Green and environment-friendly epoxy resin composition for high-power device packaging

An epoxy resin, green and environmental protection technology, applied in electrical components, circuits, electric solid devices, etc., can solve the problems of insufficient melt viscosity of epoxy resin compositions, lack of toughening effect, poor bonding force, etc. The effect of good formability and workability, good workability, low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

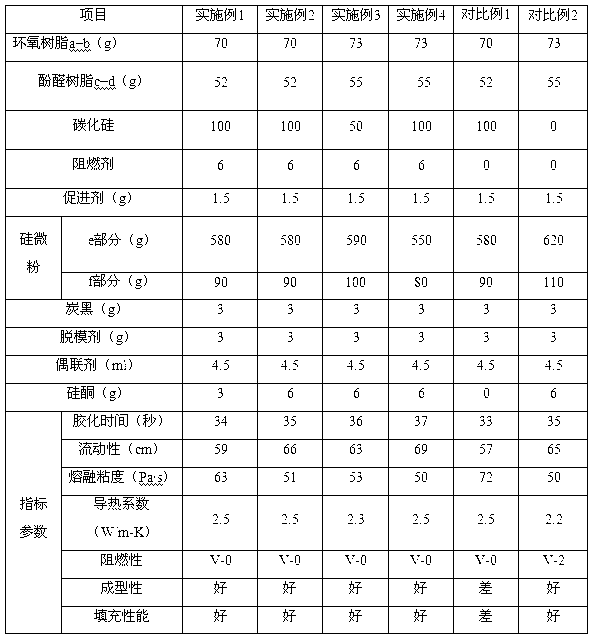

[0053] Experimental example 1. 70 grams of epoxy resin (a+b) described in embodiment 1; 52 grams of phenolic resin (c+d); 100 grams of high thermal conductivity filler silicon carbide; inorganic filler: 580 grams of e part, 90 grams of f part; Accelerator 1.5 grams; flame retardant 6 grams; coupling agent KH-560 4.5 grams; colorant carbon black 3 grams; release agent carnauba wax 3 grams; silicone 3 grams. After the components of the raw materials in the above formula are accurately weighed, the silicon micropowder is treated with a coupling agent in the mixer for 5 minutes, then other components are added, and melted and kneaded on a two-roll kneader at a temperature of 90 o C. The mixing time is 10 minutes. Press the mixed material into a 1.5mm thick sheet. After mixing evenly, cool and pulverize it, press it into a cake, and conduct a performance test.

experiment example 2

[0054] Experimental example 2. 70 grams of epoxy resin (a+b) described in embodiment 2; 52 grams of phenolic resin (c+d); Inorganic filler: 580 grams of e part, 90 grams of f part; 100 grams of silicon carbide; 1.5 grams of accelerator; 6 grams of flame retardant; 4.5 grams of coupling agent KH-560; 3 grams of colorant carbon black; 3 grams of release agent carnauba wax; 6 grams of silicone. After the components of the raw materials in the above formula are accurately weighed, the silicon micropowder is treated with a coupling agent in the mixer for 5 minutes, then other components are added, and melted and kneaded on a two-roll kneader at a temperature of 90 o C. The mixing time is 10 minutes. Press the mixed material into a 1.5mm thick sheet. After mixing evenly, cool and pulverize it, press it into a cake, and conduct a performance test.

experiment example 3

[0055] Experimental example 3. 73 grams of epoxy resin (a+b) described in embodiment 3; 55 grams of phenolic resin (c+d); Inorganic filler: 590 grams of e part, 100 grams of f part; 100 grams of silicon carbide; 1.5 grams of accelerator; 6 grams of flame retardant; 4.5 grams of coupling agent KH-560; 3 grams of colorant carbon black; 3 grams of release agent carnauba wax; 6 grams of silicone. After the components of the raw materials in the above formula are accurately weighed, the silicon micropowder is treated with a coupling agent in a mixing machine for 5 minutes, and then other components are added, and melted and mixed on a double-roller mixer. The mixing temperature is 90 o C. The mixing time is 10 minutes. Press the mixed material into a 1.5mm thick sheet. After mixing evenly, cool and pulverize it, press it into a cake, and conduct a performance test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com