Automatic ink-jet printing machine for packaging

A technology for inkjet printers and packaging, which is applied in the field of packaging, can solve the problems of waste of conveyor belt transmission space, etc., and achieve the effect of ensuring quality and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

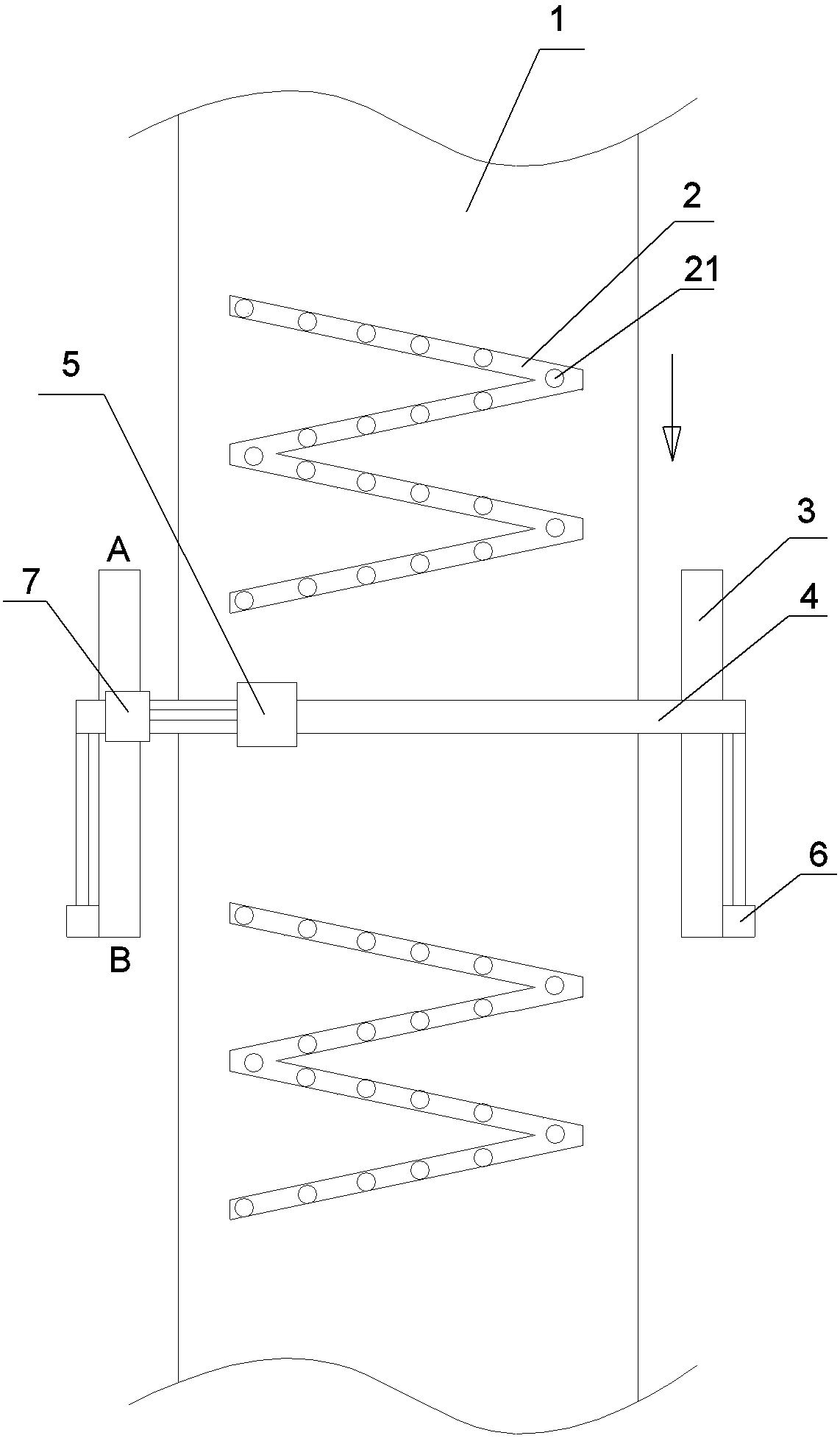

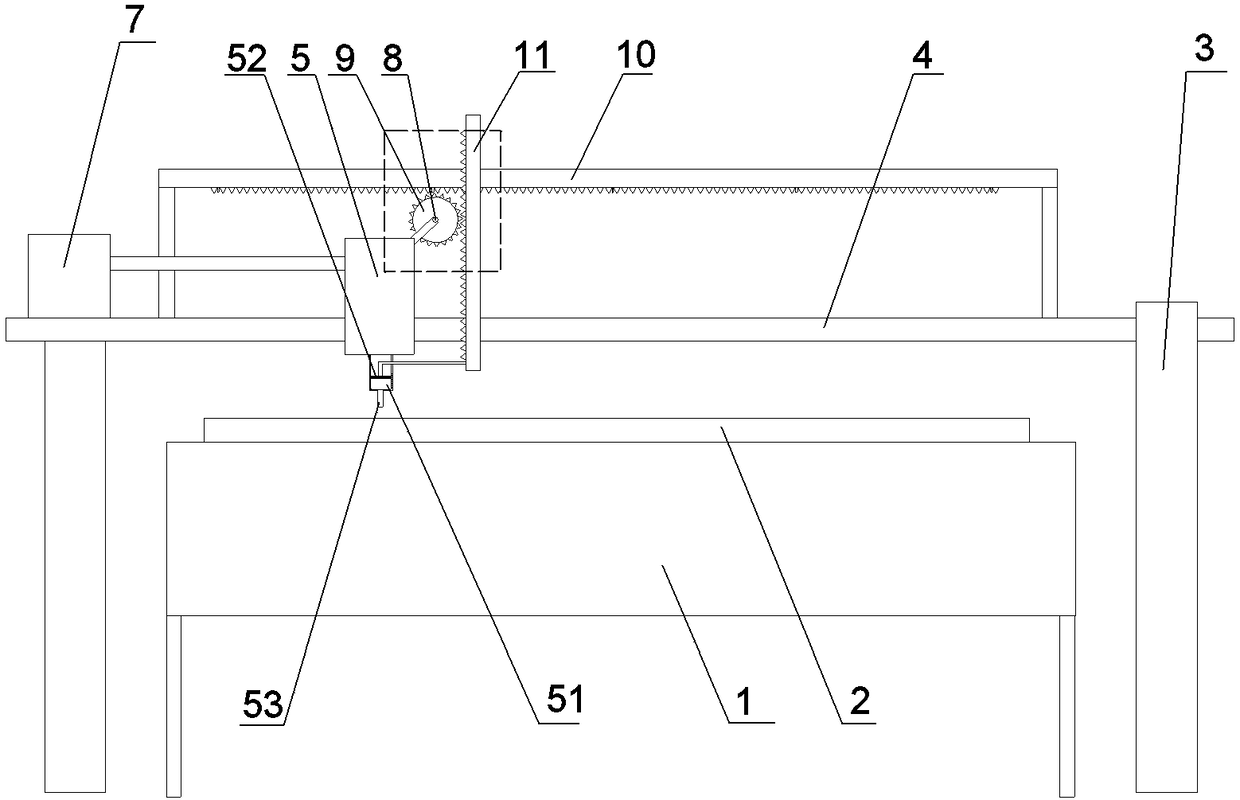

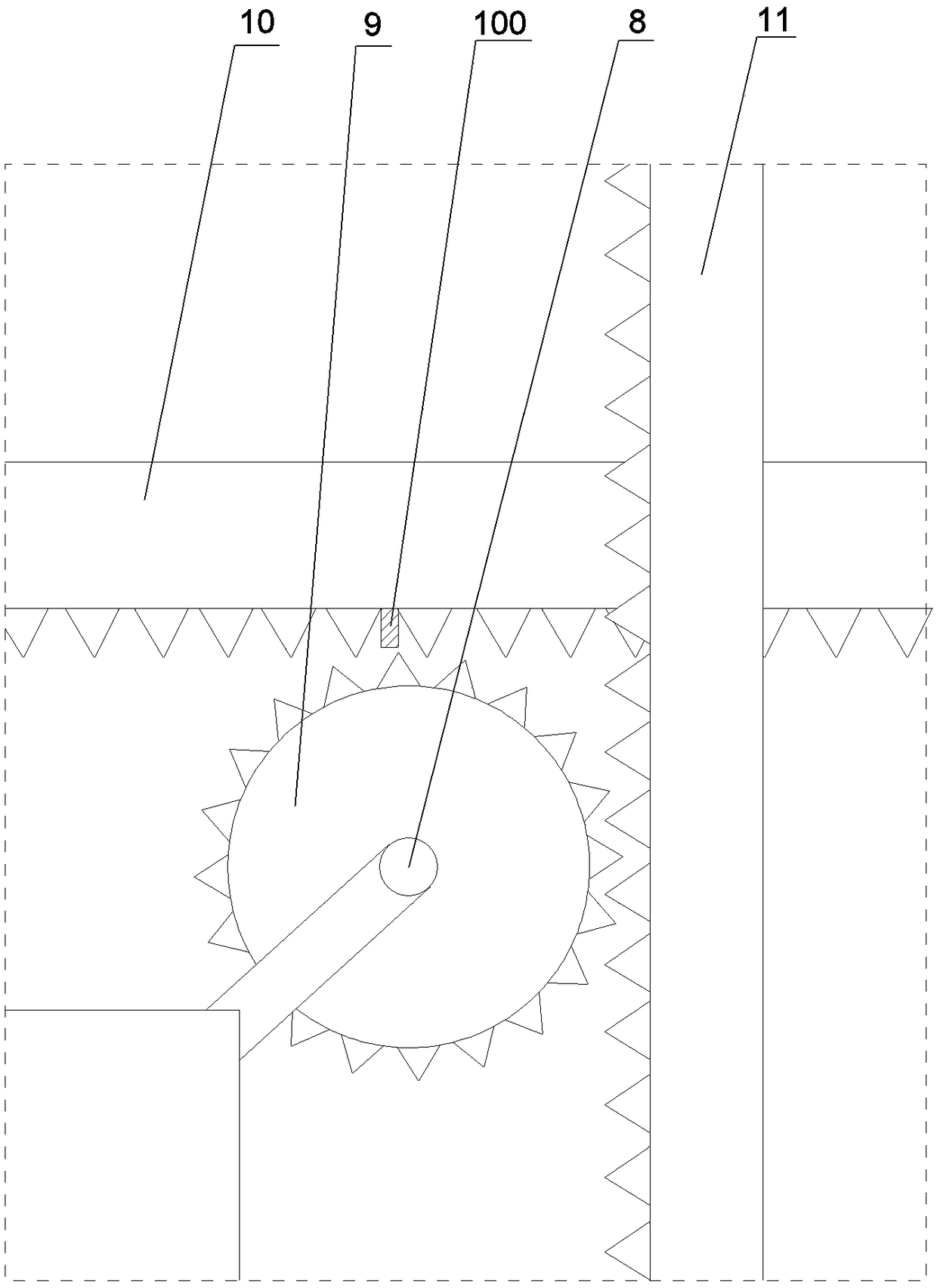

[0023] The reference signs in the drawings of the description include: conveyor belt 1, product placement tank 2, accommodation chamber 21, track 3, slideway 4, inkjet printer body 5, ink chamber 51, piston 52, ink outlet 53, first hydraulic cylinder 6. The second hydraulic cylinder 7, the rotating shaft 8, the gear 9, the first rack 10, the coding switch 100, and the second rack 11.

[0024] In the present embodiment, when the gear 9 rolls to the left, the gear 9 is forward rotation, and when the gear 9 rolls to the right, the gear 9 is reverse rotation.

[0025] Such as figure 1 and figure 2 As shown, the automatic inkjet printer for packaging in this embodiment includes a conveyor belt 1, which is provided with a broken-line product placement groove 2 on the conveyor belt 1. The product placement groove 2 is evenly distributed with accommodating chambers 21, and the left and right sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com