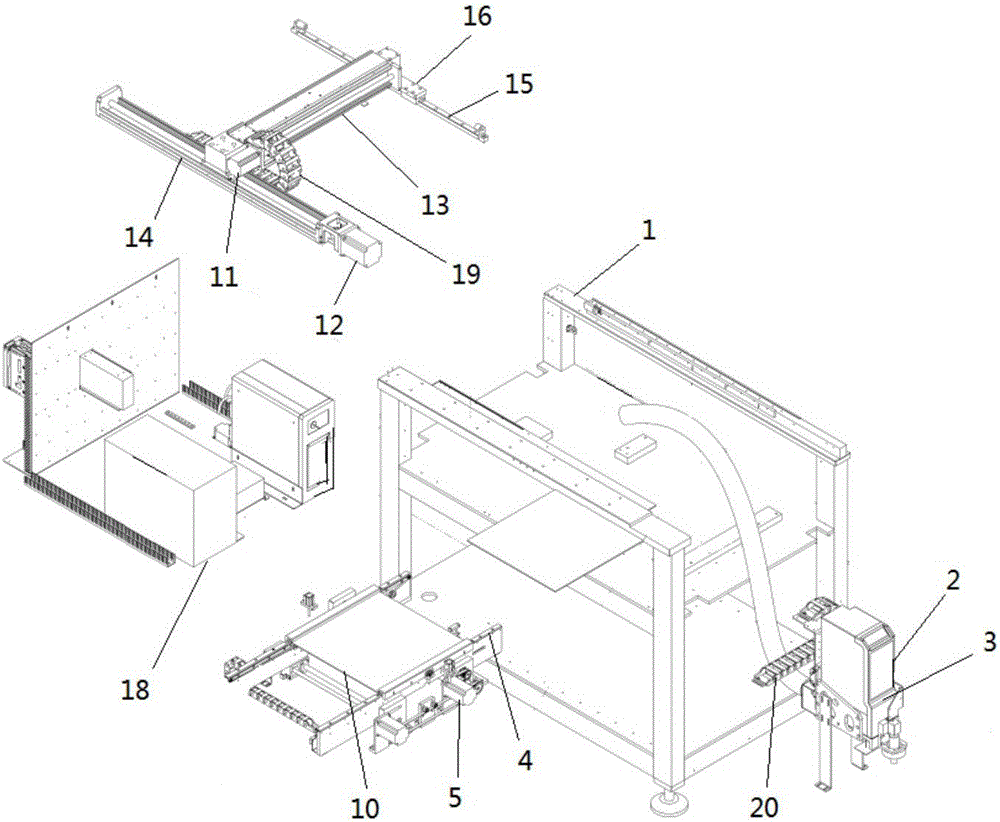

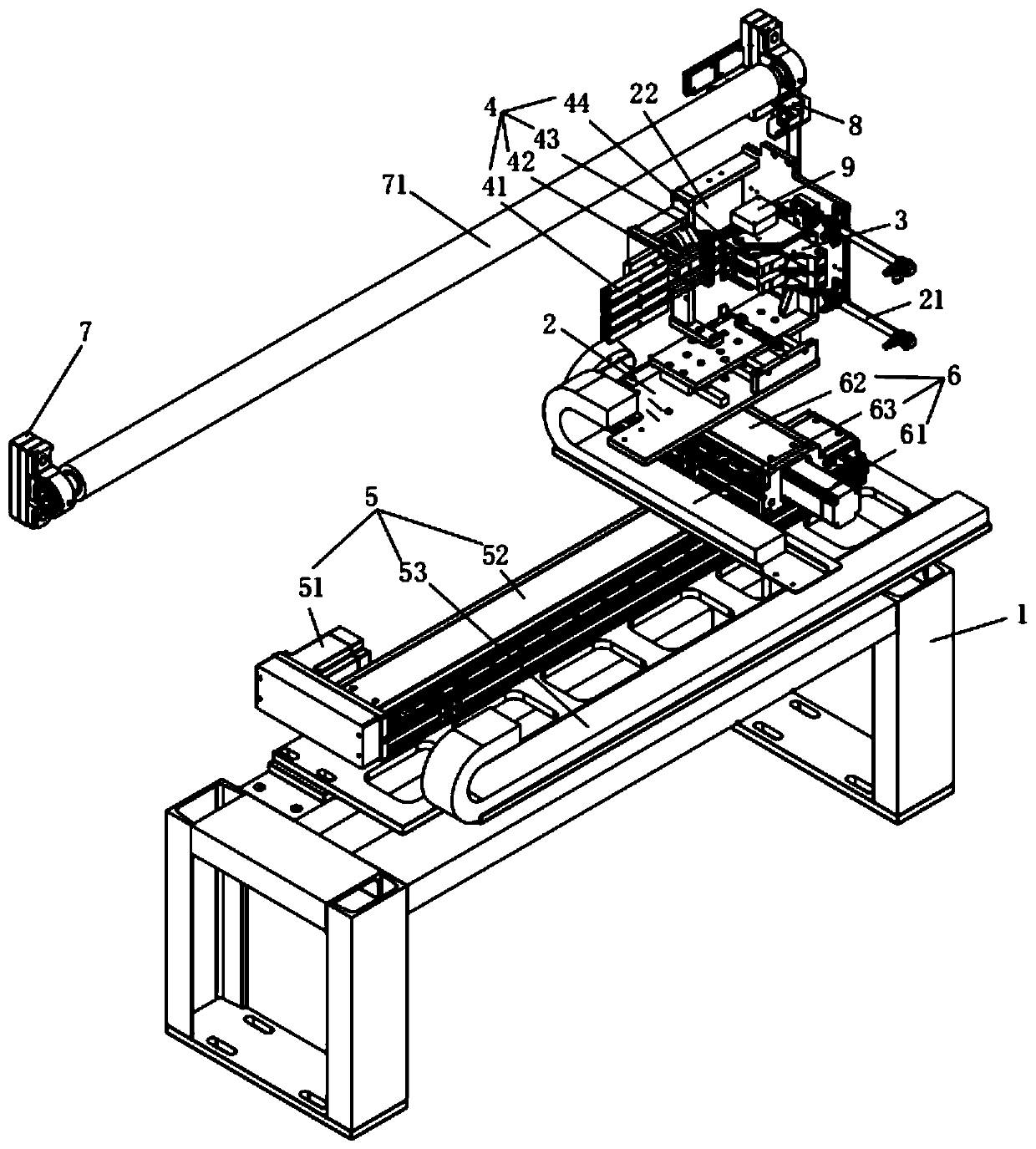

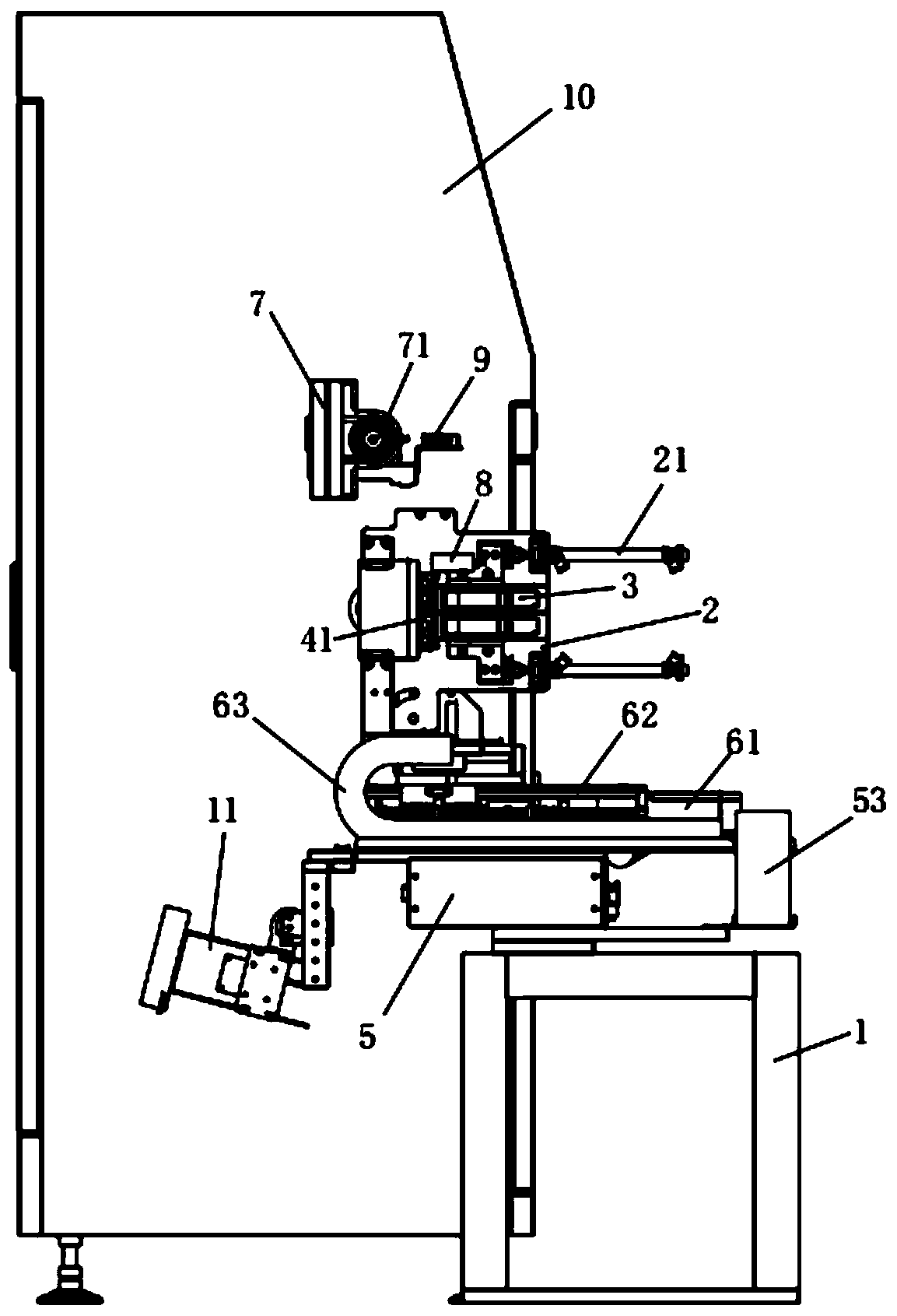

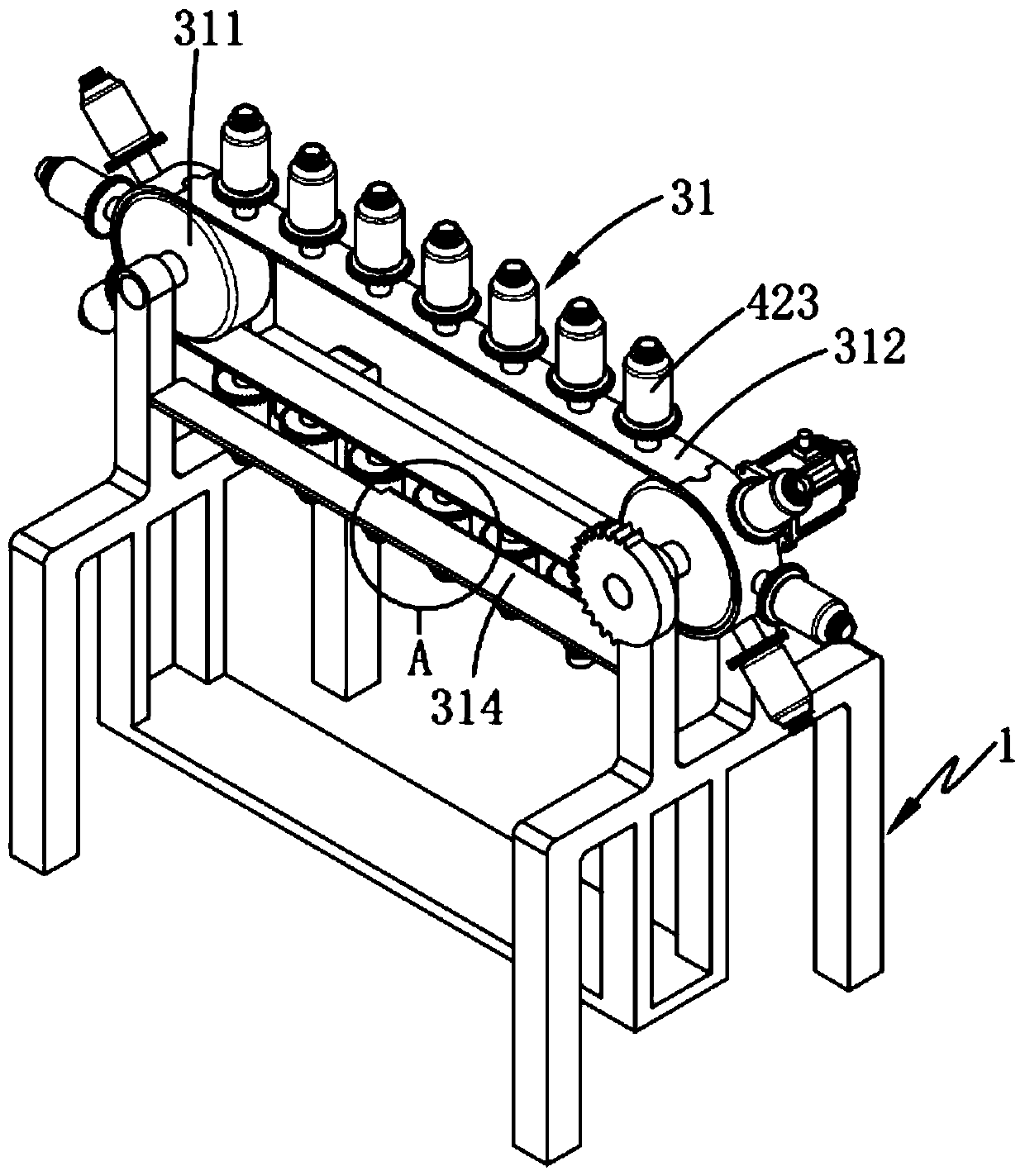

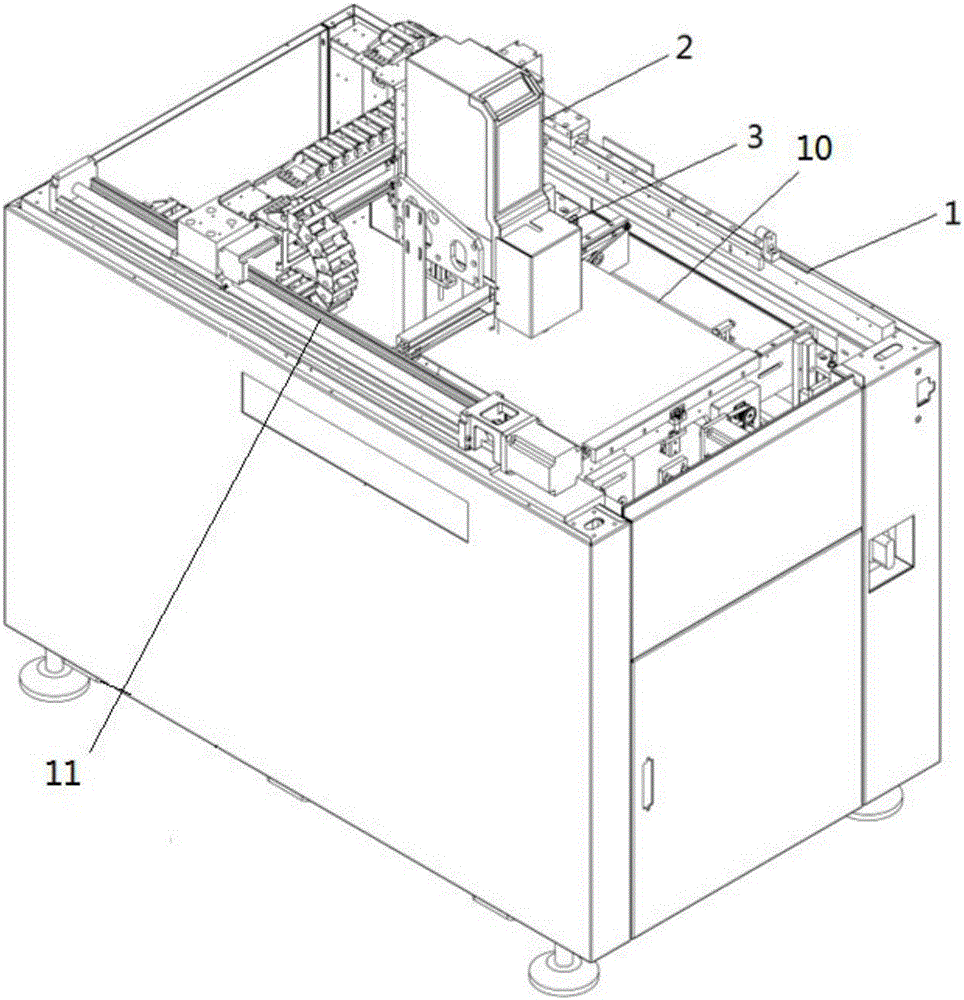

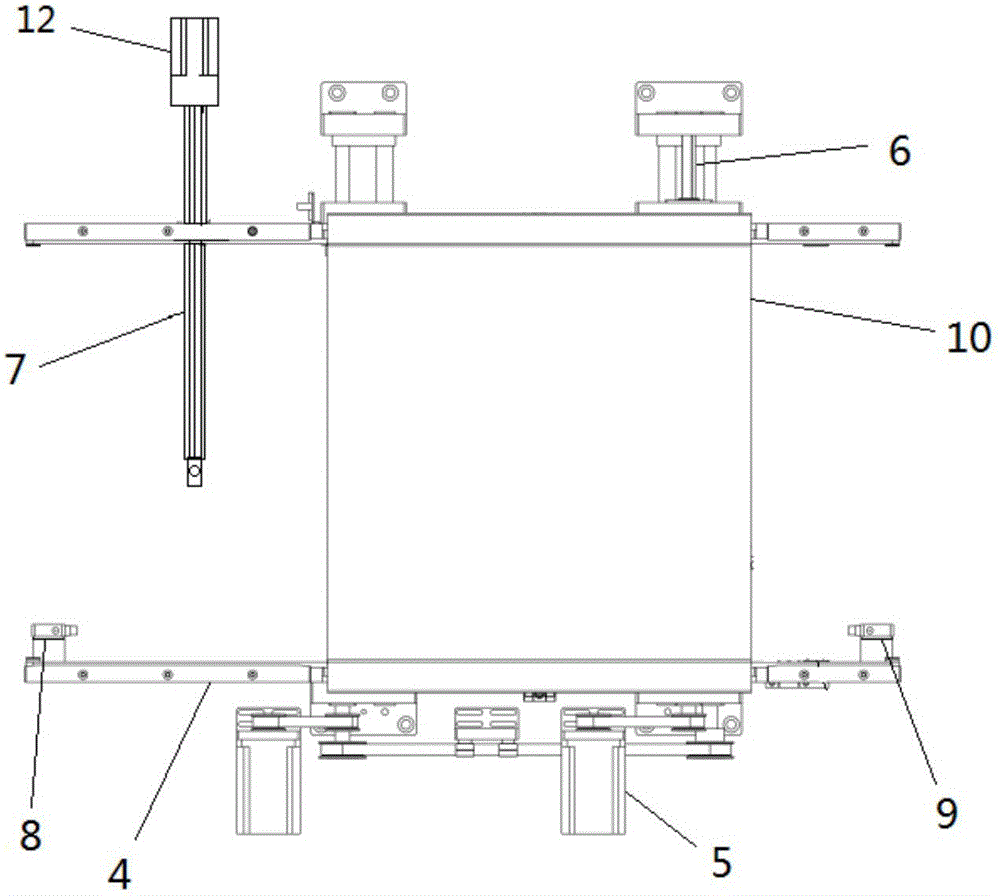

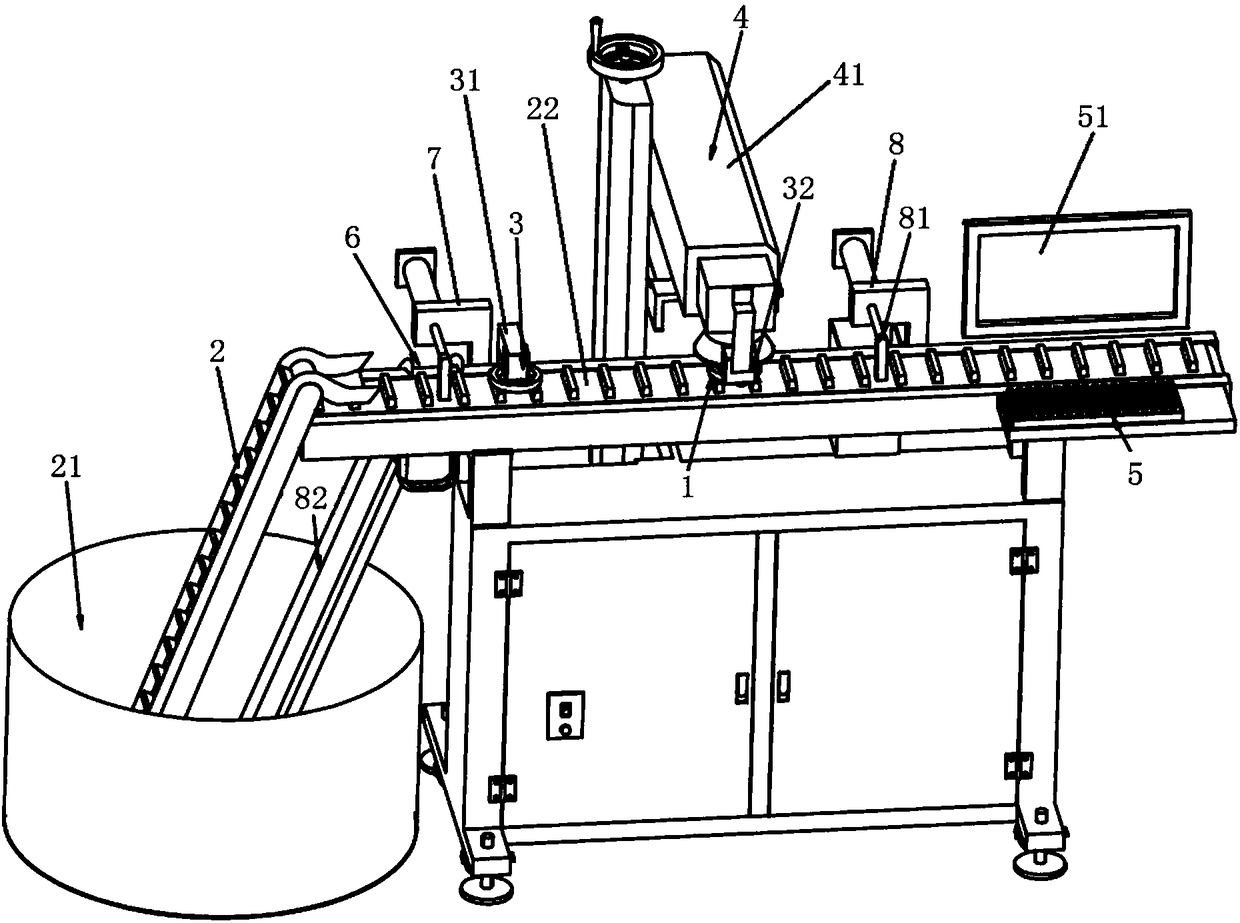

Automatic detection and code-spraying equipment for lithium batteries

PendingCN111229618AQuick checkImprove code qualityTypewritersSortingProcess engineeringMaterial transfer

The invention discloses automatic detection and code-spraying equipment for lithium batteries. The automatic detection and code-spraying equipment includes a machine table and an intelligent control system. The automatic detection and code-spraying equipment is characterized in that the machine table is provided with a feeding device, an automatic detection device, a material transfer device, a sampling device, a code-spraying device, a material bearing device and a discharging device; according to the automatic detection and code-spraying equipment for the lithium batteries, the lithium batteries of jig trays are fed to the automatic detection device for detection by the feeding device in the machine table, after the detection, the jig trays are sent to the sampling device through the material transfer device, the unqualified lithium batteries are drawn out to the material bearing device, the remaining qualified lithium batteries are sequentially subjected to code-spraying and numbering by the code-spraying device, and the qualified lithium batteries after code-spraying in the jig trays are output by the discharging device in the machine table; and the automatic detection and code-spraying equipment for the lithium batteries not only has high working efficiency, but also can greatly reduce the labor intensity of employees, and is very suitable for lithium battery manufacturers.

Owner:广东浪鲸智能自动化装备有限公司

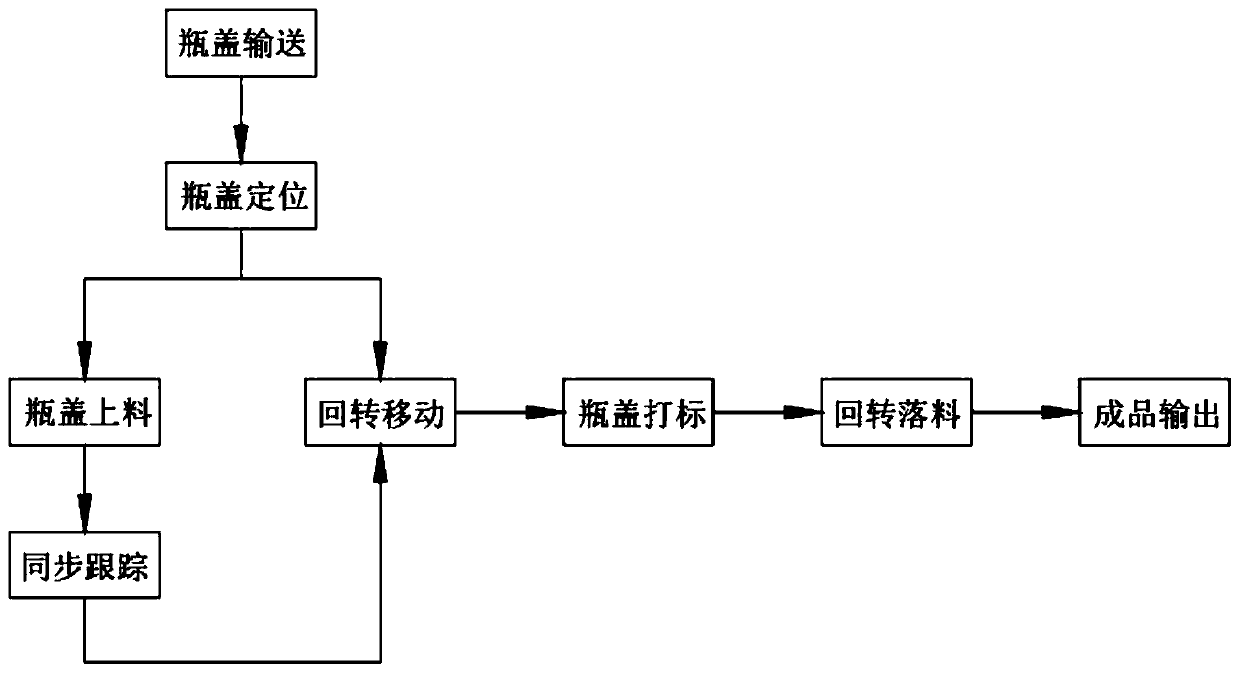

Tracking type dynamic bottle cap marking method

ActiveCN110064847ARealize automatic outward outputRealize automated productionLaser beam welding apparatusEngineeringBottle cap

