Movable type code spraying flow line used for code spraying of packing boxes

A packaging box and mobile technology, applied in the field of packaging box processing equipment, can solve the problems of inability to work for a long time, high labor intensity of operators, and restriction of production efficiency, so as to prevent deviation, improve automation, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

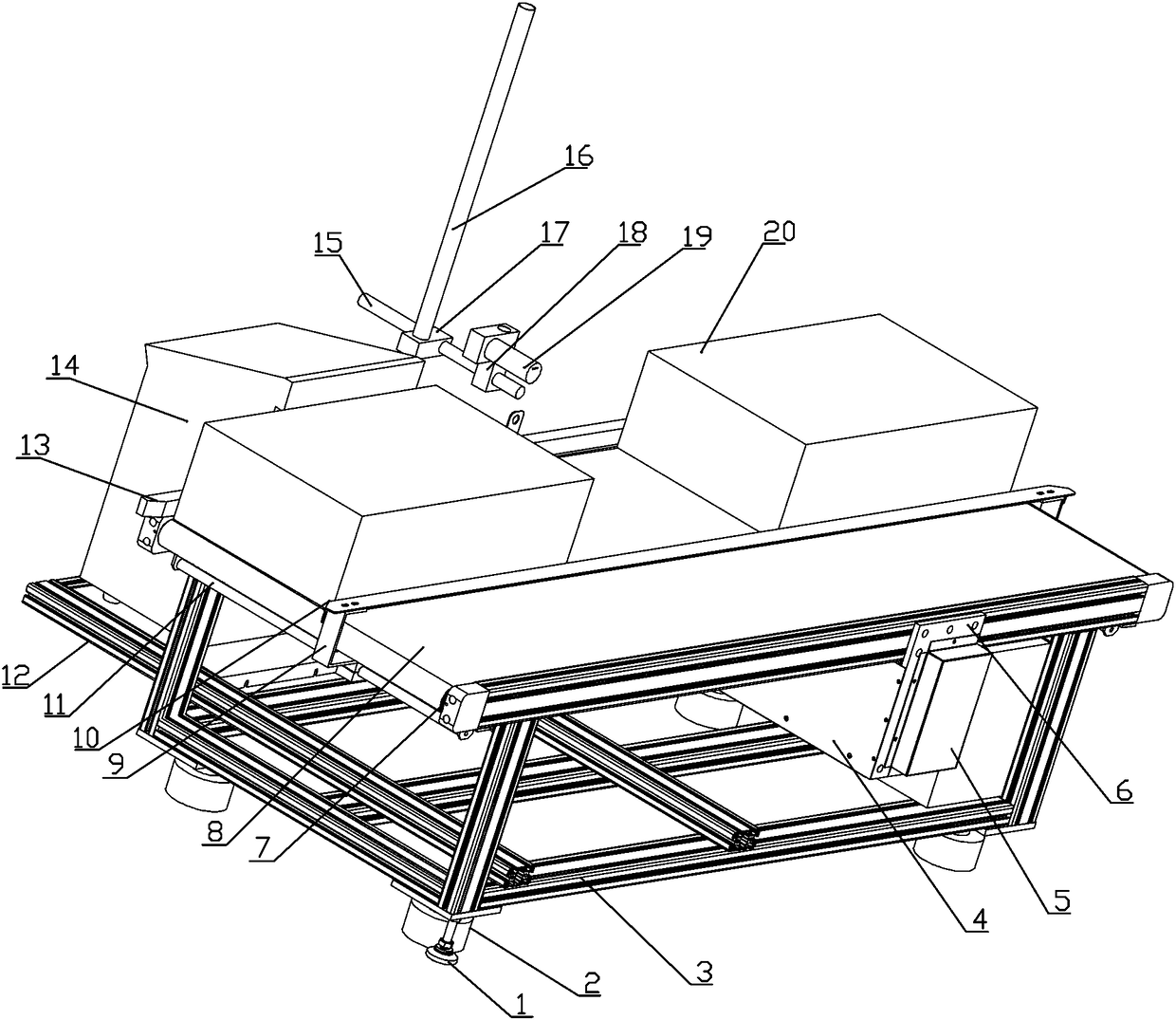

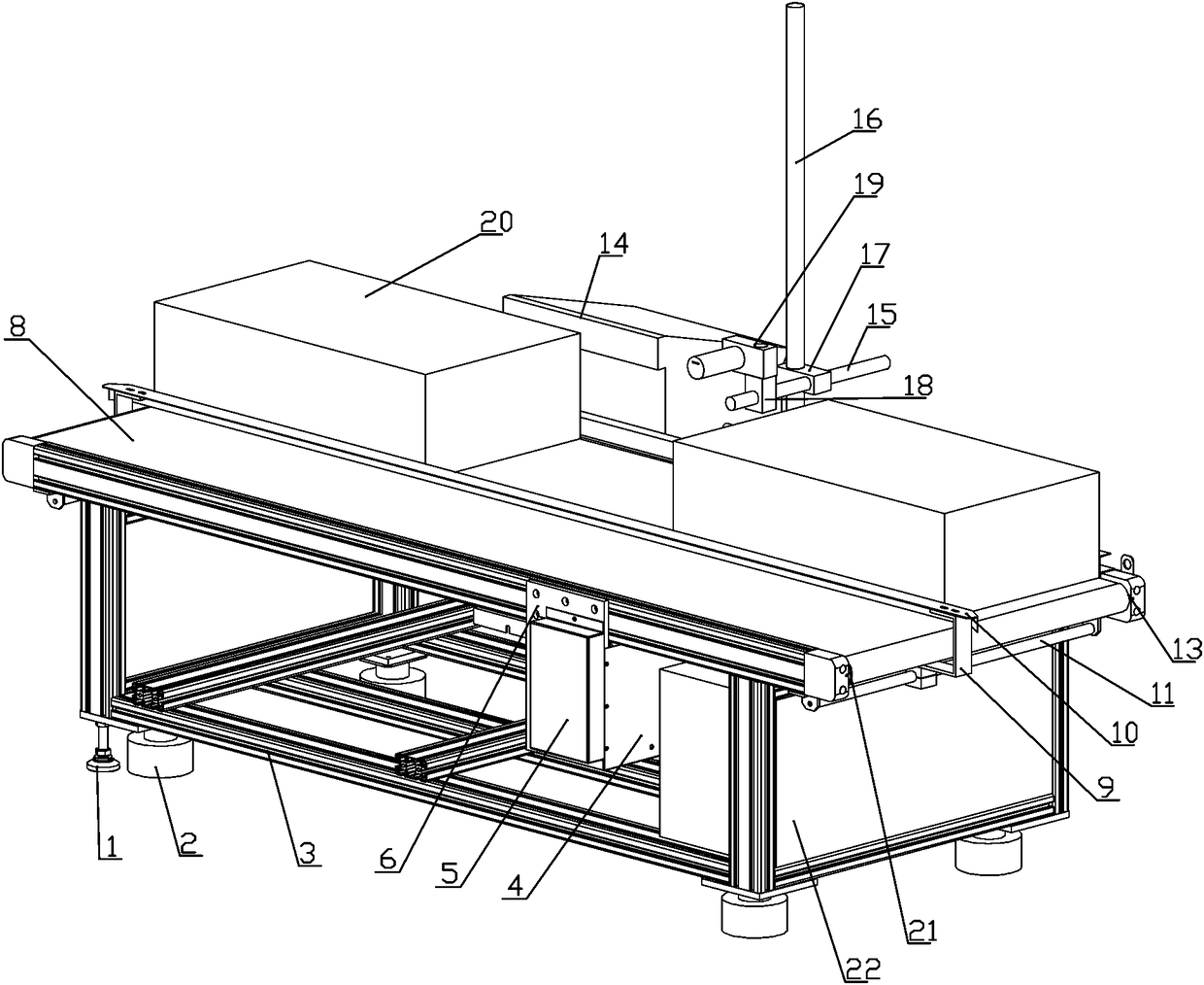

