Construction method of sliding formwork for large-diameter silo

A large-diameter, sliding form technology, which is applied in the fields of formwork/formwork/workframe, formwork treatment, and on-site preparation of building components. It can solve the problems of outdated construction technology and low construction efficiency, and achieve the construction procedure. The effects of standardization, operation standardization, and control of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

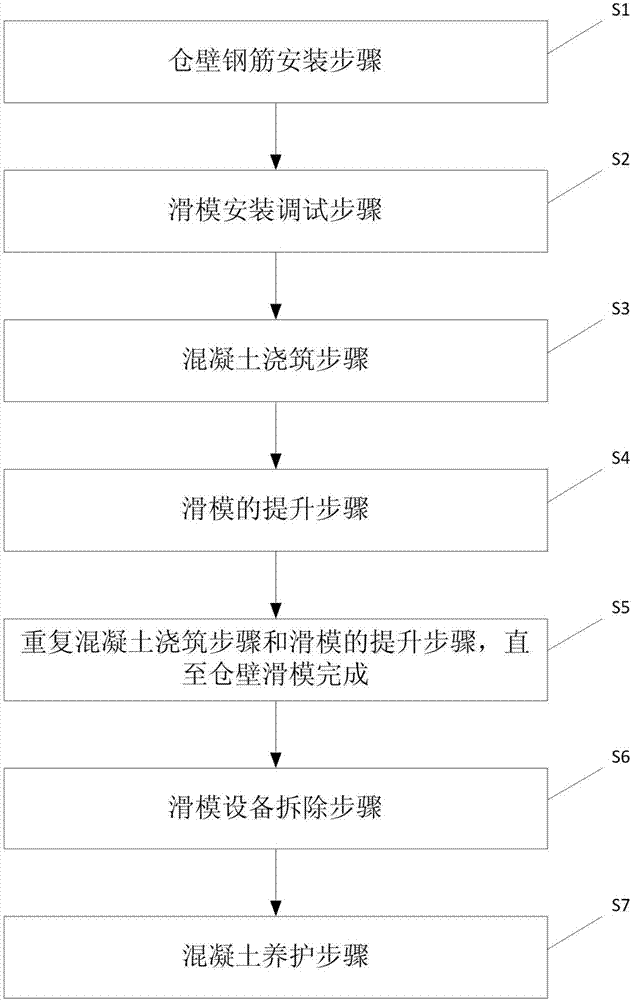

[0063] This embodiment discloses a specific sliding form construction method for a large-diameter silo. The specific steps are as follows: installation of steel bars on the silo wall → sliding form installation, debugging → concrete pouring (concrete trimming, surface plastering) → sliding form lifting (concrete curing) → Concrete pouring (concrete trimming, surface plastering) → sliding form lifting (concrete curing) → concrete pouring (repeat the above 2 tasks until the warehouse wall sliding form is completed) → sliding form equipment removal → concrete curing.

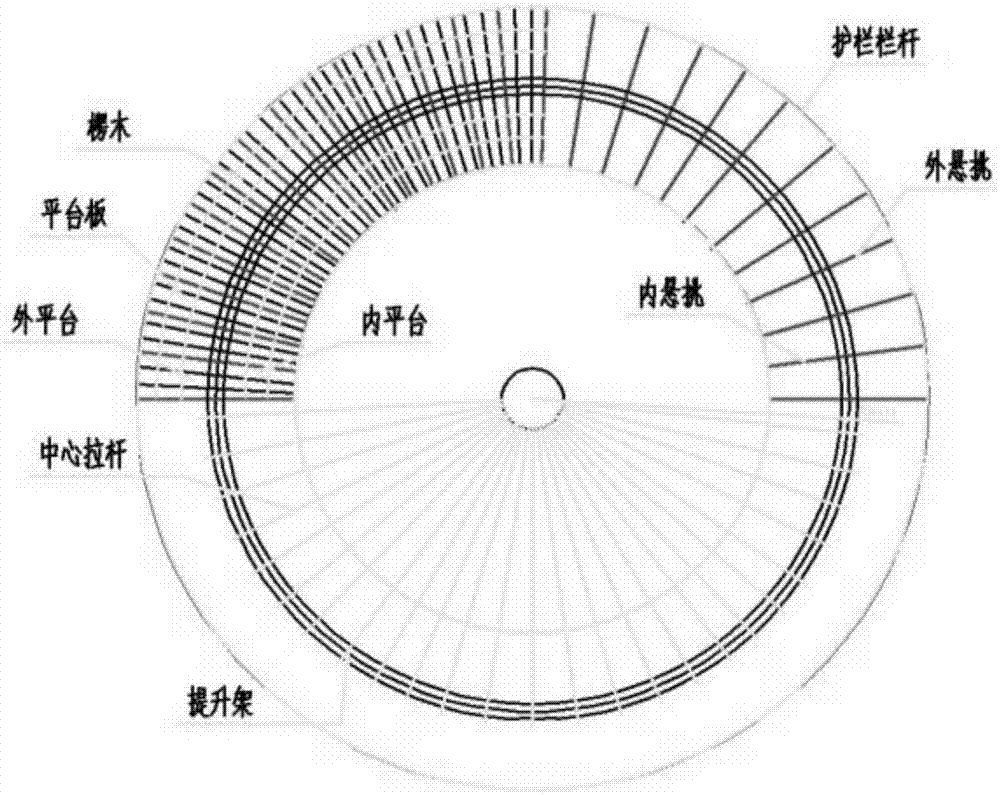

[0064] Among them, in the installation step of the steel bar on the tank wall, the steel bar binding construction is carried out before the sliding form device is assembled, the steel bar on the tank wall is bound to a height of 1.3 meters, and the vertical steel bar is thrown out, and the joints are staggered. In the normal sliding stage of the sliding form, every time the height is raised (200-300mm), the warehous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com