Template fast disassembling system

A formwork, unified technology, applied in formwork/formwork components, treatment of formwork, preparation of building components on site, etc., can solve problems such as damage, falling on the ground, unfavorable formwork turnover, etc., to reduce high-altitude operations, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

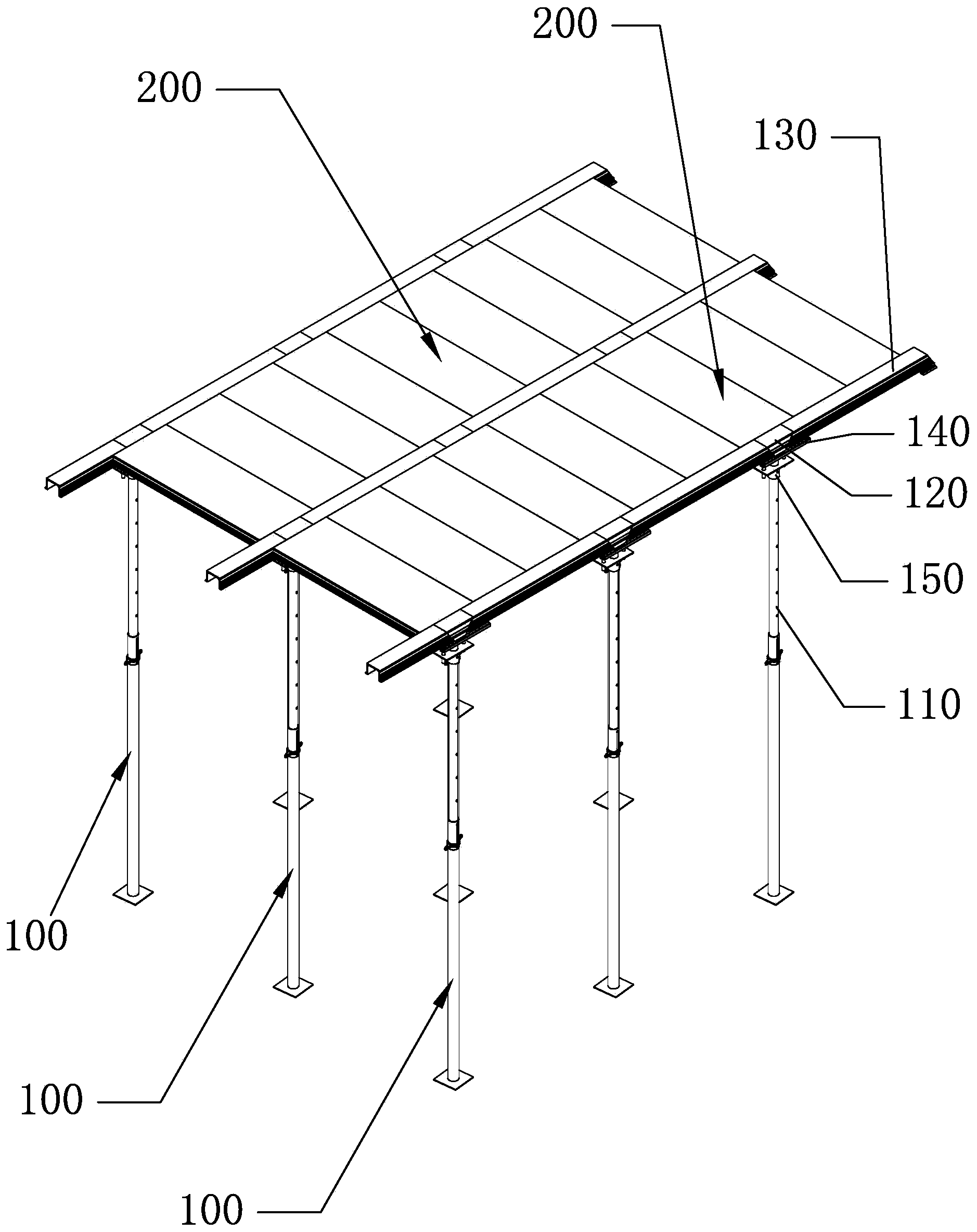

