Flame-retardant, high-transmittance and weather-proof polycarbonate composite used for LED lampshade and preparation method

A technology for LED lampshades and composite materials, which is applied in the field of flame-retardant, high-transmittance and weather-resistant polycarbonate composite materials for LED lampshades and its preparation, can solve the problems of low light transmittance, large amount of main combustion aid, and reduced transparency of products, and achieve Increase the application range, ensure comprehensive performance, and prevent the effect of continuing to burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

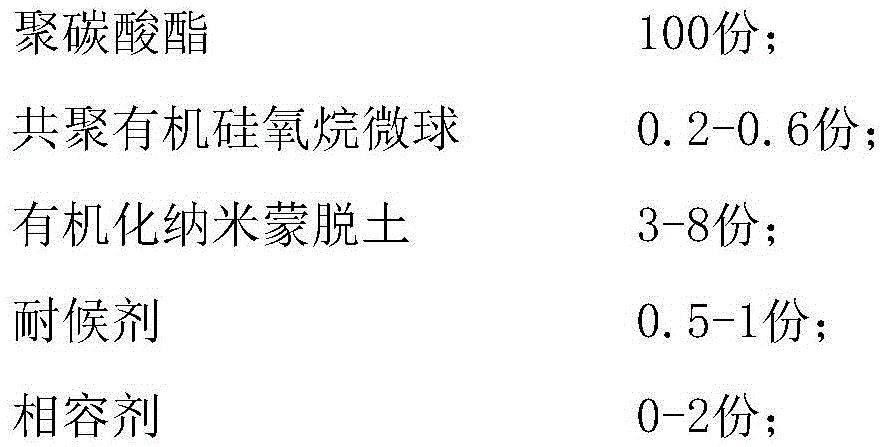

[0036] A flame-retardant, highly light-transmitting and weather-resistant polycarbonate composite material for LED lampshades is prepared from raw polycarbonate, copolymerized organosiloxane microspheres, organic nano-montmorillonite, and a weather-resistant agent. According to parts by weight, the parts by weight of the above-mentioned raw materials are respectively:

[0037]

[0038] The preparation method of the above-mentioned flame-retardant high-light-transmitting and weather-resistant polycarbonate composite material for LED lampshades: dry the above-mentioned materials in a vacuum oven at 80°C for 8 hours, fully stir them in a high-speed mixer at 25°C for 8-10 minutes, and extrude them through twin-screws. The extruder (ZSK-25 extruder of Coperion Mechanical Equipment Systems Shanghai Co., Ltd.) is melt-extruded and granulated. The extrusion temperature is controlled at 230-250°C, the die temperature is 245°C, and the screw speed is 220r / min, the flame-retardant, hig...

Embodiment 2

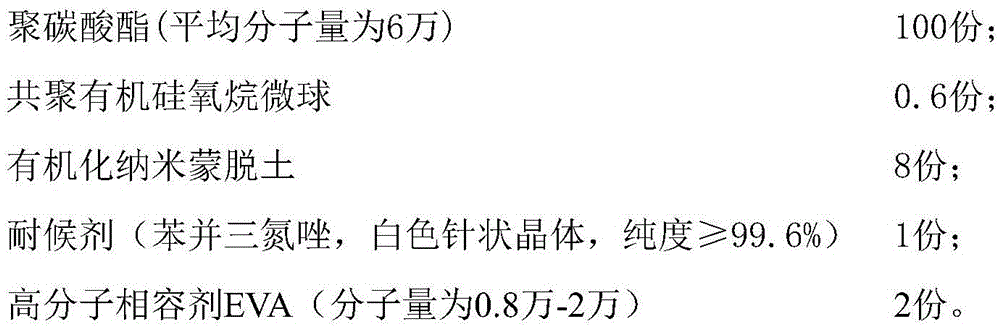

[0040] A flame-retardant, highly light-transmitting and weather-resistant polycarbonate composite material for LED lampshades is prepared from raw polycarbonate, copolymerized organosiloxane microspheres, organic nano-montmorillonite, a weather-resistant agent, and a compatibilizer. According to parts by weight, the parts by weight of the above-mentioned raw materials are respectively:

[0041]

[0042] The preparation method of the above-mentioned flame-retardant high-light-transmitting and weather-resistant polycarbonate composite material for LED lampshades: dry the above-mentioned materials in a vacuum oven at 80°C for 8 hours, fully stir them in a high-speed mixer at 25°C for 8-10 minutes, and extrude them through twin-screws. The extruder (ZSK-25 extruder of Coperion Mechanical Equipment Systems Shanghai Co., Ltd.) is melt-extruded and granulated. The extrusion temperature is controlled at 230-250°C, the die temperature is 245°C, and the screw speed is 220r / min, the ...

Embodiment 3

[0044] A flame-retardant, highly light-transmitting and weather-resistant polycarbonate composite material for LED lampshades is prepared from raw polycarbonate, copolymerized organosiloxane microspheres, organic nano-montmorillonite, a weather-resistant agent, and a compatibilizer. According to parts by weight, the parts by weight of the above-mentioned raw materials are respectively:

[0045]

[0046] The preparation method of the above-mentioned flame-retardant high-light-transmitting and weather-resistant polycarbonate composite material for LED lampshades: dry the above-mentioned materials in a vacuum oven at 80°C for 8 hours, fully stir them in a high-speed mixer at 25°C for 8-10 minutes, and extrude them through twin-screws. The extruder (ZSK-25 extruder of Coperion Mechanical Equipment Systems Shanghai Co., Ltd.) is melt-extruded and granulated. The extrusion temperature is controlled at 230-250°C, the die temperature is 245°C, and the screw speed is 220r / min, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com