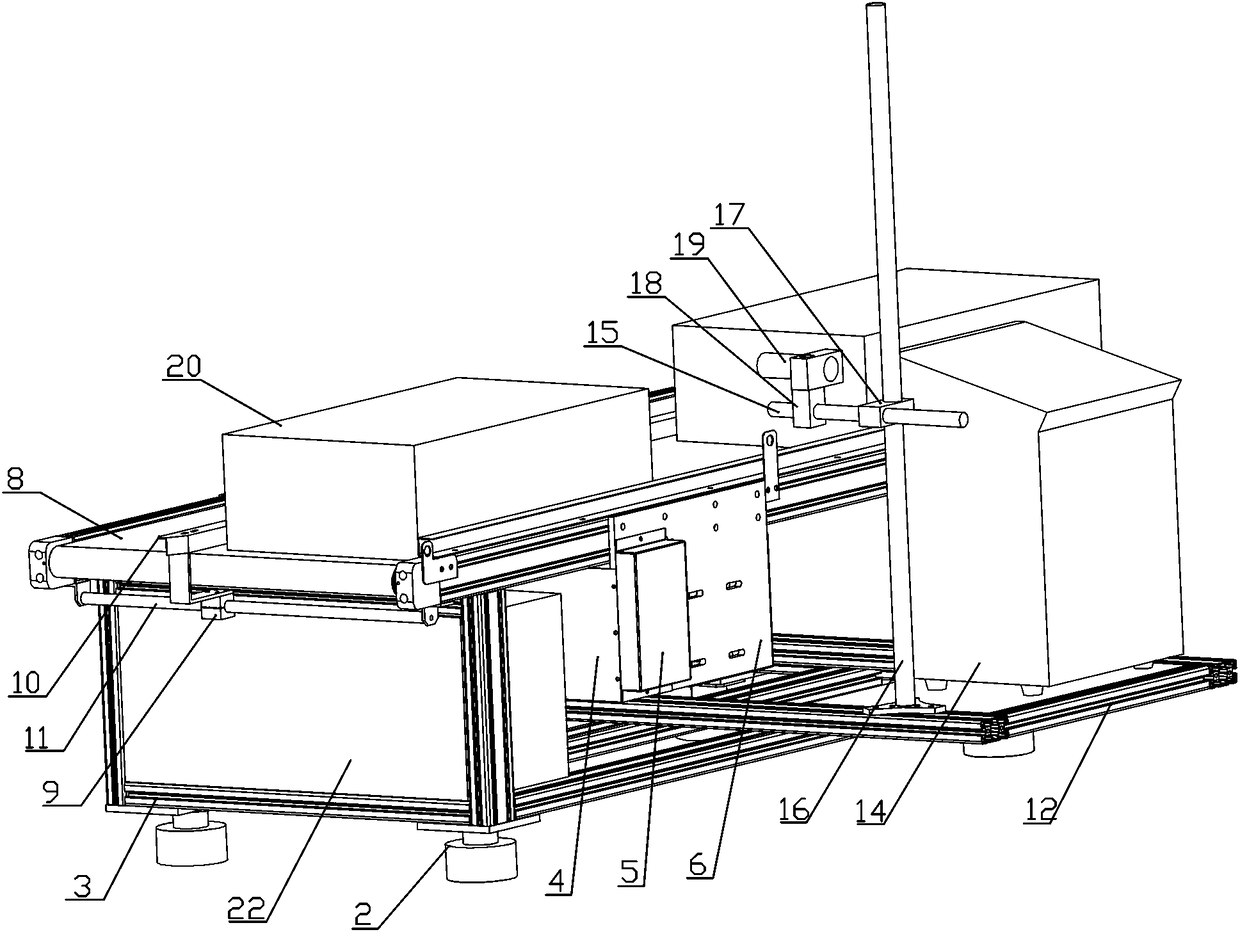

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] see Figure 1-4 , a mobile inkjet assembly line for packaging box inkjet coding, which includes a frame 3, a top frame 13 is installed on the top of the frame 3, and the two ends of the top frame 13 are respectively equipped with driving rollers 21 and driven rollers. Carrier roller 7, conveyer belt 8 is installed between described driving roller 21 and driven roller 7, and described conveyer belt 8 is installed with the width adjustment mechanism that is used to adapt to the packing box of different width; The side of described frame 3 An inkjet printer 14 is provided, and the inkjet jet 19 of the inkjet printer 14 is arranged on the top side of the conveyor belt 8 through an adjustable bracket. The device 22 is connected and drives the conveyor belt 8 to drive. During the working process, the conveyor belt 8 is driven by the transmission devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com