Automatic cleaning and brushing apparatus and method for forms

A technology of automatic cleaning and cleaning device, which is applied in the treatment of formwork, the preparation of building components on site, and construction, etc., can solve the problems of manual cleaning, waste of labor costs, etc., so as to reduce the number of personnel used and construction costs. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

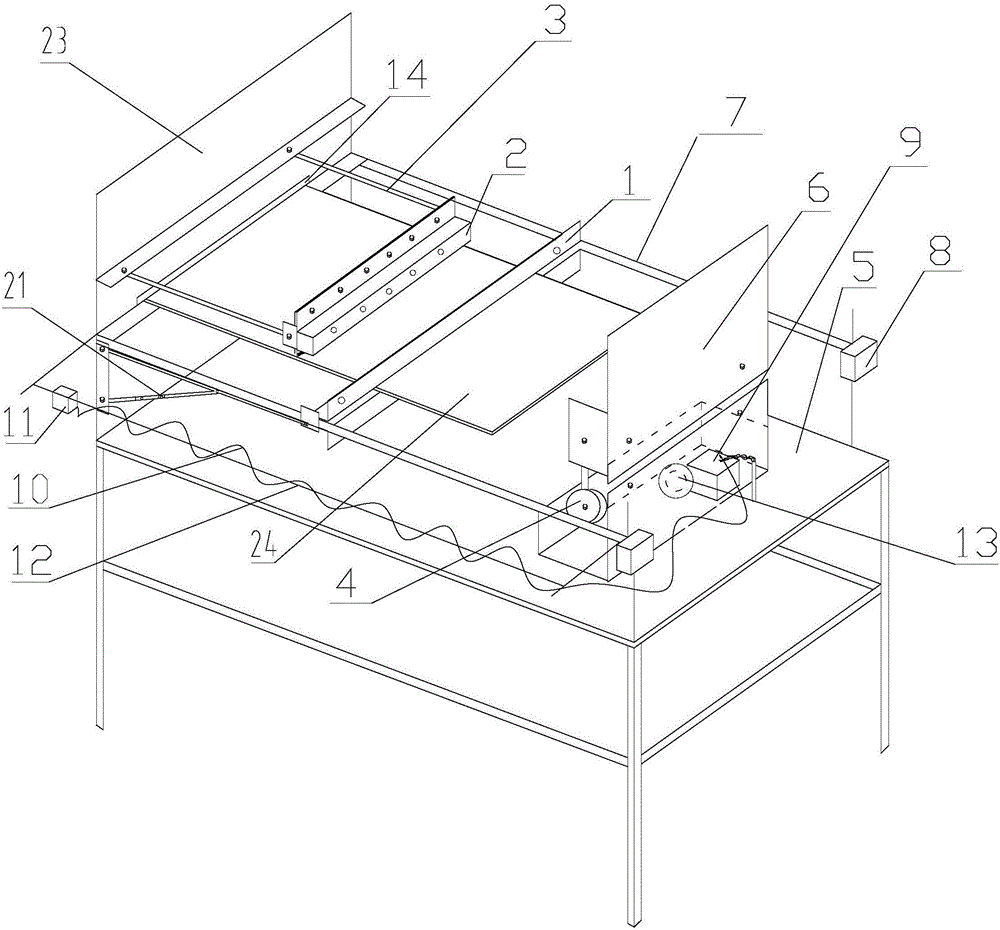

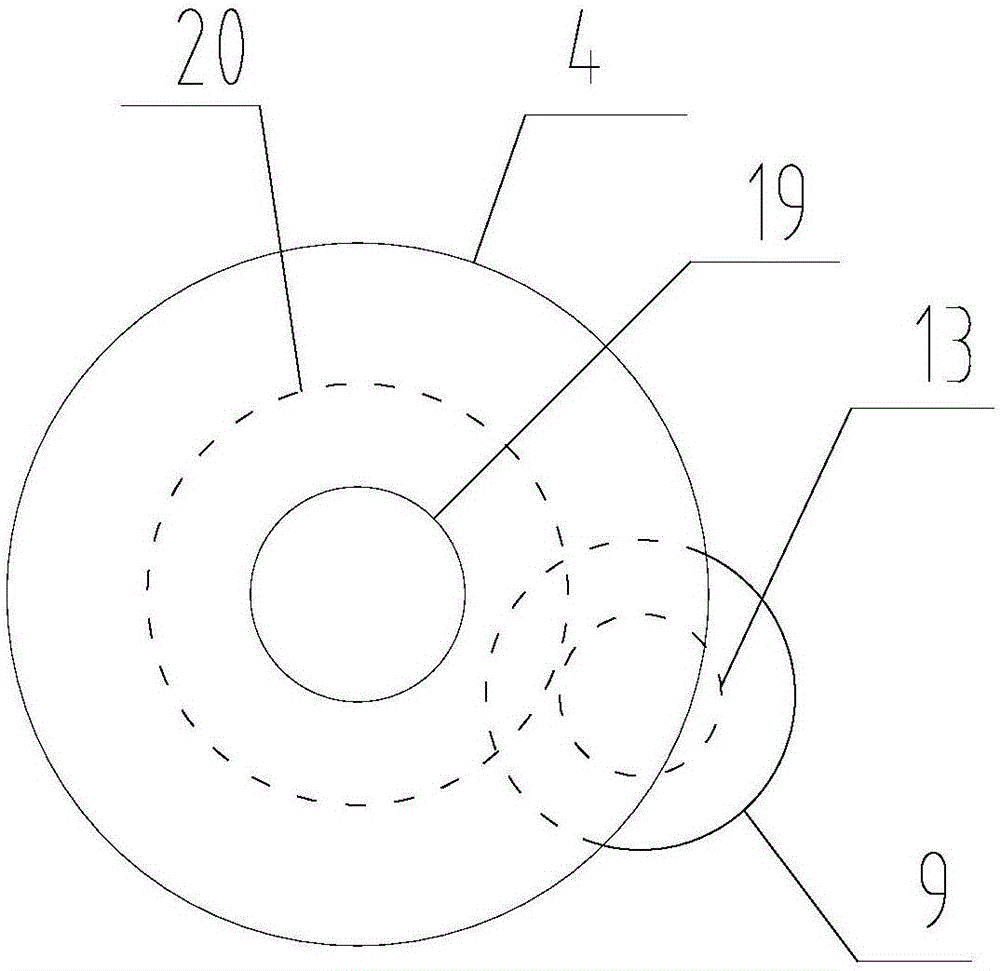

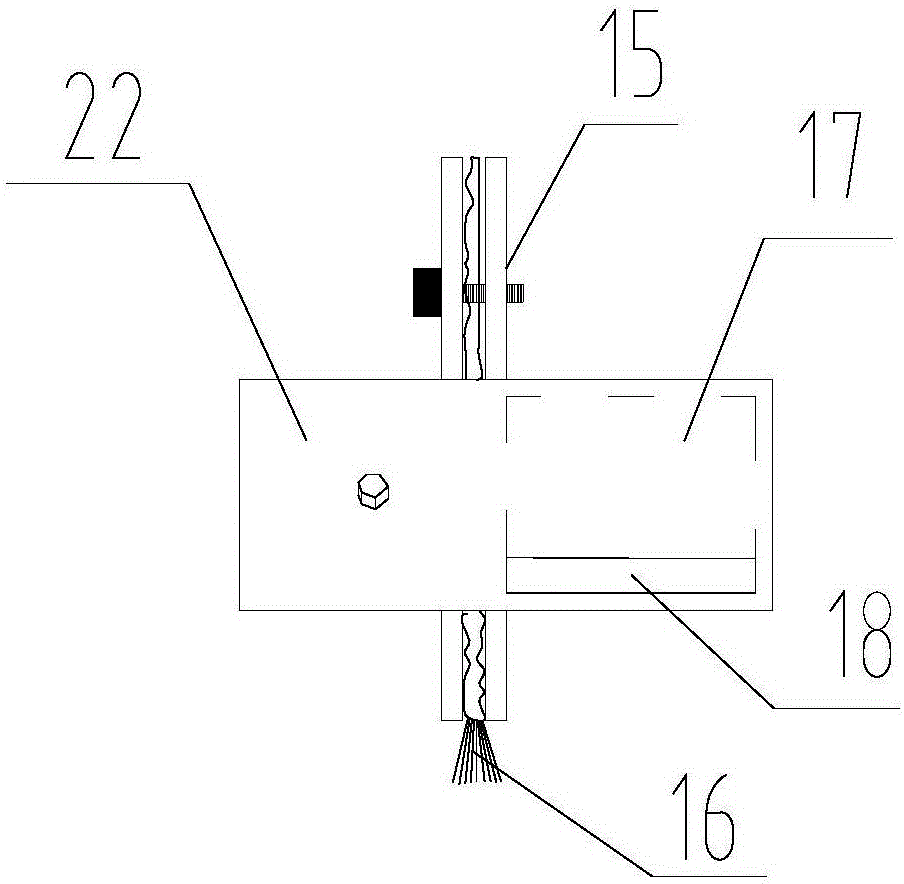

[0025] See Figure 1-Figure 3 , a template automatic cleaning and brushing device, comprising a template cleaning device platform 5, a walking pusher 6, a walking track 7, a template cleaning fixture 1, a release agent automatic spraying brush 2, a baffle plate 23, and the baffle plate 23 is fixed At one end of the template cleaning device platform 5, the template outlet 14 is set on the baffle plate 23; The wheels 4 walk on the walking track 7, and the formwork cleaning fixture 1 is set between the walking pusher 6 and the baffle plate 23. The two ends of the formwork cleaning fixture 1 are fixedly connected with the baffle plate 23 through the support frame 21, and the release agent is automatically sprayed. The squeegee 2 is fixed on the baffle 23 through the bracket 3 , and the release agent automatic spraying squeegee 2 is arranged between the baffle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com