Large-length-diameter ratio silver nanowire based on one-pot polyol method and preparation method and application thereof

A technology of silver nanowires and high aspect ratio, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of cumbersome operation, high cost, complicated operation, etc., and achieve broad application prospects , the effect of rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

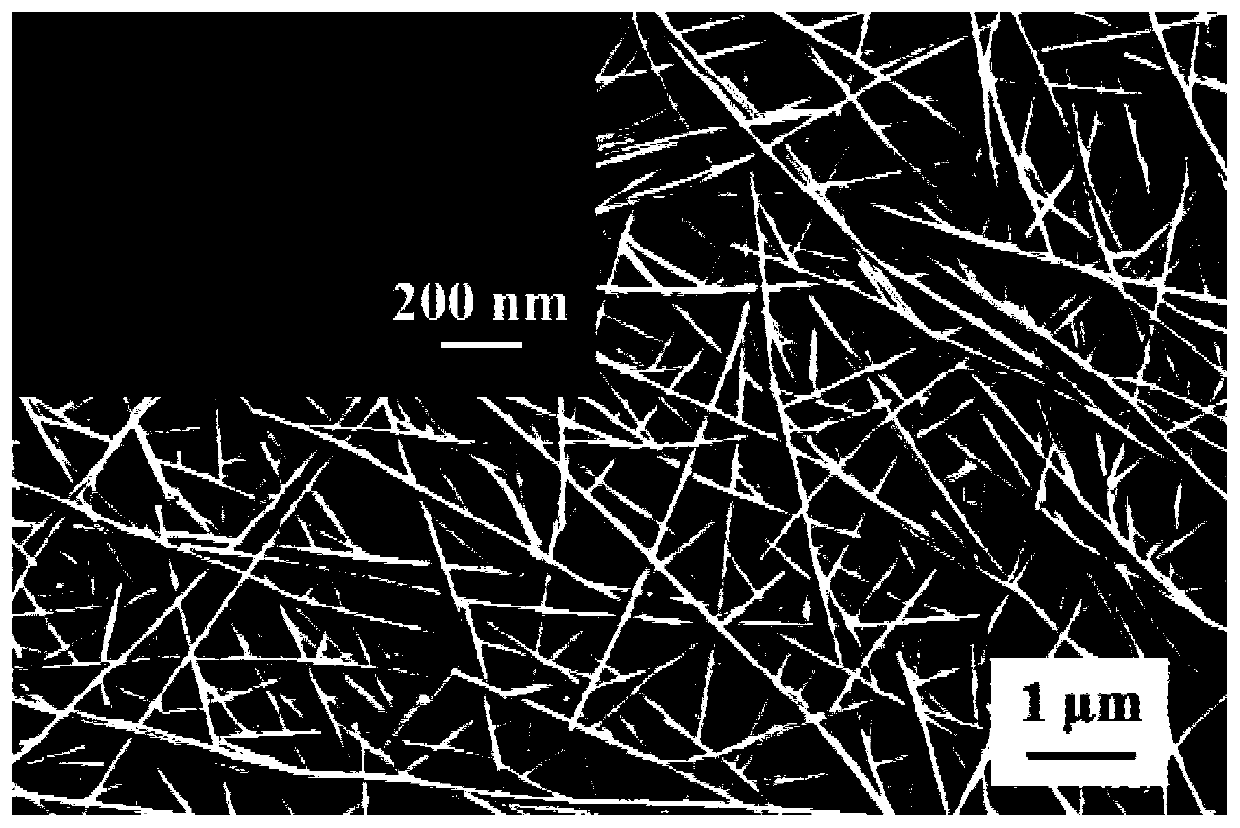

[0032] This embodiment provides a high aspect ratio silver nanowire based on a one-pot polyol method and a preparation method thereof, and the specific steps are as follows:

[0033] 1. Prepare polyvinylpyrrolidone (PVP) ethylene glycol solution: weigh a certain amount of PVP powder, add it to 80°C ethylene glycol solution, and stir at a constant speed to dissolve the PVP. The molecular weight of PVP is 1,300,000.

[0034] 2. Preparation of silver nitrate (AgNO 3 ) of ethylene glycol solution: weigh a certain amount of AgNO 3 powder, add it to the ethylene glycol solution at room temperature, and stir rapidly to make the AgNO 3 dissolve.

[0035] 3. Prepare the ethylene glycol solution of the alkali metal chloride: weigh a certain amount of sodium chloride (NaCl) powder, add it to the ethylene glycol solution at room temperature, and stir at a constant speed to dissolve the sodium chloride.

[0036] 4. Take 50mL of ethylene glycol solution in a 100mL round bottom flask, an...

Embodiment 2

[0041] This embodiment provides a high aspect ratio silver nanowire based on a one-pot polyol method and a preparation method thereof, and the specific steps are as follows:

[0042] On the basis of Example 1, the reaction time in step 5 was changed to: constant temperature reaction for 1 h.

