Halogen-free phosphorus-nitrogen composite flame retardant and halogen-free flame-retardant plastic polymer containing composite flame retardant

A thermoplastic polymer, composite flame retardant technology, applied in the field of halogen-free flame retardants, can solve the problem of unmentioned polyamide glow wire performance, etc., to achieve improved glow wire performance, improved flame retardant performance, good flame retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

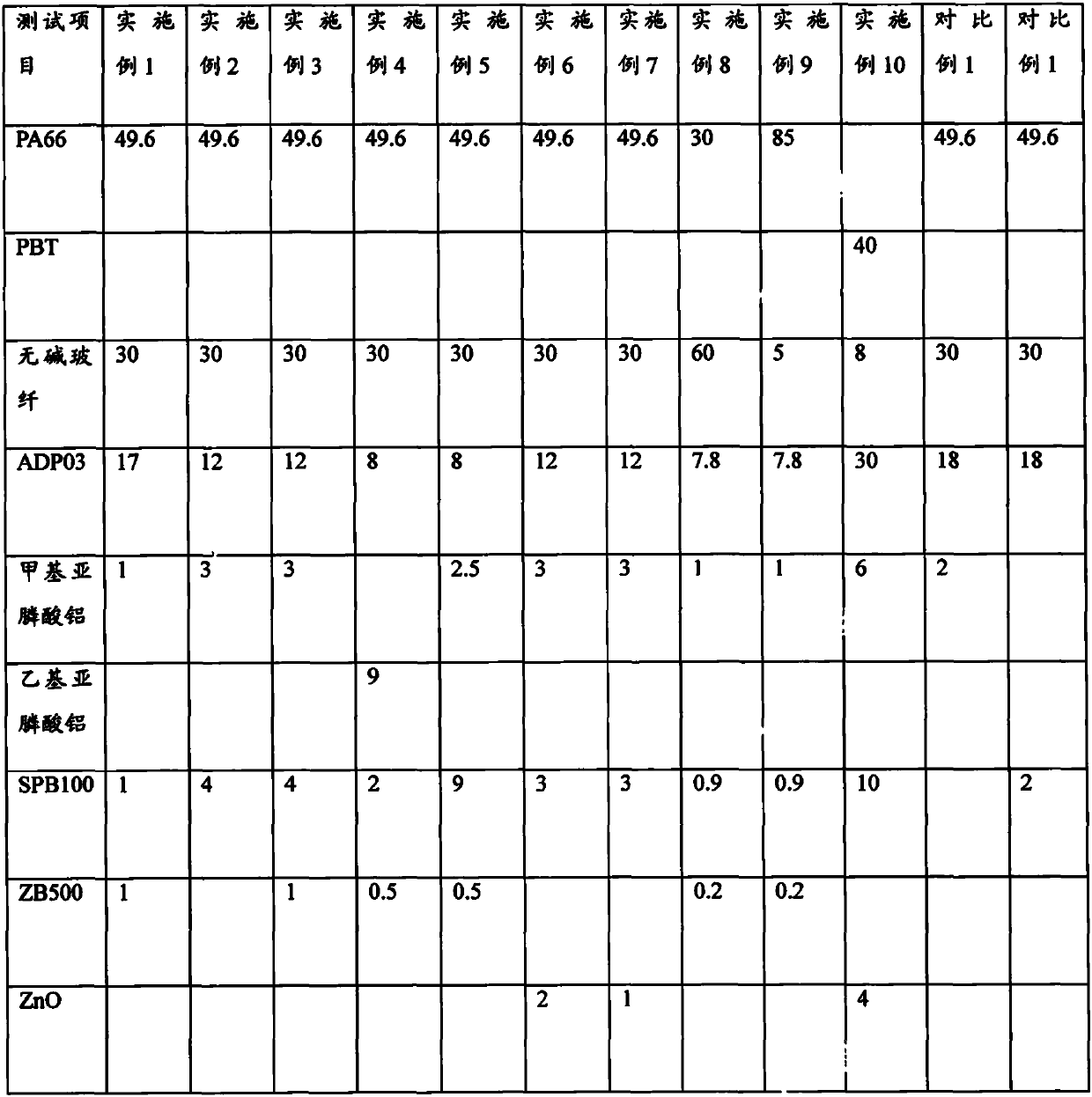

Embodiment 1

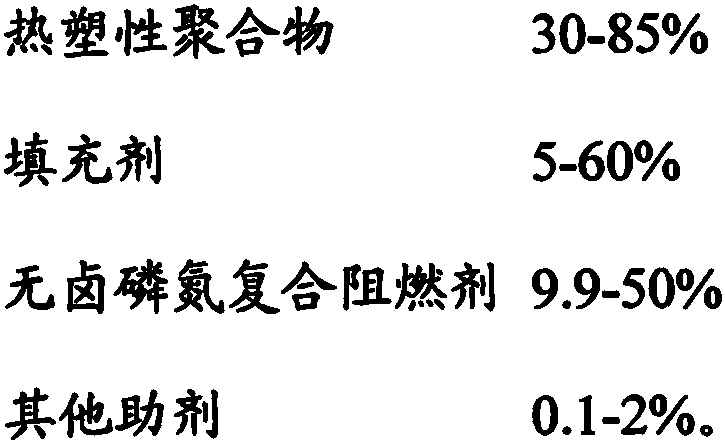

[0042] A halogen-free flame-retardant thermoplastic polymer, comprising the following components by weight percentage:

[0043]Polyamide 66 49.6%, alkali-free glass fiber 30%, halogen-free phosphorus nitrogen composite flame retardant 20%, PETS 0.2%, antioxidant 1098 0.2%;

[0044] Among them, halogen-free phosphorus nitrogen composite flame retardant: ADP03 17%, aluminum methyl phosphinate 1%, SPB100 1%, ZB5001%.

Embodiment 2

[0046] A halogen-free flame-retardant thermoplastic polymer, comprising the following components by weight percentage:

[0047] Polyamide 66 49.6%, alkali-free glass fiber 30%, halogen-free phosphorus nitrogen composite flame retardant 20%, PETS 0.2%, antioxidant 1098 0.2%;

