Novel wire feeding machine achieving automatic material replacing and continuous printing of material breakage

A wire feeder and material cutting technology, which is applied in metal processing equipment, 3D object support structures, manufacturing tools, etc., can solve the problems of difficult use of tailings, accidental material breaking and normal printing, etc., to achieve convenient operation and avoid single-wheel The wire feeding speed is not constant, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments.

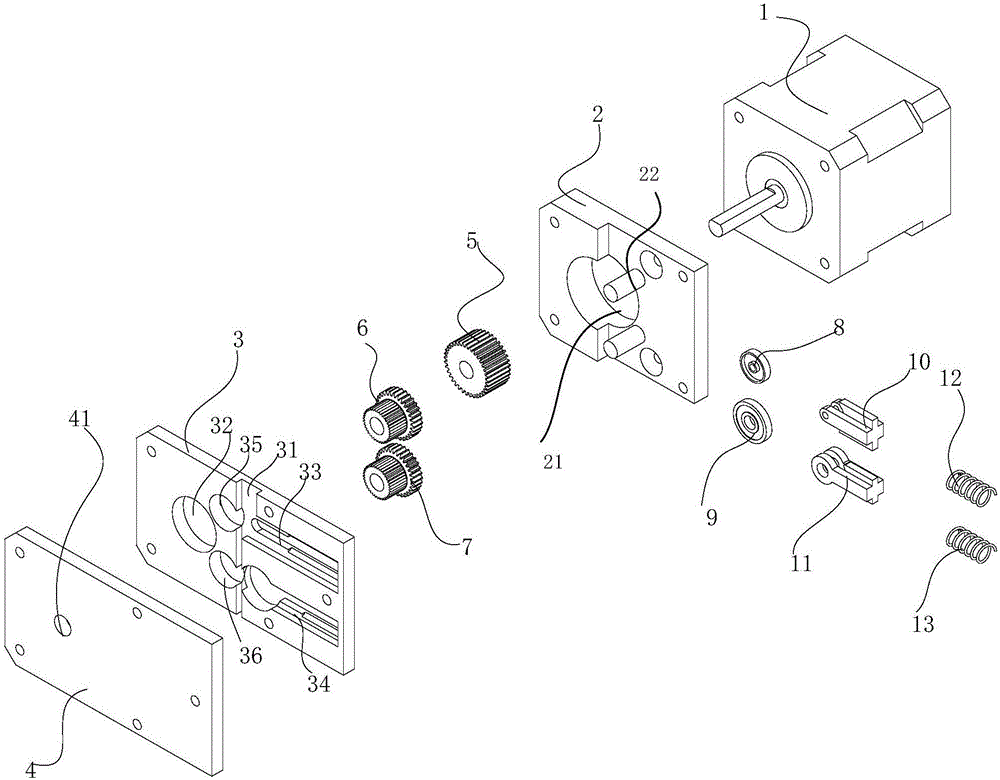

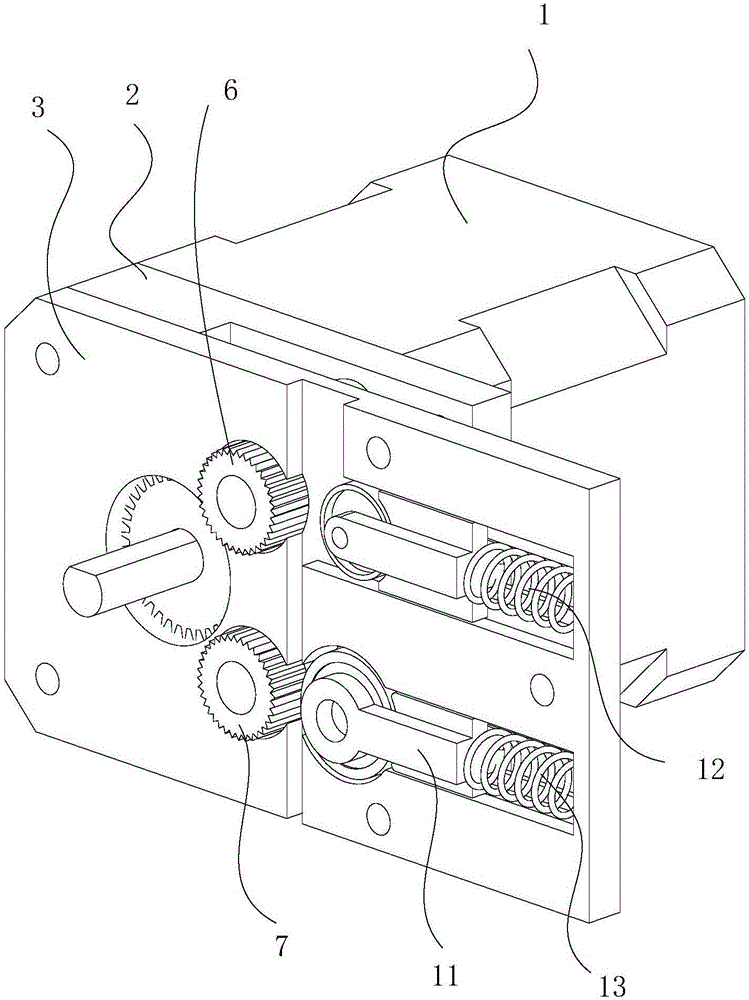

[0024] refer to Figure 1-3 , the new wire feeder of the present invention for automatic refueling and continuous printing after material breaking includes a motor 1 set in sequence, a