The invention provides a tracking type dynamic bottle cap marking method. The method comprises the steps of bottle cap conveying, bottle cap positioning, bottle cap feeding, rotary moving, synchronoustracking, bottle cap marking, rotary discharging and finished product output. Through the arrangement of the synchronous tracking step and the synchronous linkage arrangement of the bottle cap feeding after the rotary moving, the automatic outward output of bottle caps after the bottle caps are marked is achieved, the full-automatic production of the bottle caps from feeding, marking to automaticoutput is achieved; and the technical problems that the synchronous tracking between the bottle caps and a bottle cap transferring device cannot be achieved and the bottle cap feeding effect is poorin the prior art are solved.

Owner:DEMARK (CHANGXING) INJECTION SYST CO LTD

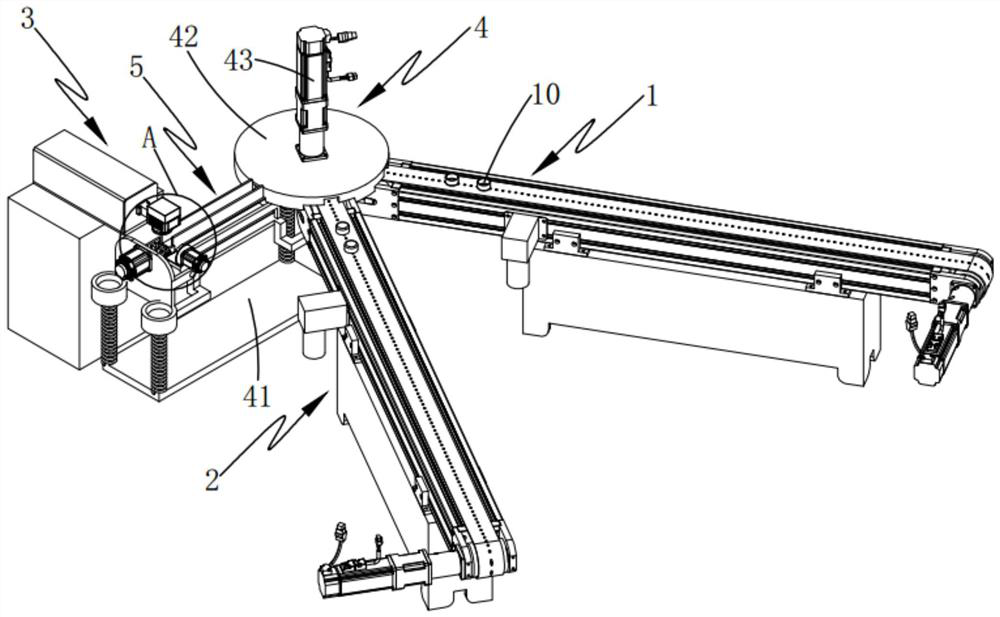

Automatic food can coding equipment

PendingCN110125554AImprove code qualityThe logo is consistentLaser beam welding apparatusEngineeringMechanical engineering

The invention belongs to the technical field of food can production equipment, in particular to automatic food can coding equipment. The automatic food can coding equipment comprises a machine frame,a storing disc, a conveying channel, a conveying device and a laser coder, the storing disc is mounted on the machine frame, a sliding way is arranged on the storing disc, the conveying channel is mounted at the upper portion of the machine frame through a supporting shell and located on one side of the storing disc, the conveying channel is docked with the lower portion of the tail end of the sliding way so as to be used for bearing a food can sliding from the sliding way, and the conveying device is mounted on the machine frame and located in the supporting shell; and the conveying device islocated below the conveying channel so as to be used for driving the food can on the conveying channel to slide along the established route, and the laser coder is mounted on the machine frame and located on the other side of the conveying channel so as to be used for coding the food can sliding through the conveying channel. The fact that the identification of each coded food can maintains consistent is ensured, moreover, the manual operation is reduced, the labor fatigue is reduced, the production efficiency of coding is improved, and the coding quality of the food can is improved accordingly.

