Code spraying printer for plastic packaging box and capable of facilitating ink adding

A packaging box and printer technology, applied in typewriters, printing devices, transportation and packaging, etc., can solve the problems of only one side coding and low coding efficiency of packaging boxes, so as to improve convenience, reduce process steps, increase The effect of coding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

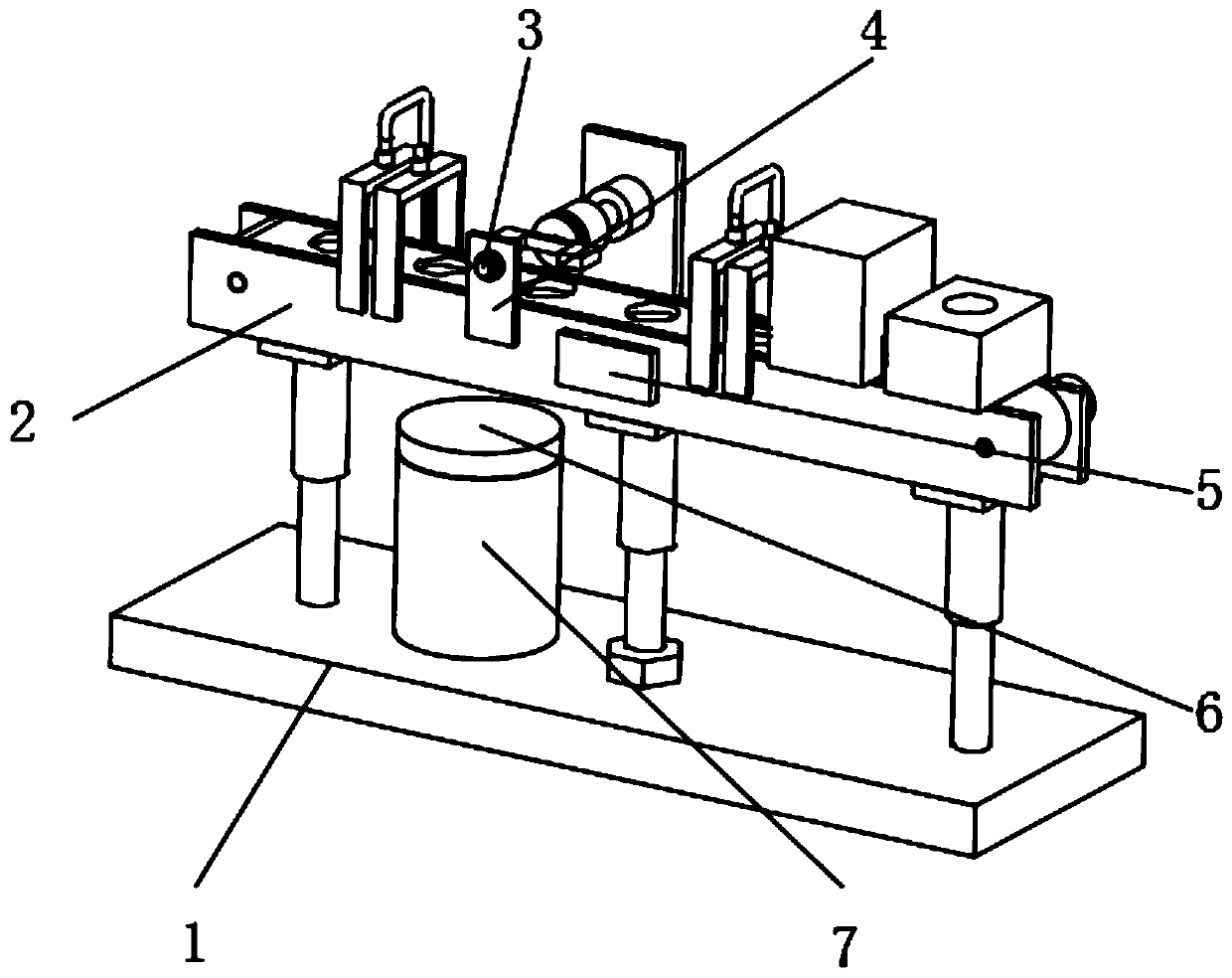

[0034] A kind of inkjet printer for plastic packing box that is convenient to add ink, such as figure 1As shown, it includes a base 1, the outer wall of the top of the base 1 is provided with a height adjustment mechanism, the top of the height adjustment mechanism is provided with two parallel side plates 2, the inner walls of the two side plates 2 are provided with a conveying mechanism, and the top of the side plate 2 Two inductive coding mechanisms, a turning mechanism and a positioning mechanism are provided respectively. The top outer wall of the base 1 is fixed with an ink barrel 7 by bolts, and the top outer wall of the ink barrel 7 is fixed with a barrel cover 6 by bolts. One of the side plates 2 The side outer wall is fixed with a control board 5 by bolts; when in use, just remove the barrel cover 6 and pour the ink into the interior of the ink barrel 7, which improves the convenience of adding ink, and the height adjustment mechanism can make the height of the entire...

Embodiment 2

[0042] A kind of inkjet printer for plastic packing box that is convenient to add ink, such as figure 1 , 6 As shown, in order to enable this device to cooperate with other automation equipment to realize the automatic control degree of the entire production line of the packaging box; this embodiment makes the following improvements on the basis of embodiment 1: the height adjustment mechanism includes a threaded cylinder 31, a screw 32 and Outer hex nut 33, base 1 top outer wall is welded with two parallel telescopic rods 28, and the outer wall of two telescopic rods 28 is all slidably connected with sleeve 29, and the top inner wall of base 1 is connected with screw rod 32 in rotation, and the outer wall of screw rod 32 is connected with The inside of the threaded cylinder 31 is threaded, the top outer walls of the threaded cylinder 31 and the two sleeves 29 are fixed with a third support plate 30 by bolts, and the top outer walls of the three third support plates 30 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com