Calcium sulfate whisker aerogel foam concrete and preparation method thereof

A calcium sulfate whisker and foam concrete technology, which is applied in the fields of civil construction and thermal insulation materials, can solve the problems of reduced mechanical properties of foam concrete, difficulty in obtaining ultra-light foam concrete, and affecting the engineering application of foam concrete, so as to improve the blockability, Good high temperature resistance, strong flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

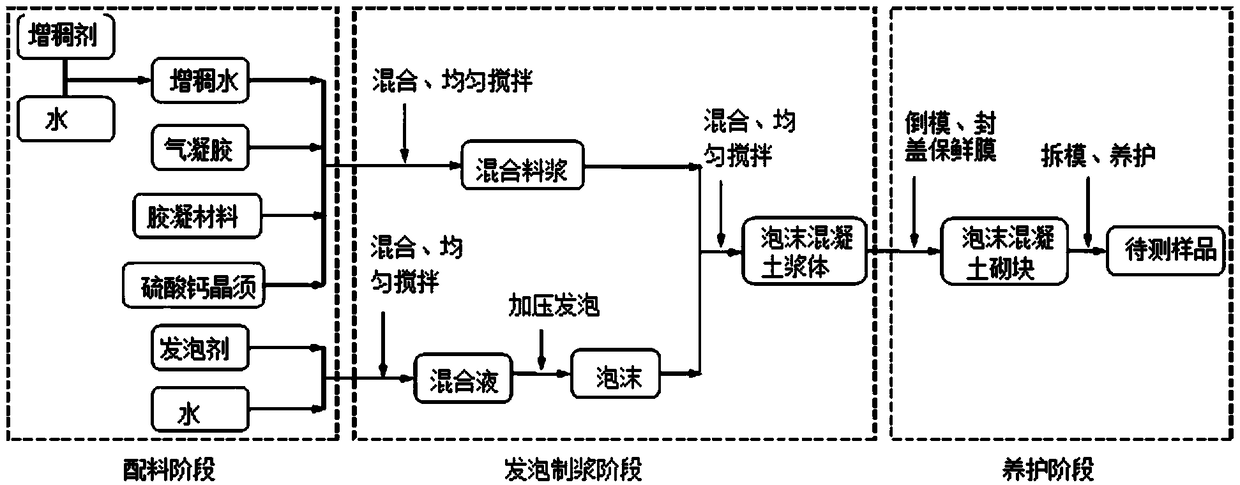

Method used

Image

Examples

Embodiment 1

[0037]The present embodiment prepares calcium sulfate whisker clay airgel foam concrete, is to take clay airgel powder as filling material, and its particle diameter is 85 orders (about 162 μ m), porosity is 95%, and pore diameter is 45nm; Dispersed calcium sulfate whiskers are reinforcements with a diameter of 1 μm and an aspect ratio of 10. Concrete preparation steps are as follows:

[0038] (1) Mix water and organic bentonite according to the mass ratio of 1000:1.5, and stir evenly to obtain thickened water;

[0039] (2) Carry out dry mixing with silicate PO42.5 cement and clay airgel powder, then add the thickening water that step (1) obtains, stir well, obtain clay airgel concrete slurry; Wherein silicate The mass ratio between PO42.5 cement, clay airgel powder and thickening water is 1:0.10:0.7;

[0040] (3) Slowly add dispersed calcium sulfate whiskers into the clay airgel concrete slurry obtained in step (2), stir evenly to obtain calcium sulfate whiskers / clay airgel...

Embodiment 2

[0044] The present embodiment prepares calcium sulfate whisker carbon airgel foam concrete, is to take carbon airgel powder as filling material, and its particle diameter is 80 orders (about 180 μ m), porosity is 93%, and pore diameter is 40nm; Dispersed calcium sulfate whiskers are reinforcements with a diameter of 5 μm and an aspect ratio of 100. Concrete preparation steps are as follows:

[0045] (1) Mix water and barstone soil in a mass ratio of 1000:3, and stir evenly to obtain thickened water;

[0046] (2) Carry out dry mixing with magnesium oxychloride PO42.5 cement and carbon airgel powder, then add the thickening water prepared in step (1), stir evenly, obtain carbon airgel concrete slurry; The mass ratio between magnesium PO 42.5 cement, carbon airgel powder and thickening water is 1:0.2:0.8;

[0047] (3) Slowly add calcium sulfate whiskers in dispersed form into the carbon airgel concrete slurry obtained in step (2), stir evenly to obtain calcium sulfate whisker / c...

Embodiment 3

[0051] The present embodiment prepares calcium sulfate whisker SiO 2 Airgel foam concrete, based on SiO 2 Airgel powder is used as filling material, its particle size is 70 mesh (about 212μm), porosity is 90%, and pore diameter is 35nm; dispersed calcium sulfate whiskers are used as reinforcement, diameter is 10μm, aspect ratio for 500. Concrete preparation steps are as follows:

[0052] (1) Mix water and diatomaceous earth in a mass ratio of 1000:5, and stir evenly to obtain thickened water;

[0053] (2) Combine sulfoaluminate PO 42.5 cement with SiO 2 The airgel powder is dry-mixed, and then the thickened water prepared in step (1) is added, and stirred evenly to obtain SiO 2 Airgel concrete paste; the sulphoaluminate PO 42.5 cement, SiO 2 The mass ratio between airgel powder and thickening water is 1:0.3:0.9;

[0054] (3) Slowly add dispersed calcium sulfate whiskers to the SiO obtained in step (2) 2 In the airgel concrete slurry, stir evenly to get calcium sulfate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com