Large earthed concrete tank dome steel support structure and mounting method thereof

A supporting structure and concrete technology, which is applied in the field of large-scale earth-covered concrete tank dome steel supporting structure and installation, can solve the problems of high rental costs of scaffolding and long construction period, etc., and achieve the effect of low construction efficiency, improved work efficiency, and simple structural force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

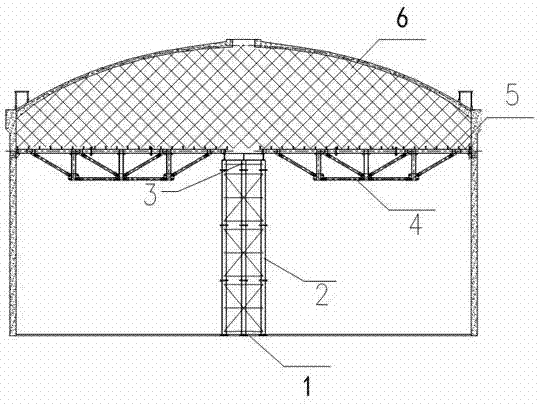

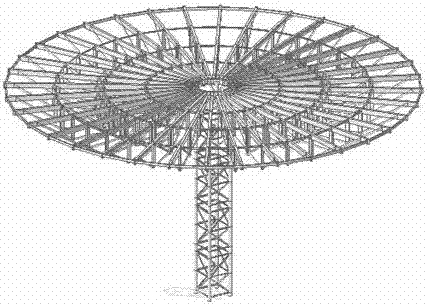

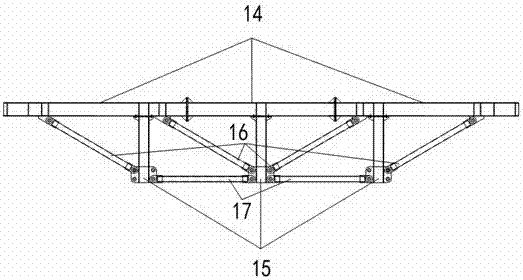

[0035] The present invention is a large-scale soil-covered concrete tank dome steel support structure, which is used for the construction of a dome structure with variable plate thickness spherical surface, large span, and high formwork with a thin shell span of more than 30m, a lower clearance of more than 20m, and a thin shell with different thicknesses. support. It includes full house scaffolding 6, lattice column foundation 1, standard section tire frame 2, support frame center disc 3, truss 4 and I-beam 5; lattice column foundation 1 is set in the center of the tank room, which can usually be set as a square steel bar The structural form of the concrete cap, and pre-embedded anchor bolts. The standard section tire frame is composed of several lattice columns. The lattice column is four circular pipe columns as the main load-bearing structure. The four circular pipe columns are connected by angle steel to form a whole. After the parts are assembled, they are hoisted into ...

Embodiment 2

[0038] A method for installing a steel support structure of a large earth-covered concrete tank dome comprises the following steps:

[0039] Step 1, the setting of the lattice column foundation, the lattice column foundation is set in the structural form of a square reinforced concrete cap, and the anchor bolt corresponding to the central column is pre-embedded in the cap, so that it can be fixed and pre-embedded when the lattice column is installed later The diameter of the anchor bolts is 25mm.

[0040] Step 2, the installation of the standard section tire frame, the installation of the standard section tire frame is hoisted by tower crane or truck crane, the standard section tire frame is composed of several lattice columns, and each section of lattice column needs to be assembled on the ground before the whole Hoisting into the tank room, the columns are connected by high-strength bolts, and the next hoisting can only be carried out after the bolts are connected; each latt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com