Hydraulic telescopic device for elevator shaft mold and operating method thereof

A hydraulic telescopic and elevator shaft technology, which is applied in the treatment of formwork, formwork/template/work frame, and on-site preparation of building components, can solve the problems of time-consuming, excessive structural stress, and high cost, and achieves The effect of requiring low quality, small safety risk and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

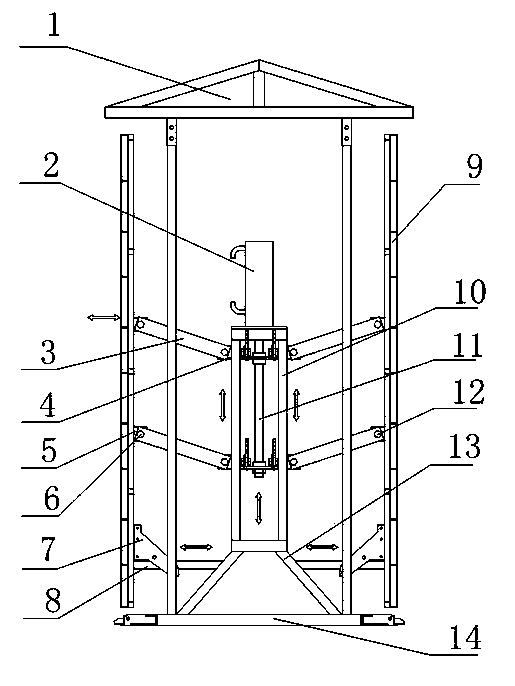

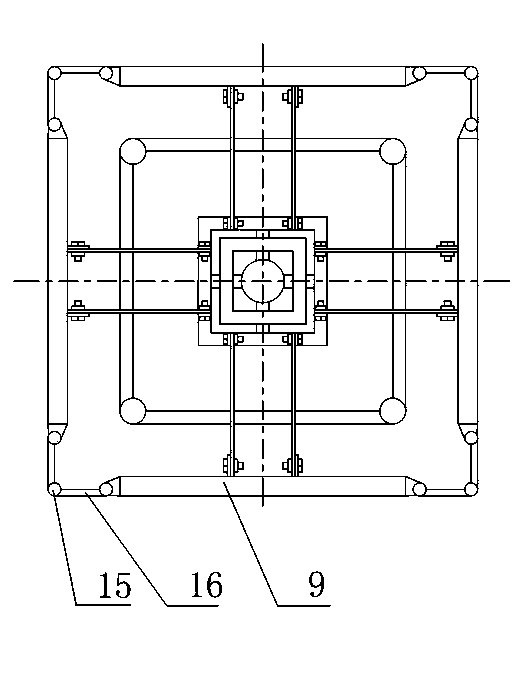

[0025] Such as figure 1 , figure 2 As shown, the hydraulic expansion device for the shaft mold of the elevator shaft includes a cylinder mold connected in turn by several telescopic templates 9, and several angle molds are arranged between adjacent telescopic templates 9 in the telescopic template 9; The cylinder mold is provided with a hydraulic rod 2 and a bracket 10 inside, the hydraulic rod 2 is installed on the upper end of the bracket 10, a transmission screw 11 is arranged in the bracket 10, and the transmission screw 11 is connected with the hydraulic rod 2, and the outer wall of the transmission screw 11 is set There are two groups of linkage mechanisms, and the two ends of the linkage mechanisms are respectively connected with the transmission screw 11 and the corresponding telescopic formwork 9 . Telescopic formwork 9 adopts steel formwork, the plane size of steel formwork is 2.2m*2.2m, and the elevator shaft is generally a regular square shape, so four steel form...

Embodiment 2

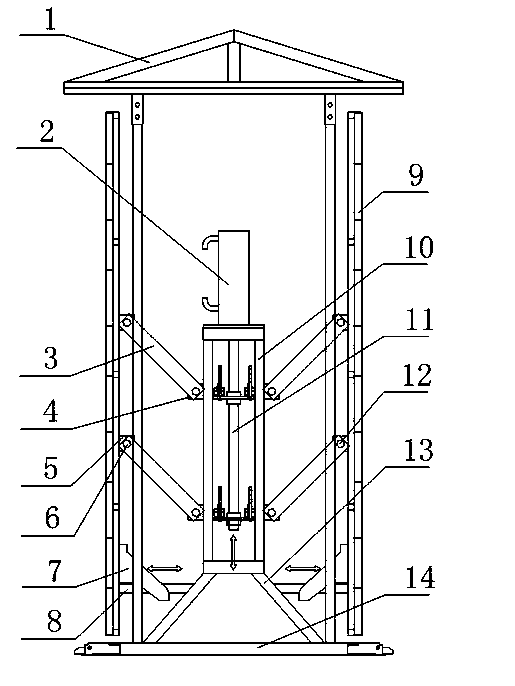

[0035] like image 3 , Figure 4 As shown, when the concrete reaches the demoulding strength, the hydraulic pump starts, the hydraulic rod 2 descends, and drives the transmission screw 11 to descend, the horizontal pulley frame 7 and the synchronous adjustment connecting rod 3 shrink inward, the horizontal telescopic beam 5 moves inward, and the telescopic formwork is pulled toward the Move and release the mold from inside to realize that the horizontal telescopic beam 5, the synchronous adjustment connecting rod 3 and the fixed rod 4 are not on the same straight line, so that the fixed rod 4 is below the corresponding horizontal telescopic beam 5, and the corner mold is in a contracted state at the same time, and the same corner mold The included angle between the two hinges 16 inside is an acute angle, and the smaller the angle, the more obvious the demoulding effect.

[0036] During the demoulding process, the bracket 10 is fixed, the hydraulic pump is activated, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com