Preparation method of FeSi2 modified C/SiC braking material

A brake material and modification technology, which is applied in the field of preparation of C/SiC brake materials, can solve the problems of affecting fiber reinforcement and affecting the mechanical properties of materials, and achieve the effects of reducing raw material costs, improving mechanical properties, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

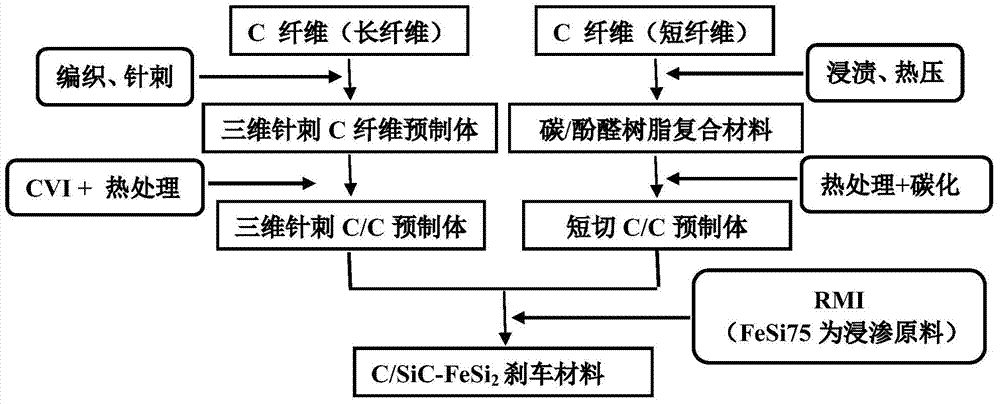

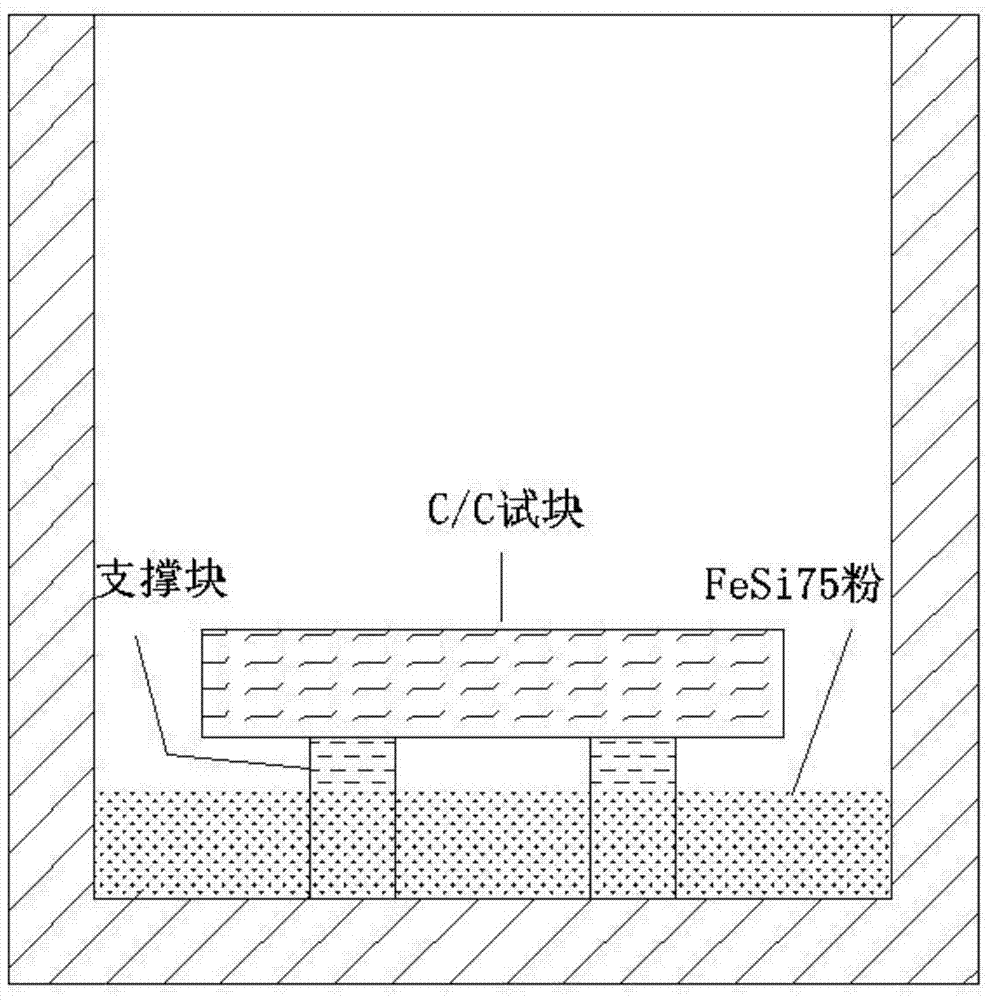

[0036] This embodiment is a preparation of FeSi 2 The method for modifying the C / SiC brake material test block, the specific process is:

