High-mechanical-strength coal-based agriculture and forestry water-retaining agent and preparing method thereof

A technology of mechanical strength and water-retaining agent, applied in agricultural machinery and tools, chemical instruments and methods, agriculture, etc., can solve problems such as water-retaining agent performance defects, soil compaction, soil aggregate structure damage, etc., to improve and regulate plant nutritional status, The effect of improving soil aggregate structure and strong resistance to economic risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

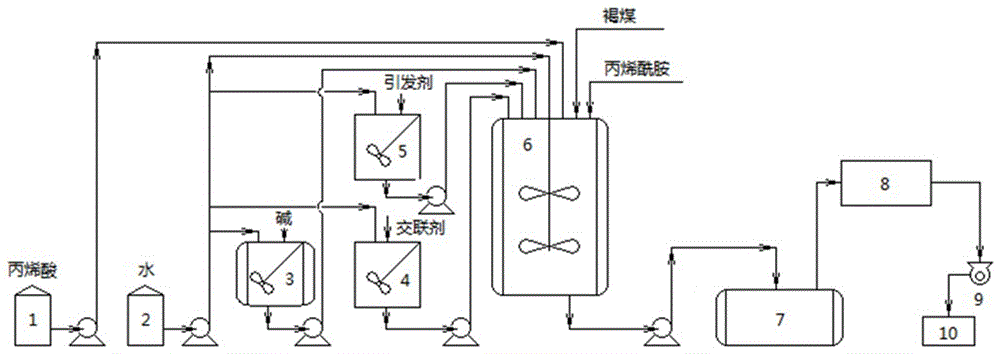

Method used

Image

Examples

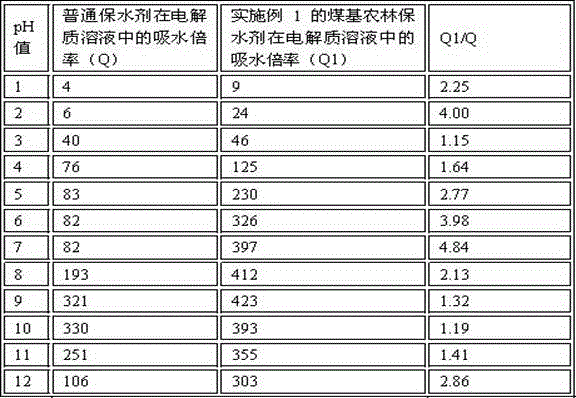

Embodiment 1

[0031] (1) Add 1000g of water, 30g of acrylamide and 50g of acrylic acid into the reactor, and fully stir at room temperature for 0.5 hours;

[0032] (2) Add a certain amount of potassium hydroxide solution with a concentration of 30.00%, adjust the neutralization degree of acrylic acid to 60-80%, and strictly control the temperature, not exceeding 40 o C;

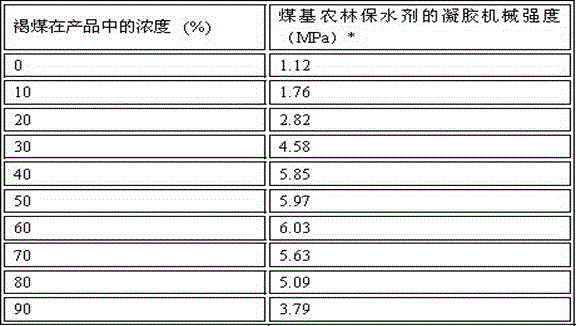

[0033] (3) Add 800g lignite and stir well until the lignite is evenly dispersed in the solution;

[0034] (4) Add 2g of N,N'-methylenebisacrylamide and 2g of ammonium persulfate, and stir for 5-10 minutes;

[0035] (5) Raise the temperature of the reaction solution to 70-80 o C to react, strictly control the temperature, not more than 80 o c. React for 1-2h to stop the reaction when forming a viscous gel-like product;

[0036] (6) The product was taken out, cooled to room temperature, cut into small pieces, dried, and crushed with a pulverizer to obtain the high mechanical strength coal-based agricultural and forestry w...

Embodiment 2

[0038] (1) Add 1000g of water, 100g of acrylamide and 150g of acrylic acid into the reactor, and fully stir at room temperature for 0.5 hours;

[0039] (2) Add a certain amount of potassium hydroxide solution with a concentration of 30.00%, adjust the neutralization degree of acrylic acid to 60-80%, and strictly control the temperature, not exceeding 40 o C;

[0040] (3) Add 700g lignite and stir well until the lignite is evenly dispersed in the solution;

[0041] (4) Add 1g of N,N'-methylenebisacrylamide and 3g of ammonium persulfate, and stir for 5-10 minutes;

[0042] (5) Raise the temperature of the reaction solution to 70-80 o C to react, strictly control the temperature, not more than 80 o c. React for 1-2h to stop the reaction when forming a viscous gel-like product;

[0043] (6) The product was taken out, cooled to room temperature, cut into small pieces, dried, and pulverized with a pulverizer to obtain the high mechanical strength coal-based agricultural and for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com