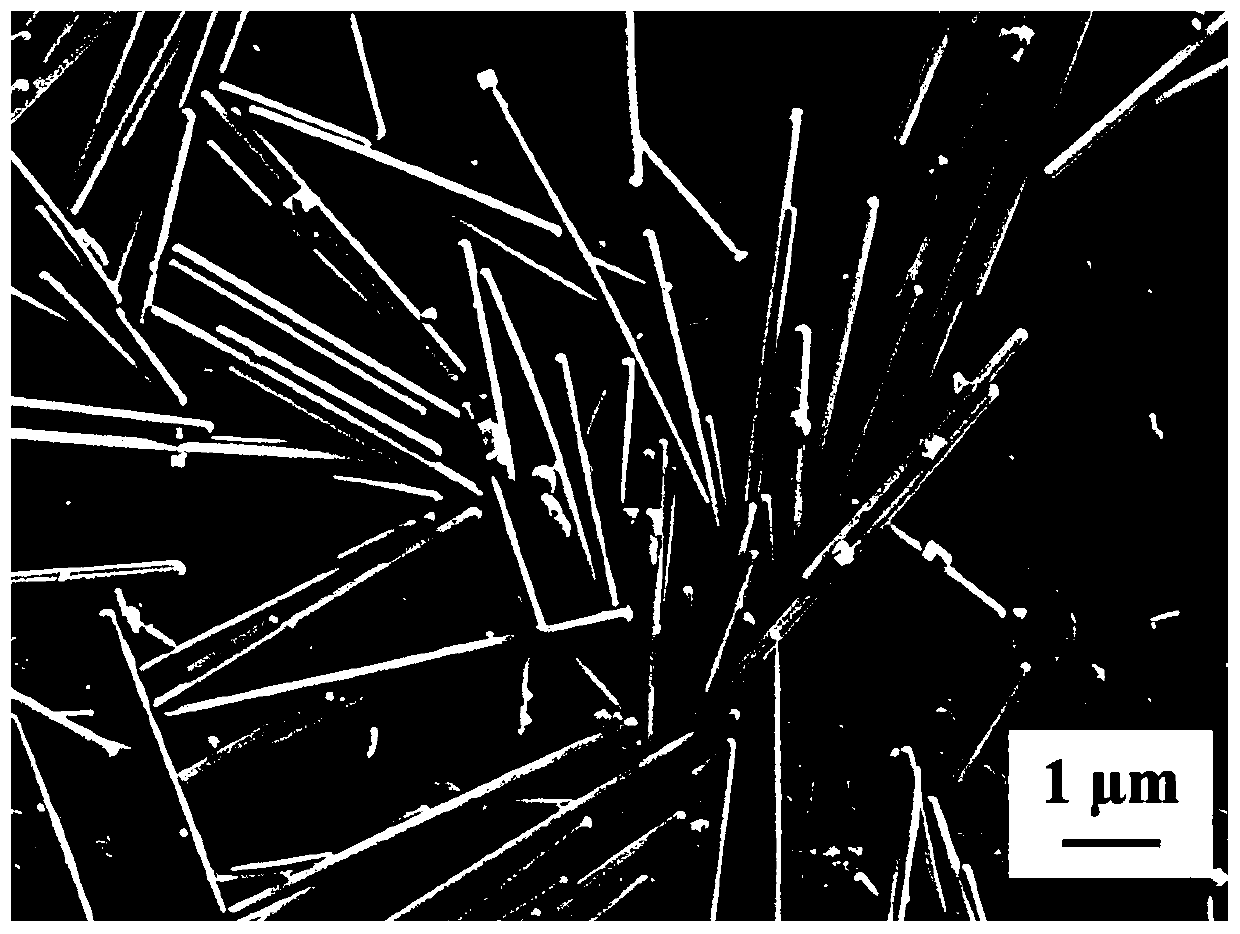

[0043] The silver nanowire dispersion liquid particle content that obtains is less, slightly more than embodiment 1, as figure 2 shown. The diameter of the silver nanowire is 50-100 nm; the length is 10-30 μm. Compared with Example 1, although the silver nanowires have larger diameters and shorter lengths, they can still meet the requirements for the preparation of transparent electrodes, and the reaction time is shorter.

Embodiment 3

[0045] This embodiment provides a high aspect ratio silver nanowire based on a one-pot polyol method and a preparation method thereof, and the specific steps are as follows:

[0046] On the basis of Example 1, change the reaction conditions in step 5 to: place the flask containing the reaction solution in an oil bath, heat up to 120°C within 20min, and react at a constant temperature for 0.5h; then heat up to 160°C within 10min. ℃, constant temperature reaction for 1h. The round bottom flask was connected to the reflux device and sealed during this process.

[0047] The diameter of the silver nanowire obtained in this embodiment is greater than 100 nm, and the length is less than 10 μm. The silver nanowire becomes thicker and shorter, and the aspect ratio decreases obviously. The influence of the temperature change in the reaction process on the quality of silver nanowires is illustrated. The stable reaction temperature during the synthesis is conducive to the formation of u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com