Owner:DONGGUAN TINSHINE TIN BOX

Laser engraving machine

InactiveCN105728953AAvoid confusionRun fastLaser beam welding apparatusMaterial consumptionLaser engraving

The invention aims to provide a laser engraving machine with high coding efficiency, good quality and wide application range. The laser engraving machine comprises a frame, a laser engraving unit arranged on the frame, and a feeding unit aligned to the laser engraving unit; the laser engraving unit includes a laser and a scanning motor horizontally moving along the frame; the feeding unit includes a feeding belt aligned to the laser and the scanning camera; and the feeding belt is driven by a transmission mechanism on the frame. The laser engraving machine prevents the material consumption to largely reduce the use cost, is high in coding quality, and prevents such phenomenon as contamination, scraping and falling compared with printing or labeling.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

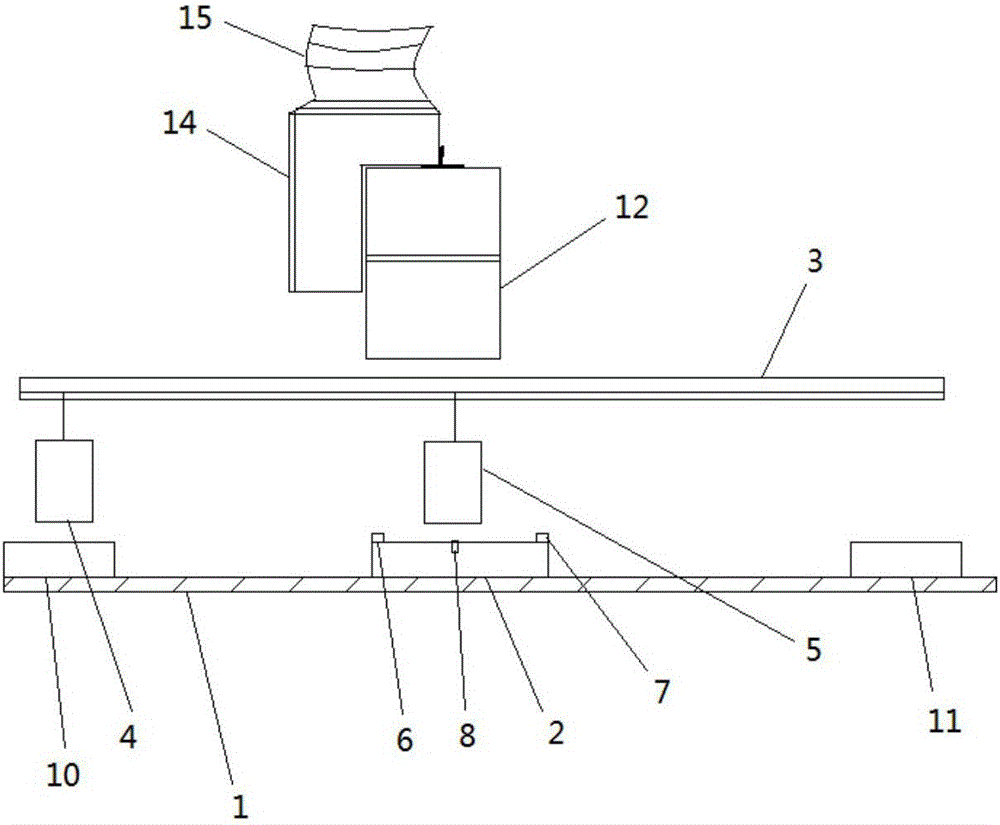

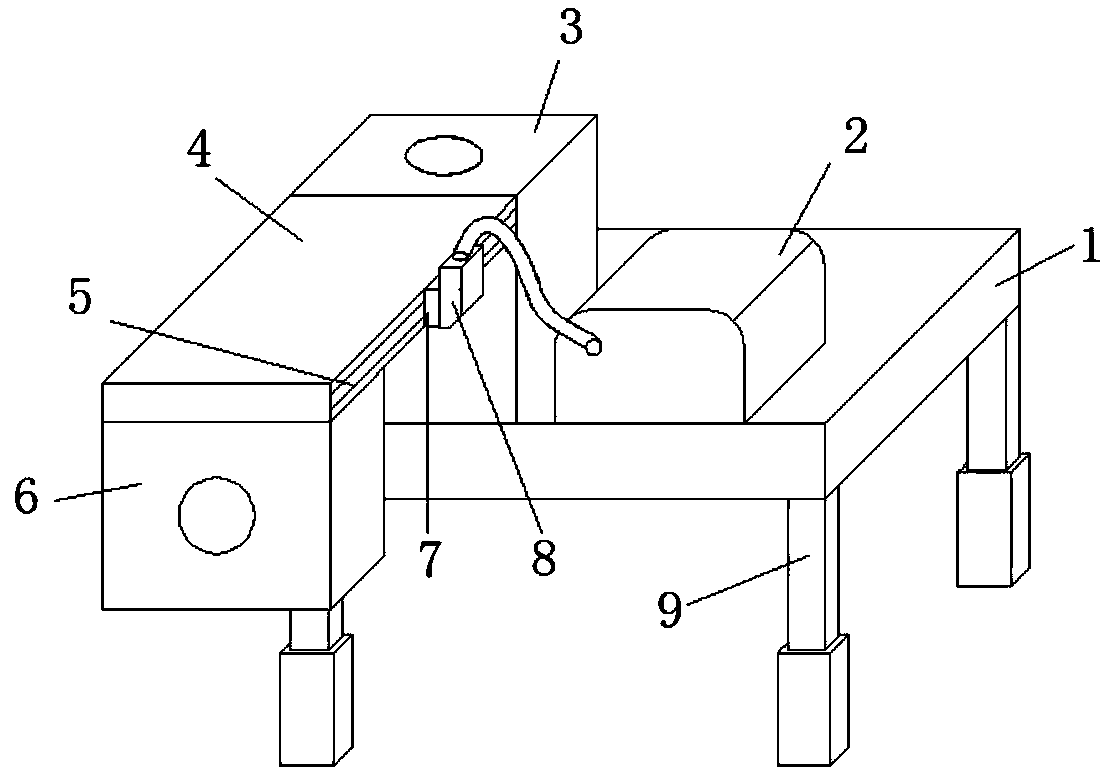

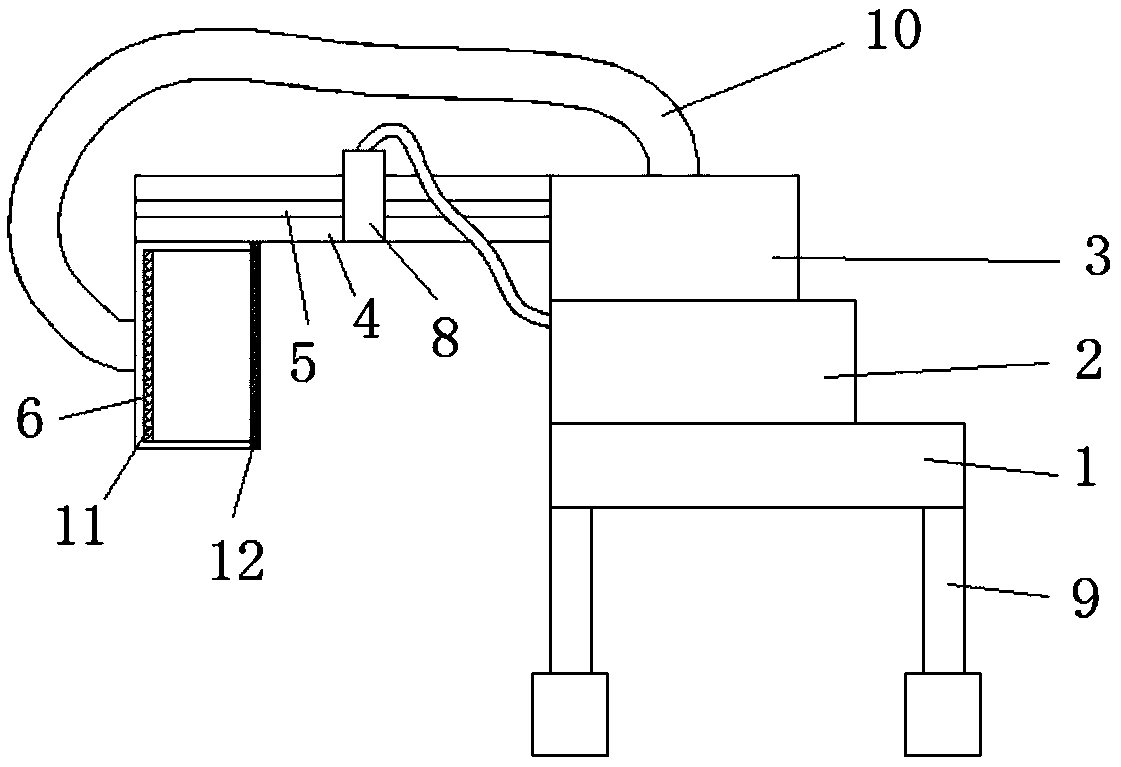

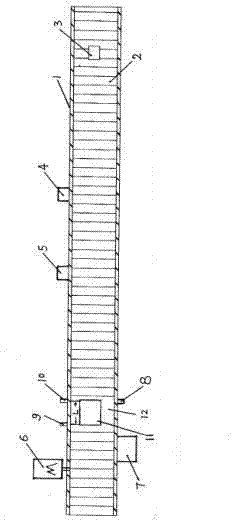

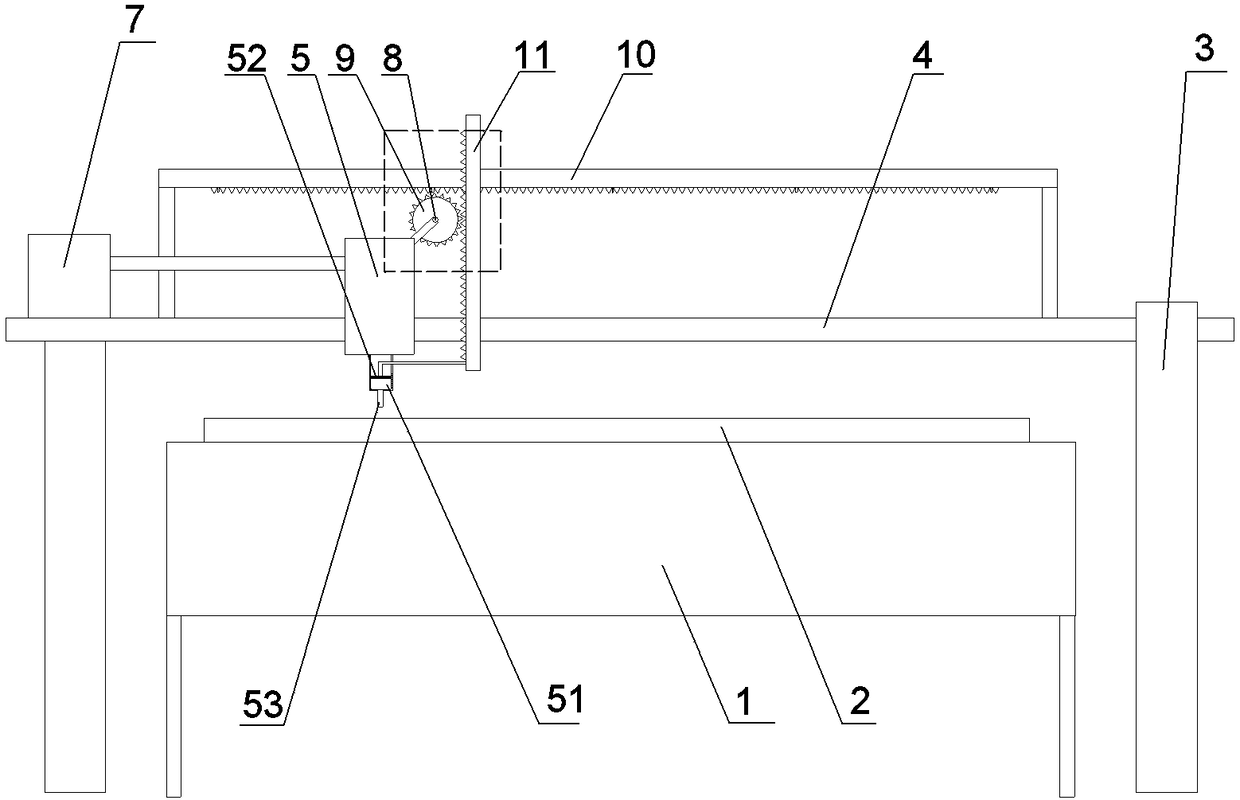

Urea finished product packing and conveying line capable of preventing missing code spraying

ActiveCN103538756ASolve the problem of inkjet leakageSolve the phenomenon of inkjet leakagePackaging automatic controlProduction lineConveyor belt

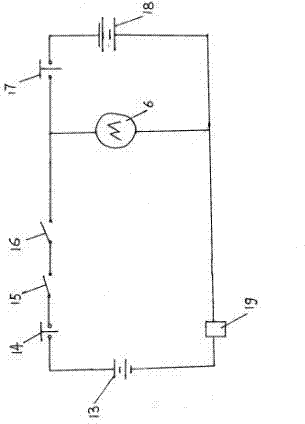

The invention discloses a urea finished product packing and conveying line capable of preventing missing code spraying, and the urea finished product packing and conveying line solves the problem that the code spraying can be missed under the condition that an existing automatic packing and conveying line stops running. The urea finished product packing and conveying line comprises a conveyor belt frame body (1), a conveyor belt (2) and a conveyor belt direct current driving motor (6) are respectively arranged on the conveyor belt frame body (1), a packing bag code spraying machine (7) and a code spraying machine inductive switch (8) are respectively arranged at the left end of the conveyor belt frame body (1), a code spraying area (12) is arranged at the left end of the conveyor belt frame body (1), urea finished product packing bags (11) are arranged on the conveyor belt (2), two optoelectronic switches preventing from missing code spraying are respectively arranged on one side of the code spraying area (12), and the distance (L) between the first optoelectronic switch (9) preventing from missing code spraying and the second optoelectronic switch (10) preventing from missing code spraying is equal to the width of the urea finished product packing bags (11) . The quality of the code spraying of an automatic packing production line is improved.

