Preparation method for short carbon fiber/copper composite material

A short carbon fiber and composite material technology, applied in the field of fiber/copper composite material preparation, can solve the problems of long time period, high temperature requirements, and large fiber damage, so as to reduce energy waste, avoid environmental pollution, and fiber damage less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

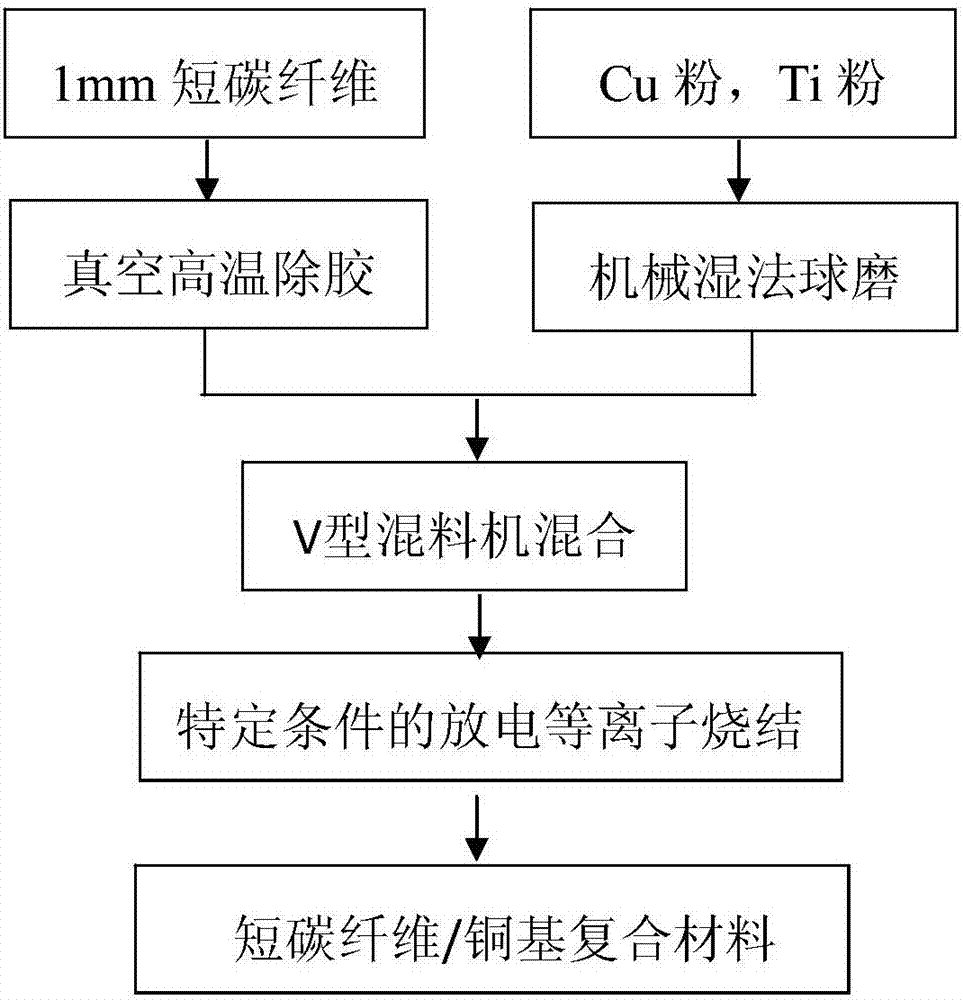

Method used

Image

Examples

Embodiment 1

[0042](1) Short carbon fibers with a diameter of 7 μm and a length of 1 mm were put into a vacuum high-temperature furnace at a temperature of 1200° C., and kept in a vacuum environment for 2 hours.

[0043] (2) The Cu / Ti powder is milled by wet method, the milling time is 8 hours, and the ball-to-alcohol ratio is 2:1:0.3; after vacuum drying, it is mixed with 1mm short carbon fiber with a V-shaped agitator, and the V-shaped mixed The material speed was 90r / min, and the mixture was stirred for 5 hours; a composite powder was uniformly mixed with short carbon fibers and metal powder, containing 9% Ti, 3% short carbon fibers, and copper as the balance.

[0044] (3) During the discharge plasma sintering process, first use a Roots pump to evacuate with a vacuum degree of 0.05mbar, then pre-press at a pressure of 30MPa for 20min, then raise the temperature to 790°C at a speed of 100°C / min and a pressure of 5MPa, and keep warm The time is 10 minutes; after the sintering is completed...

Embodiment 2

[0047] (1) Short carbon fibers with a diameter of 7 μm and a length of 1 mm were put into a vacuum high-temperature furnace at a temperature of 1200° C., and kept in a vacuum environment for 2 hours.

[0048] (2) The Cu / Ti powder is milled by wet method, the milling time is 8 hours, and the ball-to-alcohol ratio is 2:1:0.3; after vacuum drying, it is mixed with 1mm short carbon fiber with a V-shaped agitator, and the V-shaped mixed The material speed was 90r / min, and the mixture was stirred for 5 hours; a composite powder was uniformly mixed with short carbon fibers and metal powder, containing 9% Ti, 3% short carbon fibers, and copper as the balance.

[0049] (3) During the discharge plasma sintering process, first use a Roots pump to evacuate with a vacuum degree of 0.05mbar, then pre-press at a pressure of 30MPa for 20min, then raise the temperature to 820°C at a speed of 100°C / min and a pressure of 5MPa, and keep warm The time is 10 minutes; after the sintering is complete...

Embodiment 3

[0052] (1) Short carbon fibers with a diameter of 7 μm and a length of 1 mm were put into a vacuum high-temperature furnace at a temperature of 1200° C., and kept in a vacuum environment for 2 hours.

[0053] (2) The Cu / Ti powder is milled by wet method, the milling time is 8 hours, and the ball-to-alcohol ratio is 2:1:0.3; after vacuum drying, it is mixed with 1mm short carbon fiber with a V-shaped agitator, and the V-shaped mixed The material speed was 90r / min, and the mixture was stirred for 5 hours; a composite powder was uniformly mixed with short carbon fibers and metal powder, containing 9% Ti, 3% short carbon fibers, and copper as the balance.

[0054] (3) In the process of spark plasma sintering, first use a Roots pump to evacuate, the vacuum degree is 0.05mbar, then pre-press at a pressure of 30MPa for 20min, and then raise the temperature to 850℃ at a speed of 100℃ / min, and the pressure is 5MPa, and keep warm The time is 10 minutes; after the sintering is completed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com