Super high-rise core tube horizontal direction and vertical direction synchronous construction top formwork system and construction method

A technology of synchronous construction and core tube, applied in the field of construction, can solve the problems of difficult horizontal structure organization, unable to insert key processes in time, etc., to achieve green and environmental protection in the construction process, reduce production and energy consumption, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

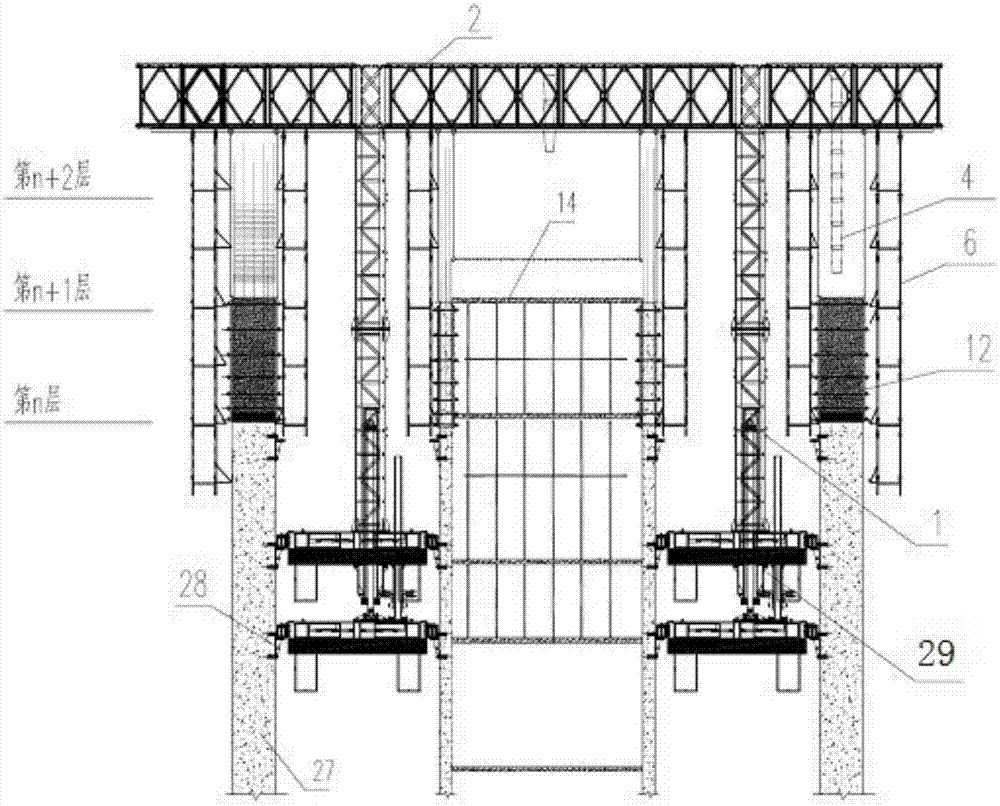

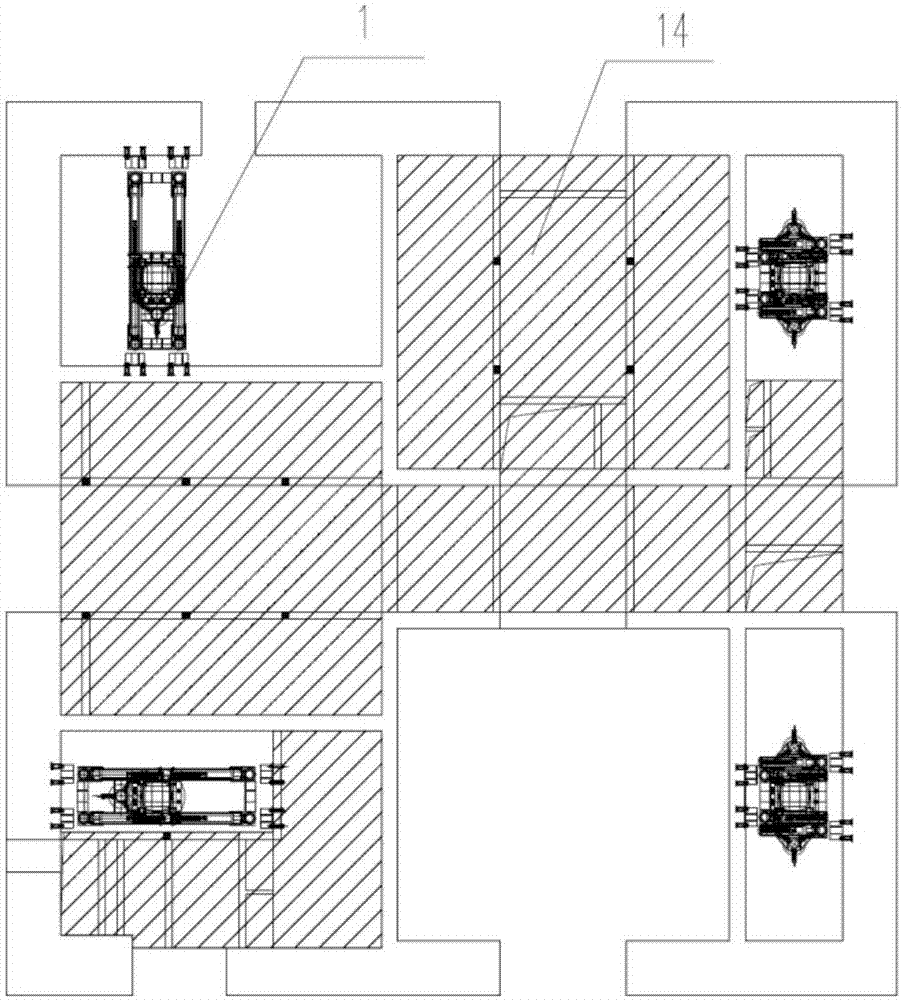

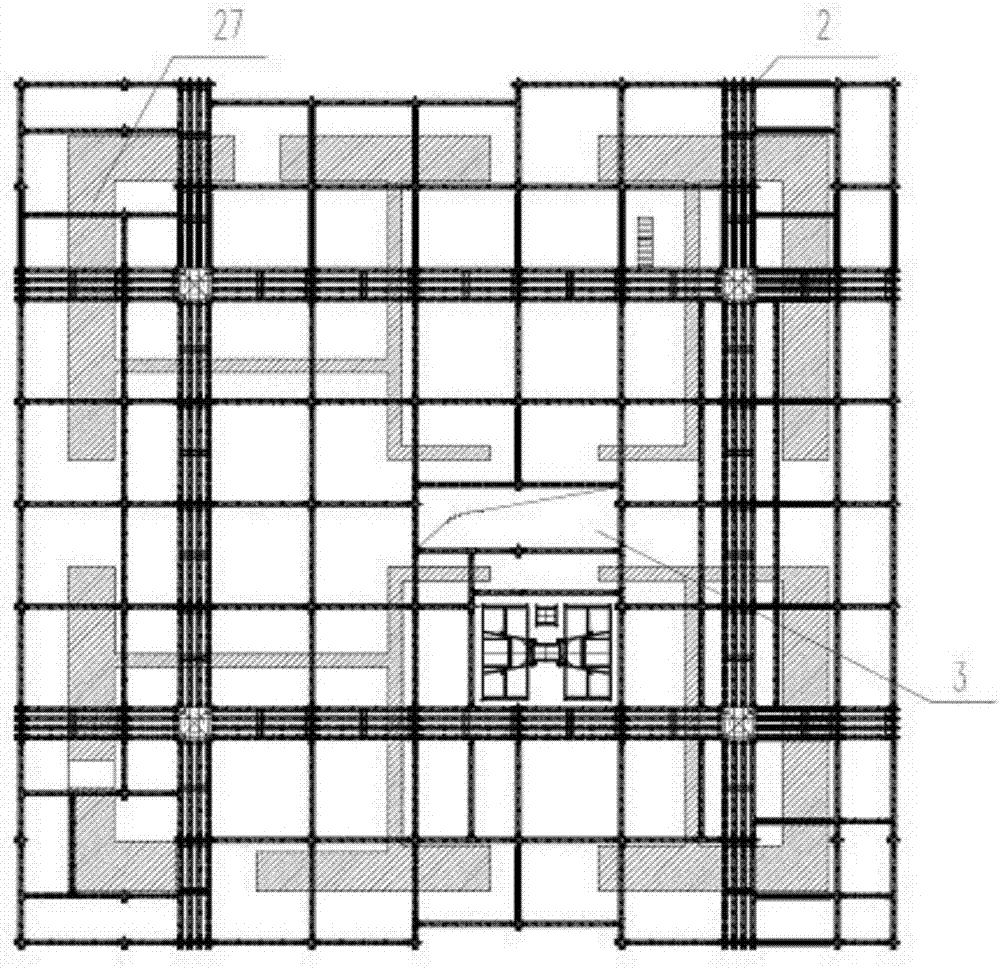

[0046] refer to figure 1 , Figure 6 to Figure 10 , in this preferred embodiment, a super high-rise core tube horizontal and vertical synchronous construction top formwork system, including truss platform system 2, hanger enclosure system, support system 1, formwork system 12 and hydraulic control system 29, formwork system 12 is the aluminum alloy formwork system. The aluminum alloy formwork system includes vertical wall formwork 13 (for the outer wall of the core tube and the vertical wall of the well shaft) and horizontal formwork (for the horizontal synchronous construction of the floor slab and the wall connected with the beam slab) and stairs), where,

[0047] The vertical wall formwork 13 includes a plurality of horizontally spliced aluminum alloy standard unit panels 19 and an aluminum alloy C-groove 16 ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com