Owner:SHANXI FENGXI HUARUI COAL CHEM IND

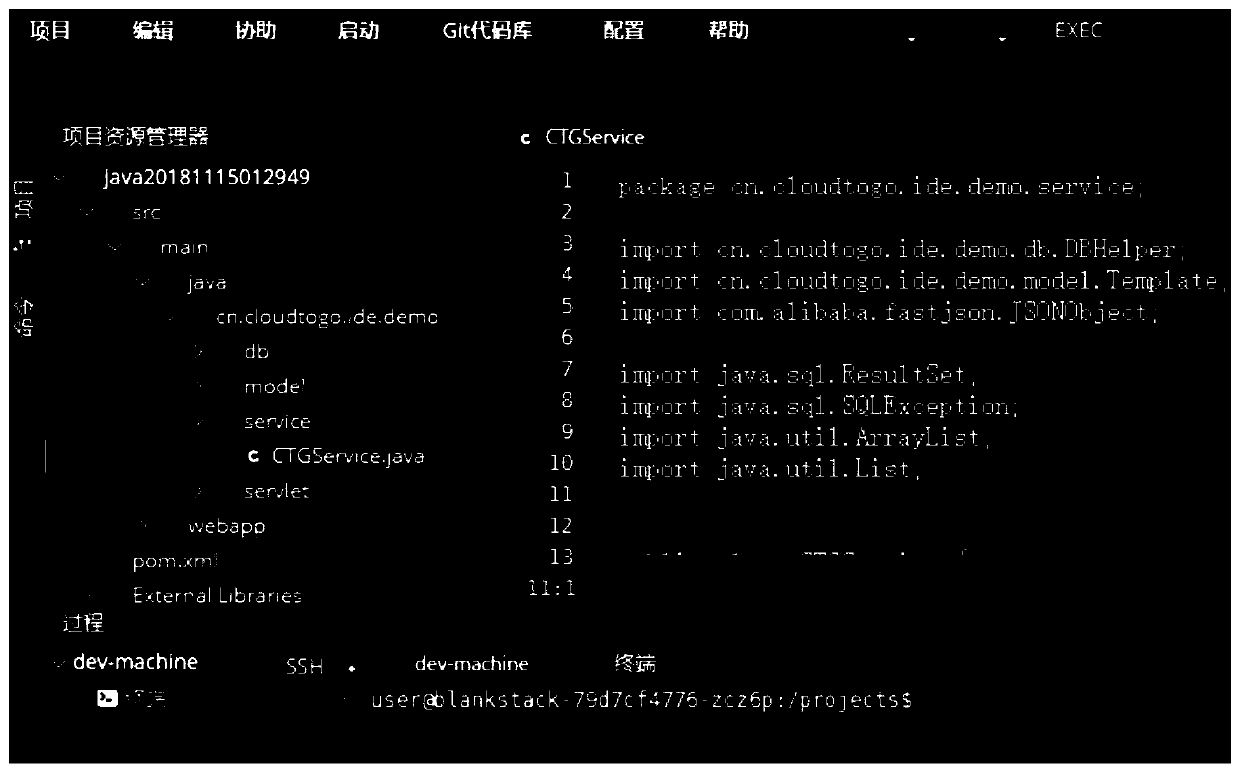

Software debugging management method, device and system and storage medium

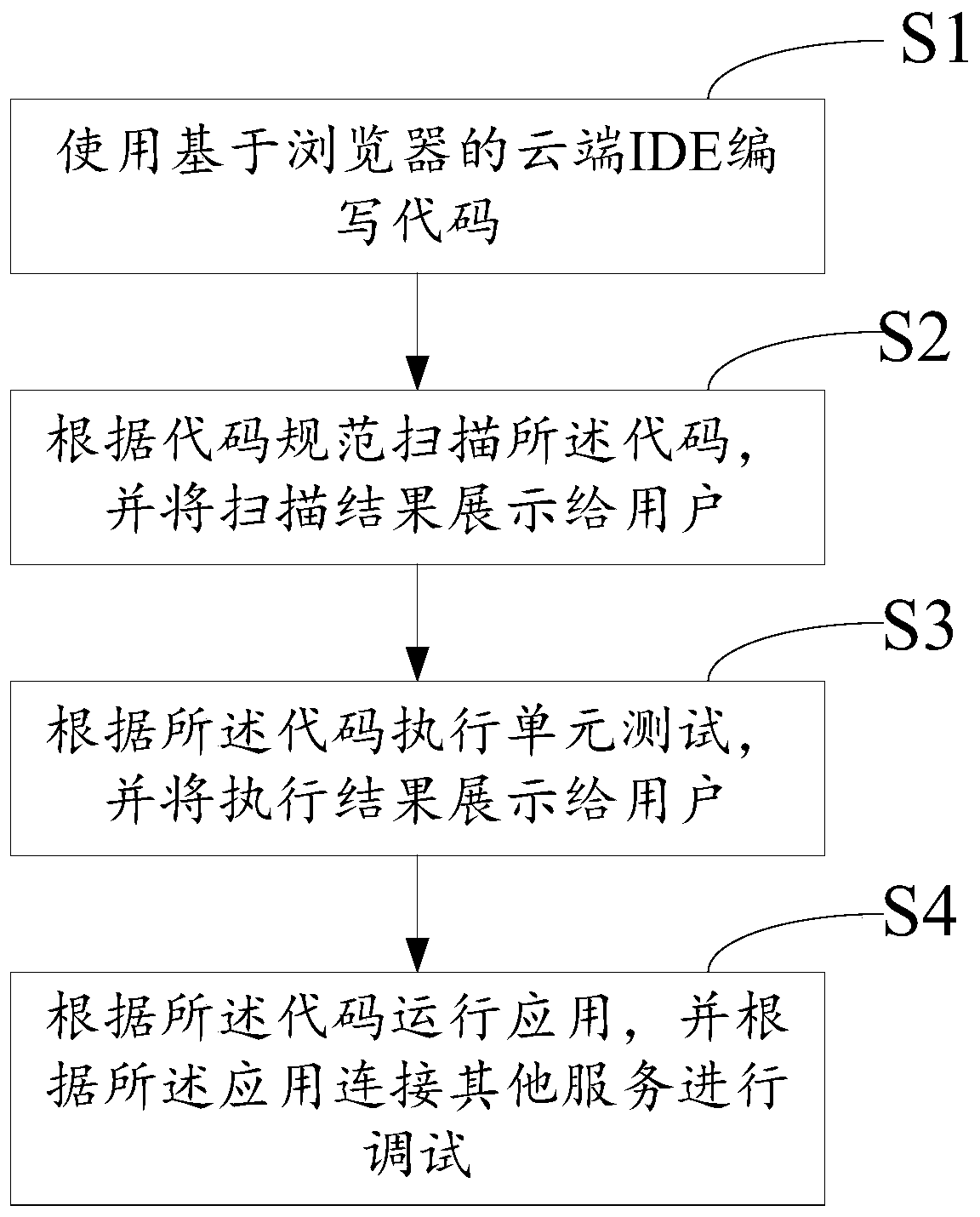

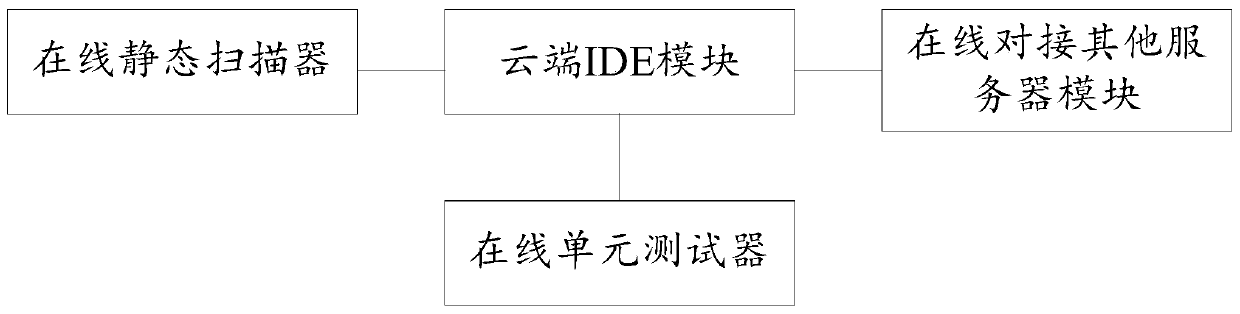

PendingCN110109830AImprove code qualityPromotionSoftware testing/debuggingUser codeSoftware debugging

The invention provides a software debugging management method, device and system and a storage medium The management method comprises the steps that S1, using a cloud IDE based on a browser to write codes; s2, scanning the code according to a code standard, and displaying a scanning result to a user; s3, executing unit testing according to the code, and displaying an execution result to a user; and S4, running an application according to the code, and connecting other services according to the application for debugging. The method has the beneficial effects that the improvement of the qualityof terminal user codes can be promoted, and meanwhile, the investment cost of debugging between services is also reduced.

Owner:深圳行云创新科技有限公司

Counting and code spraying equipment for production line

The invention discloses a counting and code spraying equipment for production line. The equipment comprises a base, supporting rods are fixedly connected to the four corners of the lower end of the base, a material receiving box is fixedly connected to the left end of the base, a conveying belt is in transmission connection with the middle of the upper end of the base, a lifting device is fixedly connected to the upper end of a supporting frame, the front end of the lifting device is fixedly connected with a displacement device, the other end of the conveying pipe is fixedly connected with an ink-jet printer, the left portion of the upper end of the base is fixedly connected with a stabilizing seat and an infrared sensor, the front portion and the rear portion of the upper end of the base are fixedly connected with auxiliary devices, the two auxiliary devices are located on the two sides of the conveying belt, and the left portion and the right portion of the front end of the supporting frame are each provided with a first sliding groove. According to the counting and code spraying equipment for the production line, the whole equipment is reasonable in structural design, the adjusting steps are simple, the code spraying position of a machined part is accurate, the code spraying quality of the machined part is high, and the counting and code spraying equipment is suitable for wide application.