wire feed wheel mounting plate 2, a bearing mounting plate 3 and a fixing plate 4; these four parts are connected in a detachable manner .

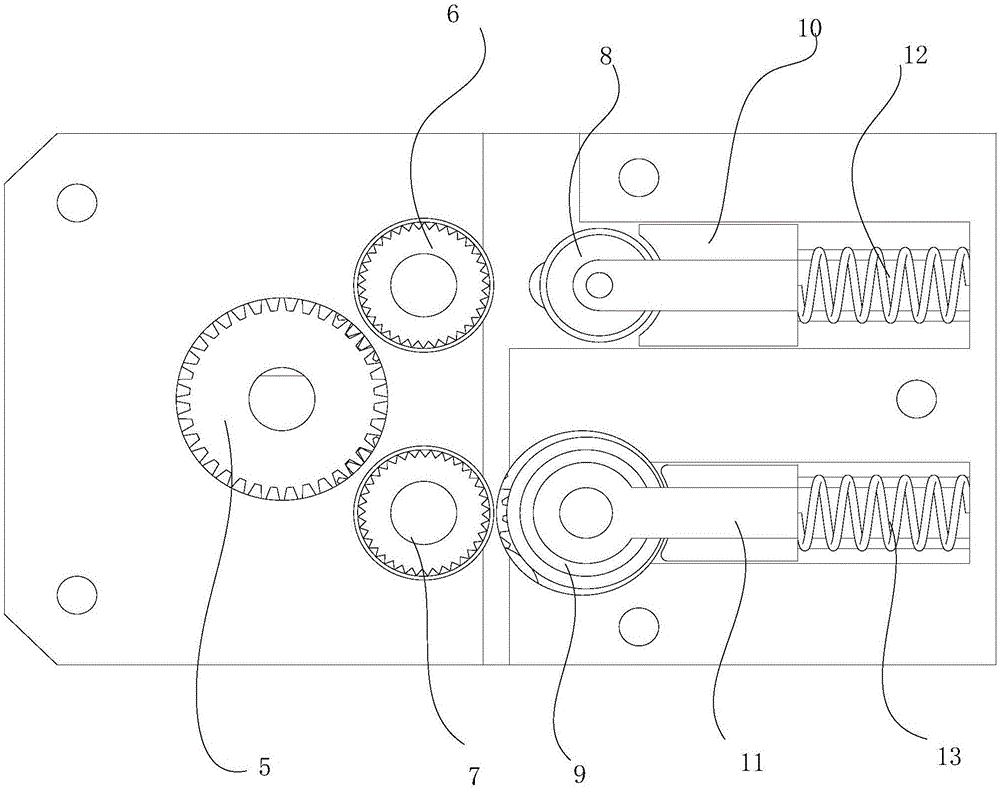

[0025] Wherein, a gear 5 is sheathed on the output shaft of the motor 1 , and a motor output shaft piercing hole 21 is provided on the fixed plate 4 . The wire feed wheel installation plate 2 is provided with a gear piercing hole 21, and the wire feed wheel installation plate 2 is also equipped with an upper wire feed wheel 6 and a lower wire feed wheel 7, and the gear 5 is connected with the upper and lower wire feed wheels. Wheels are meshed, driven by gears so that the upper and lower wire feed wheels rotate in the same direction and at the same spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com