Building construction formwork waste removing device

A technology for building construction and removal devices, which is applied in the fields of building, building structure, and on-site preparation of building components, and can solve problems such as collection work, troublesome collection and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

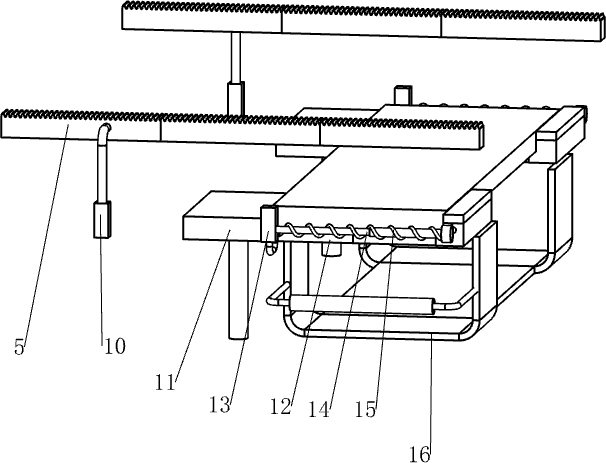

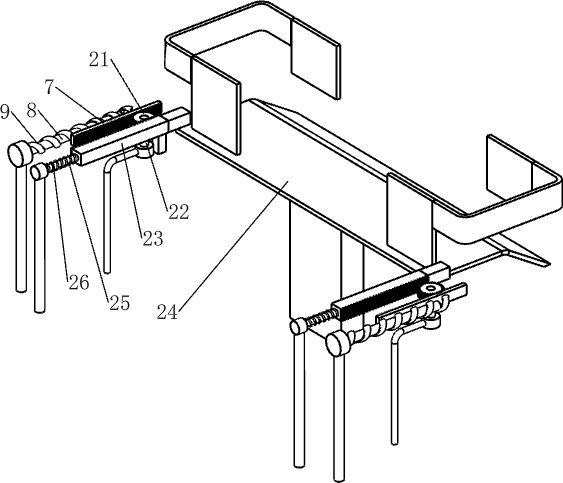

[0020] A building construction template waste removal device, such as Figure 1-3 As shown, it includes a frame 1, a removal assembly and a collection assembly. The upper part of the right side of the frame 1 is provided with a removal assembly that is powered by a motor to remove the cement blocks on the building construction formwork. Collection of completed building construction templates for collection.

[0021] When using this device to remove building construction formwork waste, first place the formwork to be removed on the upper end of the collection component, and then control the removal component to remove the cement waste on the building construction formwork. After the cement waste is removed, the cleaning work has been carried out The formwork will fall into the collection component for collection, and when all the cement waste on the building construction formwork has been removed, the removal component will stop working, and then the building construction formw...

Embodiment 2

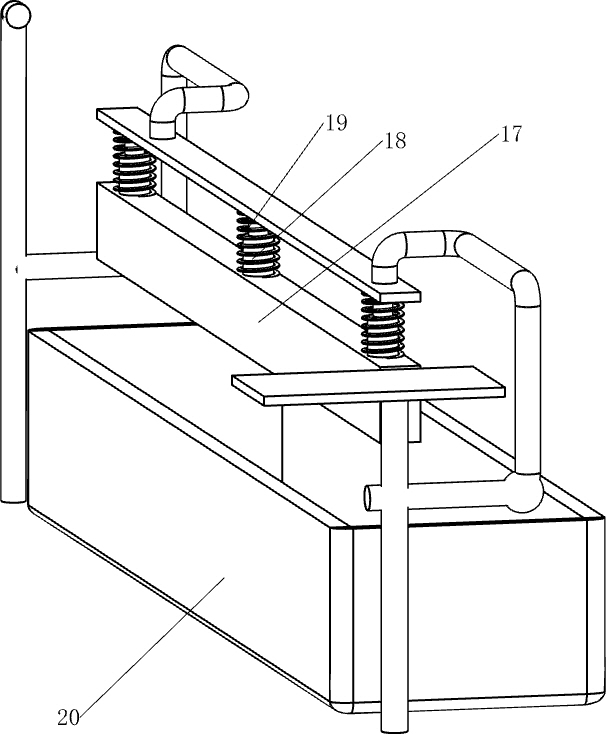

[0027] On the basis of Example 1, such as figure 1 , 4 Shown in and 5, also include pushing material block 17, the second telescopic rod 18, the 3rd spring 19 and waste material collection box 20, frame 1 right side middle part is evenly spaced and is fixed with three second telescopic rods 18 by bolts, A pusher block 17 is welded between the second telescopic rods 18, and three third springs 19 are evenly spaced between the pusher block 17 and the frame 1, and the bottom right side of the frame 1 is provided with a waste collection box 20.

[0028] After the removal of building construction formwork waste is completed, the geared motor 2 continues to rotate, driving the spatula 6 to continue to move to the right, and the spatula 6 moves to the right to contact with the pusher block 17, driving the pusher block 17 to rise upwards, The third spring 19 is compressed thereupon, and the pushing block 17 will push the residual cement on the spatula 6 into the waste collection box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com