Owner:江苏精仪达科技有限公司

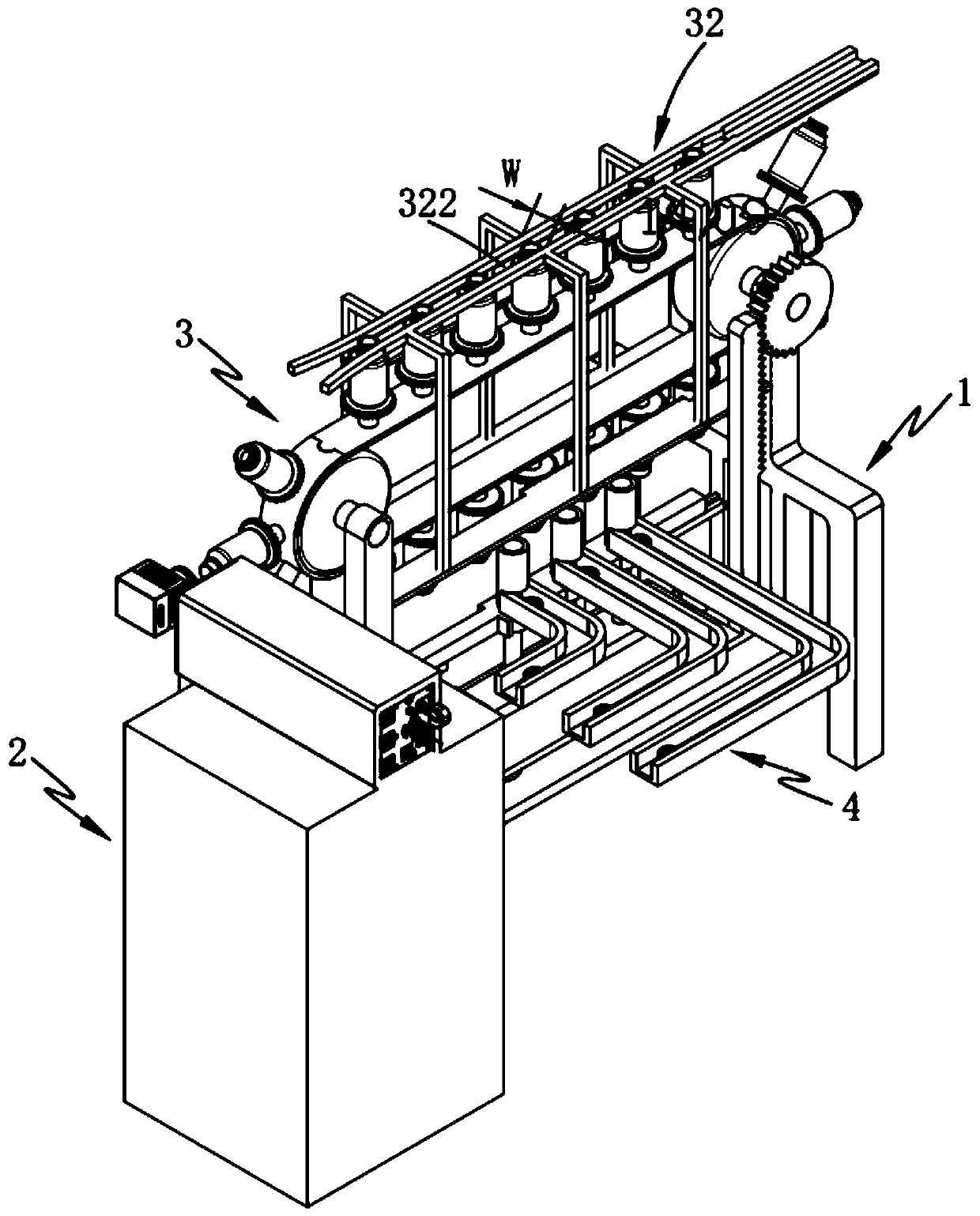

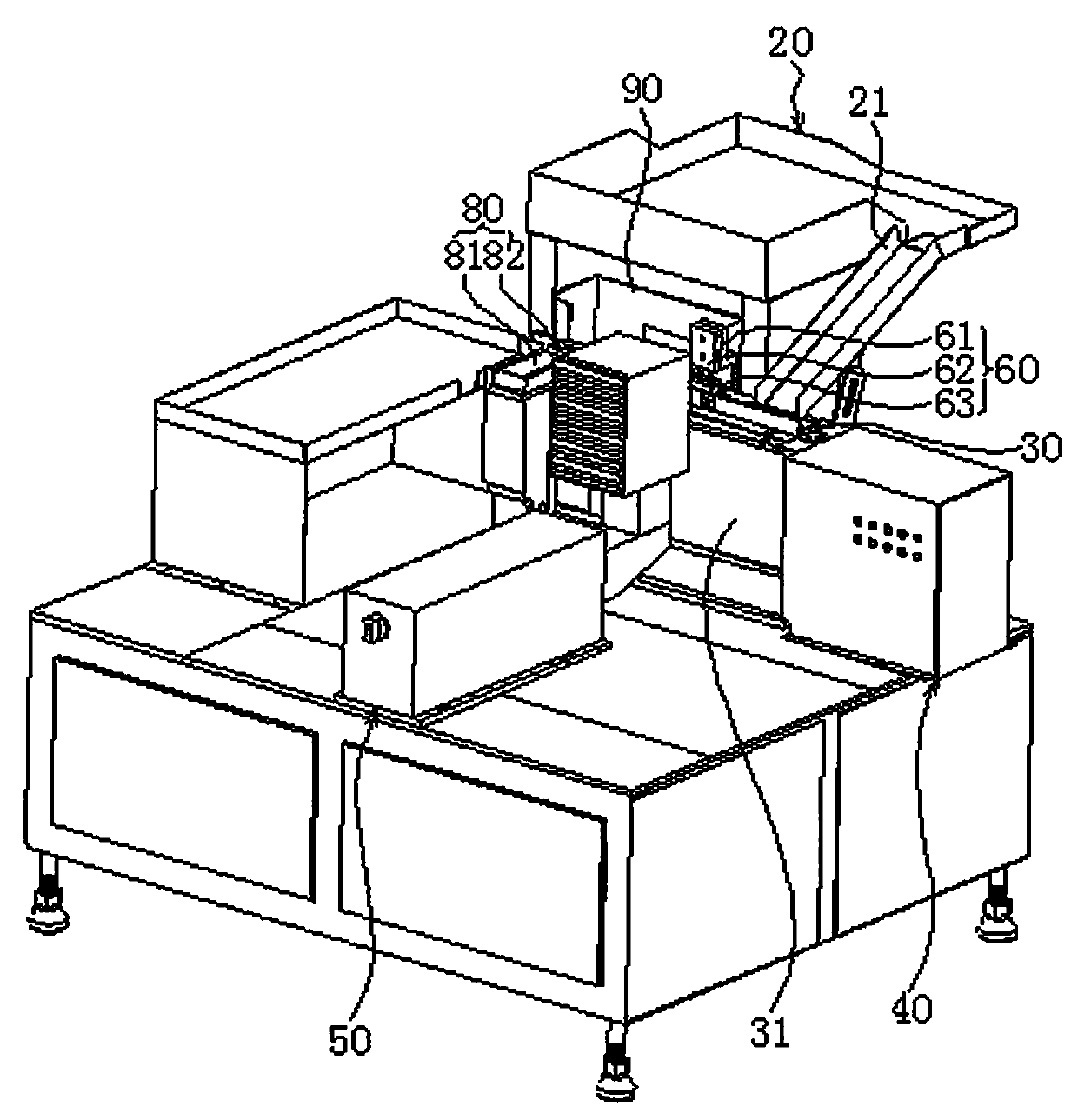

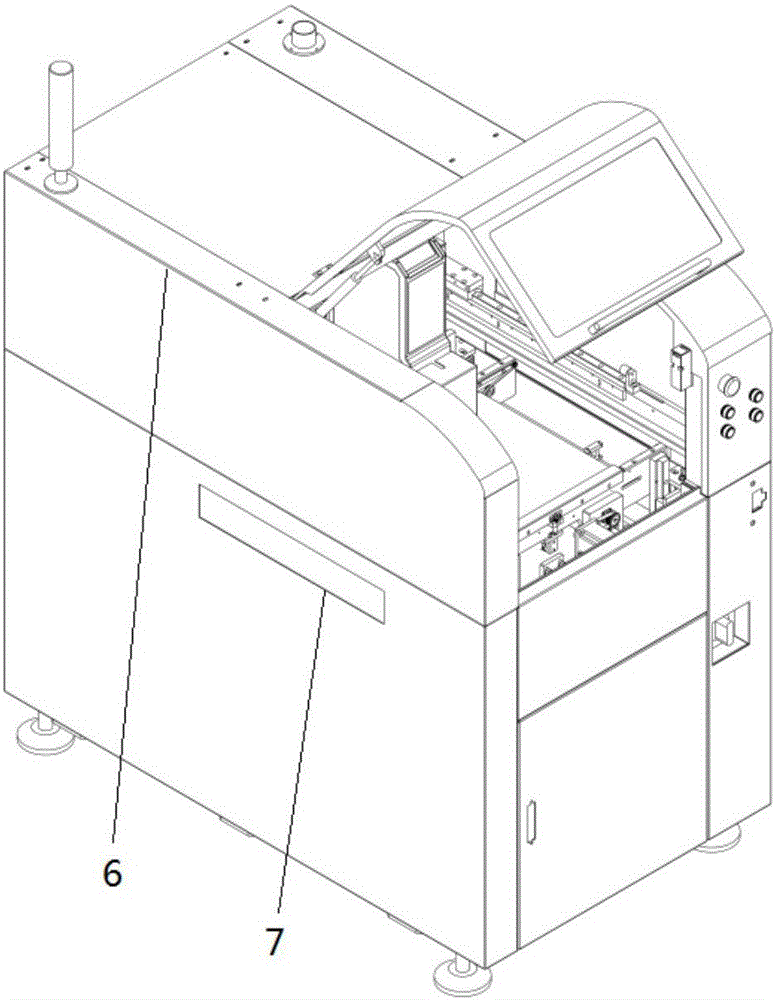

Bottle cap double-sided laser marking equipment

ActiveCN109940277AQuality improvementPermutation implementationLaser beam welding apparatusTypewritersEngineeringHeight difference

The invention provides bottle cap double-sided laser marking equipment. The bottle cap double-sided laser marking equipment comprises a front feeding device, a back feeding device, a laser code printing device, a bottle cap arranging device and a height compensating device. The bottle cap arranging device is arranged on one sides of the front feeding device and back feeding device. The height compensating device is arranged on one side of the output end of the bottle cap arranging device, and the laser coding device is arranged at the output end of the height compensating device. A code printing area is formed between the height compensating device and the laser code printing device. The bottle cap arranging device is arranged, so that bottle caps can be conveyed into the height compensating device in the manner that the bottle caps are arranged at intervals on the front and back sides. Meanwhile, when the bottle cap arranging device is used for arranging the bottle caps, the height compensating device is synchronously driven to carry out height compensation in the bottle cap turnover process, front and back code printing processing is carried out in the code printing area, and automatic height compensation is carried out. The technical problem that in the prior art, due to height differences, the code printing quality is greatly reduced during code printing of a second surfaceis solved.

Owner:德玛克(浙江)精工科技有限公司

Follow-up ink-jet printer

PendingCN109940989AImprove cleanlinessGuarantee the efficiency of inkjet codingOther printing apparatusEngineeringSponge

The invention discloses a follow-up ink-jet printer. The follow-up ink-jet printer comprises an ink-jet printer frame, wherein the ink-jet printer frame is provided with an ink-jet head frame; the ink-jet head frame is provided with an ink-jet head; the ink-jet printer frame is provided with a transverse transmission seat, a longitudinal transmission seat, a transverse servo motor and a longitudinal servo motor, and the transverse servo motor and the longitudinal servo motor are respectively used for driving the transverse transmission seat and the longitudinal transmission seat; the longitudinal transmission seat is in transmission fit with the transverse transmission seat; the ink-jet head frame is in transmission fit with the longitudinal transmission seat; the ink-jet printer further comprises a film holding frame for holding a film to be ink-jet printed; an ink-jet end of the ink-jet head is aligned with the film holding frame; one side of the film holding frame is provided with alongitudinal sensor; the ink-jet head is provided with a transverse sensor; the longitudinal sensor is in communication connection with the longitudinal servo motor; the transverse sensor is in communication connection with the transverse servo motor; the ink-jet head is provided with an automatic wiping device; and the automatic wiping device comprises a wiping cylinder, a wiping screw rod, a wiping fixing frame and a wiping sponge and the wiping cylinder, the wiping screw rod, the wiping fixing frame and the wiping sponge are sequentially connected.

Owner:深圳丰铎自动化设备有限公司

Laser engraving machine

The invention aims to provide a laser engraving machine which is high in code printing efficiency, good in quality and wide in application range. The laser engraving machine comprises a machine frame, a laser engraving unit and a feeding unit, wherein the laser engraving unit is arranged on the machine frame, and the feeding unit right faces the laser engraving unit. The laser engraving unit comprises a laser device and a scanning camera which horizontally move along the machine frame. The feeding unit comprises a feeding belt which right faces the laser device and the scanning camera. The feeding belt is driven by a transmission mechanism on the machine frame. According to the laser engraving machine, using of wastage materials is avoided, and the using cost is greatly reduced; and the code printing quality is high, and compared with label printing or pasting, the phenomena of defacing, scraping, disengagement and the like are avoided.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

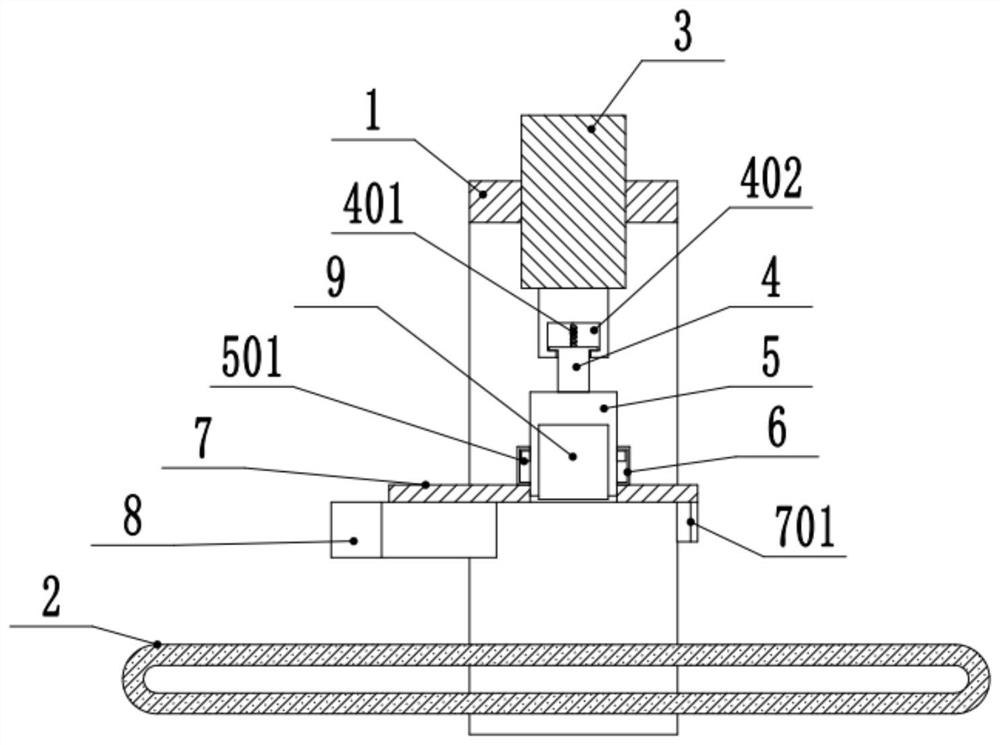

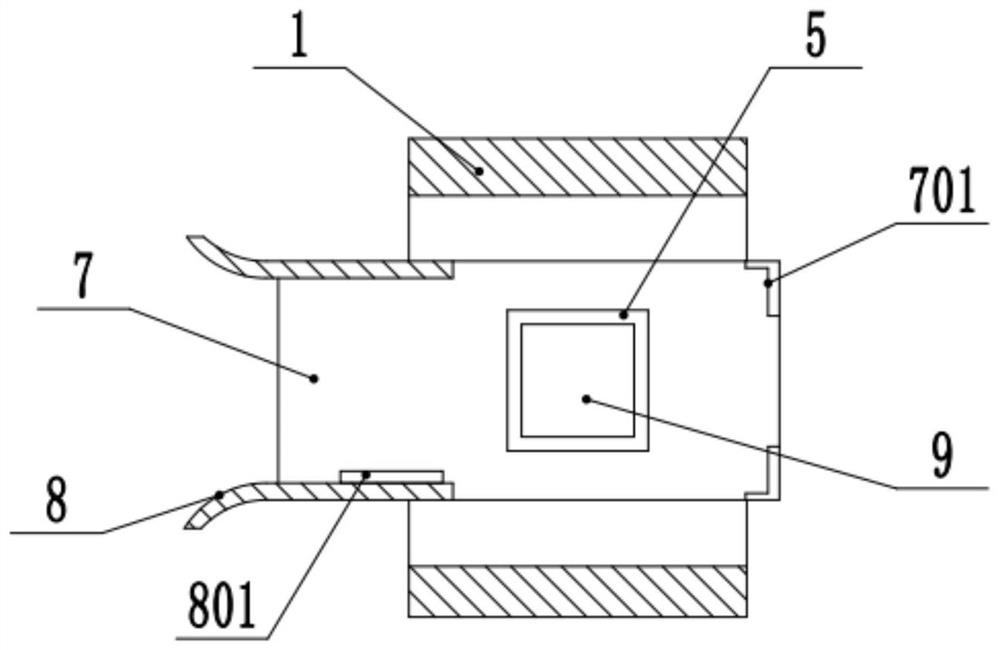

Code marking lifting device for cigarette production

PendingCN112660523AHigh coding clarityConsistent positionPackagingProgramming languageStructural engineering

The invention discloses a code marking lifting device for cigarette production. The code marking lifting device comprises a bridge-shaped rack (1) and a conveyor belt (2), the bridge-shaped rack (1) is arranged on the conveyor belt (2) in a spanning manner, a telescopic device (3) arranged in the vertical direction is arranged on a top plate of the bridge-shaped rack (1), a stand column (4) is arranged on a telescopic rod on the telescopic device (3), the lower end of the stand column (4) is fixedly connected with a code marking box (5), a code marking machine (9) is installed in the code marking box (5), a supporting table (501) is arranged on the periphery of the code marking box (5), and the code marking box (5) is connected with a packaging box limiting mechanism in a sliding mode through the supporting table (501). The code marking lifting device can replace manual work to automatically mark codes on the packaging boxes, the code marking efficiency is improved, and the code marking error rate is reduced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

