Preparation method of polypropylene plastic particles

A technology of polypropylene plastic and polypropylene, which is applied in the field of preparation of polypropylene plastic particles, can solve problems such as poor compatibility and lack of performance of polypropylene plastic particles, and achieve enhanced toughness, improved compatibility and binding force, and improved Effect of grafting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

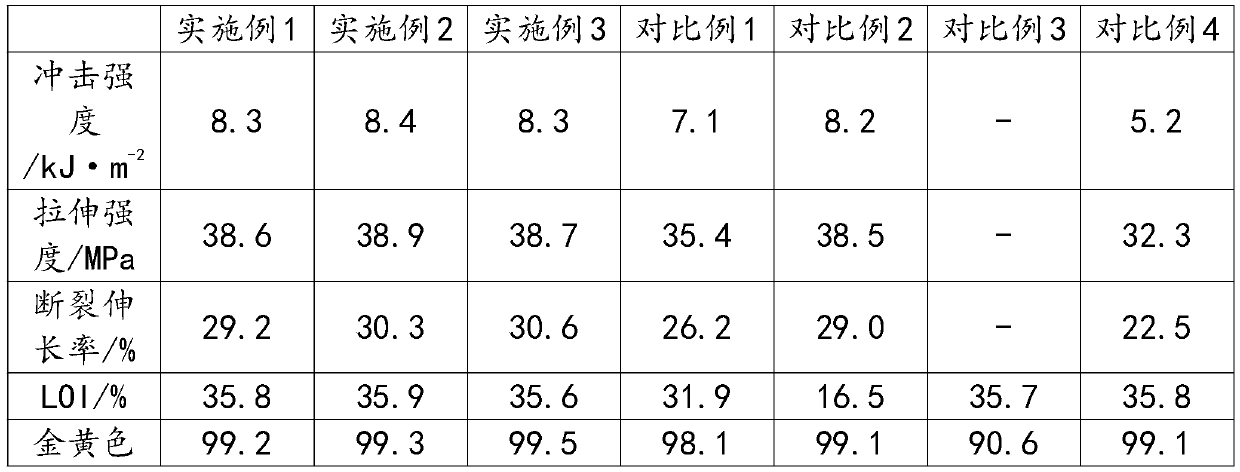

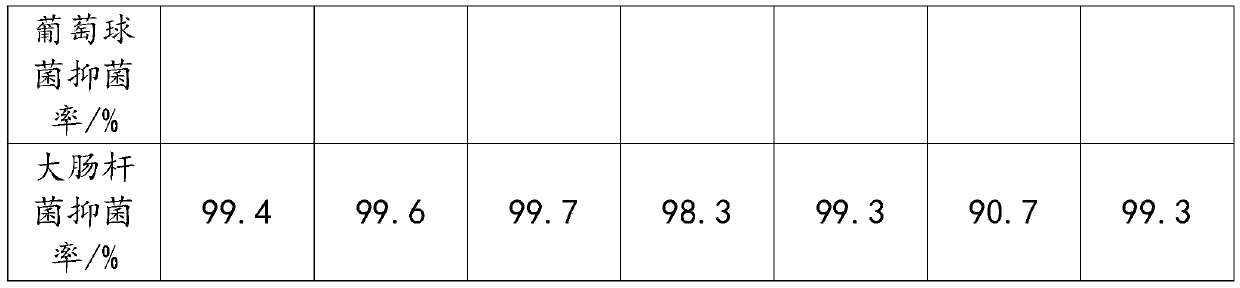

Examples

preparation example Construction

[0026] A method for preparing polypropylene plastic particles. The polypropylene plastic particles are made of the following raw materials in parts by weight: 100-120 parts of modified polypropylene, 16-20 parts of talcum powder, 10-15 parts of flame retardant, antibacterial 3-5 parts of agent, 2-3 parts of calcium stearate, 4-8 parts of dispersant;

[0027] The dispersant is liquid paraffin;

[0028] The particle size of talc powder is 4-5um; when talc powder is melt-blended with PP, talc powder in this particle size range can not only enhance the rigidity of PP, but also enhance the toughness of PP. The enhancement of PP rigidity is the reinforcing effect of inorganic fillers. There are two reasons for increasing the toughness of PP: on the one hand, the particle size of talc powder is small, and the talc powder particles are easy to move; The generation of voids is manifested in the improvement of toughness; under the promotion of calcium stearate and dispersant, the dispe...

Embodiment 1

[0045] A polypropylene plastic particle is made of the following raw materials in parts by weight: 100 parts of modified polypropylene, 16 parts of talcum powder, 10 parts of flame retardant, 3 parts of bacteriostatic agent, 2 parts of calcium stearate, and 4 parts of dispersant ;

[0046] The polypropylene plastic particles are made by the following steps:

[0047] S1. Mix the modified polypropylene, talcum powder, calcium stearate and dispersant according to the formula, stir at 120r / min for 9min, and mix evenly;

[0048] S2. Add a flame retardant and a bacteriostat to the above mixture, first stir and mix at 300r / min for 4.5min, then increase the speed to 1100r / min and stir for 2.5min to obtain a blend;

[0049] S3. Put the blend into a twin-screw extruder, melt blend, extrude, and granulate to obtain polypropylene plastic particles.

Embodiment 2

[0051] A polypropylene plastic particle is made of the following raw materials in parts by weight: 110 parts of modified polypropylene, 18 parts of talcum powder, 13 parts of flame retardant, 4 parts of bacteriostatic agent, 2.5 parts of calcium stearate, and 6 parts of dispersant ;

[0052] The polypropylene plastic particles are made by the following steps:

[0053] S1. Mix the modified polypropylene, talcum powder, calcium stearate and dispersant according to the formula, stir at 125r / min for 10min, and mix evenly;

[0054] S2. Add a flame retardant and a bacteriostat to the above mixture, first stir and mix at 300r / min for 4.5min, then increase the speed to 1100r / min and stir for 2.5min to obtain a blend;

[0055] S3. Put the blend into a twin-screw extruder, melt blend, extrude, and granulate to obtain polypropylene plastic particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com