Polylactic acid composition, and toughened transparent material and preparation method thereof

A composition and polylactic acid technology, applied in the field of polylactic acid materials, can solve the problems of low transparency of polylactic acid, unsuitable for large-scale production, complex process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The embodiment of the present invention further provides a method for preparing the above-mentioned toughened transparent material, comprising the following steps:

[0050] S10, melt and knead polylactic acid resin, polyether polyol, epoxy-based oil or polylactic acid resin, polyether polyol, epoxy-based oil, and other additives to obtain a toughened transparent material preform;

[0051] S20, extruding the obtained toughened transparent material preform into granules or extrusion molding.

[0052] In step S10, the temperature of the melting and kneading step is 140°C-240°C.

[0053] For the mixing of the components, known and commonly used methods and kneading techniques can be applied. For example, when using a twin-screw extrusion mixer to extrude, mix and granulate powdery or granular polylactic acid resin, polyether polyols, epoxy oils and other additives can be added, heating, It can be sheared and mixed to carry out extrusion kneading and granulation. For the ...

Embodiment

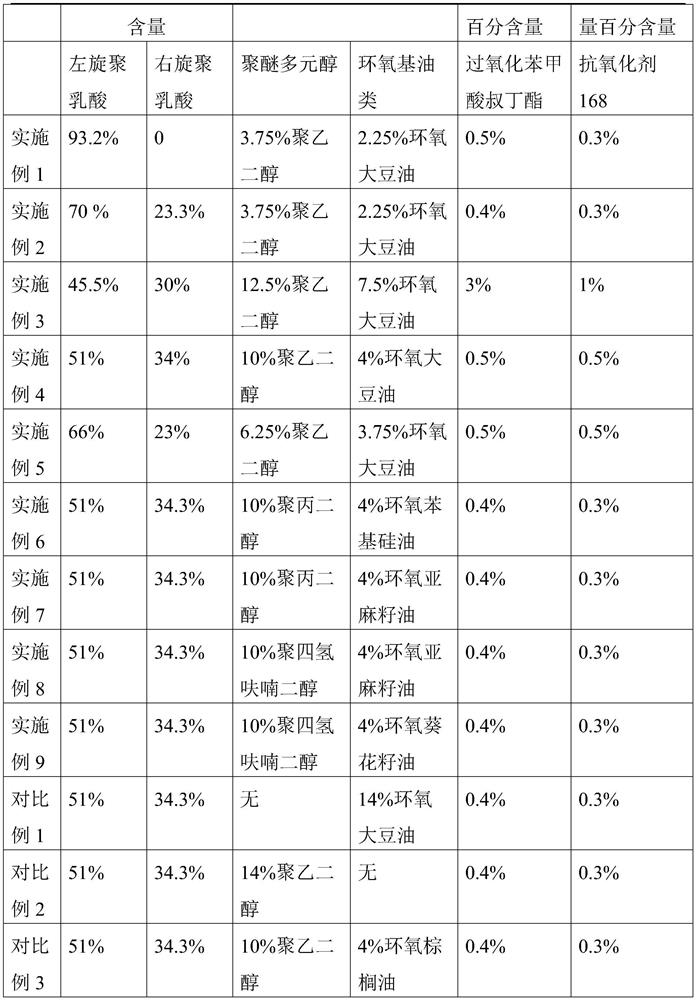

[0065] Preparation of Toughened Transparent Materials

[0066] Using a twin-screw extruder (manufactured by Perker, HK25D, cylinder diameter 25.2mm, rotating speed 100rpm, melt index is 3g / min~40g / min, when ejection amount 8kg / , the composition raw material shown in table 1 is in Melting and kneading at a melting and kneading temperature of 140°C to 240°C, and cutting the strands to obtain pellets of toughened transparent materials. Dry the obtained pellets at 110°C under reduced pressure for 2 hours, so that the moisture content reaches Below 500ppm. Each raw material is pre-dried before being fed into the extruder, the drying temperature is 80°C, and the drying time is 6h.

[0067] Extrusion conditions:

[0068] Cylinder temperature in the biaxial mixing section: 190°C;

[0069] T-die (outlet) temperature: 190°C;

[0070] Extrusion speed: 8kg / h (cooling roll contact time reaches 34 seconds);

[0071] Cooling roll surface temperature: 25°C;

[0072] Heating roller surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com