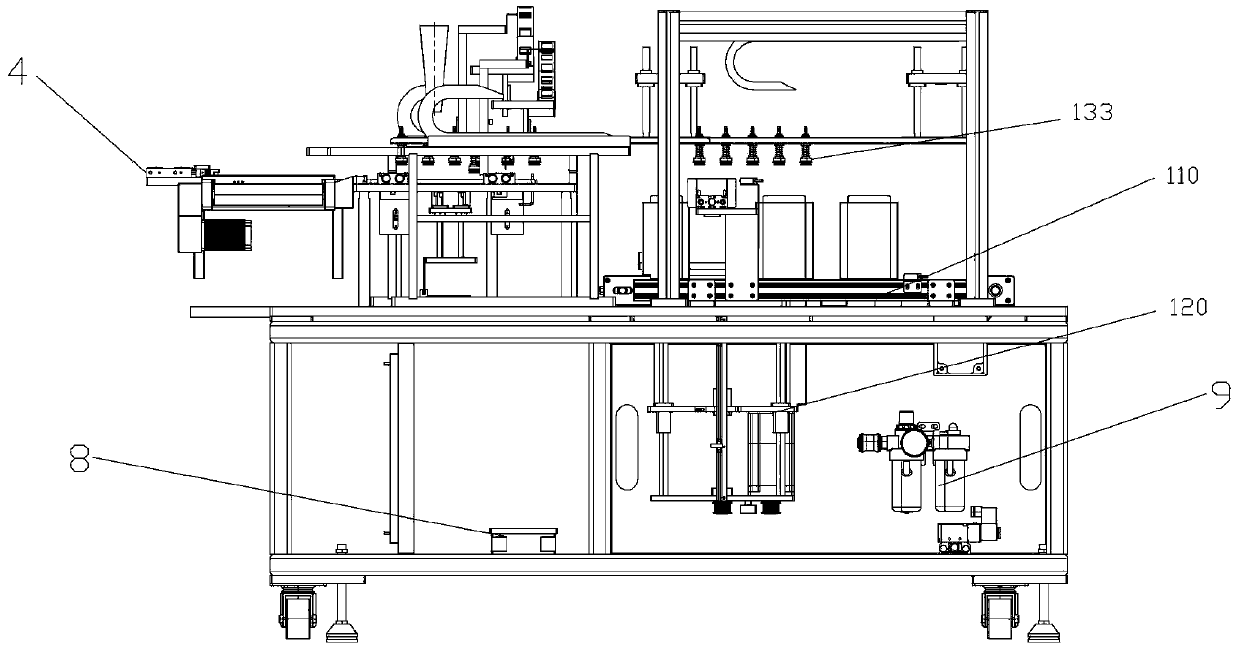

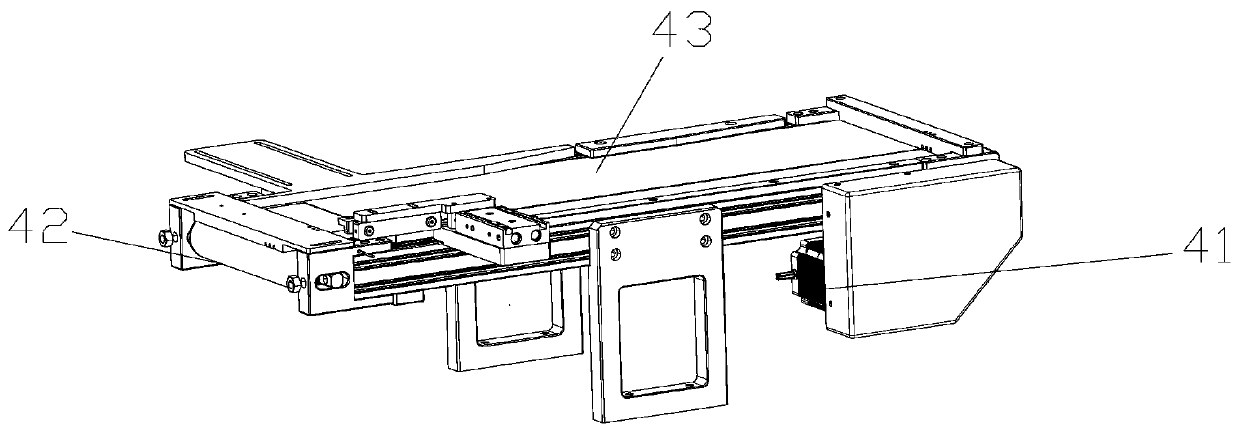

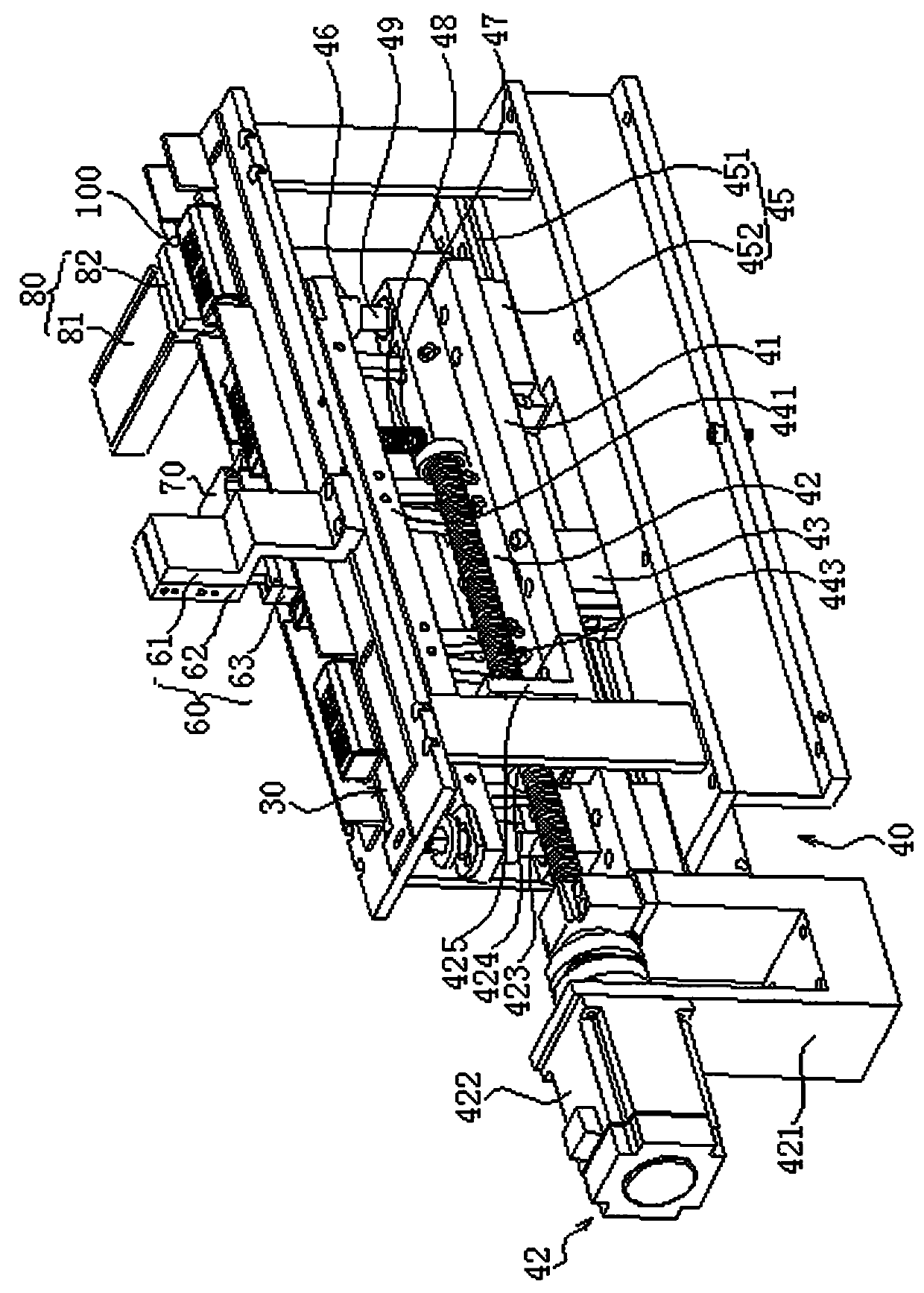

Tracking type dynamic bottle cap marking equipment

ActiveCN110052717ASave powerPushing and rotating with high precisionLaser beam welding apparatusProblem of timeBiomedical engineering

The invention provides tracking type dynamic bottle cap marking equipment. The tracking type dynamic bottle cap marking equipment comprises a bracket, a marking device, a rotating device and a feedingdevice, the rotating device comprises a rotating assembly and an outputting assembly, the feeding device is slidably arranged on the bracket and comprises an interval pushing assembly and a trackingassembly, and the interval pushing assembly and one end of the rotating assembly are arranged in a linkage mode; and by arranging the feeding device and the rotating device, the feeding device pushesa bottle cap needing marking upwards to a bottle cap limiting piece of the rotating device and keeps a tracking state with the rotating device in the upward pushing process, the rotating device drivesthe bottom cap located on the bottle cap limiting piece to rotate and be transported, marking processing is conducted on the bottle cap on the marking device to achieve the automatic outward output,and the problems of time and labor wasting due to the manual linear distribution of the bottle cap in the prior art and the poor feeding effect due to the asynchrony of the bottle cap and the rotatingand transporting device in the feeding process are solved simultaneously.

