Multi-element modified phenolic resin/basalt fiber composite board and preparation method thereof

A technology of basalt fiber and phenolic resin, which is applied in the field of building materials, can solve the problems of easy oxidation and deformation of phenolic insulation boards, poor filler bonding performance, high brittleness and easy fracture, etc., and achieve the effects of lower specific gravity, excellent compression resistance, and high deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

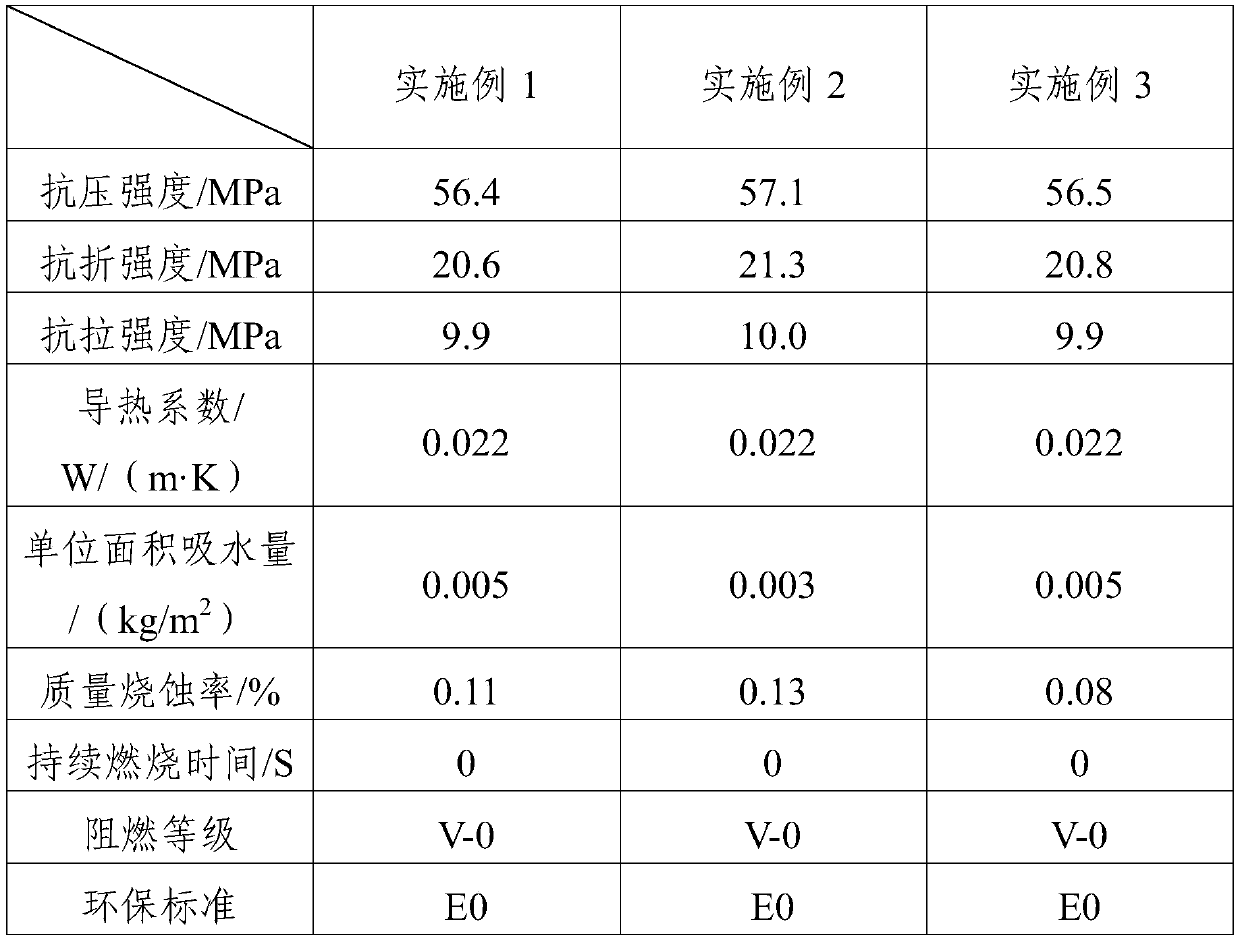

Examples

Embodiment 1

[0033] A multi-component modified phenolic resin / basalt fiber composite plate is prepared from the following raw materials in parts by weight:

[0034] 140 parts of multi-component modified phenolic resin, 55 parts of basalt fiber, 40 parts of carboxy-terminated nitrile rubber modified epoxy resin, 2 parts of thiourea modified diethylenetriamine, 16 parts of graphite powder, 3 parts of butyl titanate, poly 1 part of vinyl acetal, 5 parts of modified nano-cerium borate, 28 parts of basic magnesium sulfate whiskers, 20 parts of aluminum borosilicate whiskers, 4 parts of ammonium polyphosphate, 18 parts of barium hydroxide, 8 parts of melamine, 8 parts of silane coupling agent, 120 parts of absolute ethanol.

[0035] Wherein, the preparation method of multivariate modified phenolic resin is as follows:

[0036] Mix phenol and formaldehyde solution and stir evenly, then add tetraethyl orthosilicate and sodium hydroxide solution in sequence, after the addition is completed, stir a...

Embodiment 2

[0044] A multi-component modified phenolic resin / basalt fiber composite plate is prepared from the following raw materials in parts by weight:

[0045] 150 parts of multi-component modified phenolic resin, 60 parts of basalt fiber, 50 parts of carboxy-terminated nitrile rubber modified epoxy resin, 1 part of thiourea modified diethylenetriamine, 12 parts of graphite powder, 3 parts of butyl titanate, poly 1 part of vinyl acetal, 6 parts of modified nano-cerium borate, 20 parts of basic magnesium sulfate whiskers, 15 parts of aluminum borosilicate whiskers, 4 parts of ammonium polyphosphate, 10 parts of barium hydroxide, 10 parts of melamine, 5 parts of silane coupling agent, 125 parts of absolute ethanol.

[0046] Wherein, the preparation method of multivariate modified phenolic resin is as follows:

[0047] Mix the phenol and formaldehyde solution and stir evenly, then add tetraethyl orthosilicate and sodium hydroxide solution in sequence, after the addition is completed, st...

Embodiment 3

[0055] A multi-component modified phenolic resin / basalt fiber composite plate is prepared from the following raw materials in parts by weight:

[0056] 135 parts of multi-component modified phenolic resin, 50 parts of basalt fiber, 40 parts of carboxyl-terminated nitrile rubber modified epoxy resin, 1 part of thiourea modified diethylenetriamine, 20 parts of graphite powder, 3 parts of butyl titanate, poly 2 parts of vinyl acetal, 5 parts of nano cerium borate, 22 parts of basic magnesium sulfate whiskers, 18 parts of aluminum borosilicate whiskers, 3 parts of ammonium polyphosphate, 20 parts of barium hydroxide, 10 parts of melamine, silane 5 parts of joint agent, 120 parts of absolute ethanol.

[0057] Wherein, the preparation method of multivariate modified phenolic resin is as follows:

[0058] Mix the phenol and formaldehyde solution and stir evenly, then add tetraethyl orthosilicate and sodium hydroxide solution in turn, after the addition is completed, stir at a speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com