[0048] Among them, halogen-free phosphorus nitrogen composite flame retardant: ADP03 12%, aluminum methyl phosphinate 3%, SPB100 4%, cerium oxide 1%.

Embodiment 3

[0050] A halogen-free flame-retardant thermoplastic polymer, comprising the following components by weight percentage:

[0051] Polyamide 66 49.6%, alkali-free glass fiber 30%, halogen-free phosphorus nitrogen composite flame retardant 20%, PETS 0.2%, antioxidant 1098 0.2%;

[0052] Obtained through commercially available or conventional test methods:

[0053] Aluminum diethylphosphinate: FR-ADP03 (Guangzhou Yinyuan New Material Technology Co., Ltd.)

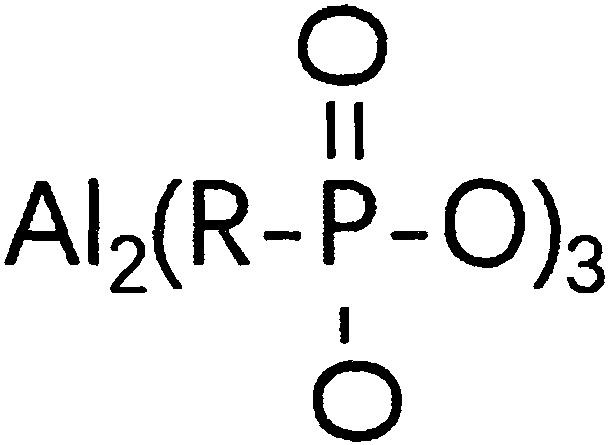

[0054] Aluminum methylphosphonous acid: self-made (formed by dehydration condensation of methylphosphonous acid and aluminum hydroxide at high temperature)

[0055] Aluminum ethylphosphonous acid: self-made (dehydration condensation of ethylphosphonous acid and aluminum hydroxide at high temperature);

[0056] Methyl phosphonous acid or ethyl phosphonous acid can be obtained through commercially available channels, or obtain by hydrolyzing methyl phosphonous acid ester or ethyl phosphonous acid ester; Its molecular structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com