Owner:德玛克(长兴)注塑系统有限公司

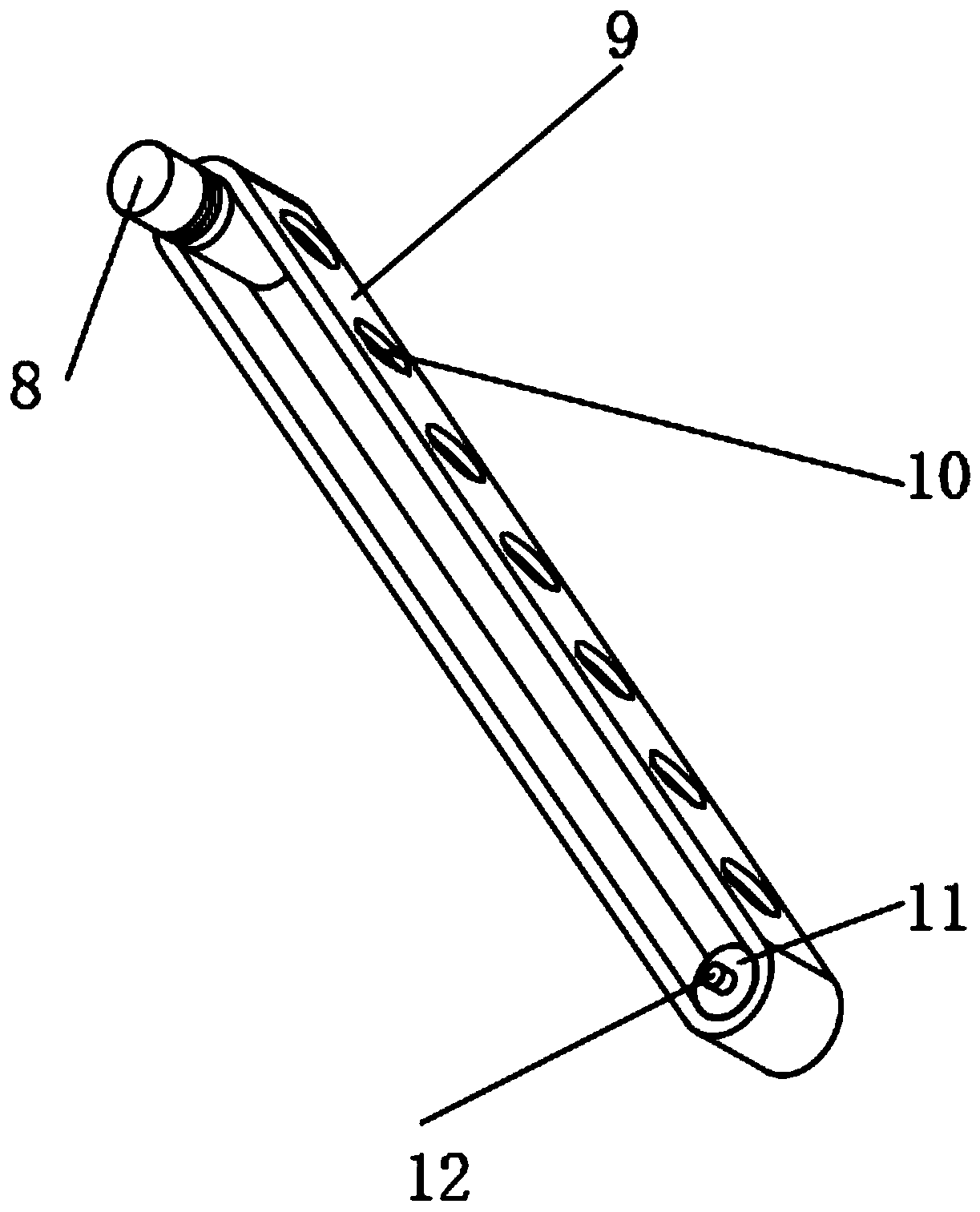

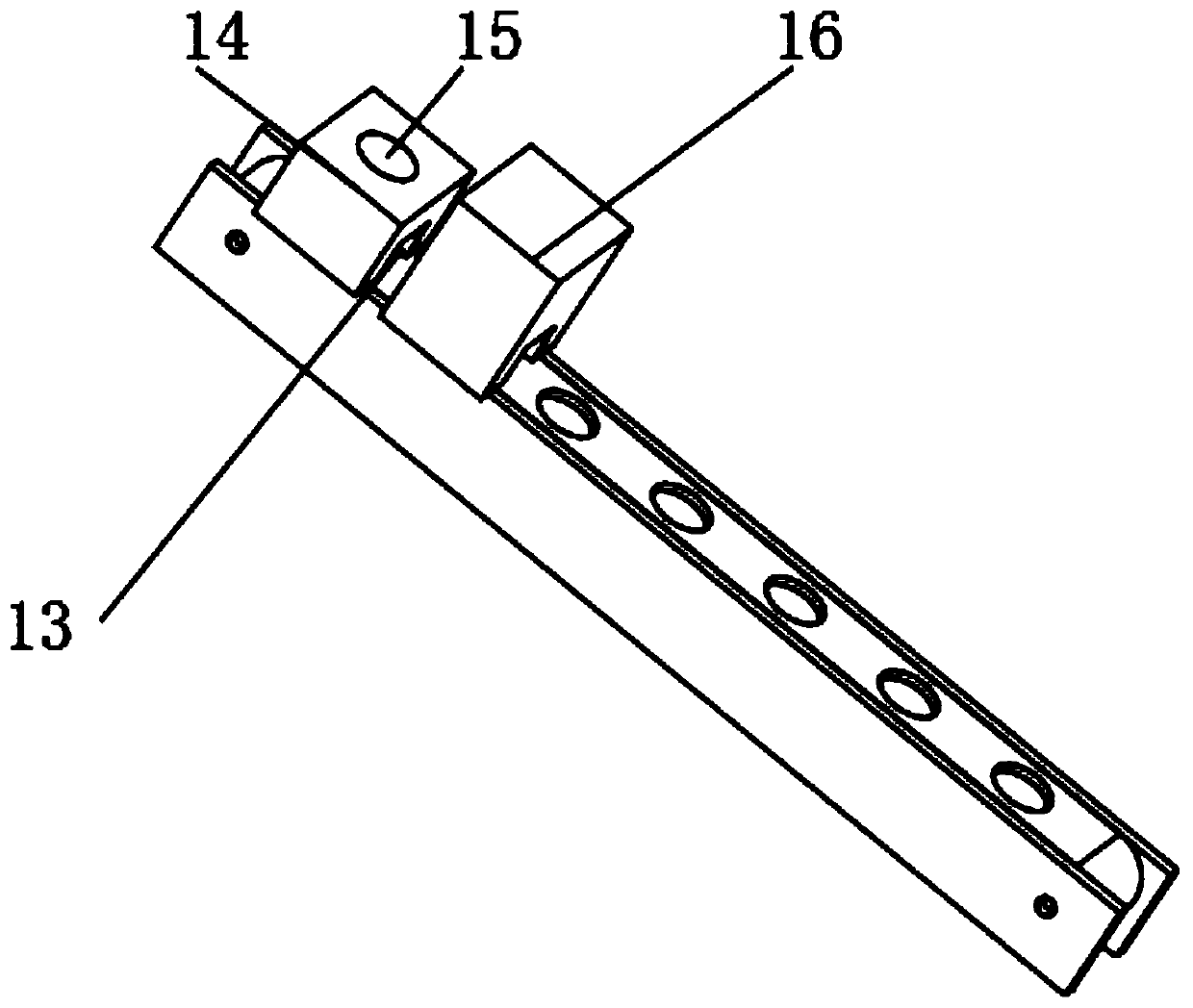

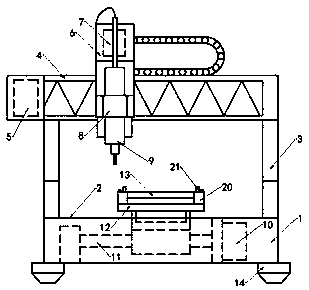

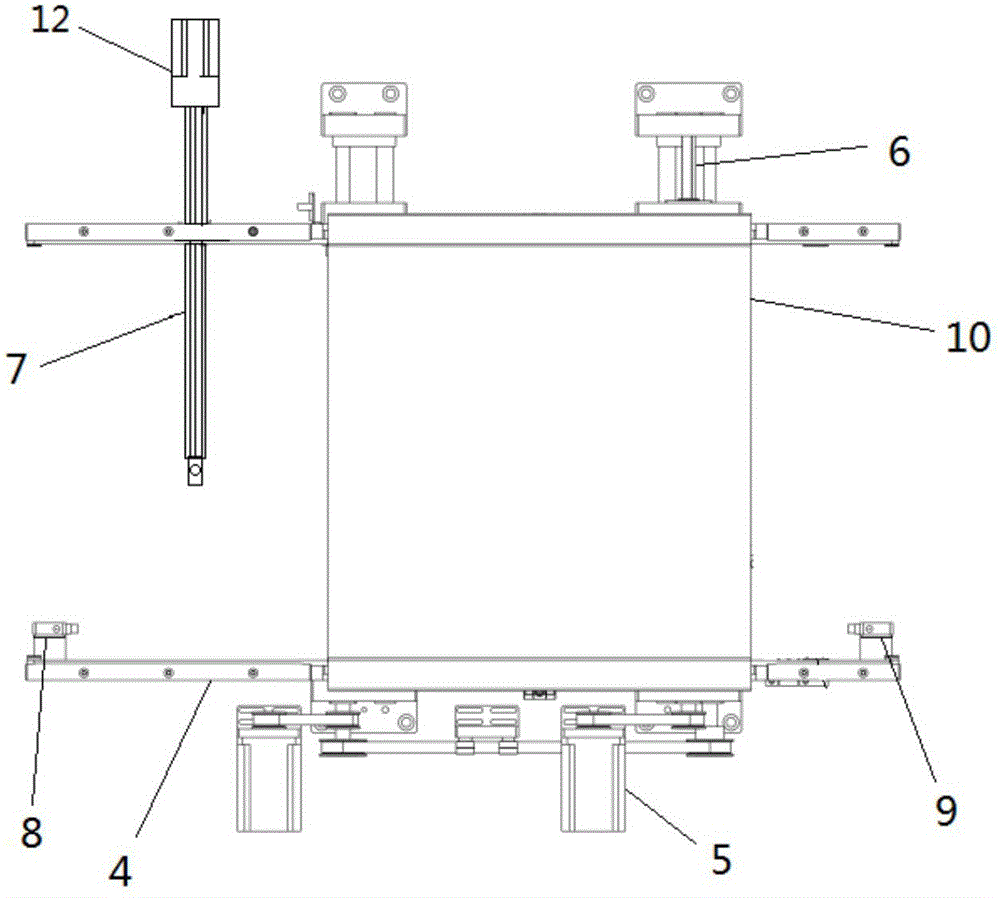

Laser engraving device for plastic spectacle frame

InactiveCN108067738AAvoid wasting materialReduce use costLaser beam welding apparatusMoving partsEngineering

The invention discloses a laser engraving device for a plastic spectacle frame. The laser engraving device is characterized in that a first driving device (5) is arranged at the left end of a cross beam (4), and the cross beam (4) is internally provided with a first screw rod connected with the first driving device (5); the first screw rod is movably connected with a longitudinal moving part (6),and the longitudinal moving part (6) is controlled to move left and right through the first driving device (5); a second driving device (7) is arranged at the top end of the longitudinal moving part(6), and the longitudinal moving part (6) is internally provided with a second screw rod connected with the second driving device (7); the second screw rod is movably connected with a moving seat (8),a laser engraving part (9) is fixed on the moving seat (8), and the laser engraving part (9) is controlled to move up and down through the second driving device (7); and a material clamping seat (12)arranged on a workbench (2) is driven to move forwards and backwards by a third driving device (10). The laser engraving device is simple in structure and convenient and rapid to operate.

Owner:江苏裕昌光学眼镜有限公司

Laser engraving machine

The invention aims to provide a laser engraving machine which has high marking efficiency, high quality and a wide application range. The laser engraving machine comprises a machine frame, a laser engraving unit arranged on the machine frame and a feeding unit facing the laser engraving unit, wherein the laser engraving unit comprises a laser device and a scanning camera, which move horizontally along the machine frame; the feeding unit comprises feeding belts which face the laser device and the scanning camera; and the feeding belts are driven by a transmission mechanism on the machine frame. The laser engraving machine provided by the invention avoids material waste, greatly reduces the use cost and has high marking quality, and compared with printing or labeling, the laser engraving machine avoids the phenomena of staining, stripping, falling and the like.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

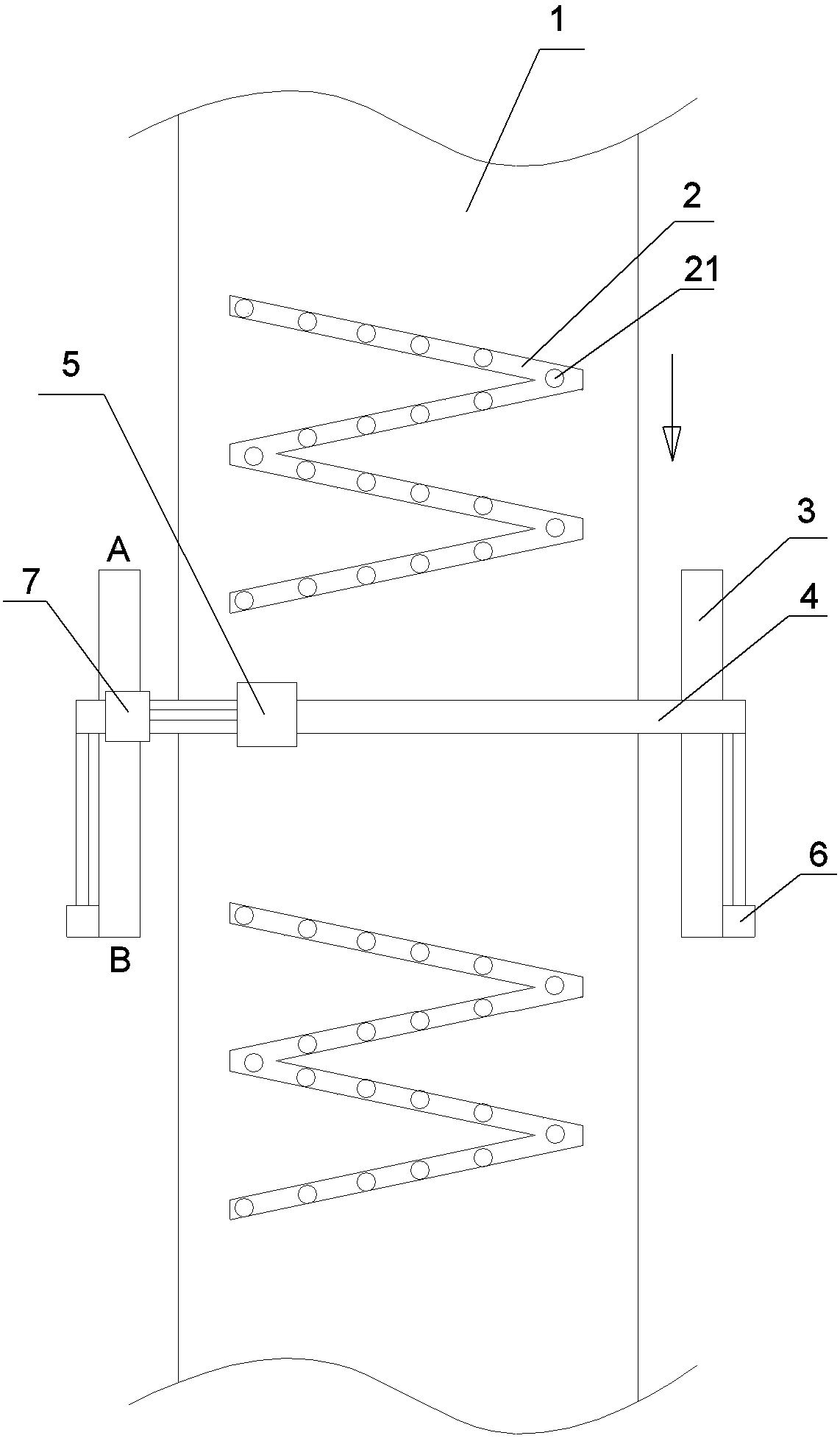

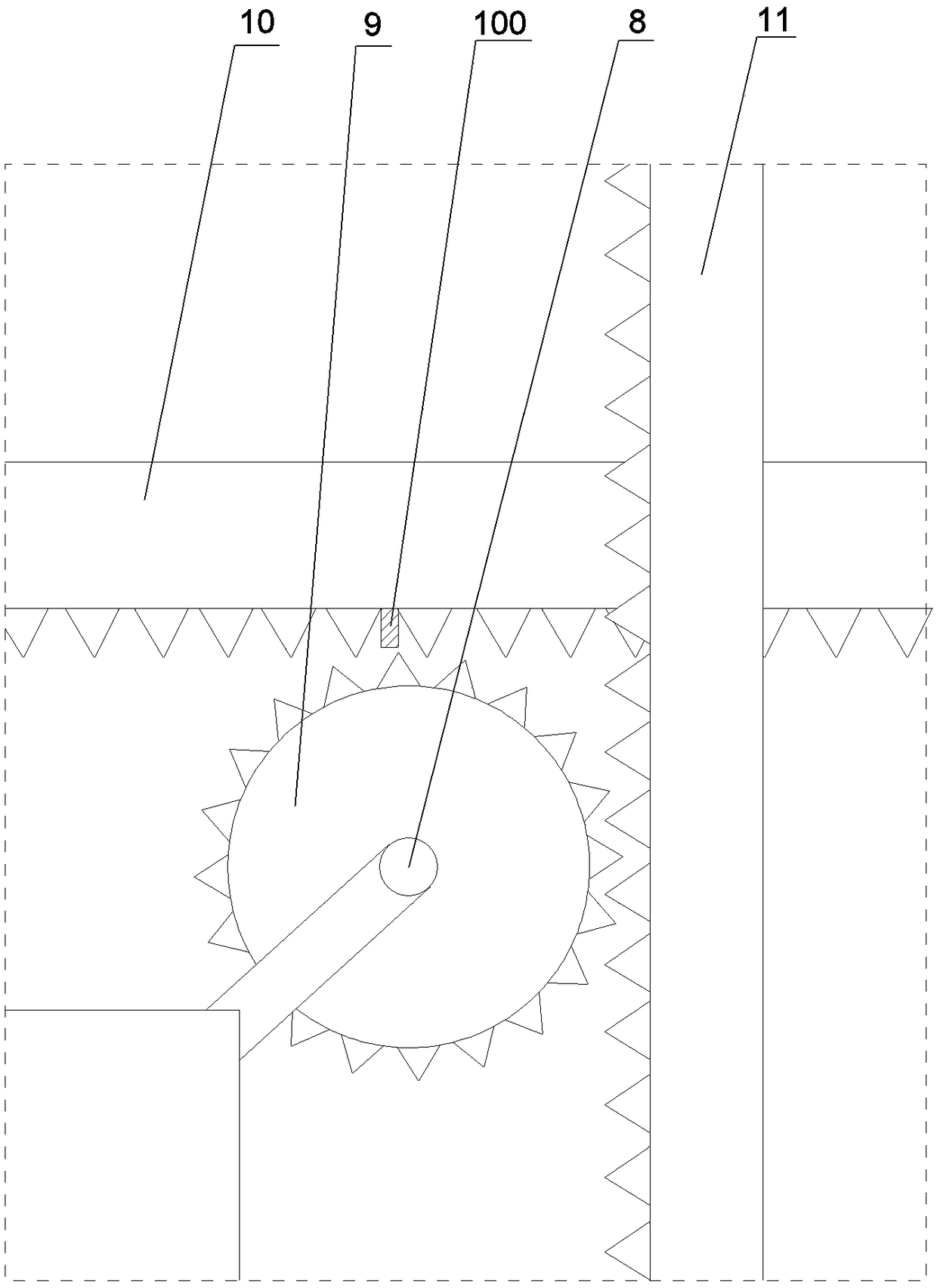

Automatic ink-jet printing machine for packaging

The invention belongs to the technical field of packaging, and particularly discloses an automatic ink-jet printing machine for packaging. The automatic ink-jet printing machine comprises a conveyingbelt, the conveying belt is provided with a broken-line-shaped product containing groove, rails are arranged on the two sides of the conveying belt, a sliding way is arranged above the conveying belt,the two ends of the sliding way are in sliding connection to the two rails, an ink-jet printing machine body is arranged on the sliding way in a sliding manner, the ink-jet printing machine body comprises a printing ink cavity, a piston is arranged in the printing ink cavity in a sliding manner, and a printing ink outlet is communicated to the bottom of the printing ink cavity; a rotating shaft is rotationally connected to the ink-jet printing machine body and is sleeved with a gear, a first rack meshed with the gear is fixedly connected to the sliding way, and a code spraying switch used foropening a printing ink outlet is arranged in a tooth groove of the first rack; and a second rack is meshed to the gear and is vertically connected to the ink-jet printing machine body in a sliding manner, the second rack is fixedly connected with the piston, a one-way bearing is arranged between the gear and the rotating shaft, and the one-way bearing is in the locking state when the gear rotatesreversely. By means of the automatic ink-jet printing machine for packaging, the space using rate of the conveying belt can be improved.