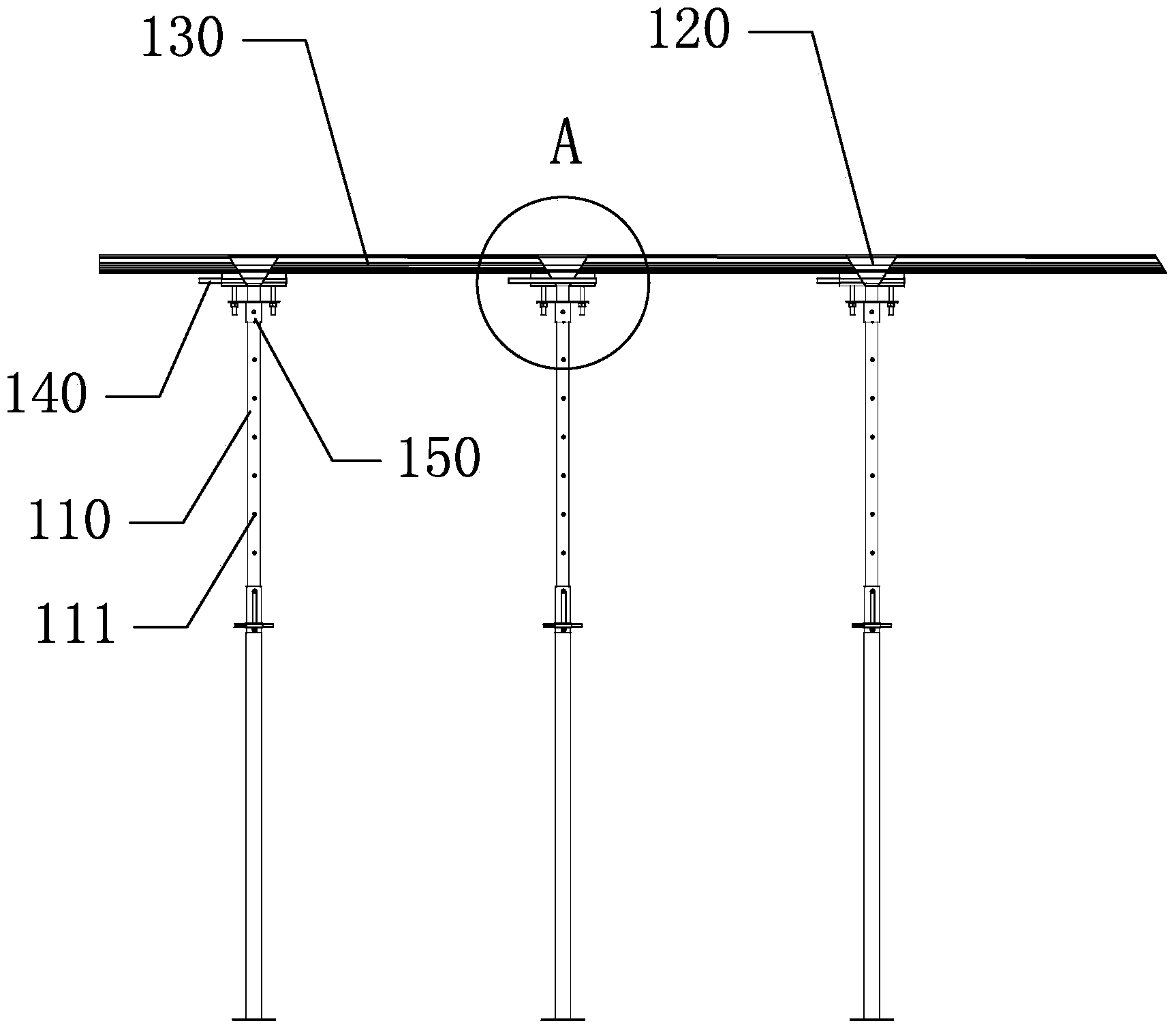

[0026] Such as figure 1 and figure 2 As shown, it is a preferred embodiment of the present invention. The template quick release system includes multiple rows of early release brackets 100 arranged at intervals and a plurality of templates 200, and each template 200 is erected between two adjacent rows of early release brackets 100 .