[0037] Step 1, preparation of C fiber preform:

[0038] Firstly, PAN-based T-300 (12K) carbon fiber is made into short-fiber tire mesh and non-weft fabric, and then the single-layer 0° non-weft fabric, tire mesh, 90° non-weft fabric, and tire mesh are laminated in sequence, and then Using acupuncture technology, the non-weft fabric and the tire net are integrated. According to the required thickness, after repeated lamination, acupuncture, lamination, acupuncture..., a three-dimensional acupuncture carbon fiber preform is obtained, and the density of the preform is about 0.55g / cm 3 .

[0039] Step 2, preparation of C / C composite material:

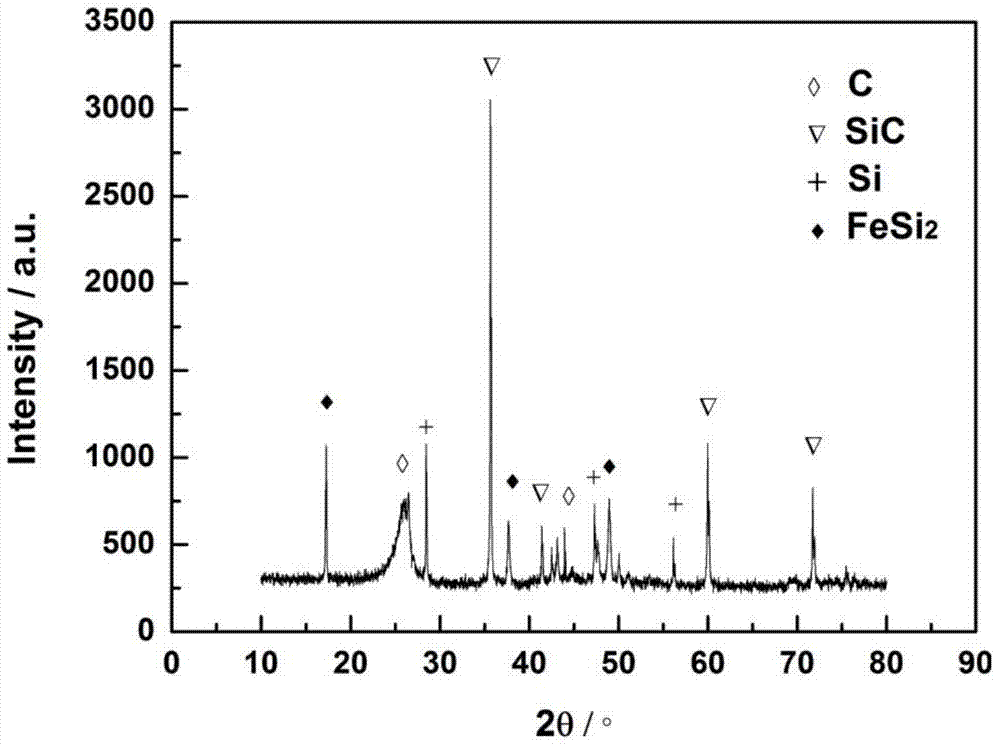

[0040] Using propylene as the precursor, PyC was deposited in the three-dimensional needle-punched C fiber preform at a deposition temperature of 900 °C and a deposition time of 500 h to prepare a de...

Embodiment 2

[0051] This embodiment is to prepare FeSi 2 The method of modifying the C / SiC brake test ring, the specific process is:

[0052] Step 1, preparation of C fiber preform:

[0053] Firstly, PAN-based T-300 (12K) carbon fiber is made into short-fiber tire mesh and non-weft fabric, and then the single-layer 0° non-weft fabric, tire mesh, 90° non-weft fabric, and tire mesh are laminated in sequence, and then Using acupuncture technology, the non-weft fabric and the tire net are integrated. According to the required thickness, after repeated lamination, acupuncture, lamination, acupuncture..., a three-dimensional acupuncture carbon fiber preform is obtained, and the density of the preform is about 0.55g / cm 3 .

[0054] Step 2, preparation of C / C composite material:

[0055] Using propylene as the precursor, PyC was deposited in the three-dimensional needle-punched C fiber preform at a deposition temperature of 900 °C and a deposition time of 400 h, and the prepared density was 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com