Owner:重庆云新包装有限公司

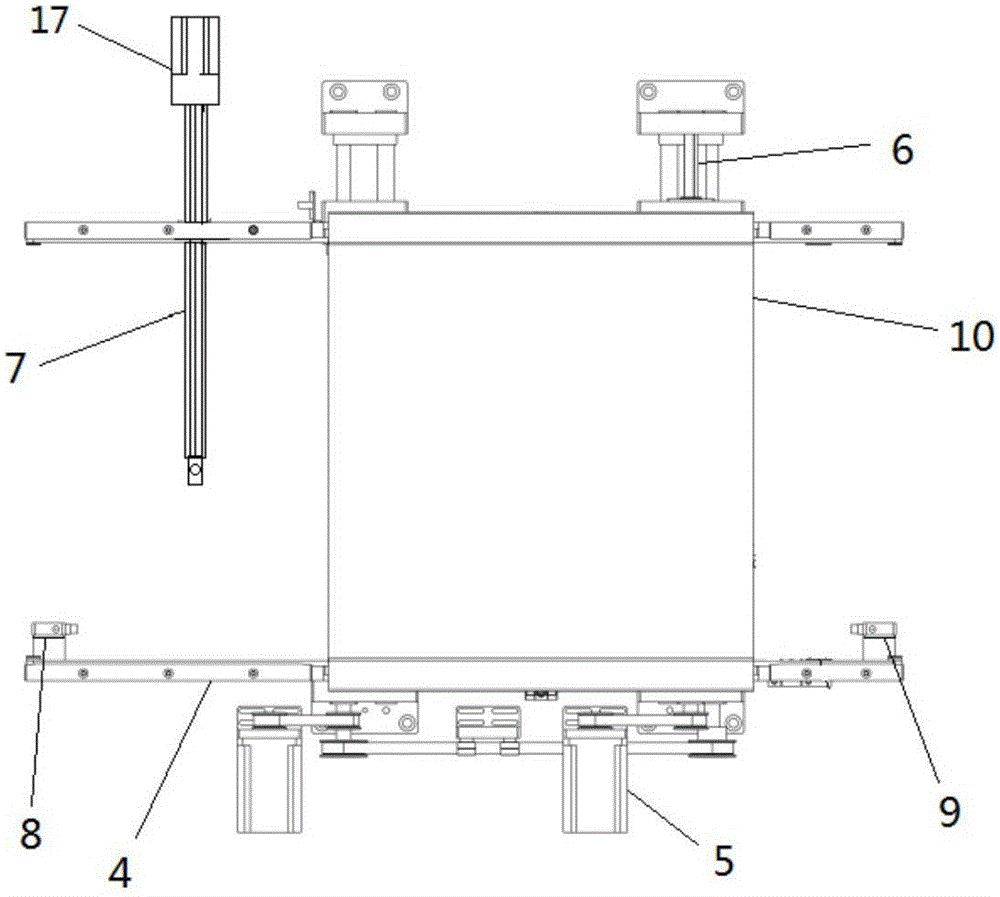

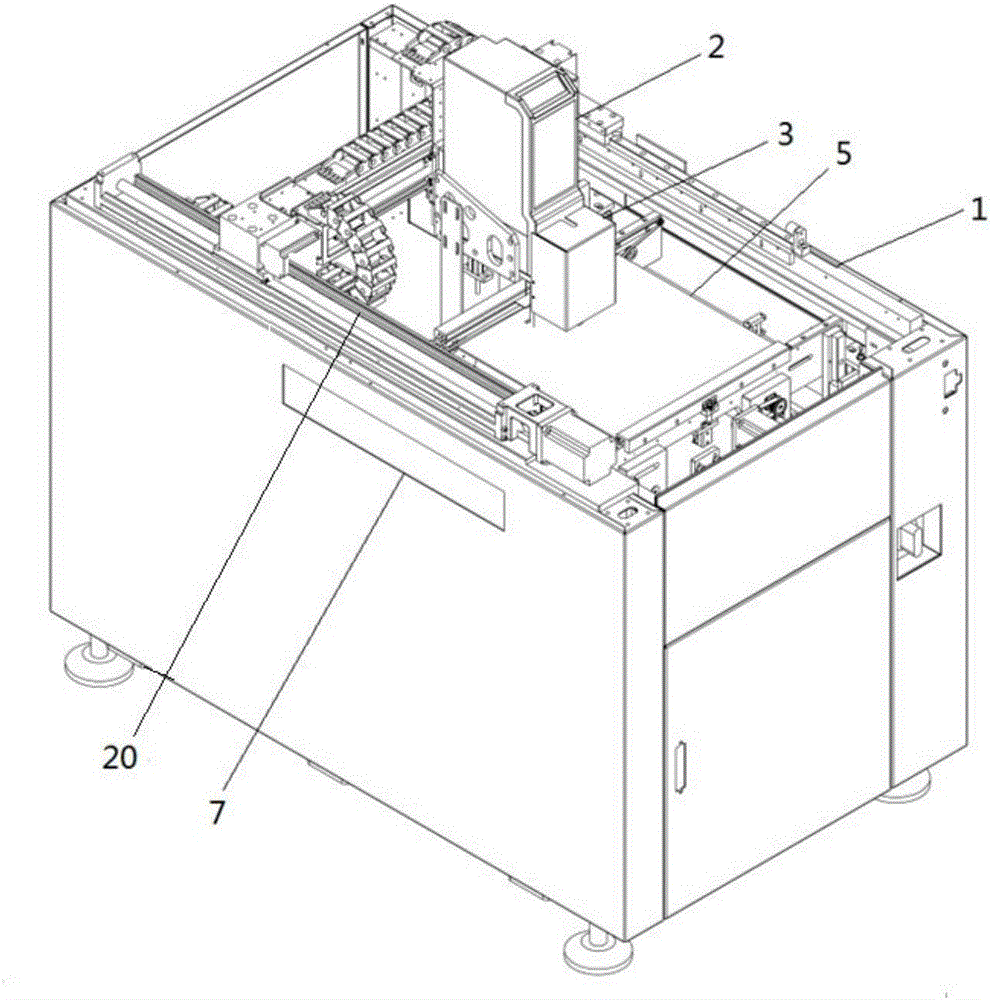

Non-directional laser coding machine and coding method

ActiveCN105345267BPrecise laser codingIncrease productivityLaser beam welding apparatusProcessing InstructionControl system

The invention discloses an astatic laser coding machine which comprises a rack, a feeding system, a visual identifying system, a laser coding system and a control system, wherein the feeding system is used for feeding a product and transmitting the product on the rack; the visual identifying system and the laser coding system are arranged above the rack; the visual identifying system is used for capturing a product picture, comparing the product picture with a standard picture, and counting a current product position and current product angular offset; the laser coding system is used for regulating the product position and coding the product according to the obtained product offset coordinates and the obtained product offset angle; the control system is connected with the visual identifying system, the laser coding system and a product sensor, and is used for sending a trigger signal sent by the product sensor and then sending a processing instruction to the visual identifying system, and processing the data obtained by the visual identifying system; and the laser coding system is used for sending the coding instruction. The astatic laser coding machine can be used for realizing laser coding with a precise position, so that the production efficiency and the coding quality are greatly improved.

Owner:广州市比美高智能系统科技有限公司

Laser engraving machine

The invention aims to provide a laser engraving machine which has high marking efficiency, high quality and a wide application range. The laser engraving machine comprises a machine frame, a laser engraving unit arranged on the machine frame and a feeding unit facing the laser engraving unit, wherein the laser engraving unit comprises a laser device and a scanning camera, which move horizontally along the machine frame; the feeding unit comprises feeding belts which face the laser device and the scanning camera; and the feeding belts are driven by a transmission mechanism on the machine frame. The laser engraving machine provided by the invention avoids material waste, greatly reduces the use cost and has high marking quality, and compared with printing or labeling, the laser engraving machine avoids the phenomena of staining, stripping, falling and the like.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

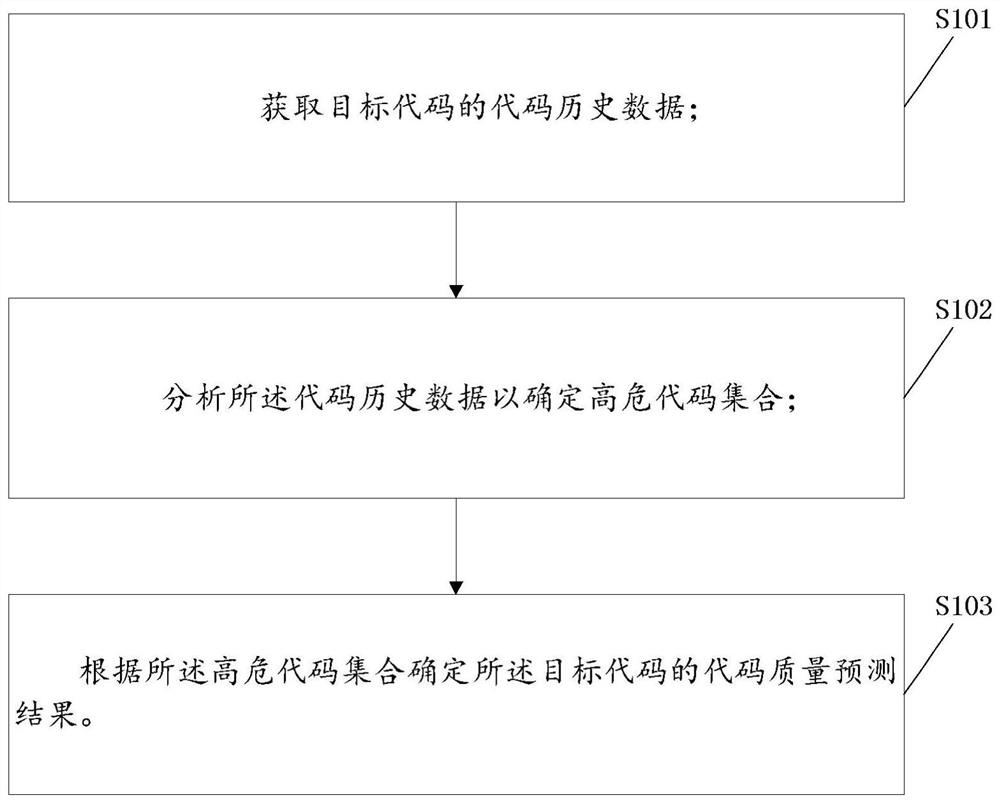

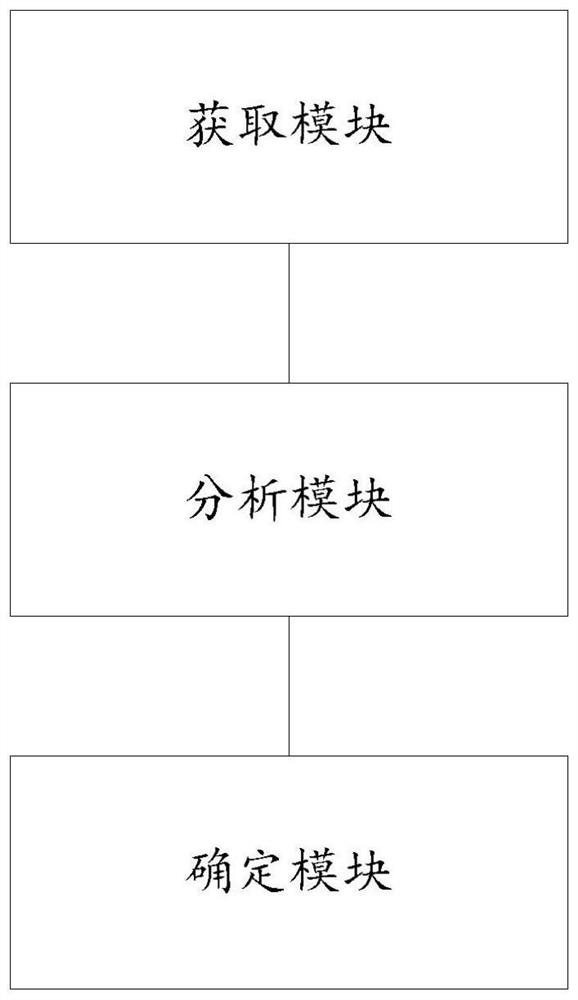

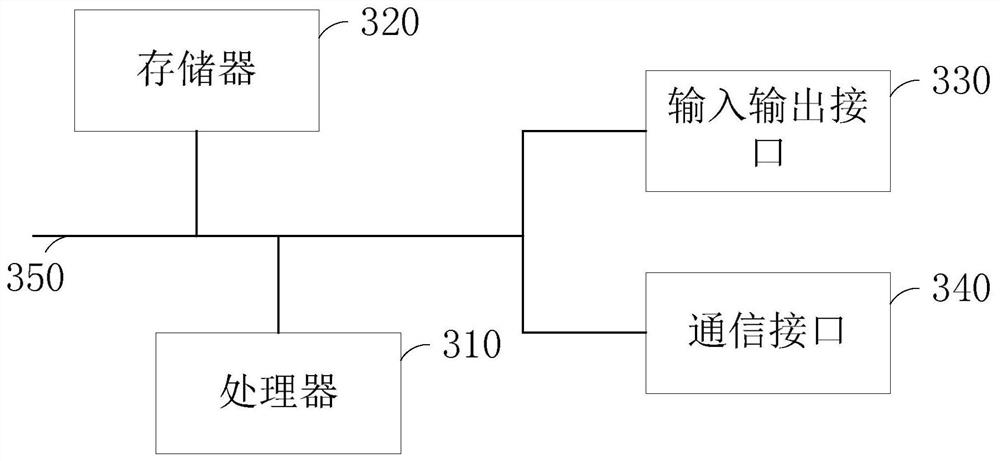

Code quality early warning method and device, electronic equipment and storage medium

PendingCN112416799AImprove code qualityReduce operational riskSoftware testing/debuggingRisk CodesOperating system

One or more embodiments of the invention provide a code quality early warning method and device, electronic equipment and a storage medium. The method comprises the steps of obtaining code historicaldata of a target code; analyzing the code historical data to determine a high-risk code set; and determining a code quality prediction result of the target code according to the high-risk code set. The code historical data of the target code is analyzed to realize early warning of the code quality of the target code, and the high-risk code set is established and analyzed, so that the overall codequality of the system is improved and the operation risk of the system is reduced while the code quality early warning of the target code is performed based on the high-risk code set.

Owner:CHINA LIFE INSURANCE COMPANY

A double-sided laser marking equipment for bottle caps

ActiveCN109940277BQuality improvementPermutation implementationLaser beam welding apparatusEngineeringHeight difference

The invention provides a double-sided laser marking equipment for bottle caps, which includes a front feeding device, a reverse feeding device, a laser coding device, a bottle cap arrangement device and a height compensation device; the bottle cap arrangement device is arranged on the front feeding device and One side of the reverse feeding device; the height compensation device is set on the side of the output end of the bottle cap arrangement device, and the laser marking device is set on the output end of the height compensation device, forming a code between the height compensation device and the laser marking device area; by setting up the bottle cap arrangement device, the bottle caps are transported to the height compensation device in the way of front and back sides arranged at intervals, and at the same time, the bottle cap arrangement in the bottle cap arrangement device synchronously drives the height compensation device to perform height compensation during the bottle cap flipping process Finally, the front and back sides are coded in the coding area, and automatic height compensation is performed, which solves the technical problem that the coding quality is greatly reduced when the second side is coded due to the height difference in the prior art.

Owner:德玛克(浙江)精工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com