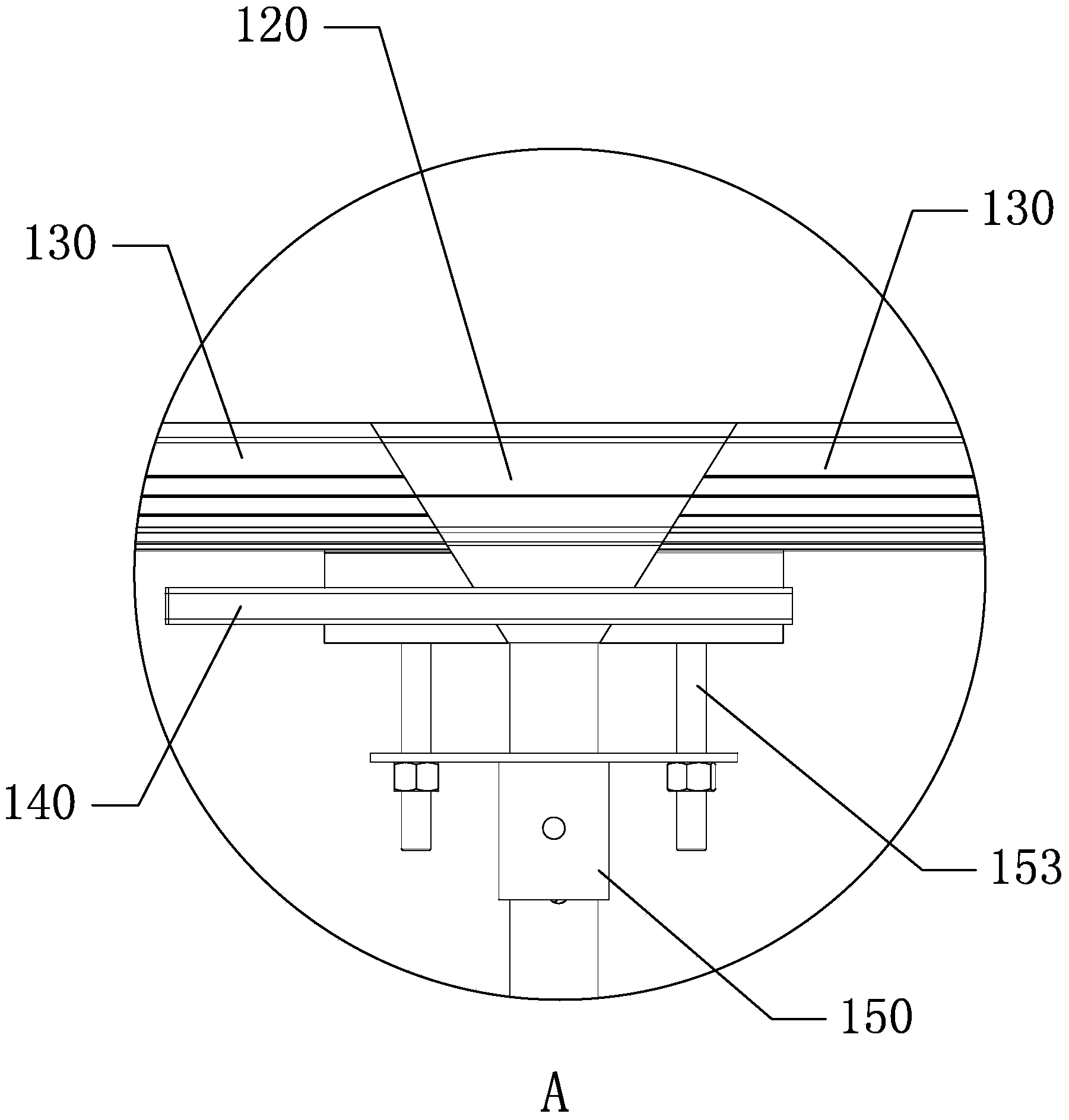

[0027] Please refer to image 3 Each row of early dismantling brackets 100 includes a plurality of supporting columns 110, early dismantling heads 120 and main keels 130, and a plurality of supporting columns 110 are arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com