Remote intelligent type maintenance system for prefabricated concrete components

A technology for prefabricated components and maintenance systems, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as difficulty in guaranteeing thermal insulation and maintenance effects, hidden quality problems, construction periods, delays, etc. The effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

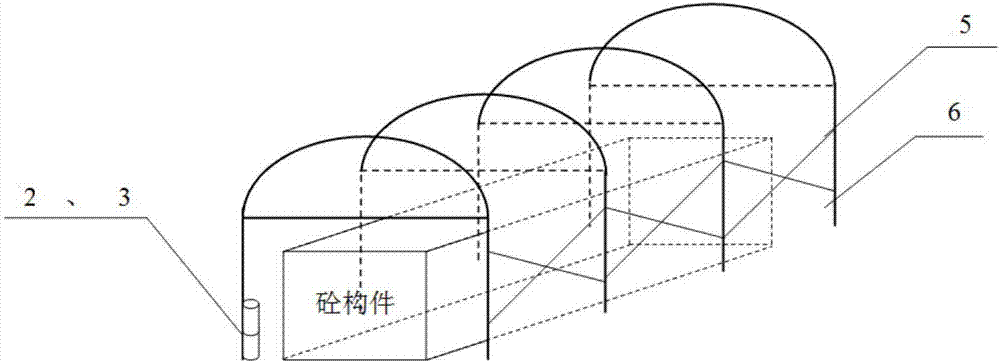

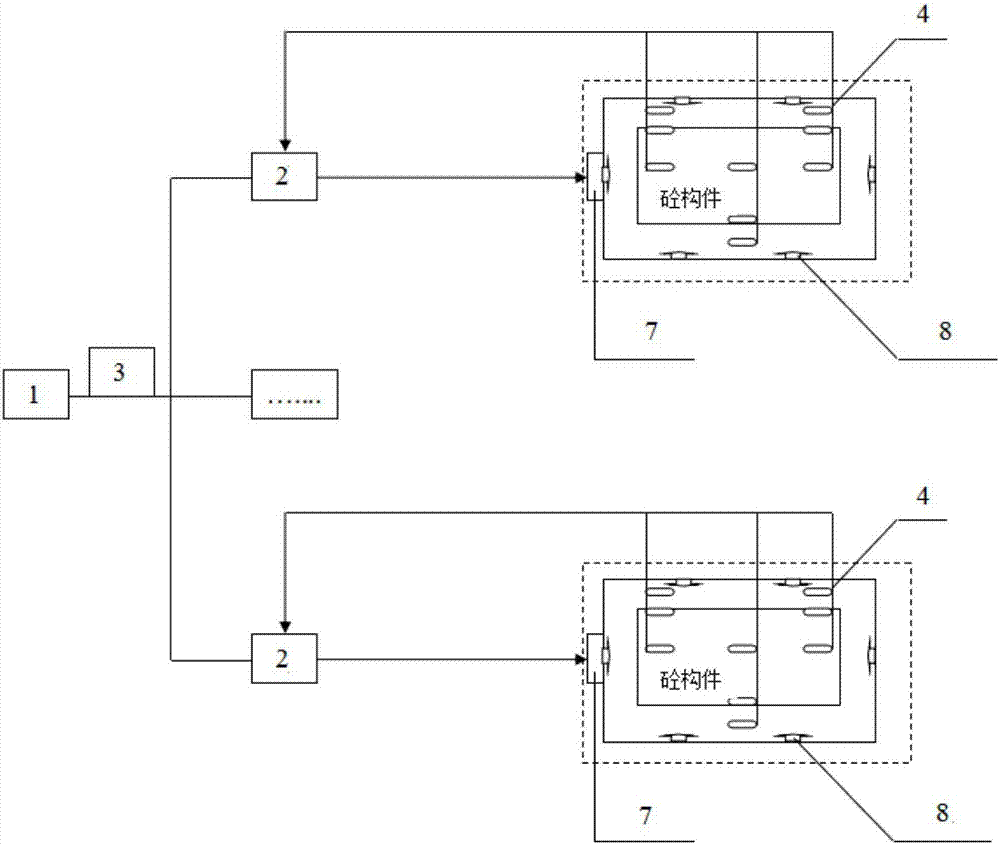

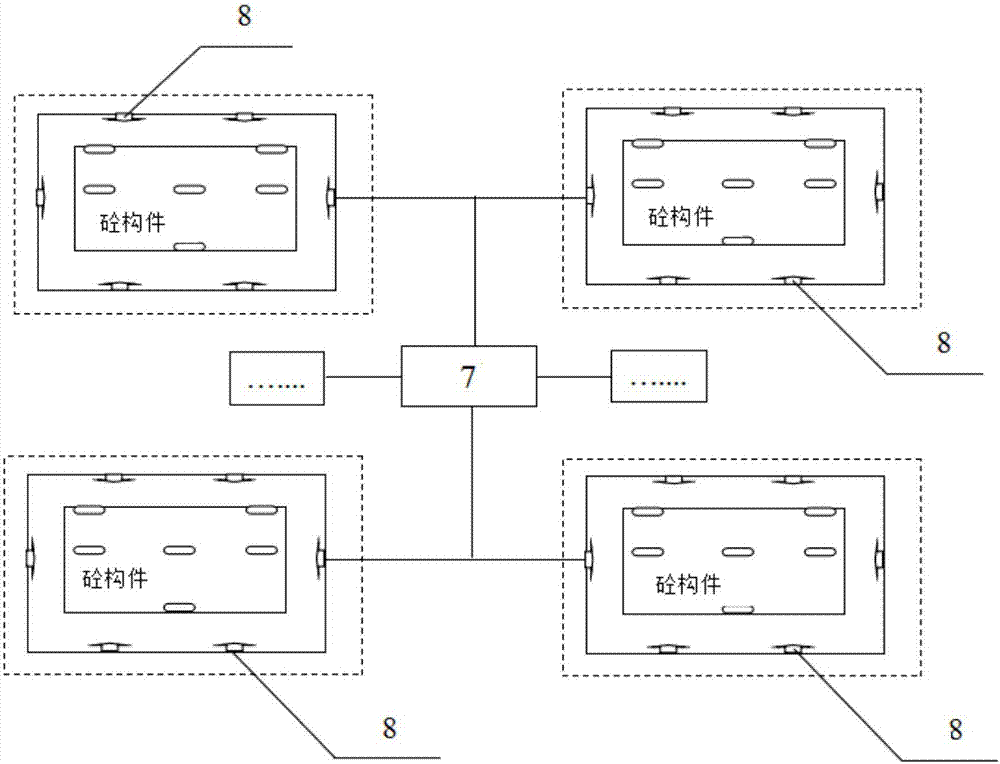

[0021] like figure 1 , figure 2 and image 3 As shown, a remote intelligent concrete prefabricated component maintenance system is characterized in that: it is composed of an intelligent monitoring system and a maintenance system, wherein the intelligent monitoring system consists of a main monitoring device 1, a distributed data acquisition and control device 2, and a wireless data sending and receiving device. The device 3 and the temperature and humidity sensor 4 are composed; the maintenance system consists of a stretchable framework 5 built outside the concrete prefabricated component, an insulating canvas 6 laid on the stretchable framework 5, and a temperature-controlled heating water storage device 7 set outside the concrete prefabricated component Composed of spraying device 8;

[0022] Among them, the temperature and humidity sensor 4 is pre-embedded in the concrete prefabricated component or suspended on the scalable framework 5 of the maintenance system, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com