Laser engraving machine

A laser engraving machine and laser engraving technology, applied in the field of laser engraving machines, can solve the problems of easy contamination, scraping, less correspondence of two-dimensional codes, falling off of printed products, etc., and achieves wide application range and fast running speed. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

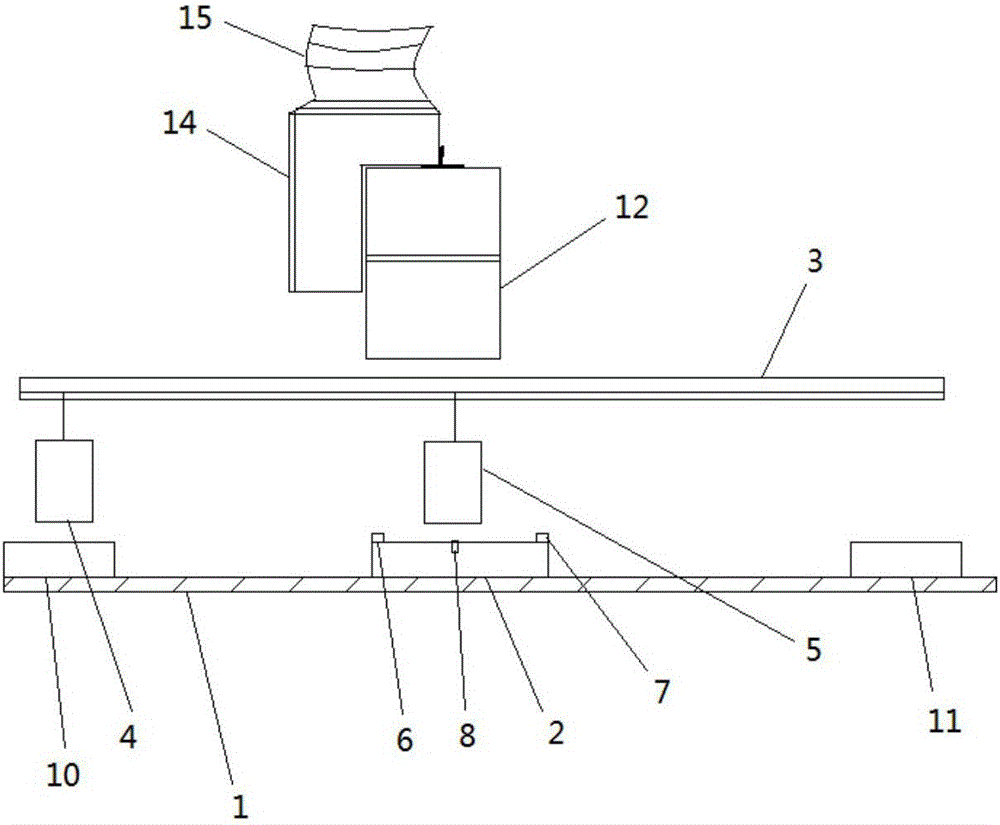

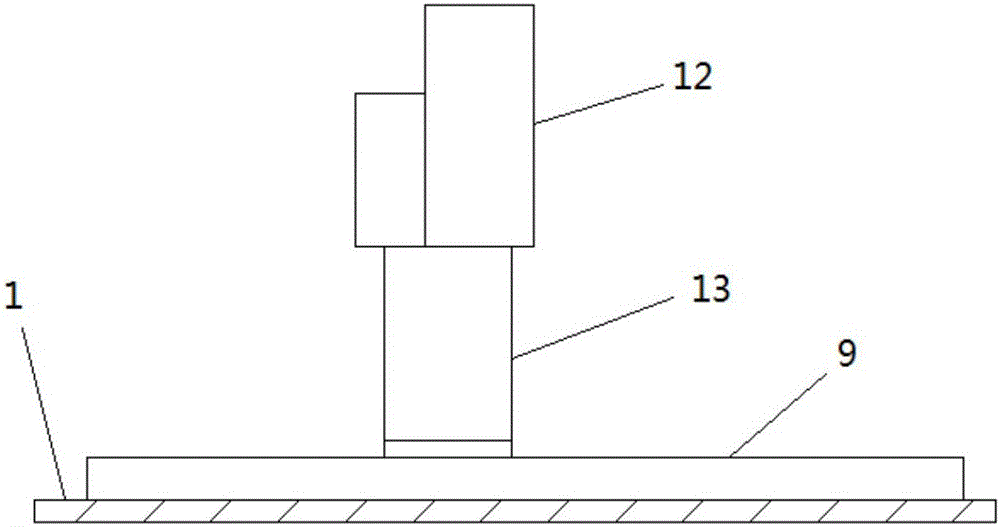

[0021] see figure 1 and figure 2 A laser engraving machine described in a preferred embodiment of the present invention includes a frame 1, a feeding unit arranged thereon, a laser engraving unit 12 and a laser engraving table 2 facing the laser engraving unit 12, the The laser engraving unit 12 includes a laser and a scanning camera that move horizontally along the frame 1; A manipulator for grabbing mobile products on a guide rail 3; the laser engraving machine is also provided with a dust removal system, and the dust removal system includes an air vent 14 arranged on one side of the laser engraving unit 12 and connected with a fan through a pipeline.

[0022] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com